Page 1

Control Valves

VALVES

CONTROL

W910 COMPACT

CONTROL VALVE

184

428 Jones Boulevard • Limerick Airport Business Center • Pottstown PA • 19464 • Tel: 610-495-5131 • Fax: 610-495-5134

www.watsonmcdaniel.com

Page 2

Control Valves

TA901

I/P TRANSDUCER

ELECTRONIC

TEMPERATURE

SENSOR

RTD or THERMOCOUPLE

TR890

ELECTRONIC

PID CONTROLLER

TA987

AIR FILTER/REGULATOR

Control Valves

W910 Series Compact Control Valve 186-196

The W910 Series Pneumatic Control Valve offers high quality at an economical price,

incorporating many features found only on more expensive units. Models are available

to provide the proper flow response required by the application.

Controllers & Sensors 197-205

Understanding a Control Loop 197

Controllers – Design & Operation 198-199

TR890 Series Electronic PID Controller 200-201

TA901 Series Electropneumatic I/P Transducer 202

TA987 Air Filter/ Regulator (for TA901 Pneumatic Control Device) 203

Electronic Temperature Sensors (RTD or Thermocouple) 204

Thermowells (for Temperature Sensors) 205

Page No.

CONTROL

VALVES

428 Jones Boulevard • Limerick Airport Business Center

www.watsonmcdaniel.com

• Pottstown PA • 19464 • Tel: 610-495-5131 • Fax: 610-495-5134

185

Page 3

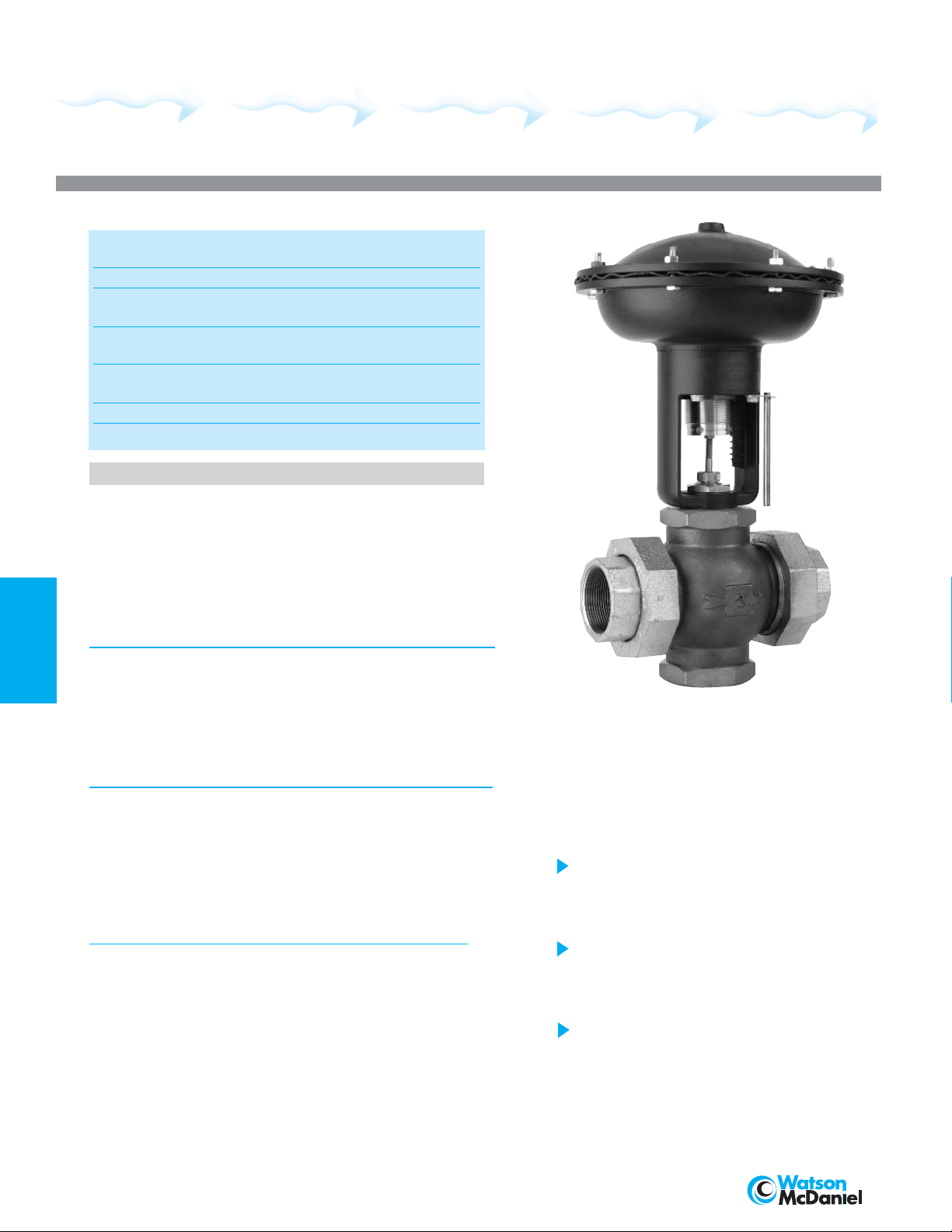

CONTROL VALVES

W910 Series

Compact Control Valve

Watson McDaniel reserves the

right to change the designs

and/or materials of its

products without notice.

©2010 Watson McDaniel Company

Models

Service

Sizes 1/2”, 3/4”, 1”, 11/4”, 11/2”, 2”,

Connections Union Ends, 125# Flanged

Body Material 1/2” – 2” Bronze

Seat Material Stainless Steel

Max. Inlet Pressure

DESIGN PRESSURE/TEMPERATURE RATING – PMA/TMA

Union Ends 250 PSIG @ 450˚ F

125# FLG 125 PSIG @ 450˚ F

Description

CONTROL

degrees between minimal flow and full capacity in response to a

signal from an external control device. The control valve, often

referred to as “the final control element,” is a critical part of any

control loop, as it performs the physical work and is the element

that directly affects the process.

A control valve is a device capable of modulating flow at varying

VALVES

Principles of Operation

A control valve is comprised of an actuator mounted to a valve.

The valve modulates flow through movement of a valve plug in

relation to the port(s) located within the valve body. The valve plug

is attached to a valve stem, which, in turn, is connected to the

actuator. The actuator, which can be pneumatically or electrically

operated, directs the movement of the stem as dictated by the

external control device.

Pneumatic/Diaphragm Actuated

Watson McDaniel Pneumatic Actuators are direct acting and

utilize an air signal from an external control device to create a

modulating control action. The force of the air signal is received

into the actuator through a top port and distributed across the full

area of the actuator’s diaphragm. The diaphragm presses down on

the diaphragm plate and spring return assembly, which then moves

the valve stem and plug assembly downward to stroke the valve.

This actuator will move to a stem-out position in the event of air

signal failure. The choice of valve action (stem-In-To-Close or

stem-In-To-Open) will determine its signal failure position.

W910A, W910B, W910C, W910TB,

W910EPA, W910EPC

Water, Steam, Other Liquids

21/2”, 3”, 4”

250# Flanged (optional)

21/2” – 4” Cast Iron

250 PSIG

The W910 Series Pneumatic Control Valve

ers high quality at an economical price,

off

incorporating many features found only on

more expensive units. The following Models are

available to provide the proper flow response

required by the application:

The W910A, W910B & W910C are used

for On/Off control applications, providing a

quick-opening flow response when used

with single or double seated valves.

The W910TB is used for proportional or

PID control applications, providing a throttling

flow response when used with double seated

or 3-way valves.

The W910EPA & W910EPC are used for

proportional or PID control applications,

providing equal percentage flow response

when used with single seated valves.

186

428 Jones Boulevard • Limerick Airport Business Center • Pottstown PA • 19464 • Tel: 610-495-5131 • Fax: 610-495-5134

www.watsonmcdaniel.com

Page 4

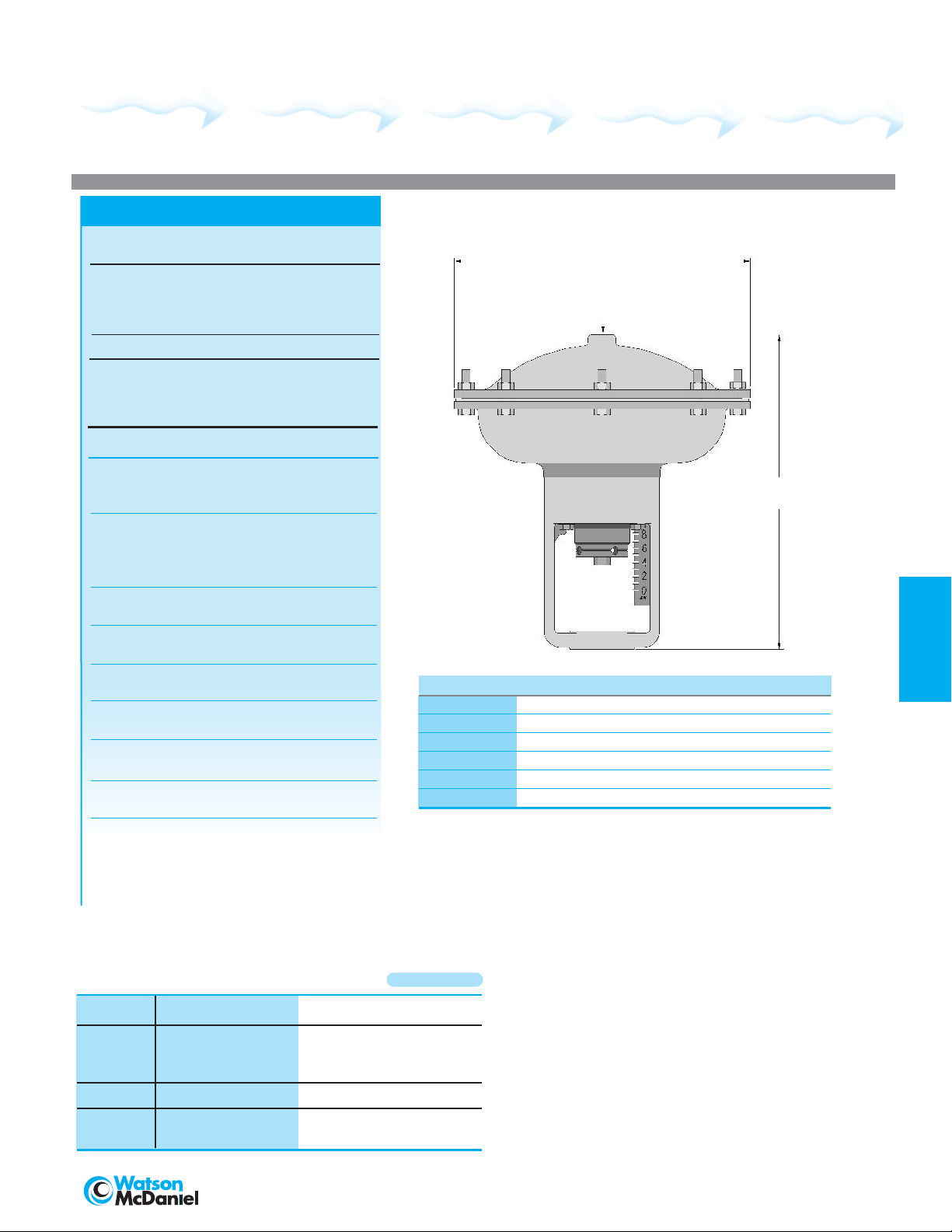

CONTROL VALVES

W910 Series

Compact Control Valve

Specifications

Actuator

Model Size Action Signal

W910A 7" On/Off 15 PSIG

W910B 10" On/Off 15 PSIG

W910C 12" On/Off 15 PSIG

W910TB 10" Throttling* 3-15 PSIG

W910EPA 7" Equal

W910EPC 12" Equal

* Includes 3-Way Valves

Actuator Housing

Setting Scale

Adjustment Screw

Adjustment Screw Bushing

Range Adjustment Spring

Pressure Plate

Diaphragm

Air Pressure to Diaphragm

Air Pressure Connection

Operating Temperature

Diaphragm

Die cast aluminum, epoxy powder

coated blue finish.

Integral to housing

Brass

Lubricant impregnated sintered bronze

Cadmium plated

Aluminum

Nylon reinforced EDPM

30 PSIG maximum

1

/8“ NPT Female

Ambient:

-40°F (-40°C) to 180°F (82°C)

Process Flow:

-40°F (-40°C) to 410°F (210°C)

Control Input

Percentage 3-15 PSIG

Percentage 3-15 PSIG

Units: inches [mm]

A

AIR INLET

1/8” NPT

B

Actuator Number A B Approx. Shipping Weight

W910A 7.0 [178] 9.8 [249] 6.6 lbs [2.97 kg]

W910B 9.3 [236] 9.8 [249] 8.5 lbs [3.83 kg]

W910C 11.4 [290] 9.8 [249] 12.0 lbs [5.41 kg]

W910TB 9.3 [236] 9.8 [249] 9.6 lbs [4.32 kg]

W910EPA 7.0 [178] 9.8 [249] 7.6 lbs [3.42 kg]

W910EPC 11.4 [290] 9.8 [249] 13.1 lbs [5.90 kg]

Actuator

• W910 Series Pneumatic Actuators are used in conjunction with

the W910 Series Control Valve. Choose the appropriate Actuator

model based on the intended service.

CONTROL

VALVES

HOW TO ORDER Sample Order Number: W910TB - A56

Actuator

Model

W910A

W910B On/Off Refer to pages 188-190

W910C

W910TB Throttling Refer to pages 191-193

W910EPA

W910EPC

Control Action Valve Body Number

Equal Percentage Refer to page 188

428 Jones Boulevard • Limerick Airport Business Center • Pottstown PA • 19464 • Tel: 610-495-5131 • Fax: 610-495-5134

www.watsonmcdaniel.com

Procedure:

1. Determine the Actuator Model ( W910A, W910B, W910C,

W910TB, W910EPA or W910EPC) required.

Note: Refer to the maximum close-off pressur

the Valve Body Selection tables to deter

equired by your application.

r

2. Determine the

Size, style and material required by the application.

Note: Consult the Valve Selection tables on the following

pages to determine the required Valve Body Number.

Valve Body Number based on the Valve

e columns in

mine the Actuator size

187

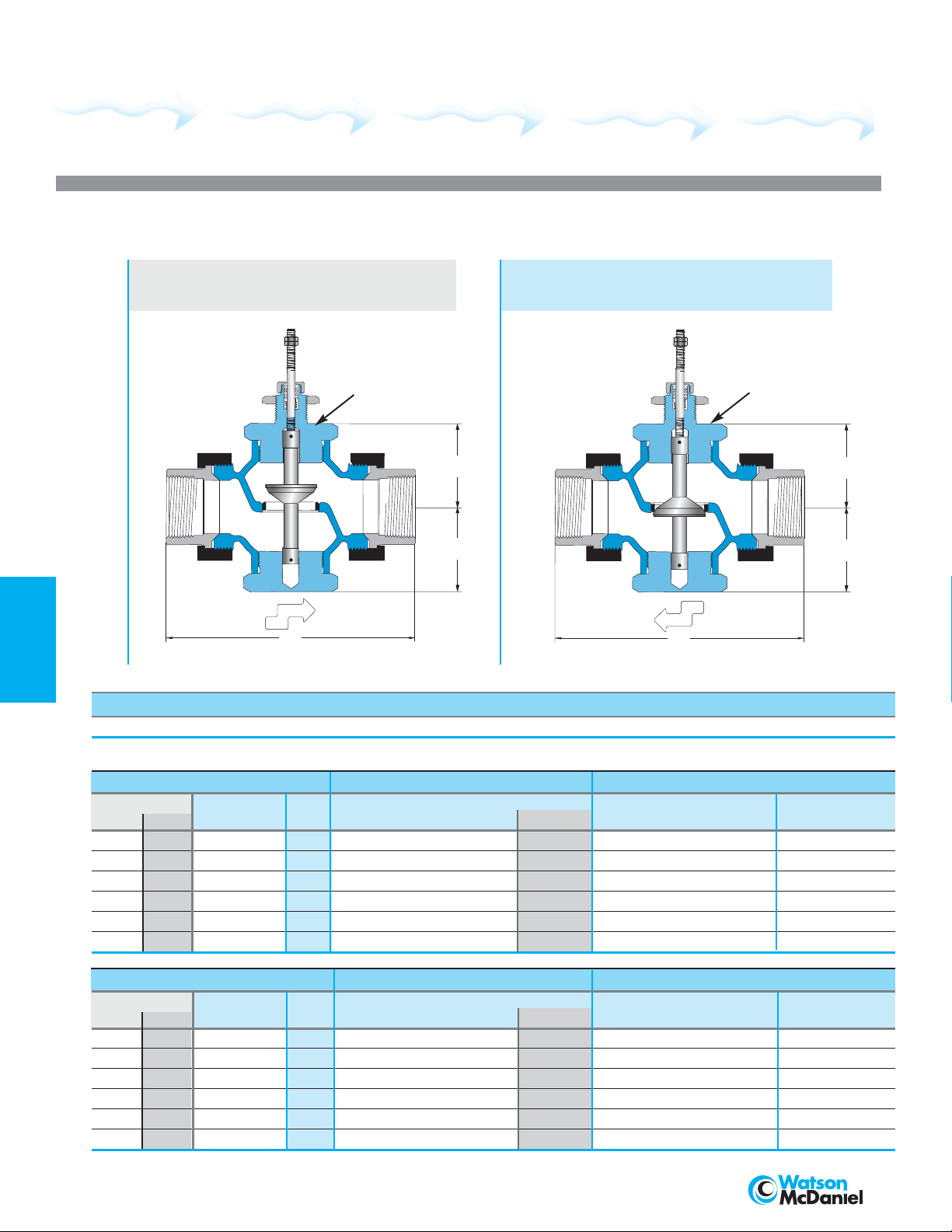

Page 5

CONTROL VALVES

W910 Series

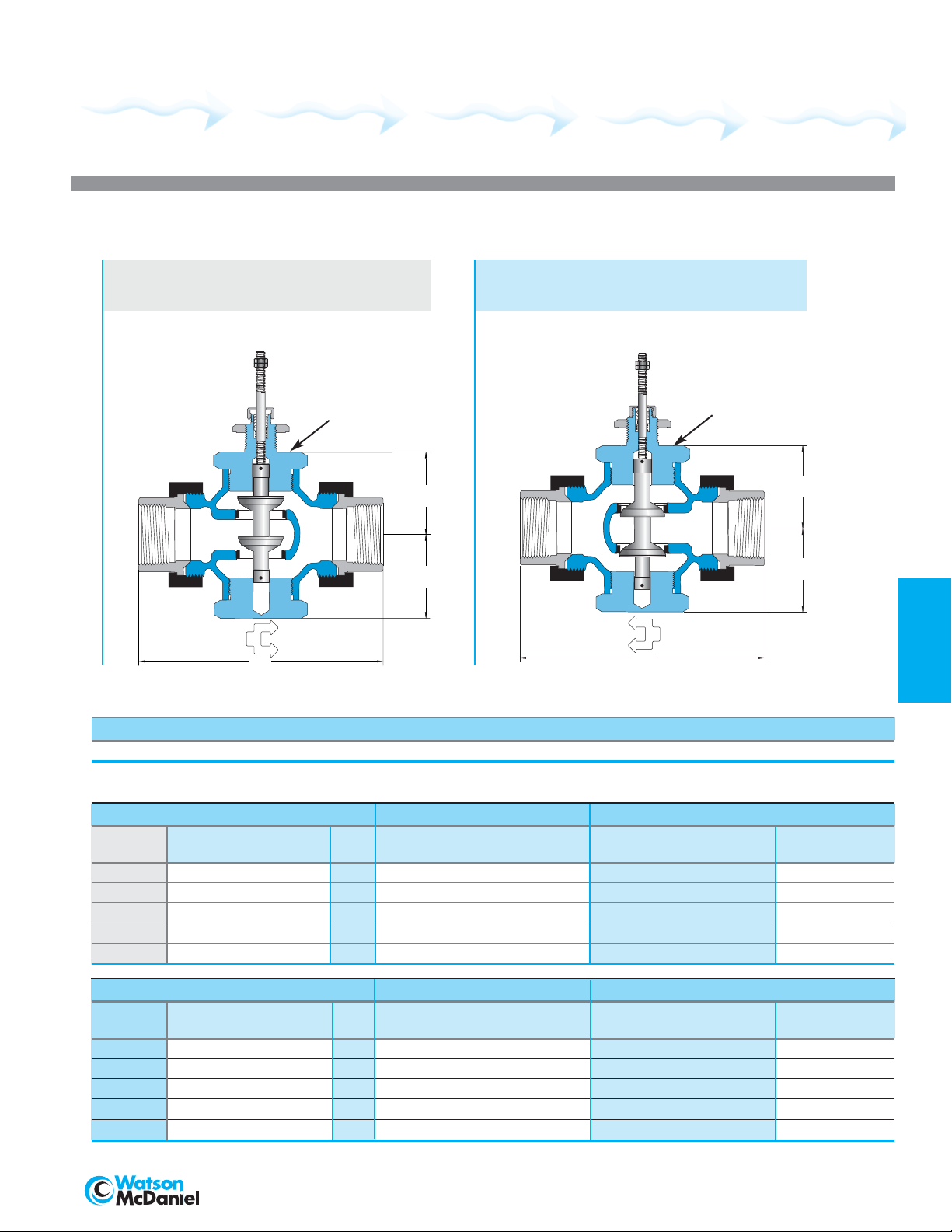

Valve Body for W910A, W910B, W910C, W910EPA & W910EPC

Single Seat • 1/2” – 2”

Stem In-To-Close

(normally closed)

VALVES

CONTROL

Specifications

Body Material Trim Material Trim Style Connection Pressure & Temperature Rating

Bronze Stainless Steel ML or EP NPT with Malleable Iron Union Ends 250 PSI @ 410°F (210°C)

Valve Body Selection

In-To-Close (Normally Open)

(normally open)

Actuator

Mounting

Surface

C

C

B

B

FLOW

A

A

Maximum Close-Off Pressure (PSI ΔP)

Valve Body No. Size Actuator Dimensions Approximate

ML EP

A14 E14

A19 E19

A26 E26 1" 8.4 200 250 x 200 6.0 [152] 2.3 [58] 2.3 [58] 6.0 lbs [2.70 kg]

A36 E36 11/4" 15 100 250 x 150 7.2 [183] 2.6 [66] 2.6 [66] 9.7 lbs [4.37 kg]

A47 E47 11/2" 21 50 150 250 100 7.7 [196] 2.6 [66] 2.6 [66] 10.8 lbs [4.86 kg]

A58 E58 2" 33 25 50 250 50 8.6 [218] 3.1 [79] 3.1 [79] 16.3 lbs [7.34 kg]

Connection (NPT)

1

/2" 2.8 250 x x 250 4.8 [122] 1.8 [46] 1.8 [46] 3.0 lbs [1.35 kg]

3

/4" 5.6 250 x x 250 5.6 [142] 2.3 [58] 2.3 [58] 4.9 lbs [2.21 kg]

C

W910A W910B W910C W910EPC A B C Shipping Wt.

v

BRONZE

Stem In-To-Open

FLOW

A

A

ML = Modified Linear (On/Off); EP = Equal Percentage

Actuator

Mounting

Surface

C

C

B

B

188

In-To-Open (Normally Closed)

alve Body No.

V

ML EP

A15 E15

A22 E22

A30 E30 1" 8.4 200 x x 200 6.0 [152] 2.3 [58] 2.3 [58] 6.0 lbs [2.70 kg]

A41 E41 11/4" 15 150 x x 150 7.2 [183] 2.6 [66] 2.6 [66] 9.7 lbs [4.37 kg]

A52 E52 11/2" 21 100 x x 100 7.7 [196] 2.6 [66] 2.6 [66] 10.8 lbs [4.86 kg]

A63 E63 2" 33 50 x x 50 8.6 [218] 3.1 [79] 3.1 [79] 16.3 lbs [7.34 kg]

All dimensions are inches [mm].

428 Jones Boulevard • Limerick Airport Business Center • Pottstown PA

Size Actuator

Connection (NPT)

1

/2"

3

/4" 5.6

C

v

2.8 250 x x 250 4.8 [122] 1.8 [46] 1.8 [46] 3.0 lbs [1.35 kg]

Maximum Close-Off Pressure (PSI ΔP)

Dimensions Approximate

W910A

250 x x 250 5.6 [142] 2.3 [58] 2.3 [58] 4.9 lbs [2.21 kg]

W910B W910C W910EPA A B C Shipping Wt.

• 19464 • Tel: 610-495-5131 • Fax: 610-495-5134

www.watsonmcdaniel.com

Page 6

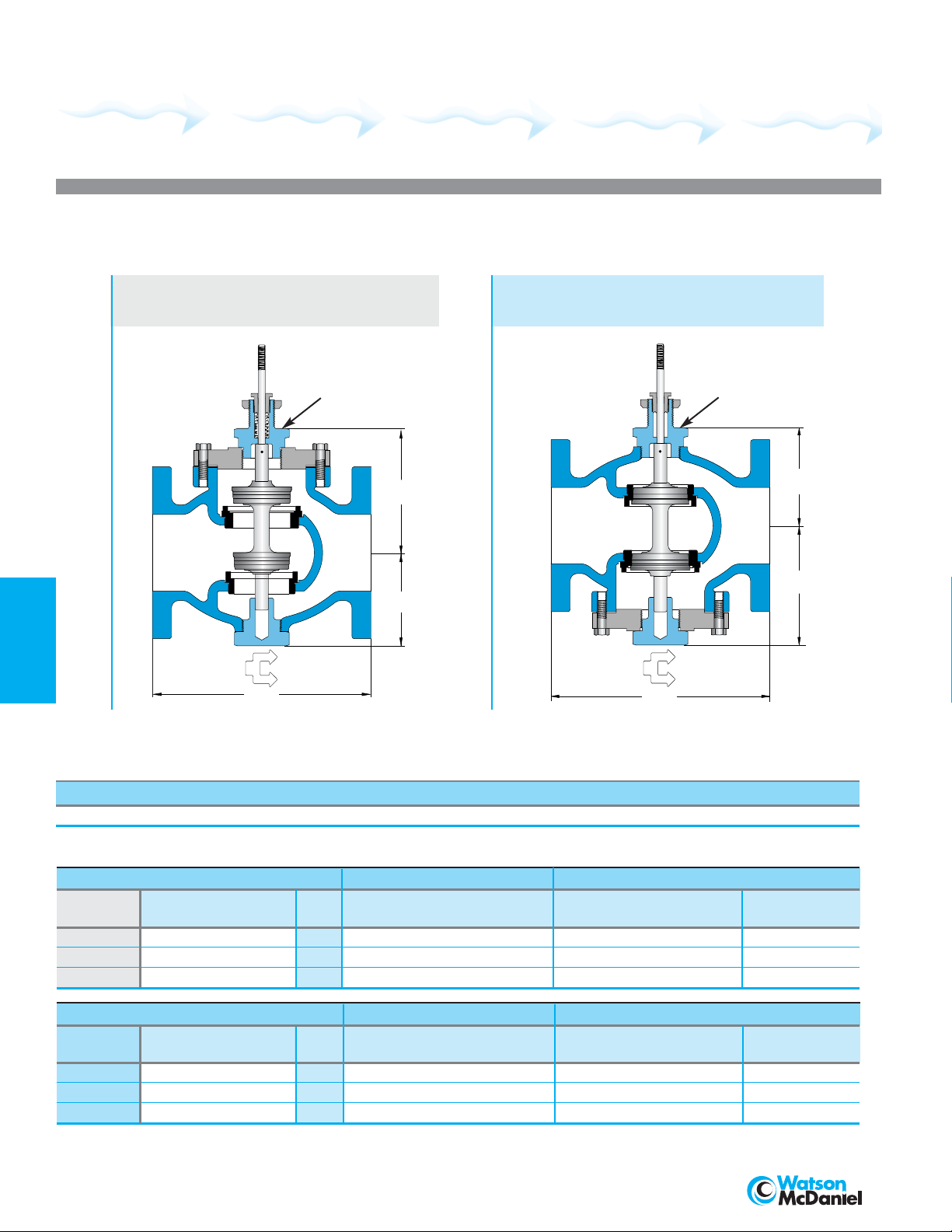

CONTROL VALVES

W910 Series

BRONZE

Stem In-To-Close

(normally open)

Valve Body for W910A,W910B & W910C

Double Seat • 3/4” – 2”

Stem In-To-Open

(normally closed)

Actuator

Mounting

Surface

C

C

B

B

FLOW

A

A

FLOW

A

A

Actuator

Mounting

Surface

C

C

B

B

CONTROL

VALVES

Specifications

Body Material Trim Material Trim Style Connection Pressure & Temperature Rating

Bronze Stainless Steel Modified Linear NPT with Malleable Iron Union Ends 250 PSI @ 410°F (210°C)

Valve Body Selection

In-To-Close (Normally Open)

Valve Body

Number

A21

A29 1" 1" 12 250 x x 6.0 [152] 2.3 [58] 2.3 [58] 6.1 lbs [2.75 kg]

A39 11/4"1

A50 11/2"1

A61 2" 2" 47 200 x x 8.6 [218] 3.1 [79] 3.1 [79] 17.0 lbs [7.65 kg]

In-To-Open (Normally Closed)

Valve Body

Number

A24

A33 1" 1" 12 250 x x 6.0 [152] 2.3 [58] 2.3 [58] 6.1 lbs [2.75 kg]

A44 11/4"1

A55 11/2"1

A66 2" 2" 47 200 x x 8.6 [218] 3.1 [79] 3.1 [79] 17.0 lbs [7.65 kg]

All dimensions are inches [mm].

Connection (NPT) Nominal Port

Connection (NPT) Nominal Port

Size Actuator Dimensions Approximate

3

/4"

3

/4"

3

/4" 8 250 x x 5.6 [142] 2.3 [58] 2.3 [58] 5.0 lbs [2.25 kg]

1

/4" 21 250 x x 7.2 [183] 2.6 [66] 2.6 [66] 10.1 lbs [4.55 kg]

1

/2" 30 250 x x 7.7 [196]

Size Actuator Dimensions Approximate

3

/4" 8 250 x x 5.6 [142] 2.3 [58] 2.3 [58] 5.0 lbs [2.25 kg]

1

/4" 21 250 x x 7.2 [183] 2.6 [66] 2.6 [66] 10.1 lbs [4.55 kg]

1

/2" 30 250 x x 7.7 [196] 2.6 [66] 2.6 [66] 11.1 lbs [5.00 kg]

Maximum Close-Off Pressure (PSI ΔP)

C

W910A W910B W910C A B C Shipping Wt.

v

2.6 [66] 2.6 [66] 11.1 lbs [5.00 kg]

Maximum Close-Off Pressure

C

W910A W910B W910C A B C Shipping Wt.

v

(PSI ΔP)

428 Jones Boulevard • Limerick Airport Business Center • Pottstown PA • 19464 • Tel: 610-495-5131 • Fax: 610-495-5134

www.watsonmcdaniel.com

189

Page 7

CONTROL VALVES

W910 Series

Valve Body for W910A, W910B & W910C

Double Seat • 21/2”–4”

Stem In-To-Close

(normally open)

Actuator

Mounting

Surface

C

C

B

B

Stem In-To-Open

(normally closed)

CAST IRON

Actuator

Mounting

Surface

C

C

B

B

VALVES

CONTROL

FLOW

A

FLOW

A

A

Specifications

Body Material Trim Material Trim Style Connection Pressure & Temperature Rating

Cast Iron Stainless Steel Modified Linear 125# Flanged 125 PSI @ 350°F (176°C)

Valve Body Selection

In-To-Close (Normally Open)

Valve Body

Number

B73 21/2"2

B78 3"

B83 4" 4" 196 125 x x 11.4 [290] 6.3 [160] 6.5 [165] 100 lbs [45 kg]

In-To-Open (Normally Closed)

Valve Body

Number

B74 21/2"2

B79 3" 3" 90 125 x x 9.0 [229] 5.0 [127] 5.6 [142] 70 lbs [32 kg]

B84 4" 4" 196 125 x x 11.4 [290] 6.3 [160] 6.5 [165] 100 lbs [45 kg]

All dimensions are inches [mm].

Connection Nominal PortC

Connection Nominal Port

Size Actuator Dimensions Approximate

1

/2" 69 125 x x 7.8 [198] 4.8 [122] 5.4 [137] 45 lbs [20 kg]

3" 90 125 x x 9.0 [229] 5.0 [127] 5.6 [142] 70 lbs [32 kg]

Size Actuator

1

/2" 69 125 x x 7.8 [198] 4.8 [122] 5.4 [137] 45 lbs [20 kg]

Maximum Close-Off Pressure (PSI ΔP)

W910A W910B

v

Maximum Close-Off Pressure (PSI ΔP)

C

W910A W910B W910C A B C Shipping Wt.

v

W910C A B C Shipping Wt.

Dimensions Approximate

190

428 Jones Boulevard • Limerick Airport Business Center • Pottstown PA • 19464 • Tel: 610-495-5131 • Fax: 610-495-5134

www.watsonmcdaniel.com

Page 8

CONTROL VALVES

W910 Series

BRONZE

Stem In-to-Close

(normally open)

Single Seat

FLOW

A

A

Actuator

Mounting

Surface

Stem In-to-Close

Double Seat

Single Seat

C

C

B

B

(normally open)

Actuator

Mounting

Surface

Valve Body for W910TB

Stem In-to-Open

(normally closed)

FLOW

A

A

Double Seat

Actuator

Mounting

Surface

C

C

B

B

Stem In-to-Open

(normally closed)

Single or Double Seat

1/2” – 2”

Actuator

Mounting

Surface

CONTROL

VALVES

C

C

C

B

B

FLOW

A

A

FLOW

A

A

C

B

B

Specifications

Body Material Trim Material Trim Style Connection Pressure & Temperature Rating

Bronze Stainless Steel Modified Linear NPT with Malleable Iron Union Ends 250 PSI @ 410°F (210°C)

Valve Body Selection

Valve Body Number

ITC ITO

Normally Normally

Connection

Size

Nominal

Number of

Open Closed (NPT) Port Seats C

A02 A03

A05 A06

A08 A09

A11 A12

A14 A15

A21 A24

1

/2"

1

/2"

1

/2"

1

/2"

1

/2"

3

/4"

1

/8" 1 0.17 250 4.8 [122] 1.8 [46]

3

/16" 1 0.35 250 4.8 [122] 1.8 [46] 1.8 [46] 3.0 lbs [1.35 kg]

1

/4" 1 0.7 250 4.8 [122] 1.8 [46] 1.8 [46] 3.0 lbs [1.35 kg]

3

/8" 1 1.4 250 4.8 [122] 1.8 [46] 1.8 [46] 3.0 lbs [1.35 kg]

1

/2" 1 2.8 250 4.8 [122] 1.8 [46] 1.8 [46] 3.0 lbs [1.35 kg]

3

/4" 2 8 250 5.6 [142] 2.3 [58] 2.3 [58] 5.0 lbs [2.25 kg]

A29 A33 1" 1" 2 12 250 6.0 [152] 2.3 [58] 2.3 [58] 6.1 lbs [2.75 kg]

A39 A44 11/4"1

A50 A55 11/2"1

1

/4" 2 21 250 7.2 [183] 2.6 [66] 2.6 [66] 10.1 lbs [4.55 kg]

1

/2" 2 30 250 7.7 [196] 2.6 [66] 2.6 [66] 11.1 lbs [5.00 kg]

A61 A66 2" 2" 2 47 250 8.6 [218] 3.1 [79] 3.1 [79] 17.0 lbs [7.65 kg]

All dimensions are inches [mm].

428 Jones Boulevard • Limerick Airport Business Center • Pottstown PA • 19464 • Tel: 610-495-5131 • Fax: 610-495-5134

www.watsonmcdaniel.com

Maximum Close-Off Pressure

(PSI ΔP)

Actuator

v

W910TB A B C Shipping Wt.

Dimensions

Approximate

1.8 [46] 3.0 lbs [1.35 kg]

191

Page 9

CONTROL VALVES

W910 Series

Valve Body for W910TB

3-Way • 1/2” – 2”

for Mixing or Diverting

MIXING

FLOW DIAGRAM

AIR

UPPER

PORT

(C)

G

F

AIR

Actuator

Mounting

Surface

LOWER

PORT

(B)

BRONZE

DIVERTING

FLOW DIAGRAM

AIR

AIR

VALVES

CONTROL

CAUTION: 3-Way Valves are not designed for use in steam applications.

To properly control the mixing of two flows, inlet pressures at ports B and C should be as equal as possible.

AIR

Specifications

Body Material Trim Material Trim Style Connection Pressure & Temperature Rating

Bronze Bronze Modified Linear NPT with

Valve Body Selection

Mixing or Diverting

Valve Body

Number

A18

A25

A34 1" 1" 8.4 250 6.0 [152] 2.3 [58] 2.3 [58] 5.7 lbs [2.57 kg]

A45 11/4"1

A56 11/2"1

A67 2" 2" 33 250 8.6 [218] 4.1 [104] 3.1 [79] 16.7 lbs [7.55 kg]

All dimensions are inches [mm].

Size

Connection (NPT) Nominal Port

1

/2"

3

/4"

1

/2" 2.8 250 4.8 [122] 1.8 [46] 1.8 [46] 2.9 lbs [1.31 kg]

3

/4" 5.6 250 5.6 [142] 2.3 [58] 2.3 [58] 4.7 lbs [2.12 kg]

1

/4" 15 250 7.2 [183] 2.8 [71] 2.6 [66] 9.5 lbs [4.28 kg]

1

/2" 21 250 7.7 [196] 3.5 [89] 2.6 [66] 11.1 lbs [5.00 kg]

COMMON

Malleable Iron Union Ends

Maximum Close-Off Pressure (PSI ΔP)

Actuator

C

v

W910TB E F G Shipping Wt.

AIR

E

PORT

(A)

250 PSI @ 300°F (149°C)

Dimensions Approximate

192

428 Jones Boulevard • Limerick Airport Business Center • Pottstown PA

• 19464 • Tel: 610-495-5131 • Fax: 610-495-5134

www.watsonmcdaniel.com

Page 10

CONTROL VALVES

W910 Series

CAST IRON

MIXING

FLOW DIAGRAM

AIR

AIR

Valve Body for W910TB

for Mixing or Diverting

Actuator

Mounting

Surface

LOWER

LOWER

ORT

P

PORT

(B)

(B)

UPPER

PORT

(C)

3-Way • 21/2”–4”

DIVERTING

FLOW DIAGRAM

AIR

G

G

AIR

CONTROL

VALVES

F

F

AIR

COMMON PORT (A)

E

E

COMMON

PORT

(A)

CAUTION: 3-Way Valves are not designed for use in steam applications.

To properly control the mixing of two flows, inlet pressures at ports B and C should be as equal as possible.

AIR

Specifications

Body Material Trim Material Trim Style Connection Pressure & Temperature Rating

Cast Iron Bronze Modified Linear 125# Flanged 125 PSI @ 300°F (149°C)

Valve Body Selection

Mixing or Diverting

Valve Body

Number

B75 21/2"2

B80 3" 3" 72 125 10.0 [254] 8.0 [203] 6.0 [152] 80 lbs [36 kg]

B85 4" 4" 102 125 13.0 [330] 10.0 [254] 6.9 [175] 140 lbs [64 kg]

All dimensions are inches [mm].

Connection (NPT) Nominal Port

Size

1

/2" 58 125 9.0 [229] 7.1 [180] 5.2 [132] 62 lbs [28 kg]

Maximum Close-Off Pressure (PSI ΔP)

Actuator

C

v

W910TB E F G Shipping Wt.

Dimensions Approximate

428 Jones Boulevard • Limerick Airport Business Center • Pottstown PA • 19464 • Tel: 610-495-5131 • Fax: 610-495-5134

www.watsonmcdaniel.com

193

Page 11

CONTROL VALVES

W910 Series

Capacity Charts

CAPACITIES –

Note: All steam capacities based on Critical Drop (Choked Flow).

VALVES

CONTROL

CAPACITIES –

ITC = In-to-Close; ITO = In-to-Open

Steam (lbs/hr)

1/2” 3/4” 1” 11/4”1

Inlet A14/E14 ITC A19/E19 ITC A26/E26 ITC A36/E36 ITC A47/E47 ITC A58/E58 ITC

Pressure

(PSIG) Cv = 2.8 Cv = 5.6 Cv = 8.4 Cv = 15 Cv = 21 Cv = 33

1 80 160 240 428 599 942

3 90 180 270 483 676 1062

5 100 201 301 537 752 1182

10 126 252 377 674 943 1482

15 151 302 454 810 1134 1782

20 177 353 530 946 1325 2082

25 202 404 606 1083 1516 2382

30 228 455 683 1219 1701 2682

40 279 557 838 1492 2089 3283

50 329 659 988 1765 2471 3883

60 380 761 1141 2038 2853 4483

70 431 863 1294 2310 3235 5083

80 482 964 1447 2583 3617 5683

90 533 1066 1599 2856 3999 6283

100 584 1168 1752 3129 4380 6884

125 711 1423 2134 3811 5335 8384

150 839 1677 2516 4493 6290 9884

175 966 1932 2898 5175 7245 11385

200 1093 2187 3280 5857 8200 12885

250 1348 2696 4044 7221 10109 15886

Size, Body Number & Coefficient (Cv)

Water (GPM)

1/2” 3/4” 1” 11/4”1

Pressure A14/E14 ITC A19/E19 ITC A26/E26 ITC A36/E36 ITC A47/E47 ITC A58/E58 ITC

Drop

(PSI ΔP) Cv = 2.8 Cv = 5.6 Cv = 8.4 Cv = 15 Cv = 21 Cv = 33

1 2.8 5.6 8.4 15 21 33

3 4.8 10 15 26 36 57

5 6.3 13 19 34 47 74

10 8.9 18 27 47 66 104

15 11 22 33 58 81 128

20 13 25 38 67 94 148

25 14 28 42 75 105 165

30 15 31 46 82 115 181

40 18 35 53 95 133 209

50 20 40 59 106 148 233

60 22 43 65 116 163 256

70 23 47 70 125 176 276

80 25 50 75 134 188 295

90 27 53 80 142 199 313

100 28 56 84 150 210 330

125 31 63 94 168 235 369

150 34 69 103 184 257 404

175 37 74 111 198 278 437

175 37 74 111 198 278 437

200 40 79 119 212 297 467

225 42 84 126 225 315 495

250 44 89 133 237 332 522

A15/E15 ITO A22/E22 ITO A30/E30 ITO A41/E41 ITO A52/E52 ITO A63/E63 ITO

Size, Body Number & Coefficient (Cv)

SINGLE SEATED VALVES

1

/2”2”

SINGLE SEATED VALVES

1

/2”2”

Note:

Verify that Maximum

Close-Off Pressure does

not exceed max rating

for selected valve body

number and actuator.

(Refer to Valve Body

No. charts for Single

Seated Valves.)

Note:

Verify that Maximum

Close-Off Pressure does

not exceed max rating

for selected valve body

number and actuator.

(Refer to Valve Body

No. charts for Single

Seated Valves.)

194

428 Jones Boulevard • Limerick Airport Business Center • Pottstown PA • 19464 • Tel: 610-495-5131 • Fax: 610-495-5134

www.watsonmcdaniel.com

Page 12

CONTROL VALVES

W910 Series

Capacity Charts

CAPACITIES –

Inlet A21 ITC A29 ITC A39 ITC A50 ITC A61 ITC B73 ITC B78 ITC B83 ITC

Pressure

(PSIG) Cv = 8 Cv = 12 Cv = 21 Cv = 30 Cv = 47 Cv = 69 Cv = 90 Cv = 196

1 288 343 599 856 1342 1970 2569 5595

3 257 386 676 965 1513 2221 2896 6308

5 287 430 752 1075 1684 2472 3224 7021

10 359 539 943 1347 2111 3099 4042 8803

15 432 648 1134 1620 2538 3726 4861 10585

20 505 757 1325 1893 2966 4354 5679 12368

25 578 866 1516 2166 3393 4981 6497 14150

30 650 975 1707 2439 3820 5609 7316 15932

40 796 1194 2089 2984 4675 6864 8953 19497

50 941 1412 2471 3530 5530 8119 10589 23080

60 1087 1630 2853 4075 6385 9380 12240 26650

70 1232 1848 3235 4621 7240 10640 13870 30210

80 1378 2067 3617 5167 8094 11890 15510 33780

90 1523 2285 3999 5712 8949 13150 17150 37350

100 1669 2503 4380 6258 9804 14400 18790 40920

125 2032 3049 5335 7622 11941 17540 22880 49830

150 2396 3594 6290 8986 14078

175 2760 4140 7245 10350 16215

200 3124 4685 8200 11714 18352

250 3851 5777 10109 14442 22625

Note: All steam capacities based on Critical Drop (Choked Flow).

Steam (lbs/hr)

3/4” 1” 11/4”1

Size, Body Number & Coefficient (Cv)

1

/2”2”2

DOUBLE SEATED VALVES

1

/2”3” 4”

CONTROL

VALVES

CAPACITIES –

Pressure A21 ITC A29 ITC A39 ITC A50 ITC A61 ITC B73 ITC B78 ITC B83 ITC

Drop A24 ITO A33 IT0 A44 IT0 A55 IT0 A66 IT0 B74 ITO B79 ITO B84 ITO

(PSI ΔP) Cv = 8 Cv = 12 Cv = 21 Cv = 30 Cv = 47 Cv = 69 Cv = 90 Cv = 196

1 8 12 21 30 47 69 90 196

3 14 21 36 52 81 120 156 339

5 18 27 47 67 105 154 201 438

10 25 38 66 95 149 218 285 620

15 31 46 81 116 182 267 349 759

20 36 54 94 134 210 309 402 877

25 40 60 105 150 235 345 450 980

30 44 66 115 164 257 378 493 1074

40 51 76 133 190 297 436 569 1240

50 57 85 148 212 332 488 636 1386

60 62 93 163 232 364 534 697 1518

70 67 100 176 251 393 577 753 1640

80 72 107 188 268 420 617 805 1753

90 76 114 199 285 446 655 854 1859

100

125 89 134 235 335 525 771 1006 2191

150 98

175 106 159 278 397 622

200 113 170 297 424 665

225 120 180 315 450 705

250 126 190 332 474 743

ITC = In-to-Close; ITO = In-to-Open

Water (GPM)

3/4” 1” 11/4”1

Size, Body Number & Coefficient (Cv)

80 120 210 300 470 690 900 1960

147 257 367 576

1

/2”2” 2

DOUBLE SEATED VALVES

1

/2”3” 4”

428 Jones Boulevard • Limerick Airport Business Center • Pottstown PA • 19464 • Tel: 610-495-5131 • Fax: 610-495-5134

www.watsonmcdaniel.com

195

Page 13

CONTROL VALVES

W910 Series

Capacity Charts

CAPACITIES –

Inlet pressures should be within 5% of each other. Specify if service is for other than water.

VALVES

CONTROL

Note: Oil service or high temperature service requires special O-ring.

Water (GPM)

1/2” 3/4” 1” 11/4”1

Size, Body Number & Coefficient (Cv)

Pressure

Drop A18 A25 A34 A45 A56 A67 B75 B80 B85

(PSI ΔP) Cv = 2.8 Cv = 5.6 Cv = 8.4 Cv = 15 Cv = 21 Cv = 33 Cv = 58 Cv = 72 Cv = 102

1 2.8 5.6 8.4 15 21 33 58 72 102

3 4.8 10 15 26 36 57 100 125 177

5 6.3 13 19 34 47 74 130 161 228

10 8.9 18 27 47 66 104 183 228 323

15 11 22 33 58 81 128 225 279 395

20 13 25 38 67 94 148 259 322 456

25 14 28 42 75 105 165 290 360 510

30 15 31 46 82 115 181 318 394 559

40 18 35 53 95 133 209 367 455 645

50 20 40 59 106 148 233 410 509 721

60 22 43 65 116 163 256 449 558 790

70 23 47 70 125 176 276 485 602 853

80 25 50 75 134 188 295 519 644 912

90 27 53 80 142 199 313 550 683 968

100 28 56 84 150 210 330 580 720 1020

125 31 63 94 168 235 369 648 805 1140

150 34 69 103 184 257 404

175 37 74 111 198 278 437

200 40 79 119 212 297 467

225 42 84 126 225 315 495

250 44 89 133 237 332 522

1

/2”2” 2

1

/2”3”4”

3-WAY VALVES

CAPACITIES –

Inlet

Pressure

(PSIG) Cv = 0.17 Cv = 0.35 Cv = 0.7

1 4.9 10 20 40

3 5.5 11 23 45

5 6.1 13 25 50

10 7.6 16 31 63

15 9.2 19 38 76

20 11 22 44 88

25 12 25 51 101

30 14 28 57 114

40 17 35 70 139

50 20 41 82 165

60 23 48 95 190

70 26 54 108 216

80 29 60 121 241

90 32 67 133 267

100 35 73 146 292

125 43 89 178 356

150 51 105 210 419

175 59 121 241 483

200 66 137 273 547

250 82 168 337

Note: All steam capacities based on Critical Drop (Choked Flow).

Reduced Port Reduced Port

Steam (lbs/hr)

Size, Body Number & Coefficient (Cv)

1/8” 3/16” 1/4” 3/8”

A02 ITC A05 ITC A08 ITC A11 ITC

SINGLE SEATED

Reduced Port Reduced Port

Cv = 1.4

674

CAPACITIES –

essure A02 ITC A05 ITC A08 ITC A11 ITC

Pr

Drop

(PSI ΔP) Cv = 0.17 Cv = 0.35 Cv = 0.7

1 0.2 0.4 0.7

3 0.3 0.6 1.2 2.4

5 0.4 0.8 1.6 3.1

10 0.5 1.1 2.2 4.4

15 0.7 1.4 2.7 5.4

20 0.8 1.6 3.1 6.3

25 0.9 1.8 3.5 7.0

30 0.9 1.9 3.8 7.7

40 1.1 2.2

50 1.2 2.5 4.9 10

60 1.3 2.7 5.4 11

70 1.4 2.9 5.9 12

80 1.5 3.1 6.3 13

90 1.6 3.3 6.6 13

100 1.7 3.5 7.0 14

125 1.9 3.9 7.8 16

150 2.1 4.3

175 2.2 4.6

200 2.4 4.9 10 20

250 2.7 5.5 11 22

ITC = In-to-Close; ITO = In-to-Open

Reduced Port Reduced Port

Water (GPM)

Size, Body Number & Coefficient (Cv)

1/8” 3/16” 1/4” 3/8”

A03 ITO A06 ITO A09 ITO A12 ITO

SINGLE SEATED

Reduced Port Reduced Port

4.4 8.9

8.6 17

9.3 19

Cv = 1.4

1.4

196

428 Jones Boulevard • Limerick Airport Business Center • Pottstown PA

• 19464 • Tel: 610-495-5131 • Fax: 610-495-5134

www.watsonmcdaniel.com

Page 14

CONTROL VALVES

Control Loop

Understanding a Control Loop

SEMI-INSTANTANEOUS WATER HEATER TEMPERATURE CONTROL LOOP

AIR SIGNAL LINE

TA901 I/P

TRANSDUCER

W910 SERIES

TEAM

S

INLET

CONTROL VALVE

WVBSS

BYPASS

LINE

VACUUM

BREAKER

4

Affect

Respond

3

AV2000

AIR VENT

SET

POINT

TA987

AIR FILTER/REGULATOR

AIR INLET

HOT WATER

OUTLET

Compare

2

TR890 CONTROLLER

SEMI-INSTANTANEOUS

WATER HEATER

STEAM

TRAP

Control Loop

A control loop is a process management system designed to

maintain a process variable at a desired set point. Each step in the

loop works in conjunction with the others to manage the system.

Once the set point has been established, the control loop operates

using a four-step process.

1

Sense

COLD

WATER

INLET

Sense

1

Measure the current condition of the process using a

sensor, which can be an electronic (thermocouple, RTD or

transmitter) or mechanical device (thermal system).

2

Compare

Evaluate the measurement of the current condition against

the set point using an electronic or electric contact controller.

3

Respond

React to any error that may exist between the measured

value and set point by generating a corrective pneumatic

or electric control signal.

4

Affect

Actuate a final control element (valve, heater or other

device) that will produce a change in the process variable.

The loop continually cycles through the steps, affecting the

process variable in order to maintain the desired set point.

Watson McDaniel is unique in its ability to provide all of

the necessary components to create a complete

control loop.

RTD or THERMOCOUPLE

TEMPERATURE SENSOR

CONTROL

VALVES

428 Jones Boulevard • Limerick Airport Business Center • Pottstown PA • 19464 • Tel: 610-495-5131 • Fax: 610-495-5134

www.watsonmcdaniel.com

197

Page 15

CONTROL VALVES

Controllers

Design & Operation

Description

A controller is a comparative device that receives an input signal from a measured process variable,

c

ompares this value with that of a predetermined control point value (set point), and determines the

appropriate amount of output signal required by the final control element to provide corrective action

within a control loop. Watson McDaniel offers an

and digital algorithms to perform its receptive, comparative and corrective functions.

Principles of Operation (Electronic PID Controller)

An electronic sensor (thermocouple, RTD or transmitter) installed at the measurement location

continuously sends an input signal to the controller. At set intervals, the controller compares this signal

to a predefined set point. If the input signal deviates from the set point, the controller sends a corrective

electric output signal to the control element. This electric signal must be converted to a pneumatic signal

when used with an air operated valve, such as a Watson McDaniel W910 Series Control Valve. The

conversion can be made using a Watson McDaniel TA901 I/P Transducer, which converts a 4 to 20 mA

electric signal to a 3 to 15 PSI air signal.

Electronic PID Controller, which uses electrical signals

Features (Electronic PID Controller)

An electronic controller is best suited for applications where large load changes are encountered and/or

fast response changes are required. Watson McDaniel Electronic Controllers have full auto-tuning and

PID capabilities, and offer a host of available options, including user selectable inputs and ranges,

VALVES

CONTROL

outputs, setback functions and alarms.

PID Control is a feature of most Watson McDaniel Electronic Controllers. PID combines the proportional,

integral and derivative functions into a single unit.

Auto-Tuning

Auto-tuning will automatically select the optimum values for P, I and D, thus eliminating the need for the

user to calculate and program these values at system startup. This feature can be overridden when so

desired. On some models, the control element can be manually operated.

• Proportional (P) — Proportional control reacts to the size of the deviation from set point when

sending a corrective signal. The size of the corrective signal can be adjusted in relation to the size of

the error by changing the width of the proportional band. A narrow proportional band will cause a

large corrective action in relation to a given amount of error, while a wider proportional band will cause

a smaller corrective action in relation to the same amount of error.

• Integral (I) — Integral control reacts to the length of time that the deviation from set point exists when

sending a corrective signal. The longer the error exists, the greater the corrective signal.

• Derivative (D) — Derivative control reacts to the speed in which the deviation is changing. The cor-

rective signal will be proportional to the rate of change within the process.

198

428 Jones Boulevard • Limerick Airport Business Center • Pottstown PA • 19464 • Tel: 610-495-5131 • Fax: 610-495-5134

www.watsonmcdaniel.com

Page 16

CONTROL VALVES

Controllers

Design & Operation

Selecting an Electronic PID Controller

All Watson McDaniel Electronic Controllers are designed to control the temperature or pressure of general industrial

equipment and should be carefully selected to meet the demands of the particular application. The information contained within this catalog is offered only as a guide to assist in making the proper selection. Selection of the proper

controller is the sole responsibility of the user. Improper application may cause process failure, resulting in possible

personal injury or property damage.

Case Size

Case Size selection is determined by both available and designed space, and controller features.

Watson McDaniel Electronic Controllers are available in the following panel sizes:

48 x 48 mm (1/16 DIN), 72 x 72 mm, 96 x 96 mm (1/4 DIN) and 48 x 96 mm (1/8 DIN).

The depth of the unit varies with the model selected.

Input

The Input is the measurement signal received by the controller from the sensor. A variety of input

types are available, including thermocouple, RTD, voltage and current.

Control Output

The Control Output is the corrective signal transmitted from the controller to the control element.

Various control output types are available, including contact, voltage, current and

solid state relay driver.

Analog Output

The Analog Output is an optional secondary signal that transmits the measurement signal from the

controller to a remote data acquisition device, such as a recorder, personal computer or display unit.

Alarms

Most models can be ordered with alarms, event outputs, or heater break alarms, which signal an

external device to perform a specific task at a predetermined set point.

Setback Function

This feature, optionally available on some models, is designed to provide energy savings in applications

where the process is idled at regular intervals through the connection of an external timer or switch.

CONTROL

VALVES

428 Jones Boulevard • Limerick Airport Business Center • Pottstown PA • 19464 • Tel: 610-495-5131 • Fax: 610-495-5134

www.watsonmcdaniel.com

199

Page 17

CONTROL VALVES

TR890 Series

Electronic PID Controllers • Features PID & Auto-tuning

Specifications

VALVES

CONTROL

Multiple Sizes

+

0.3% Accuracy

Keyboard

Programmable

Reverse or Direct Acting

Manual Output Override

The TR890 Series Electronic

PID Controller is designed for

use on applications where

large load changes are

expected, or extreme

accuracy and fast response

times are needed. With full

auto-tune capabilities and

a large selection of available

inputs, the TR890 Series is

ideally suited for use with

a Watson McDaniel

Control Valve.

Use of a Watson McDaniel

No. TA987 Air Filter/Regulator

is recommended for filtering

and regulating the pressure of

plant compressed air, and for

delivering clean, dry air at

the proper pressure to

pneumatic control devices.

Approximate Shipping Weights:

TR891: 0.4 lbs [0.17 kg]

TR892: 0.6 lbs [0.28 kg]

TR893: 0.7 lbs [0.33 kg]

TR894: 0.5 lbs [0.24 kg]

Models TR891: 48 x 48 mm (1/16 DIN)

Control Control Mode: Auto-Tuning PID

Proportional

Band Integral Time: Off, 1-6000 sec.

Accuracy

Display Process Value: 4 Digit, 20 mm red LED

Inputs Multi: (switchable between)

Control

Output

Power

Requirements

Data Storage

Case Material

Ambient Temp.

Humidity Maximum: 90% RH, non-condensing

Event Outputs

(Contact Capacity: 240 VAC, 1 A/resistive load)

Options:

TR892: 72 x 72 mm

TR893: 96 x 96 mm (1/4 DIN)

TR894: 96 x 48 mm (1/8 DIN)

Action: Reverse acting (field switchable to direct acting)

Off, 0.1-999.9% Full Scale

Derivative Time: Off, 1-3600 sec.

+

0.3%

Set Value: 4 digit, 10.2 mm green LED

Sampling Cycle: 0.25 seconds

Thermocouple: B, R, S, K, E, J, T, N, PL II, WRe5-26 (U,L (DIN 43710)

RTD: Platinum 100 Ω, 3-Wire

mV: (scalable) -10–10, 0-10, 0-20, 0-50, 10-50, 0-100 mV DC

Current: (scalable) 4-20, 0-20 mA

Voltage: -1–1, 0-1, 0-2, 0-5, 1-5, 0-10 VDC

Current: 4-20 mA (load resistance: 600 Ω maximum)

Contact: Proportional cycle,

1-120 sec. (capacity: 240 VAC 2 A resistive / 1.2 A inductive)

SSR Drive Voltage: Proportional cycle 1-120 sec.

(output rating: 12 ± 1.5 VDC / 30 mA maximum)

Voltage: 0-10 VDC

Load Current 2 mA max

Supply Voltage: 100-240 VAC, 50/60 Hz or 24 VAC/VDC 50/60 Hz

Consumption: 100-240 VAC, 15VA

Nonvolatile EEPROM memory

Polyphenylene Oxide (PPO)

14°F (-10°C) to 122°F (50°C)

Dual Event Outputs (High and/or Low Alarms)

Single Event Output + Heater Break Alarm (includes CT30A sensor)

Single Event Output + Heater Break Alarm (includes CT50A sensor)

Analog Output: 0-10 mV DC (output resistance 10 Ω )

Analog Output: 4-20 mA DC (load resistance 300 Ω max )

Analog Output: 0-10 VDC (load current 2 mA max )

Digital Input (switch) including:

Setback Function setting range of -1999 - 5000, standby or DA/RA Selection

Operated by either non-voltage contact or open collector

24 VDC, 8W

24 VAC, 9VA

200

428 Jones Boulevard • Limerick Airport Business Center • Pottstown PA • 19464 • Tel: 610-495-5131 • Fax: 610-495-5134

www.watsonmcdaniel.com

Page 18

CONTROL VALVES

TR890 Series

Electronic PID Controllers

W

H

C

D

A

B

PANEL CUTOUT DIMENSIONS

HOW TO ORDER Sample Order Number: TR893 8 A C 90 1 00

Model Input Control Output Power Supply Event Output Options

TR891 8 Multi A 4-20 mA 90 100-240 VAC, 50/60 Hz 0 None 00 None

TR892 4 mA C On/Off Contact 08 24 VAC/VDC, 50/60 Hz 1 Dual Event 30 Analog Output (0-10 mVDC)

TR893 6 VDC D SSR Driver

TR894 E 0-10 VDC 2 Single Event 60 Analog Output (0-10 VDC)

Event Outputs

2 or 3 require

Control Outputs

C or D

Electronic PID Controller Dimensions – units: inches [mm].

Model ABC DHW

TR891 1.77 [45] 1.77 [45] 0.43 [11] 3.94 [100] 1.89 [48] 1.89 [48]

TR892 2.68 [68] 2.68 [68] 0.43 [11] 3.94 [100] 2.83 [72] 2.83 [72]

TR893 3.63 [92] 3.63 [92] 0.43 [11] 3.94 [100] 3.78 [96] 3.78 [96]

TR894 1.77 [45] 3.63 [92] 0.43 [11] 3.94 [100] 3.78 [96] 3.78 [96]

(high and/or low)

(high or low) and 08 Digital Input (switch)

heater break CT30A 38 Digital Input (switch) with

3 Single Event

(high or low) and

heater break CT50A

40 Analog Output (4-20 mA)

0-10 mVDC* Analog Output

48 Digital Input (switch)

with 4-20 mA* Analog Output

68 Digital Input (switch) with

0-10 VDC* Analog Output

Not available with Model TR891

*

CONTROL

VALVES

Programmable Ranges

Thermocouple Inputs RTD Inputs Current & Voltage Inputs

T/C Range Fahrenheit Range Celsius Range Fahrenheit Range Celsius Range Range

Type Code Range Code Range Code Range Code Range Code

B

*

E 21 0° to 1300°F

J 22 0° to 1100°F

K 18 -150° to 750°F

K 19 0° to 1500°F

K 20 0° to 2200°F

L 28 0° to 1100°F

N 24 0° to 2300°F

PL II 25 0° to 2300°F

R 16 0° to 3100°F

S 17 0° to 3100°F

T 23 -300° to 400°F

U 24 -300° to 400°F

WRe5-26 26 0° to 4200°F

Range Codes are not required for ordering, but are used for field programming.

750°F (400°C) falls below the accuracy range

*

15 0° to 3300°F

01

07

08

04

05

06

14

10

11

02

03

09

13

12

0° to 1800°C 47 -300° to 1100°F

0° to 700°C 48 -150.0° to 200.0°F

0° to 600°C 49 -150° to 600°F

-100.0° to 400.0°C 50 -50.0° to 120.0°F

0° to 800°C 51 0.0° to 120.0°F

0° to 1200°C 52 0.0° to 200.0°F

0° to 600°C 53 0.0° to 400.0°F

0° to 1300°C 54 0° to 1000°F

0° to 1300°C 83 0-2 V

0° to 1700°C 84 0-5 V

0° to 1700°C 85 1-5 V

-199.9° to 200.0°C 86 0-10 V

-199.9° to 200°C 94 0-20 mA

0° to 2300°C 95 4-20 mA

31

32

33

34

35

36

37

38

-200° to 600°C 71 -10–10 mV

-100.0° to 100.0°C 72 0-10 mV

-100.0° to 300.0°C 73 0-20 mV

-50.0° to 50.0°C 74 0-50 mV

0.0° to 50.0°C 75 10-50 mV

0.0° to 100.0°C 76 0-100 mV

0.0° to 200.0°C 81 -1–1 V

0.0° to 500.0°C 82 0-1 V

(User-scalable Readout)

201

Page 19

CONTROL VALVES

TA901 Series

I/P Transducer • Electropneumatic

Specifications

Model

TA901

Input

4-20 mA

Output

1-17 PSIG Per ANSI/FCI 87-2

(can be calibrated to provide

1-9 PSIG or 9-17 PSIG)

Volume Booster

Built-in volume booster allows

flow capacity up to 20 SCFM

VALVES

CONTROL

Connections

Pneumatic: 1/4” NPT

Electric:

1

/2” NPT

4 to 20 mA

Input

3 to 15 PSI

Output

Intrinsically Safe

Zero and Span

Adjustments

The TA901 Electropneumatic (I/P) Transducer converts a milliamp

current signal to a linearly proportional pneumatic output pressure. This

transducer is designed for control applications that require a high degree

of reliability and repeatability. The TA901 is used in the control operation

of valve actuators and pneumatic valve positioners in the petrochemical,

HVAC, energy management, textile, paper, and food & drug industries.

The TA901 I/P Transducer is tested and approved by Factory Mutual as

Intrinsically Safe Class I, II and III, Division I, Groups C, D, E, F and G when

installed in accordance with the Installation, Operation and Maintenance

Instructions. It should be installed in a vertical position in a vibration-free area.

The Watson McDaniel TA987 Air Filter/Regulator is recommended for filtering

and regulating the pressure of plant compressed air, and for delivering clean,

dry air at the proper pressure to pneumatic control devices.

Air Requirements

Clean, oil-free, dry air filtered

to 40 microns

Minimum Supply Pressure:

3 PSIG

Maximum Supply Pressure:

100 PSIG

Sensitivity: < ±0.1% of span

per PSIG

Air Consumption: 0.03 SCFH

typical

Flow Rate: 4.5 SCFM at

25 PSIG supply

Relief Capacity: 2.0 SCFM at

5 PSIG above 20 PSIG setpoint

Mounting

Pipe, panel or bracket in a

vibration-free area. Field

adjustment will be required if

mounted in a nonvertical position.

Adjustment

Adjustable zero and span

Accuracy

Terminal Based Linearity:

< ±0.75% of span

Repeatability: < 0.5% of span

Hysteresis: < 1.0% of span

Response Time: < 0.25 sec. @

3-15 PSIG

Intrinsic Safety

Tested and approved by

Factory Mutual as Intrinsically

Safe Class I, II and III, Division

I, Groups C, D, E, F and G

when installed in accordance

with Installation, Operation and

Maintenance Instructions

Ambient Temperature

-20°F (-30°C) to 140°F (60°C)

Approximate Shipping

Weight

2.1 lbs [0.94 kg]

HOW TO ORDER

Please order using Item Number: TA901

MOUNTING BRACKET

.55 [14.0]

2.88

[73.1]

1.25 [31.8]

Ø

.21 [5.4]

18 GA. WIRE LEADS

18" LONG

202

BLACK-POSITIVE / WHITE-NEGATIVE

428 Jones Boulevard • Limerick Airport Business Center • Pottstown PA • 19464 • Tel: 610-495-5131 • Fax: 610-495-5134

1.10

[27.9]

.55

[14.0]

10-32 UNF-2A X .38 DEEP

MOUNTING HOLES

1.43

[36.2]

1.09

[27.7]

4.24

[107.7]

1/4 NPT

www.watsonmcdaniel.com

1/2

NPT

1.50

[38.1]

.55 [14.0]

Unit: inches [mm].

Ø

1.13

[28.7]

2.18 [55.4]

MAX. SQUARE

1.50

[38.1]

Page 20

CONTROL VALVES

TA987

Air Filter/Regulator

Specifications

Model

TA987

Air Requirements

Maximum Supply Pressure:

250 PSIG

Output Range:

0 to 30 PSIG, adjustable

Sensitivity: 0.036 PSIG

Air Consumption: < 6 SCFH

Cast Aluminum

Housing

Removable Nylon

Mesh Filter

Low Air

Consumption

Drip Well

Air Requirements (cont.)

Flow Rate: 20 SCFM at 100

PSIG supply/20 PSIG output

Relief Capacity: 0.1 SCFM at

5 PSIG above setpoint

Effect of Supply Pressure

Variation: < 0.2 PSIG for

25 PSIG

The TA987 Air Filter/Regulator is recommended for filtering

and regulating the pressure of plant compressed air, and for delivering

clean, dry air at the proper pressure to pneumatic control devices. Supply air

enters the inlet port, passes through the filtering element, and exits through

the reducing valve to the outlet port. The filtering element removes particles

as small as 40 microns. A drip well is provided for the accumulation of oil

and water and a drain cock is included to allow purging of the unit.

The filtering element is readily accessible for cleaning by removal of the

drip well bowl.

The maximum allowable supply pressure to TA987 Air Filter/Regulator

is 250 PSIG. Improper application may cause failure of the regulator,

resulting in possible personal injury or property damage.

Filter

Removes particles 40 microns

or greater

Port Size

1

/4” NPT

Housing

Cast aluminum

Mounting

Side, pipe, panel or

through body

Ambient Temperature

-20°F (-30°C) to 160°F (71°C)

Approximate Shipping

Weight

1.9 lbs [0.86 kg]

CONTROL

VALVES

Units: inches [mm].

.31 [7.9] SQUARE

1.44

[36.6]

GAUGE

PORT

.05 [1.2]

TO C

L

OF

GAUGE

PORT

2.75

[69.9]

3.19

[81.0]

428 Jones Boulevard • Limerick Airport Business Center • Pottstown PA • 19464 • Tel: 610-495-5131 • Fax: 610-495-5134

VENT

2.10

[53.3]

Ø

.44

[11.2]

2.14

[54.4]

.75

[19.1]

OUT

2.06

[52.3]

1.25

[31.8]

2.25

[57.2]

3.19

[81.0]

10-24 UNC

2 HOLES

1/4-20 UNC

.44 [11.1] DEEP

2 HOLES

Ø

.36 [9.1]

THRU 2 HOLES

7.25

[184.2]

www.watsonmcdaniel.com

203

Page 21

CONTROL VALVES

Electronic Temperature Sensors

Connection Head Type • RTD & Thermocouple

The Watson McDaniel

VALVES

CONTROL

3.40

[86.2]

3.91

[99.4]

Thermocouple

or RTD

Cast Aluminum,

Polypropylene

or Stainless

Steel Head

Weather Proof

Welded or

Spring Loaded

Stem

Ø

3.30

[83.8]

1/2 NPT

Ø

.25

[6.4]

Units: inches [mm]

STEM

LENGTH

Connection Head is

available with both Type J

and Type K Thermocouples,

as well as RTD sensors. The

weather proof head provides

a conduit connection and is

available in cast aluminum

(screw cover), polypropylene

(flip cover) and stainless steel

(screw cover). The stem is either

1

welded directly to the

/2”NPT

threaded connection, or is

spring-loaded to provide

maximum sensitivity. The

spring-loaded stem must always

be installed in a thermowell.

Extension wire and transmitter

accessories are also available.

Please consult factory.

For applications where

the process media may

be corrosive or contained

under pressure, the use of

a thermowell is required to

prevent damage to the sensor

and facilitate its removal from

the process. To prevent leakage

of the process media, spring

loaded sensors must always

be installed in a thermowell.

Sensor Specifications

Thermocouple

Type Color Code Positive Lead Negative Lead Temperature Range

J Black Iron* (Fe) Constantan (Cu-Ni) 32° to 1382°F

K Yellow Nickel-Chromium (Ni-Cr) Nickel-Aluminum* (Ni-Al) 32° to 2282°F

*magnetic lead

RTD

Type Material Resistance @ 0°C Temperature Coefficient Temperature Range

D Platinum (Pt) 100 Ω Ω a = 0.00385 Ω/Ω/°C -50° to 700°F

M Platinum (Pt) 1000 Ω a = 0.00385 Ω/Ω/°C -50° to 700°F

[white] [red] (0° to 750°C)

[yellow] [red] (0° to 1250°C)

Specifications

Sensors Description

TJD Type J T/C

TKD Type K T/C

TDD 100 Ω RTD

TMD 1000 Ω RTD

Hot Junction

T/C: Ungrounded

RTD: Platinum, 3-Wire

Stem

Insulation

Head

Process Connection

Conduit Connection

Approximate Shipping Weight

316 stainless steel

1

/4"

diameter

Ceramic

Cast aluminum, polypropylene or

stainless steel

1

/2” NPT welded or spring-loaded

3

/4” NPT Female

1.1 lbs [0.50 kg]

(-45° to 400°C)

(-45° to 400°C)

HOW TO ORDER Sample Order Number: TJD Z 04 U W A

Sensor Stem Style Stem Length Hot Junction Connection Head Material

TJD Type J T/C Z 316SS, 1/4” O.D. 02 21/2" Stem U Ungrounded (T/C) S Spring Loaded, A Aluminum

TKD Type K T/C 04 4" Stem D 3-Wire (RTD)

TDD 100 Ω RTD 06 6" Stem W Welded, S Stainless Steel

TMD1000 Ω RTD 09 9" Stem

12 12" Stem

Other sensor styles available. Other Lengths: Specify in inches (24" maximum)

Please consult factory.

204

428 Jones Boulevard • Limerick Airport Business Center • Pottstown PA • 19464 • Tel: 610-495-5131 • Fax: 610-495-5134

www.watsonmcdaniel.com

1

/2” NPT P Polypropylene

1

/2” NPT

Page 22

CONTROL VALVES

Thermowells

for RTD & Thermocouple Temperature Sensors

Standard (21/2" - 6")

STEM LENGTH

1/2 NPSM

.40 [10]

with Lagging Extension (4” - 24”)

(A)

(P)

EXTERNAL

THREAD

U

LENGTH

.61 [15]

1/2 NPSM

.75 [19]

Ø

.260 [7]

Ø

.44 [11]

LAGGING

EXTENSION

(T)

Standard (9” - 24”)

1/2 NPSM

(P)

1.00

[25]

U

LENGTH

.75 [19]

(A)

STEM LENGTH

1.00

[25]

EXTERNAL THREAD

(P)

EXTERNAL

THREAD

(A)

STEM LENGTH

LENGTH

Ø

.260 [7]

U

Ø

.50 [13]

Ø

.260 [7]

Ø

.50 [13]

Units inches: [mm]

CONTROL

VALVES

Lengths

(A) U (T) U

Stem Length Length Lagging Extension Length

21/2" 1.75 [44] — —

4” 2.50 [64] 1.00 [25] 1.50 [38]

6” 4.50 [114] 2.00 [51] 2.50 [64]

9” 7.50 [191] 3.00 [76] 4.50 [114]

12” 10.50 [267] 3.00 [76] 7.50 [191]

15” 13.50 [343] 3.00 [76] 10.50 [267]

18” 16.50 [419] 3.00 [76] 13.50 [343]

24” 22.50 [572] 3.00 [76] 19.50 [495]

Standard Lagging

Selection of the proper thermowell is the sole responsibility of the user. Temperature and pressure limitations must be considered.

Improper application may cause failure of the thermowell, resulting in possible personal injury or property damage. For correct use

and application, please refer to the Thermowells For Thermometers And Electrical Temperature Sensors Standard ASME B40.9.

HOW TO ORDER Sample Or

mowell Style (P) External Thread (A) Stem Length (T) Lagging Extension Material

Ther

1

76 -Sensor, Stepped Shank 3

1

(2

/2" - 6" Stem 43/4NPT G 4" Stem C 2" Extension (6" Stem only) 3 Steel

Straight Shank)

*Not available with 2

1

/2" Stem Length

Other thermowell styles available. Please consult factory.

/2NPT* D 21/2" Stem A 1" Extension (4" Stem only) 2 Brass

5 1 NPT* J 6" Stem E 3" Extension (9" thru 24” Stem only) 4 Monel

M 9" Stem Omit if No Extension 5 304SS

R 12" Stem 6 316SS

V 15" Stem

Wa 18" Stem

Wk 24" Stem

Pressure Ratings (PSI)

Operating Temperature

Material

Carbon steel 5000 5000 4800 4600 3500 -

304 stainless steel 6550 6000 4860 4140 3510 3130

316 stainless steel 6540 6400 6000 5270 5180 4660

Monel 5530 4990 4660 4450 4450 -

Brass 3170 PSI @ 150˚F, 2930 PSI @ 350˚F

70°F 200°F 400°F 600°F 800°F 1000°F

der Number:

76-4J6

428 Jones Boulevard • Limerick Airport Business Center • Pottstown PA • 19464 • Tel: 610-495-5131 • Fax: 610-495-5134

www.watsonmcdaniel.com

205

Loading...

Loading...