Page 1

SELECTING TEMP.

PILOTS

- 118 -

- 118 -

SELECTING TEMPERATURE PILOTS

Any of the Main Valves described in the Main Valve Section can

be combined with any of the Pilots listed below, to produce the

SPENCE Temperature Regulator. This Regulator is designed to

control the flow of fluid to a heating or cooling element so as to

maintain a constant, adjustable, precise predetermined temperature. Pilots fully stroke valve within 5°F. The table below lists

the principal Temperature Pilots.

The Thermostats of these SPENCE Pilots are of the Vapor

Tension Type. They are ruggedly constructed and will not be

injured by overheating.

These SPENCE T emperatur e Pilots can be furnished with 150°F

range of temperature adjustment on special order. It should be

noted that since heavier Adjusting Springs are required for this

greater range the regulation will not be quite so accurate.

TEMPERATURE RANGES

20°F to 120°F 150°F to 300°F Thermostats can be furn50°F to 150°F 170°F to 270°F ished for temperatures

70°F to 170°F 250°F to 350°F higher than 350°F on

120°F to 220°F special order.

HEATING CONTROL Single Pilot Types T134 and Combination Pilot Type T14D2 reduce the steam pressure as well as

regulate the output temperature. A choice should be made

according to the maximum required delivery pressure, i.e., the

pressure needed in the heater to carry the peak load. Pilot

Types T14D and T14D2 in cast steel are designed for initial

steam pressures in excess of 500°F.

Of the Air Control Pilots, the Type T61 is the general choice.

The Type T60 is used for temperature indication or for remote

adjustment. The required heater pressure will determine the

choice of the A Series Pilot. See Product Pages.

COOLING CONTROL Pilot Type T52 is employed With Type

E or C Series Main Valves to control temperature by regulating

the flow of a cooling medium. This Pilot opens the Main Valve on

rising temperature and exercises no control over the delivery

pressure. The Air Control Pilots can be furnished with increasing

air signal on temperature rise for use in cooling control.

TEMPERATURE RANGESSelection of the following ranges of

temperature adjustment is recommended for the services noted:

50°F to 150°F Room or air duct control

120°F to 220°F Domestic or laundry hot water service.

70°F to 170°F Fuel oil preheating.

170°F to 270°F Fuel oil heating.

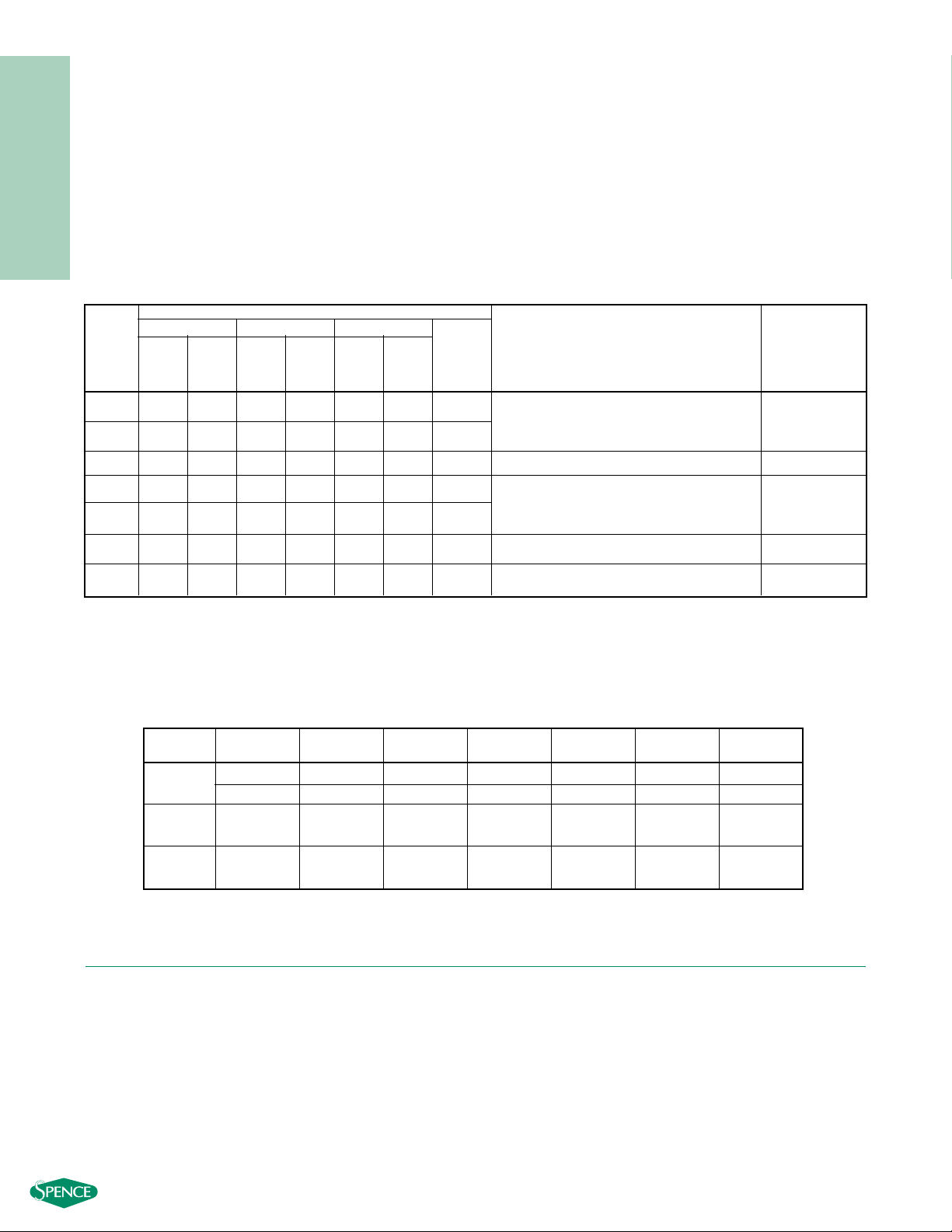

Type Service Conditions Operating Characteristics Main Valve

Cast Iron Cast Bronze

a

Cast Steel

Delivery

Maximum Maximum Maximum Maximum Maximum Maximum

Pressure

Initial Temper- Initial Temper- Initial Temper-

Pressure ature Pressure ature Pressure ature Maximum

psi °F psi °F psi °F psi

T134 250 450 — — 600 750 20

Cascade Control–Closes on rise in temperature–controls delivery pressure–decreases

E or C Series

T124 250 450 ———— 125

delivery pressure as temperature increases

& vice versa–spring loaded pressure control.

T14 250 450

——

600 750 — Closes on rise in temperature. E or C Series

T14D 250 450

——

600 750 150

Closes on rise in temperature–controls

delivery pressure at predetermined setting–

E or C Series

T14D2 250 450 — — 600 750 300

spring loaded pressure control

T52 250 450

——

— — — Opens on rise in temperature. E or C Series

Safety

Pilot

— — 300 500 — — — Prevents excessive temperature rise.

E or C Series

a

Bronze Body Pilots are recommended for water service.

* Rising output pressure on falling temperature. This action applied to an EA Series Regulator increases steam flow with decreasing

temperature. Direct action available for cooling control.

**Rate or reset available on application ***Other ranges on application 1Type 304 2Type 347 or optional Type 316

TEMPERATURE

REGULATOR PILOTS

AIR CONTROLLED TEMPERATURE PILOTS

NOTES ON SELECTION OF PILOTS

SPENCE Air Control Pilots, listed below, have been developed

to meet special conditions when used in conjunction with A

Series Pressure Pilots. The fast bi-metal thermostats have a

200°F adjustable range and protection against damage from

over-heating. By cascading an air signal onto a pressure regulator , the EAT Series temperature control reduces steam pressure

to an adjustable limit as well as regulating output temperature.

Bulb Bulb Bulb Range Maximum Bulb Control Action

Type Style Material Mounting °F Temperature °F Mode

No.736 Bronze

1

/2 NPT 50-250 350 Proportional Reverse*

T61

No. 737 St. Stl.

1

1

/

2 NPT 50-250 350 Proportional Reverse*

Sanitary

T64 No. 738 St. Stl.

1

Thermometer

50-250 350 Proportional Reverse*

Bushing

1

/2NPT

30-150 180 Proportional Reverse*

T60 No.745 St. Stl.

2

Union

100-300*** 350 Proportional Reverse*

Mounted

Page 2

SIZING TEMPERATURE REGULATORS

DATA

REQUIRED FOR ORDERING

1. SERVICE

(a) Fluid flowing though Regulator.

(b) Type heater to be controlled.

2. INITIAL (INLET) PRESSURE

(a) Maximum/Minimum.

(b) Superheat, Gravity, etc.

(1) Steam Service–Total Temperature or Degrees

Superheat, if any.

(2) Air, Gases, Water and Liquids–Temperature and

Specific Gravity.

3. DELIVERY (OUTLET) PRESSURE Maximum required on

heater.

4. CAPACITY Maximum required flow through Regulator or

the following data leading to same:

(a) Quantity and type of fluid to be heated or cooled.

(b) Temperature rise or drop, °F.

5.THERMOSTAT CHARACTERISTICS:

(a) Controlled Temperature, °F–Maximum/Minimum.

(b) Operation–Open or Close on temperature rise.

(c) Thermostat Bulb–Style Number and Material.

(d) Flexible Tubing–Length and Material.

6. END CONNECTIONS Screwed or Flanged. (If flanged,

state drilling)

S

ELECTION OF TYPE AND SIZE OF REGULATOR

MAIN VALVE

A. TYPE —See Selection Criteria

for Steam, Air, Gases or Water

and Liquids in beginning of this

Section.

B. SIZE—See applicable Valve

Capacity Tables in this Section.

C. MATERIAL— See Main Valve

Selection Chart in Technical

Reference Section or individual

Product Pages.

D. ACCESSORIES—See Accessories in Other Products

Section.

EXAMPLE

Select size and type Regulator for heating 120 gpm water from

50°F entering temperature to 170°F final temperature in an

instantaneous heater. Steam supply at 125 psi pressure to be

reduced to 30 psi maximum in heater.

1. (a) Steam

(b) Instantaneous

2. (a) 125 psi

(b) None (saturated, 353°F total temperature)

3. 30 psi

4. See Capacity Tables in this Section.

(a) 120 gpm water.

(b) 170-50 = 120°F Rise

120

x 120 = 7200#/Hr.

2

5. (a) 170°F–Select standard Temperature Range from facing

page to include this final temperature.

(b) Close on temperature rise.

(c) Style No. 700 bronze. (See Options Section)

(d) Ten (10) feet, brass–fur nished unless otherwise specified.

6. Flanged, if 2

1

/2" size or larger.

S

ELECTION OF T

YPE AND SIZE OF REGULATOR

MAIN VALVE

A. Since maximum Delivery

Pressure is less than 75%

of minimum Initial Pressure

and the least pressure drop

exceeds required “minimal

differential”.

SELECT TYPE E

B. Using Capacity Tables in

this Section, for 7200#/Hr

and 125 psi initial pressure

SELECT 2" FULL PORT

C. For 125 psi, 353°F:

SELECT CAST IRON,

NPT 250

D. None required in this case.

PILOT

Since maximum Initial

Pressure 125 psi, Total

Temperature 353°F

maximum Delivery

Pressure 30 psi

SELECT TYPE T124

For 125 psi, 353°F:

SELECT CAST IRON

None required in this case.

PILOT

See Selection Criteria

and Selection Charts

opposite.

See Pilot Selection

Chart opposite or individual Product Pages.

ECONOMICAL SOLUTION: 3" SPENCE TYPE ET124, CAST IRON BODY, NPT 250 ENDS

TEMPERATURE RANGE 120-220°F EQUIPPED WITH 10 FEET OF BRASS FLEXIBLE TUBING

AND STYLE NO. 700 BRONZE THERMOSTAT BULB.

Temperature Regulators should always be protected by properly designed Strainers.

- 119 -

SIZING TEMPERATURE

REGULATORS

Loading...

Loading...