Page 1

STEAM SCRUBBER

STAINLESS FILTER

STEAM SCRUBBER FILTER

A

PPLICATION DATA

●Culinary Grade Steam

●Sterilizers

●Autoclaves

●Pharmaceutical & Biotechnology Process Equipment

●Clean Room Humidification

●Chemical Industry

●Electronic Industry

●Plastic Industry

OPTIONS

●316L Housing

●Silicone, Viton or Buna N Gaskets

●Flange or Welded Ends

●4" to 8" with ANSI Flanged End

Canadian Registration #OE8186.8O

- 346 -

STEAM SCRUBBER

STAINLESS STEEL FILTER

SIZES 1/2" to 3"

PRESSURES to 145 PSIG at 353°F

●1 and 5 Micron Filters meet or exceed FDA

guidelines and comply with 3A

●Electropolished and Passivated 304 Stainless

Steel Housing

●Double O-ring EPDM Housing Gasket

●Inline NPT Connections

●Single Clamp Closure

●Sintered 316 Stainless Steel Filter Media

●Porosity Level greater than 50%

●Filter Media in 1, 5 or 25 Micron Absolute

Ratings

●Filter Element Endcaps of 304 Stainless Steel

●Renewable Filter Media

●Single Open End Filter Media

MODELS

●

SS2L–2" low capacity

●SS3L–3" low capacity

●SS12–1/2" standard capacity

●SS34–3/4" standard capacity

●SS1–1" standard capacity

●SS114–11/4" standard capacity

●SS112–11/2" standard capacity

●SS2–2" standard capacity

●SS212–21/2" standard capacity

●SS3–3" standard capacity

NOTE: Please specify if Material Test Reports (MTR) or Certificates of

Conformance (COC) are required.

REQUIRES DRIP TRAP.

C

OMBINE WITH DS200 TRAP

FOR MOST

CLEAN STEAM APPLICATIONS

DS200 TRAP

PAGE 340

Installation Tip: Add Uniflex Pipe Coupling for ease of maintenance

SEE PAGE 374

Page 2

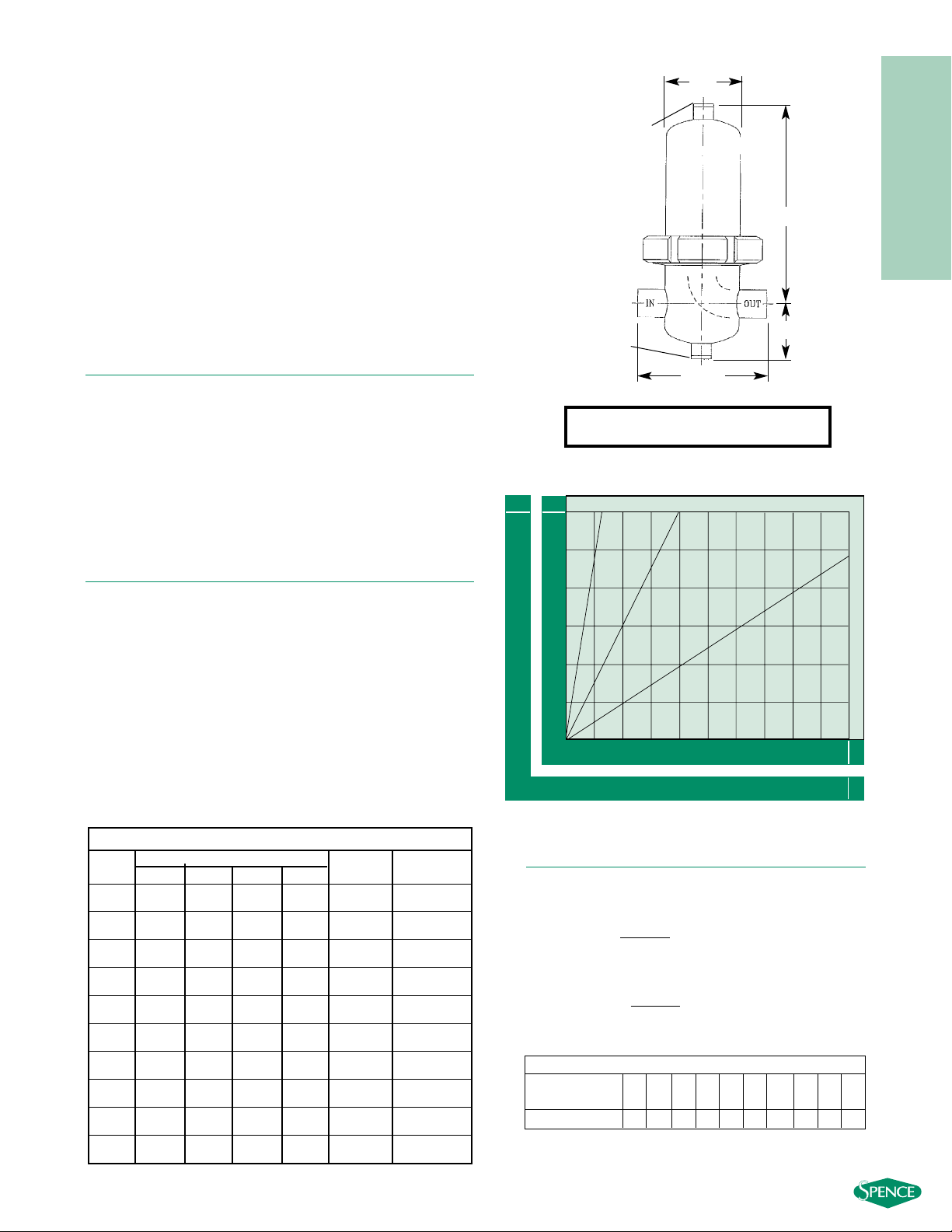

STEAM SCRUBBER

STAINLESS FILTER

- 347 -

Saturated Steam Capacity

— 2"L, 250°F, 15 PSI (Cm)*

*For other pressures and sizes, see conversion factors.

STEAM SCRUBBER

STAINLESS STEEL FILTER

SPECIFICATION

Furnish and install as shown on the plans, high efficiency, inline

horizontal, filter for air, steam or gas constructed with 304 or

316L stainless steel housing and single, open ended element.

Filter shall have an absolute rating of 1, 5 or 25 microns and utilize

double o-ring gaskets to reduce potential downstream leakage of

unfiltered medium. External surface finish of filter housing shall be

no less than 180 grit (25-35 Ra microinch) and joined utilizing a

single clamp. Filter media shall be of sintered 316L stainless steel

and be regenerable. 1 and 5 micron media shall conform to 3A

sanitary standards for production of culinary steam and be USDA

accepted. Connections shall be NPT, flanged ANSI 150 or welded.

MAXIMUM O

PERATING CONDITIONS*

PMO:Max. Operating Pressure 145 psig (10 barg)

Limit for Saturate

Steam 125 psig (8.6 barg)

TMO: Max. Operating Temperature 353°F (178°C)

PMA: Max. Allowable Pressure 232 psi/g0-400°F

(16 barg/0-204°C)

TMA: Max. Allowable Temperature 400°F/0-232 psig

(204°C/0-16 barg)

*For differential pressures greater than 75 psig, consult factory.

MATERIALS OF CONSTRUCTION

Body, Standard ……………………… 304 Stainless Steel

Body, Optional ………………………316L Stainless Steel

Clamp …………………………………304 Stainless Steel

Plug ……………………………………304 Stainless Steel

Gasket, Standard ……………………………………EPDM

Gasket, Optional ……………………………………Silicone

Gasket, Optional ………………………………………Viton

Gasket, Optional……………………………………Buna N

Filter Media…………………Sintered 316L Stainless Steel

Filter End Caps ………………………304 Stainless Steel

C

D

A

B

DIMENSIONS AND WEIGHTS

Size Dimensions, Inches (mm) Weight Conversion

in.(mm) A B C D lbs (kg) Factors (Cs)

1

/2 21/8 73/8 23/4 41/8 4.2 0.17

(15) (55) (188) (70) (108) (1.9)

3

/4 21/8 83/8 23/4 47/8 4.4 0.25

(20) (55) (211) (70) (125) (2.0)

127/8 85/8 33/8 47/8 5.7 0.39

(25) (74) (219) (85) (125) (2.6)

11/4 27/8 105/8 33/8 51/2 6.6 0.50

(32) (74) (270) (85) (140) (3)

11/2 33/4 111/2 41/8 65/8 10.1 0.67

(40) (94) (292) (104) (170) (4.6)

2L* 33/4 143/8 41/8 65/8 10.6 1.00

(50) (94) (366) (104) (170) (4.8)

233/4 193/8 41/8 65/8 11.7 1.50

(50) (94) (493) (104) (170) (5.3)

21/2 41/4 245/8 51/8 81/2 19.8 2.00

(65) (106) (626) (129) (216) (9)

3L* 41/4 345/8 51/8 81/2 23.8 2.70

(80) (106) (881) (129) (216) (10.8)

345/8 353/4 69

3

/8 35.6 4.00

(80) (119) (907) (154) (240) (16.2)

* L denotes low capacity

SELECTION EXAMPLE

For optimum service life, the filter should have a 1 psi

maximum pressure drop. Select a 5 micron filter for a

flow rate of 110 lbs/hr (w) of saturated steam at 45 psi.

Where: Cs =

w

CmCp

Designing for .75 PSI differential pressure, Cm is 225

from the capacity chart and Cp is 2.0.

Therefore: Cs =

110

=.24 so 3/4" should be

used.

(225)(2.0)

Steam Pressure Conversion Factors (Cp)

Steam Pressure

PSI 0 15 30 45 60 75 90 105 120 135

bar01 2345 6789

Conversion factor 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0

Connections:

1/2" – 3" NPT, Flanged or Welded

1/4" NPT

1/4" NPT

(kg/hr)

(lb/hr)

–114 –

–250–

– 90 –

–200–

–150–

– 68 –

25 micron

Volumetric flow

– 45 –

–100–

– 23 –

– 50 –

– 0 –

– 0 –

5 micron

icron

1 m

0 0.5 1.0

– –

0 0.05 0.07 0.140.10 bar

– –

– –

– –

Differential pressure

– –

– –

– –

– –

2.01.5 PSI

– –

– –

Loading...

Loading...