Page 1

MARSHALL ENGINEERED PRODUCTS CO.

STEAM SPECIALTIES

MODEL “OBHSS” SERIES

STAINLESS STEEL

INVERTED BUCKET STEAM TRAP Models OBHSS-1400/2400 (THD or SW)

Models OBHSS-UNIV400

Connectors OBHSS-12Conn (Thrd or SW)

OBHSS-34Conn (Thrd or SW)

APPLICATION

The MEPCO Stainless Steel Bucket Trap operates efficiently with

pressures up to 400 psi and is applicable to all types of medium

and high pressure steam systems. Its purpose is to efficiently

drain condensate, vent air and prevent the flow of steam into the

return piping. The Swivel Connector as found in the Model

OBHSS-UNIV is designed to maintain the bucket in the proper

plane. This trap is easily replaced or maintained without any

disturbance to the piping connections. Typical Applications

include: laundry equipment, main drip stations, and even hard to

reach applications.

FORM SSBT

FEATURES & BENEFITS

FEATURES

1. Simple, rugged construction. Trap body and internals are made of 304 stainless steel.

The valve and valve seat are manufacturered with chrome steel to provide a long lasting

seat. The trap construction is good for working pressures up to 400 psi, and

temperatures up to 800 deg F.

2. The MEPCO Stainless Steel Bucket Trap has a weld-sealed body which is tamper-proof,

maintenance-free, and protects against leakage, freezing conditions and waterhammer.

3. Unlike standard bucket traps, the MEPCO Stainless Steel bucket trap is self priming.

The OBHSS-UNIV Series MEPCO Stainless Steel Bucket Trap requires no additional piping in

either plane. The swivel connector allows for the trap to be mounted in the vertical plane

regardless to the plane of the piping. The OBHSS series trap is available in Socket Weld or

Threaded connections for both the OBHSS-UNIV and OBHSS-1400/2400 series. Swivel

Connector sold separately.

3056 Walker Ridge Drive Suite C • Grand Rapids, Michigan 49544 • 616-246-1431 • FAX: 616-246-1445 •

http://www.mepcollc.com

Form SSBT

Formerly Dunham Division of Dunham-Bush, Inc. Printed in U.S.A.

Page 2

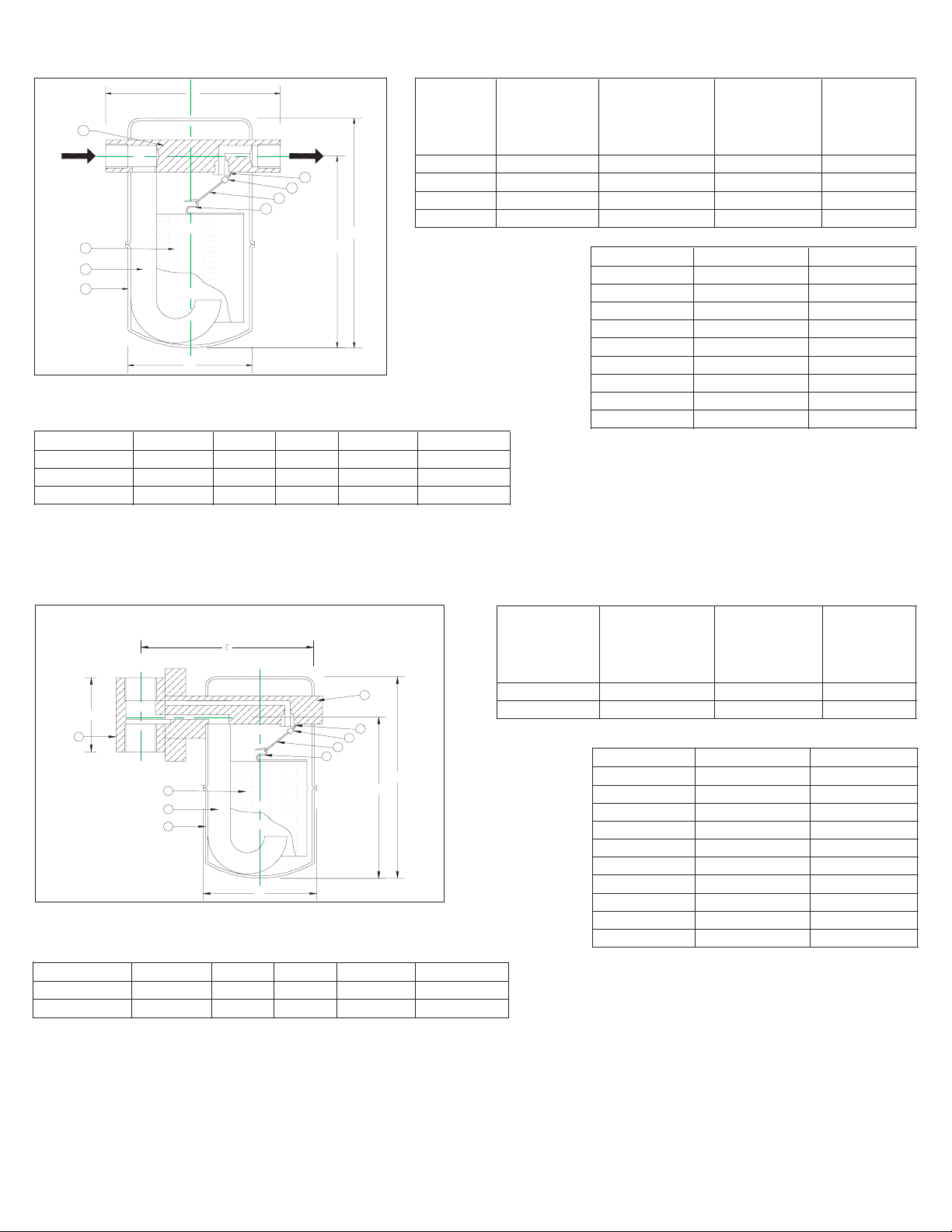

e

y

e

y

C

Max.

2

Model

Available

Conn.Sizes

Allowowable

Pressure

Max Allowable

Temp (deg F)

Max

Allowable

Pressure

(psi)

3

5

1

Model A (in

4

5

7

8

B

D

A

)

B (in) C (in) D (in) Weight (lbs)

OBHSS-1200 1/2 400 800 200

OBHSS-1400 1/2 400 800 400

OBHSS-3400 3/4 400 800 400

OBHSS-1200 2.75 5.31 4.31 4.44 1.75

OBHSS-14/3400

C

9

2.75 6.56 4.31 5.56 2.25

2

4

5

7

8

B

3

5

1

A

D

ITEM Part Material

8.00 Bucket Clip Stainless Steel

7.00 Lever Stainless Steel

6.00 Inlet Tub

Stainless Steel

5.00 Valve Chromium SS

4.00 Valve Seat Chromium SS

3.00 Bucket Stainless Steel

2.00 Connector Stainless Steel

1.00 Bod

Stainless Steel

Max

Max.

Allowowable

Model

OBHSS-Univ 400 800 800

Pressure

Max Allowable

Temp (deg F)

Allowable

Pressure

(psi)

ITEM Part Material

9.00

Swivel Connector

8.00 Bucket Clip Stainless Steel

7.00 Lever Stainless Steel

6.00 Inlet Tub

Stainless Steel

5.00 Valve Chromium SS

4.00 Valve Seat Chromium SS

3.00 Bucket Stainless Steel

2.00 Shaft Stainless Steel

1.00 Bod

Stainless Steel

Model A (in )

B (in) C (in) D (in) Weight (lbs)

OBHSS-Univ 2.75 7.19 2.38 4.81 4.75

* Connector Shown in Drawing Sold Separately

3056 Walker Ridge Drive Suite C Grand Rapids, Michigan 49544 Phone: 616-246-1433 Fax: 616-246-1445

Form SSBT Printed in U.S.A.

Loading...

Loading...