Page 1

12

845.778.5566 ● Fax: 845.778.7123 ●

www.nicholsonsteamtrap.com

Incoming air and condensate flow through the trap

body and into the control chamber. Line pressure

raises the disc off the seat, allowing complete discharge. When flashing condensate enters the cartridge, flow velocity increases, creating low pressure underneath the disc. Flashing condensate at

high velocity strikes the inside wall of the disc

chamber and is deflected to the top of the disc,

causing a pressure buildup. The disc is forced down onto

the seat by this pressure imbalance. The trap remains

closed as flashed vapor in the control chamber keeps the

disc seated. Pressure inside the cap is not lowered until the

trapped flash vapor condenses due to body radiation.

Condensing steam lowers the pressure above the disc.

Disc is then lifted and the cycle repeated.

SANITIZER NTD 230L

SERIES SANITARY

THERMODYNAMIC

STEAM TRAPS

Pressures To 150 PSIG (10.3 barg)

Temperatures to 850°F (454°C)

Sanitary — 316L stainless steel bar stock body, disc and

cap, with surface finishes better than 32m in. Ra, prevent

contamination and rouging.

Compact Design — Stainless steel disc is the only moving

part.

Inexpensive — Low initial cost is less expensive than

repairable technologies.

Simplifies Installation — Works in any position.

Rugged — Handles water hammer and superheat.

Reliable, Efficient Operation — Blast discharge quickly

draws condensate and helps maintain system temperature.

Freeze resistant — Self draining design with vertical install

drain prevents freezing.

All 316L Stainless Steel Construction — Resists both

internal and external corrosion.

Easy to Monitor — Audible discharge cycle makes

checking operation simple.

M

ODELS

●

NTD 230L–Sanitizer Thermodynamic Steam Trap

NOTE: Please specify if Material Test Reports (MTR) or Certificates of

Conformance (COC) are required.

APPLICA TIONS

●

Steam Tracing

●Drip Leg

●Heating

●Sanitary Applications

OPERA TION

Page 2

845.778.5566 ● Fax: 845.778.7123 ●

www.nicholsonsteamtrap.com

13

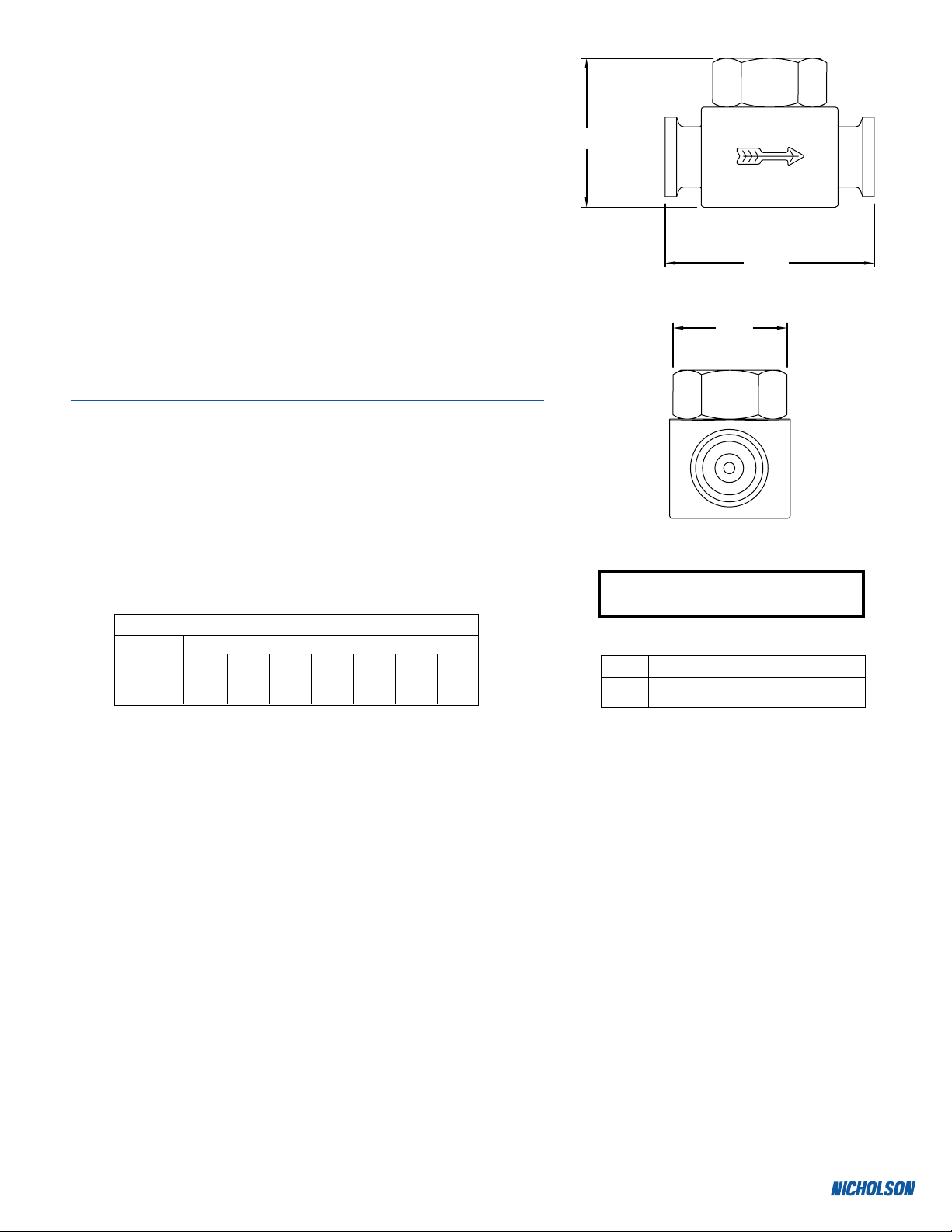

Connections: 1⁄2"/ 3⁄4"

Hygienic Clamp

SANITIZER NTD 230L

SERIES SANITARY

THERMODYNAMIC

STEAM TRAPS

SPECIFICATION

Steam Trap shall be of the thermodynamic design. Body shall be of 316L stainless steel construction. Surface finishes shall exceed 32 µ in. (0.75 µm) grade.

Trap body shall contain an integral seat. Cover shall seal to body without gaskets or seals. Trap shall be suitable for pressures through 150 PSI (10.3 barg).

Trap end connections shall be hygienic clamp and accommodate mating connection sizes of 1/2 and 3/4 inch. Trap shall function installed in any pipe configuration.

MAXIMUM

OPERA TING

CONDITIONS

PMO: Max. Operating Pressure 150 psig (10.3 barg)

TMO: Max. Operating Temperature 850°F (454°C)

PMA: Max. Allowable Pressure 230 psig (15.9 barg)

TMA: Max. Allowable Temperature 850°F (454°C)

M

ATERIALS OF CONSTRUCTION

Body ……………………………………316L Stainless Steel Bar Stock

Disc ……………………………………316L Stainless Steel Bar Stock

Cover……………………………………316L Stainless Steel Bar Stock

C

A

Maximum Capacity

— lbs/hr (10°F Below Saturation)

Differential PSIG (barg)

Orifice 5 10 20 50 100 125 150

(0.34) (0.7) (1.4) (3.4) (6.9) (8.6) (10.3)

0.141 215 236 264 345 447 486 521

For Kg/Hr Multiply by .454

A B C Weight

25⁄

8 1

1

⁄

2 2 1.31

(66) (38) (51) (0.59)

B

DIMENSIONS inches (mm) and WEIGHTS pounds (kg)

Loading...

Loading...