Page 1

34

845.778.5566 ● Fax: 845.778.7123 ●

www.nicholsonsteamtrap.com

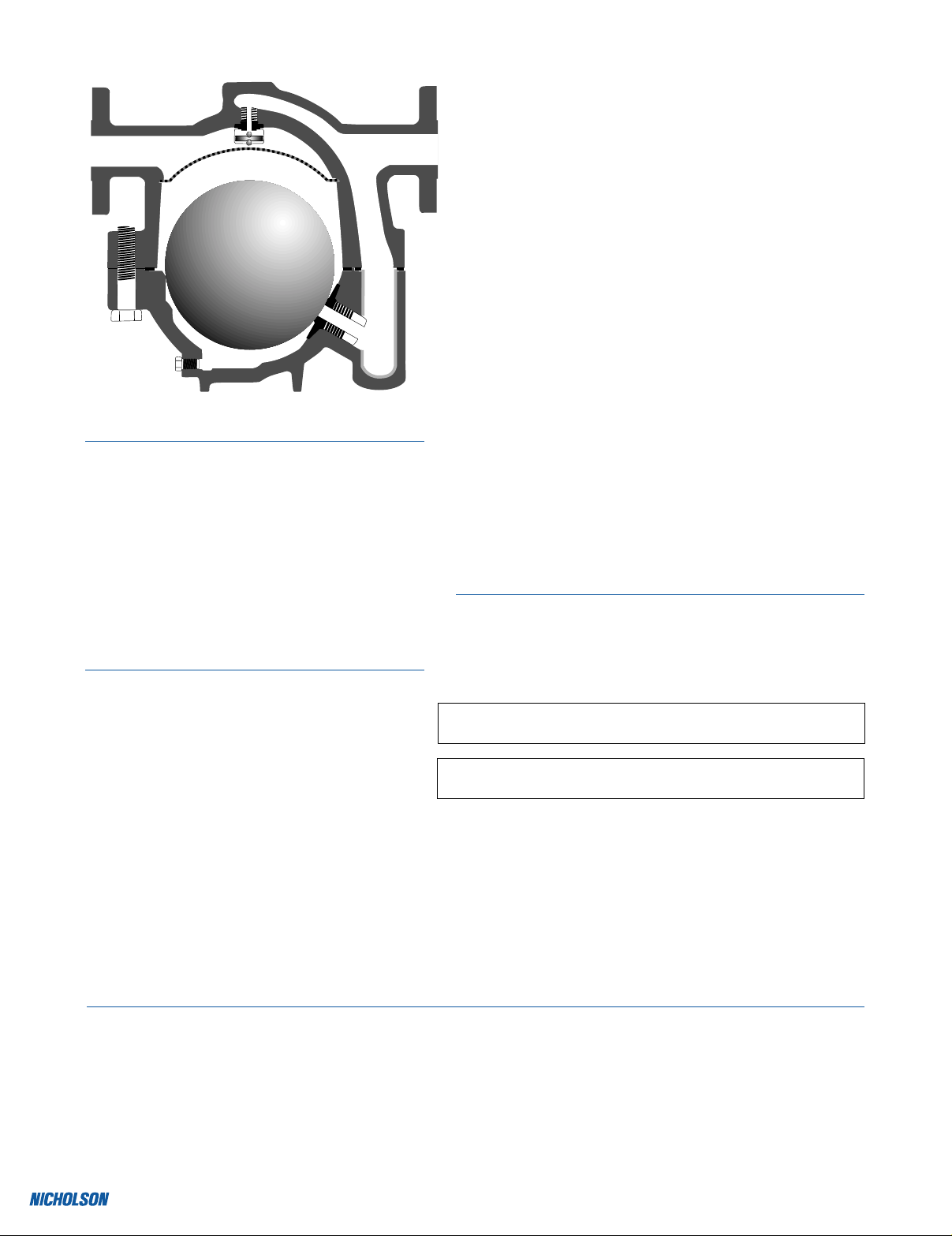

On startup, the thermostatic air vent (caged

stainless welded bellows) is open, allowing air to

flow freely through the vent valve orifice. When

condensate flows into the trap, the float rises,

allowing condensate to be discharged. Once air and

non-condensibles have been evacuated, hot

condensate will cause the thermostatic vent to

close. Condensate will continue to be discharged as

long as condensation occurs.

During normal operation, an increase in the load

causes the liquid level in the trap to rise. The float

then rises and rolls off the seat ring, allowing more

condensate to flow out. The float sinks as the

condensate load decreases, moving nearer to the

seat ring, decreasing the effective size of the orifice

and allowing less condensate to discharge. This

provides smooth, continuous operation that reacts

instantly to load variation while maintaining a water

seal over the seat ring to prevent live steam loss.

NOVA NFT650 SERIES

VARIABLE ORIFICE

STEAM TRAPS

Pressures To 650 PSIG (44.8 barg)

Temperatures to 750°F (400°C)

All Stainless Steel Internal Components — Hardened

valves and seats. Extra long life and dependable service.

Resists water hammer. Protects against erosion and

corrosion.

Erosion Proof — Discharge passage is protected with a

stainless steel liner.

Integral Strainer — Stainless Steel screen prevents dirt

problems. Blow-down connection provided.

Thermostatic Air Vent —Provided with balanced

pressure element for immediate and complete air venting.

Variable Orifice — Condensate is discharged

continuously through the seat ring which is modulated by

the float. This provides a smooth, even flow without high

velocity or steam entrainment.

SLR Orifice — Optional continuous bleed prevents flash

steam lockup when it is impossible to install trap at low

point in system.

Guarantee — Traps are guaranteed against defects in

materials or workmanship for 3 years.

M

ODELS

●

NFT651–Low capacity

●NFT652–Medium capacity

●NFT653–High capacity

A

PPLICATIONS

●

Steam Lines

●Process Equipment

●Steam Cookers

●Steam Heated Vats

●Pressing Machinery

●Unit Heaters

●Oil Preheaters

●Converters

●Coils

●Rotating Drum

O

PTIONS

●

SLR - SLR Orifice

●B - Blowdown Valve (contact factory)

●Continuous Bleed Air Vent

●300# or 600# Flanged Connection* (Raised

Face)

*Available on NFT652 and NFT653 only.

Canadian Registration # OE0591.9C

OPERA TION

Installation Tip: Add Uniflex Pipe Coupling for ease of maintenance

SEE PAGE 102

Installation Tip: Always install STV Test & Block Valve as part of trap station

SEE PAGE 118

See page 9

Page 2

845.778.5566 ● Fax: 845.778.7123 ●

www.nicholsonsteamtrap.com

35

Steam trap shall be of float and thermostatic design. Float shall be

free of levers, linkages, or other mechanical connections. Float

shall be weighted to maintain orientation and shall act as the

valve being free to modulate condensate through the seat ring.

Air vent shall be of balanced pressure design with stainless steel

welded encapsulated bellows capable of discharging air and

noncondensable gases continuously within 15°F of saturated

temperature. Trap shall contain integral strainer and stainless

steel exhaust port sleeve. Trap shall be cast steel bodied suitable

for pressures to 650 psi and available in 1/2" through 2" NPT,

Socket Weld, or flanged.

NOVA NFT650 SERIES

VARIABLE ORIFICE

STEAM TRAPS

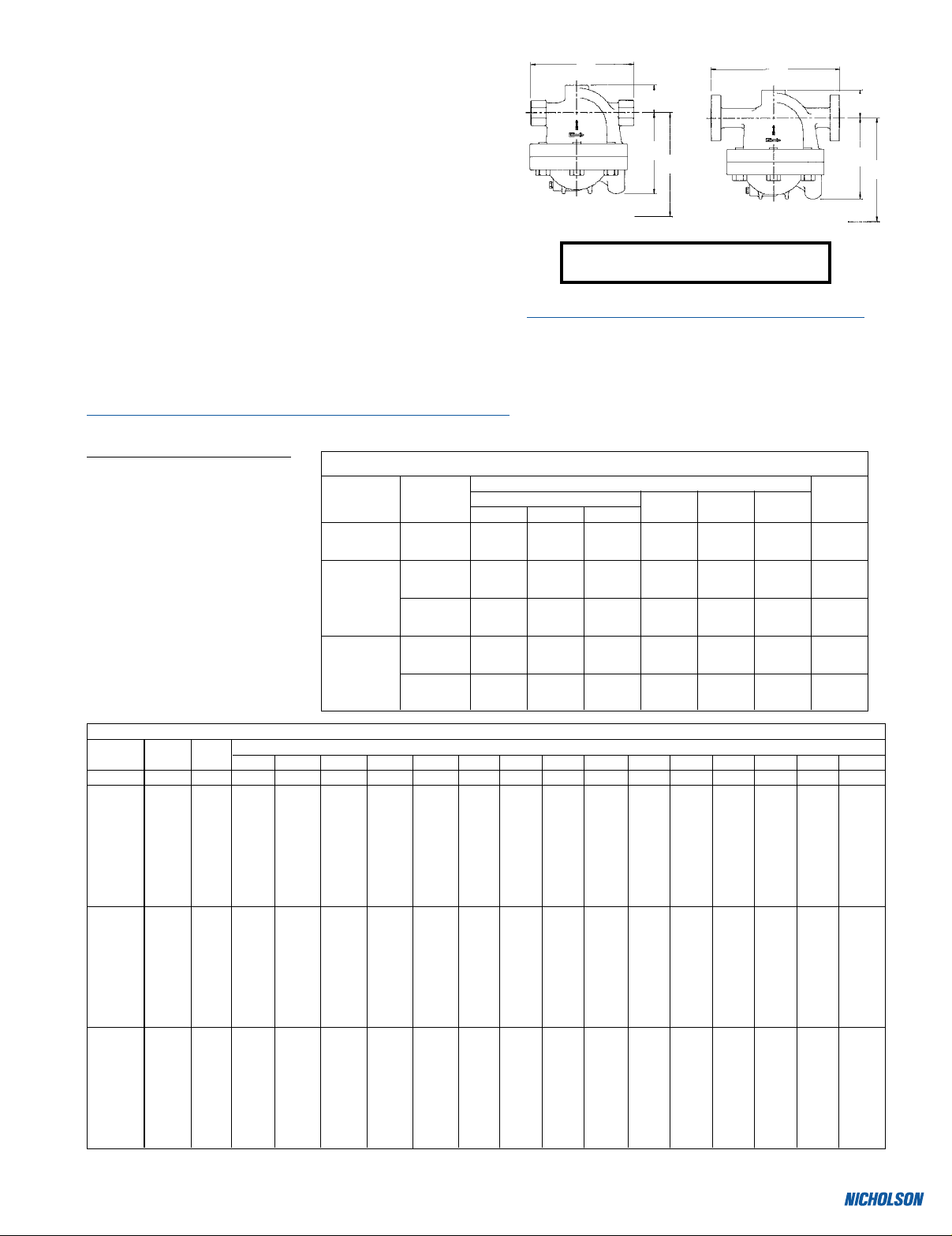

S

PECIFICATION

A

B

C

D

Clearance for Maintenance

A

B

C

Clearance for Maintenance

D

MAXIMUM OPERATING CONDITIONS

PMO: Max. Operating Pressure

ORIFICE PMO

20 20 psig (1.4 barg)

50 50 psig (3.5 barg)

100 100 psig (6.9 barg)

175 175 psig (12.1 barg)

300 300 psig (20.7 barg)

400 400 psig (27.6 barg)

600 600 psig (41.4 barg)

PMA

: Max. Allowable Pressure:

650 psig (44.8 barg)

TMA: Max. Allowable Temperature:

750°F (400°C)

Dimensions

Inches (mm)

Weight

Model Size

ABCD

Lbs.

NPT 300# 600#

(kg)

NFT6511/2

,

3

/4

& 1 5

1

/2— —

3

1

/16

5

7

/16

7

1

/4

21

(140) (78) (138) (184) (9.5)

11113

3

/4 133/4 215/16 83/4 113/8 84

NFT652

(279) (349) (349) (75) (222) (290) (38.2)

11/2 & 2 11 133/4 149/16 215/16 83/4 113/8 87

(279) (349) (370) (75) (222) (290) (39.5)

11/2 133/4 163/4 173/8 35/16 117/8 16 192

NFT653

(349) (426) (411) (84) (392) (406) (87.3)

213

3

/4 1611/16 177/16 35/16 117/8 16 195

(349) (424) (443) (84) (302) (406) (88.6)

For Kg/Hr Multiply by .454

MATERIALS OF

CONSTRUCTION

Body & Cover . . . . . .ASTM A216 Grade WCB

Cover Gasket . . . . .Spiral Wound 304 Stainless

w/graphite filler

All Internal . . . . . . . . . . . . . . . . .Stainless Steel

Air Vent . . .Balanced Pressure, Stainless Steel

Connections:

1

⁄2-2" NPT or 11⁄2-2" Flanged

Maximum Capacity - lbs/hr (10 degrees Below Saturation)

Trap Orifice MAX Differential - PSIG (barg)

Size

∆P

1 5 10 20 50 75 100 150 175 200 250 300 400 500 600

(.07) (.34) (.69) (1.38) (3.45) (5.17) (6.90) (10.3) (12.1) (13.8) (17.2) (20.7) (27.6) (34.5) (41.4)

0.277 20 590 1600 2100 2450

0.209 50 340 760 1080 1540 2460

0.157 100 200 500 650 830 1100 1300 1400

0.141 150 170 385 527 705 990 1130 1240 1415

NFT651 0.130 175 180 350 500 675 900 1000 1100 1300 1400

0.120 250 110 255 360 500 700 800 900 1000 1050 1100 1200

0.106 300 105 240 330 435 575 675 750 875 955 1020 1140 1255

0.096 400 100 220 300 390 510 585 640 740 795 835 920 1000 1140

0.081 600 75 145 180 225 300 340 375 435 465 490 540 585 665 740 800

0.593 20 2720 6280 8600 11700

0.469 50 1750 3920 5560 7900 12600

0.339 100 930 2170 3130 4460 6020 7030 7960

0.316 150 850 1935 2650 3540 4970 5685 6230 7100

NFT652 0.297 175 800 1700 2300 3200 4400 5000 5500 6400 6900

0.261 250 670 1400 1900 2540 3500 4100 4200 5100 5300 5500 6000

0.238 300 645 1240 1565 1955 2575 2940 3220 3740 4000 4220 4640 5060

0.213 400 515 995 1250 1565 2060 2355 2575 2995 3200 3380 3720 4050 4600

0.180 600 370 710 895 1120 1470 1680 1840 2140 2290 2410 2655 2890 3300 3655 3955

1.102 20 8000 15000 18000 22800

0.875 50 5460 12600 15600 18400 25400

0.593 100 2800 6350 8700 12800 16600 18700 21000

0.578 150 2690 6120 8385 11200 15700 17980 19700 22450

NFT653 0.547 175 2400 5500 7600 10300 14400 16500 18200 20750 21900

0.484 250 1600 3770 5300 7560 10400 12100 13600 15500 16300 17100 18400

0.453 300 1500 3500 5200 7075 9325 10655 11655 13545 14485 15275 16815 18315

0.404 400 1400 2800 4200 5630 7420 8480 9270 10770 11520 12150 13380 14570 16555

0.339 600 800 1800 2800 3900 5220 5970 6530 7585 8110 8555 9420 10260 11655 12960 13990

Loading...

Loading...