Page 1

14

845.778.5566 ● Fax: 845.778.7123 ●

www.nicholsonsteamtrap.com

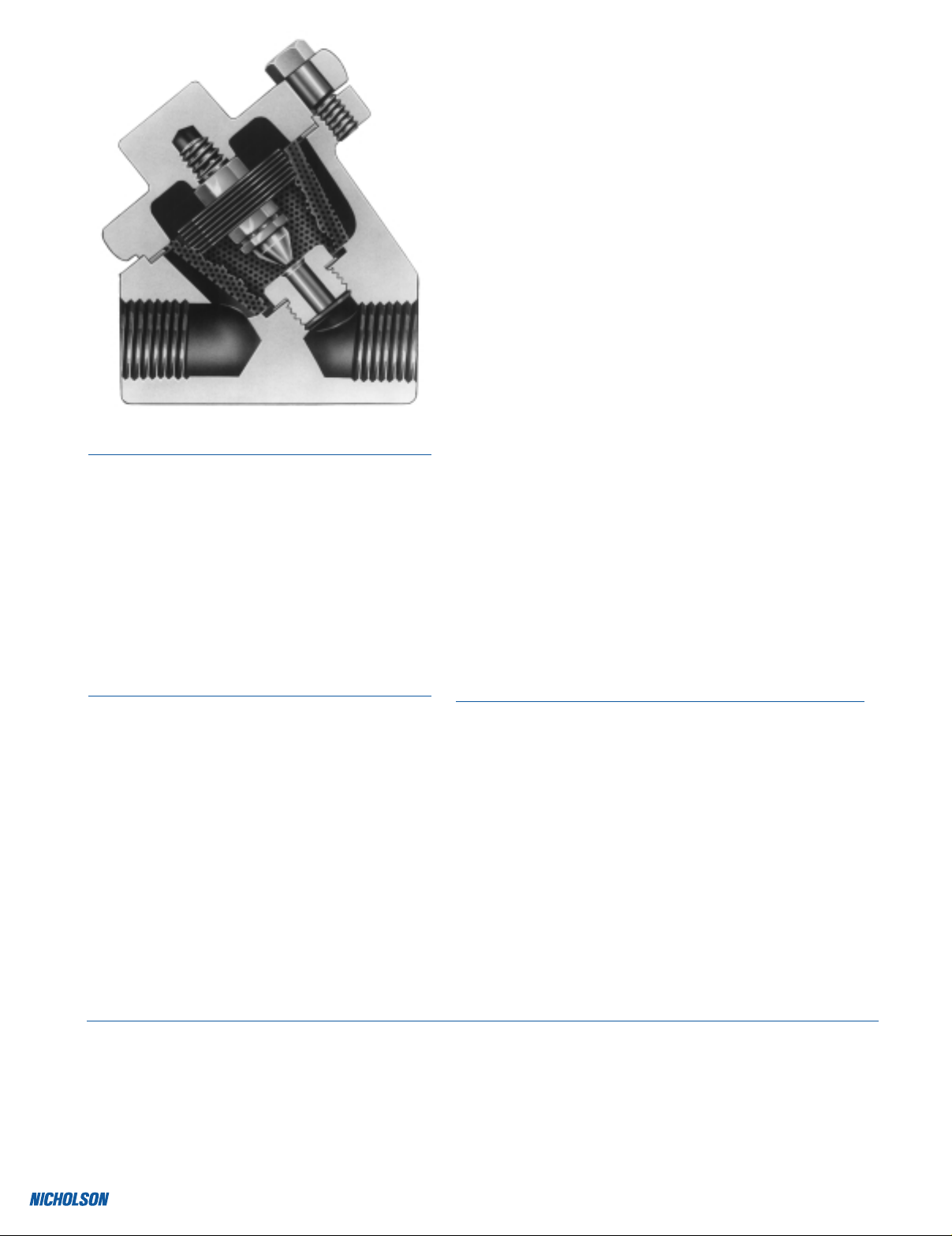

OPERA TION

Thermal actuator is filled at its free length with a

liquid having a lower boiling point than water.

On start-up, valve is normally open. When

steam enters trap, thermal actuator fill vaporizes

to a pressure higher than line pressure. This

forces valve into seat orifice to prevent any

further flow. As condensate collects, it takes

heat from thermal actuator, lowering internal

pressure.

Line pressure will then compress thermal actuator to open

valve and discharge condensate. Valve opening

automatically adjusts to load conditions from minimum on

very light loads to full lift at maximum load. Restricted

orifice in the N451 seat (small opening at bottom of valve

seat) prevents trap from discharging continuously on light

loads such as are encountered on tracer lines.

N450 SERIES

THERMOSTATIC

STEAM TRAPS

Pressures to 450 PSIG (31 barg)

Temperatures to 600°F (316°C)

Compact — Easy to Install.

Inexpensive — Low initial cost.

Improved Energy Savings — High efficiency–maximum

elimination of air and non-condensibles.

Temperature Sensitive Actuators — One moving part.

Stainless Steel, fail open, welded actuator for maximum

corrosion, thermal and hydraulic shock resistance.

Hardened Stainless Steel Valve and Seat — Long life.

Lapped as a matched set for water tight seal.

Easily Maintained — Can be inspected and serviced

without breaking pipe connections.

Freeze Proof — Self draining when installed vertically.

For Superheated Steam Applications — Because the

trap closes at saturated steam temperature, superheated

steam cannot reach trap.

Air Vent — Efficient steam service air vent when

equipped with ISO filled Actuator and installed in air vent

location.

Guaranteed — Guaranteed against defects in materials

or workmanship for 3 years.

Positive Shutoff and Long Life — Integral Stainless

Steel Strainer helps prevent debris depositing on valve

and seat.

MODELS*

● N451-FO–Low capacity, fail open only

● N452–Reduced capacity

● N453–Standard capacity

● N454–High capacity

*Add (-FC) for fail closed or (-FO) for fail open to end of model number

APPLICA TIONS

●

Unit Heaters

● Air Vents

● Steam Tracing

● Drip Legs

● Platen Presses

● Plating Tanks

● Sterilizers

● Tire Presses

● Cooking Equipment

● Laundry Equipment

● Other Process Equipment

OPTIONS

●

SK - Skirted Seat*

●SLR - SLR Orifice

●ISO - ISO Filled Actuator*

●S - Internal SS Strainer (std. on N451)

●ST - Sterilizer Trim

●SW - Socketweld

*Not available on N451

Canadian Registration # 0E0591.9

See page 9

Page 2

845.778.5566 ● Fax: 845.778.7123 ●

www.nicholsonsteamtrap.com

15

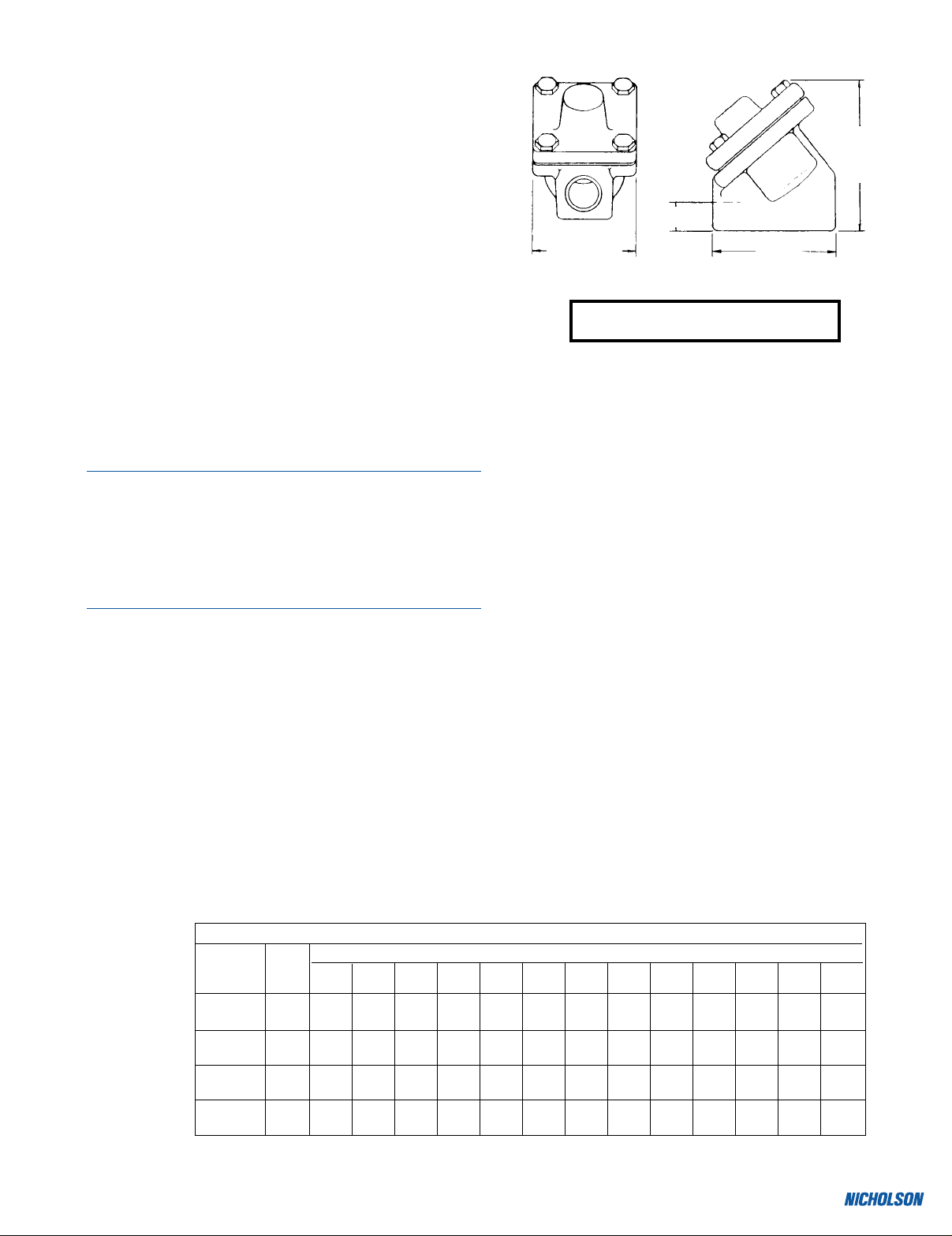

Connections:

1/2" or 3/4" NPT or socketweld

N450 SERIES

THERMOSTATIC

STEAM TRAPS

SPECIFICATIONS

Steam trap shall be of balanced pressure design with stainless

steel welded actuator capable of discharging condensate within

10°F of saturated temperature. Where greater sensitivity is

required, SLR orifice and Sterilizer trim will be available to allow

condensate evacuation at or near saturated temperatures. Where

subcooling of condensate is desired alternate thermostatic

actuator will be available to allow condensate evacuation at or

near 40°F below saturated temperatures. Thermostatic actuator

shall employ a conical valve lapped in matched sets with the seat

ring assuring tight shut off. A minimum of three orifice sizes shall

be available allowing for custom capacity sizing. Trap shall be

forged carbon steel bodied suitable for pressures through 450

psig and available in 1⁄2" and 3⁄4" NPT or socket weld.

M

AXIMUM OPERATING

CONDITIONS

PMO: Max. Operating Pressure† 450 psig (31 barg)

TMO: Max. Operating Temperature 600°F (316°C)

PMA: Max. Allowable Pressure 450 psig (31 barg)

TMA: Max. Allowable Temperature 750°F (399°C)

† Consult factory for pressures greater than 300 psi.

MATERIALS OF CONSTRUCTION

Body ……………………………ASTM A105 Forged Steel

Cover ………………………ASTM A351 Grade CF8 (304)

Cover Gasket ……304 SS Spiral Wound w/Graphite Fill

Actuator……………………………Welded Stainless Steel

Strainer …………………….033 Perf. 304 Stainless Steel

Valve & Seat ………………Hardened 416 Stainless Steel

3 (76)

35⁄8

(92)

21⁄2

(64)

WEIGHT: 3 LBS. (1.4 KG)

Maximum Capacity—lbs/hr 10°F Below Saturation (Kg/hr 5°C Below Saturation)

Trap

Orifice Differential PSIG (barg)

Inch 5 10 20 50 100 125 150 200 250 300*350*400*450

*

(mm) (0.34) (0.7) (1.4) (3.4) (6.7) (8.4) (10.1) (13.4) (16.8) (20.1) (24.1) (27.6) (31.0)

N451

5/64 84 119 168 265 348 375 398 439 472 502 529 553 575

(2) (38) (54) (76) (120) (158) (170) (181) (199) (214) (228) (240) (251) (261)

N452

1/8 216 265 375 592 778 838 890 980 1055 1121 1180 1235 1284

(3) (98) (120) (170) (269) (354) (381) (405) (445) (480) (510) (536) (561) (584)

N453

1/4 550 825 1210 1975 2825 3140 3425 3650 3960 4100 4230 4420 4600

(6) (249) (374) (549) (896) (1281) (1424) (1554) (1656) (1796) (1860) (1919) (2005) (2086)

N454

5/16 860 1220 1725 2725 3575 3850 4090 4505 4850 5155 5425 5675 5900

(8) (390) (554) (783) (1237) (1623) (1748) (1857) (2045) (2202) (2340) (2463) (2576) (2679)

* Nicholson recommends skirted seat above 300 PSIG (20.7 bar). Nicholson recommends ISO filled Actuator for superheated steam.

11

⁄16 (17)

Loading...

Loading...