Page 1

SELECTING

DIFFERENTIAL PILOTS

NOTES ON SELECTION OF PILOTS

DIFFERENTIAL P

RESSURE REGULATOR PILOTS

- 120 -

SELECTING DIFFERENTIAL PRESSURE PILOTS

SPENCE Differential Pressure Regulators may usually be classified in one or the other of the following groups:

1. Control of the delivery pressure at a constant, adjustable, predetermined differential above another source of fluid pressure.

This case is illustrated by the use of the SPENCE Type EN

Differential Pressure Regulator on a boiler feedwater make-up

line to control the delivery pressure of the feedwater at a constant differential above the boiler steam pressure. Another

example is the use of the Type EN to control the steam pres-

sure on a steam atomizing oil burner at a constant differential

above the oil pressure at the nozzle.

2. Control of the differential pressure or pressure drop across

the Pressure Regulator itself. This case is illustrated by the use

of the SPENCE Type EN24 Differential Pressure Regulator

installed in parallel with a heat exchanger to maintain a constant differential across it, thereby limiting the flow rate of

fluid through the heater.

The table below lists the principal Differential Pilots.

TYPE N AND N33 PILOTS require that the delivery pressure

(pressure of fluid discharged from the Regulator) be controlled

at a given differential above some separate source of loading

pressure.

TYPE N meets the requirements of most boiler feedwater

make-up and steam atomizing oil burner differential control

problems as described in the first group in the above table.

TYPE N33 is a version of the Type N in which two separated

diaphragms are employed to preclude the possibility of contact

between the two fluids applied to the pilot.

TYPE N20 is a differential relief pilot which causes the Main

Valve to open when its initial pressure exceeds the loading

pressure by a set differential.

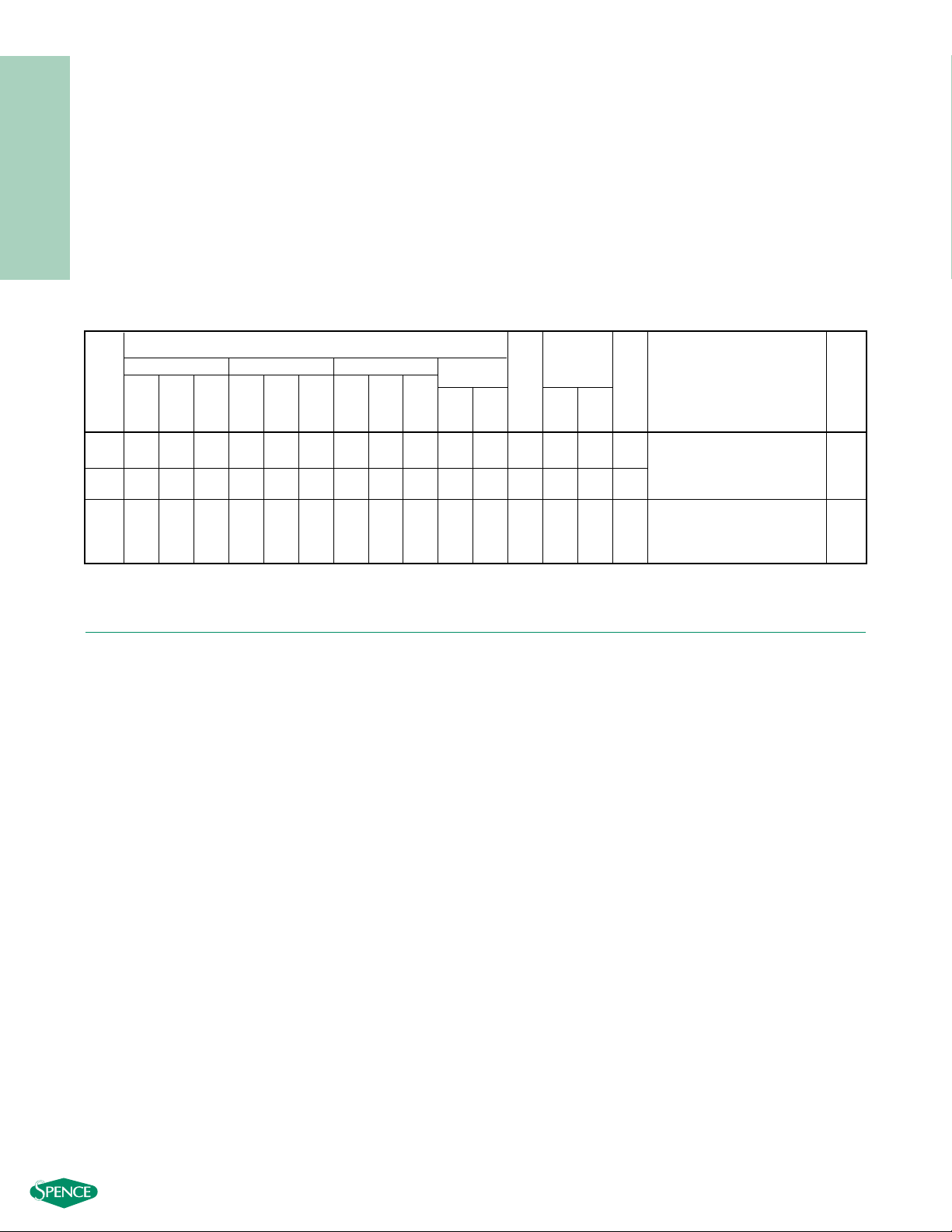

Type Service Conditions Diaphragm Operating Main

Cast Iron Cast Bronze

a

Cast Steel

Differential

Characteristics Valve

Max. Max. Max. Max. Max. Max. Max. Max. Max.

Pressure

Normal Loading

Initial Temper- Diaph. Initial Temper- Diaph. Initial Temper- Diaph. Accuracy

Pressure ature Pressure Pressure ature Pressure Pressure ature Pressure Min. Max. Diameter Material

psi °F psi psi °F psi psi °F psi psi psi ± inches

N 250 450 240 300 500 290 600 750 300 3 150 1 psi 31/2 St. Stl. Spring

Closes on increase in differential E or C

Delivery pressure controlled at set Series

N33 250 450 240 300 500 290 600 750 300 3 150 1 psi 31/2 St. Stl. Spring

differential above loading pressure E or C

Loading Pressure may be any fluid Series

Opens on increase in differential

N20 250 366 250 300 366 300 300 366 300 3 150 1 psi 31/2 St. Stl. Spring

Initial pressure controlled at set E or C

differential above loading pressure Series

Loading pressure may be any fluid

a

Bronze Body Pilots are recommended for water service.

Page 2

SIZING DIFFERENTIAL PRESSURE REGULATORS

DATA

REQUIRED FOR ORDERING

1. SERVICE Fluid flowing though Regulator.

2. INITIAL (INLET) PRESSURE

(a) Maximum/Minimum.

(b) Superheat, Gravity, etc.

(1) Steam Service–Total Temperature or Degrees

Superheat, if any.

(2) Air, Gases, Water and Liquids–Temperature and

Specific Gravity.

3. LOADING PRESSURE

(a) Maximum/Minimum.

(b) Fluid

4. CONTROLLED PRESSURE

(a) Maximum/Minimum.

(b) Fluid

5. DELIVERY PRESSURE Maximum/Minimum.

6. CAPACITY Maximum required flow through Regulator.

7.END CONNECTIONS Screwed or Flanged. (If flanged,

state drilling.)

SELECTION OF TYPE AND SIZE OF REGULATOR

MAIN VALVE

A. TYPE —See Selection Criteria

for Steam, Air, Gases or Water

and Liquids in beginning of this

Section.

B. SIZE—See applicable Valve

Capacity Tables in this Section.

C. MATERIAL— See Main Valve

Selection Chart in Technical

Reference Section or individual

Product Pages.

D. ACCESSORIES—See Accessories in Other Products

Section.

EXAMPLE

Select size and type Regulator to control the flow of water from

a Motor-Driven Centrifugal Boiler Feed Pump maintaining an

Excess or Differential pressure of 50 psi between the boiler

feedwater and the boiler steam pressure. The feedwater

temperature is 240°F. The boiler steam pressure is 150 psi.

Flow 90 gpm at 220 psi pump discharge pressure.

1. Water

2. (a) 220 psi

(b) 240°F

3. (a) 150 psi Boiler Pressure

(b) Steam

4. (a) 200 psi (Loading plus Excess Pressure)

(b) Water

5. Identical with Controlled Pressure, Item 4

6. 90 gpm

7. Flanged, if 2

1

/2" size or larger

SELECTION OF TYPE AND SIZE OF REGULATOR

MAIN VALVE

A. Since pressure drop across

valve (Initial Pressure minus

Delivery Pressure) is greater

than 10 psi:

SELECT TYPE E

B. For 90 gpm: SELECT 3"

C. For 220 psi, 240°F:

SELECT CAST IRON,

FLANGED 250 LB.

D. For Water Service:

Dashpot required.

PILOT

Since Initial Pressure 220 psi,

240°F, Differential (Excess)

Pressure 50 psi and the

Delivery and Controlled

Pressures are the same:

SELECT TYPE N

For 220 psi, 240°F:

SELECT BRONZE

None required in this case.

ANSWER: 3" SPENCE TYPE EN, CAST IRON BODY, 250 LB FLANGED ENDS,

EQUIPPED WITH BRONZE DASHPOT AND BRONZE PILOT BODY.

NOTE: Differential Regulators should always be protected by properly designed Strainers.

PILOT

See Selection Criteria

and Selection Charts

opposite.

See Pilot Selection

Chart opposite or individual Product Pages.

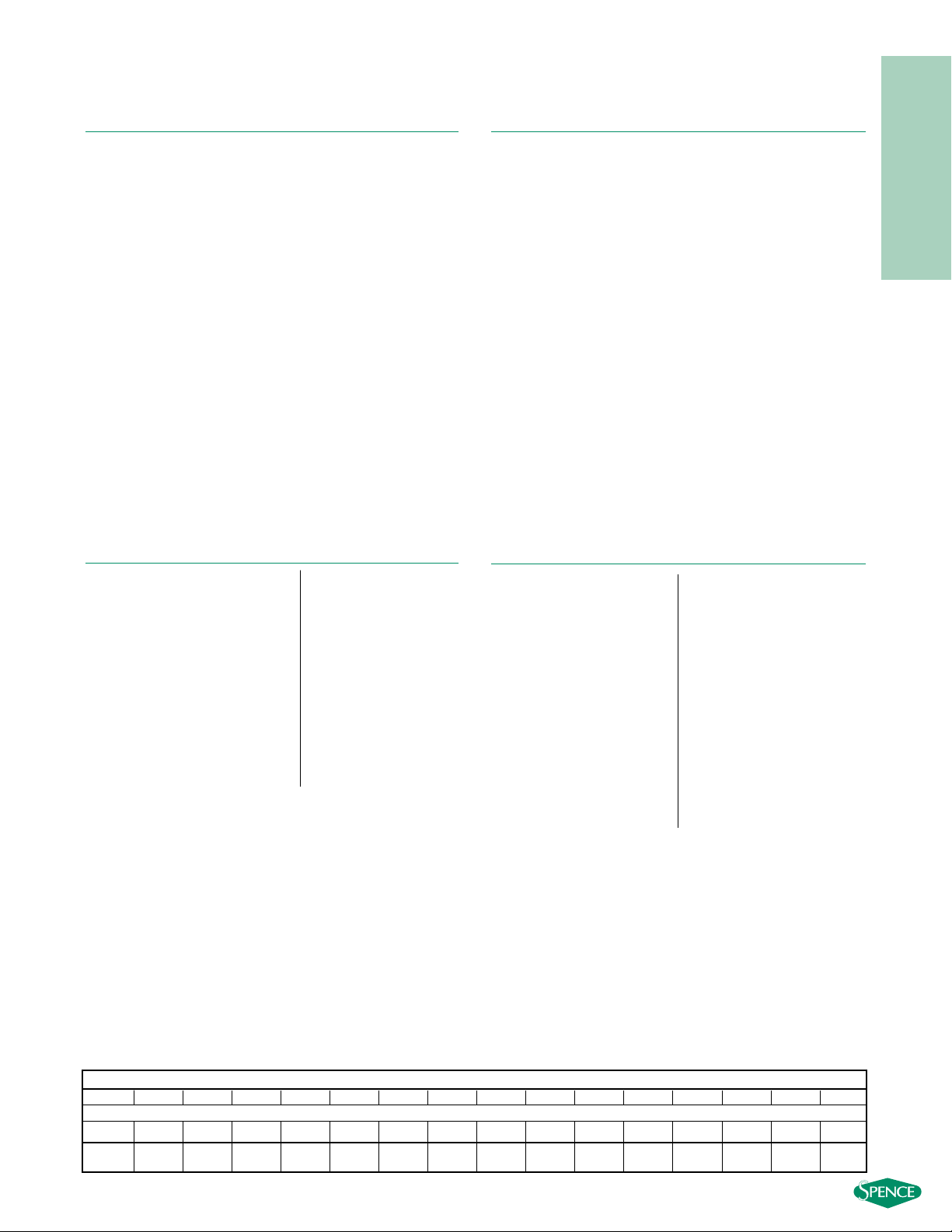

WATER CAPACITY TABLE–FLOW IN GALLONS PER MINUTE

These flow rates provide a simple method for sizing regulators or water pipes with inlet velocities in the

range of 240 to 600 fpm. Spence Regulators have variable seat sizes. The factory will select the proper

seat for particular flow and pressure drop. Additional capacity data is available on request.

VALVE OR PIPE SIZE

1

/4

3

/8

1

/2

3

/4 11

1

/4 11/2 22

1

/2 345681012

Velocity, fpm

247 251 255 262 270 277 285 300 315 330 360 390 420 480 540 600

1.3 2.5 4.0 7.3 12 22 30 52 78 127 238 405 630 1250 2210 3490

Velocity, fpm

- 121 -

SIZING DIFFERENTIAL

REGULATORS

Loading...

Loading...