Page 1

66

845.778.5566 ● Fax: 845.778.7123 ●

www.nicholsonsteamtrap.com

The Nicholson Drain Orifice Trap is an

engineered, continuous flow device. The

controlling element in the Drain Orifice

Assembly is a flat S.S. plate, 1/4" thick. Drain

Orifices discharge air, condensate and all other

non-condensible gases with minimal live steam

loss. The fixed orifice size is calculated, for a

given application, to discharge the condensate

load at a maximum thermal efficiency.

Approximately 10-25% of discharging hot

condensate flashes to steam at the downstream

side of the orifice, at a constant pressure drop.

This flashing effect further restricts the flow of

saturated steam, In actual conditions, a minimum

percentage of steam, by weight, is discharged with

condensate, since the specific volume of steam is large

compared to that of the condensate. The velocity

through the orifice is highly turbulent. The initial calculated steam loss can be expected to remain relatively

constant over the expected 10+ years trap life. The major

factor for energy efficient performance is based on initial

orifice sizing for the application. Properly sized, thermal

efficiencies of 98%+ can be attained. The Drain Orifice

Trap is ideally suited for use on high pressure steam

(saturated or superheated) from 300 PSIG to 3000 PSIG

with minimum steam loss, zero maintenance and long

service life.

TYPE DUA

ORIFICE UNION

ASSEMBLY

Pressures To 3000 PSIG (207 barg)

Temperatures to 850°F (454°C)

Reliable Operation — High reliability labyrinth-type seal:

leak tight seal is maintained when subjected to

expansion or contraction due to temperature or pressure

changes in the line. Positive, leak-tight seal eliminates

loss of product.

Ease of Installation — No danger of damaging seats or

losing seal by overtorquing during installation. Requires

normal torque to obtain a leak-tight seal. Welding repairs

reduced; no need to replace union components welded

to pipe.

Low Cost Maintenance — Downtime, labor and material

costs drastically reduced. Service is required only when

the union is disassembled, then only a change of gaskets

is required to put it back in service. Eliminates the need

to replace the union housing.

Flexibility — Orifice easily replaced where a different

orifice size is required for a specific application. Orifice

can be redrilled to a larger size, if necessary, eliminating

need to replace the entire assembly. Infinite range of

orifice sizes available from a minimum 0.020" diameter.

M

ODELS

●

DUA–Orifice Union

●RUA–Orifice Kit includes 2 gaskets, orifice plate and

inlet screen.

●DUR–Gasket Kit includes 2 gaskets and inlet screen.

●SUG–Gasket Kit includes 10 gaskets.

APPLICA TIONS

●

Condensate Removal

●Pressure Reduction

●Ratio of Flow-mixing two or more fluids at

fixed ratio

●Fixed Flow-i.e. gland seal recirculation of

cooling water on pumps, compressors,

process analyzers, etc.

●Intermittent Drainage-i.e. air tools, air storage

tanks, cleaning fixtures, air vents, etc.

●Cryogenic Storage Venting

●Low Pressure Blanking

●Sampling of process fluids at a fixed flow rate

for use with Instrument Analyzers

O

PTION

●

SW - Socketweld

Canadian Registration # 0E0591.9

OPERA TION

Page 2

845.778.5566 ● Fax: 845.778.7123 ●

www.nicholsonsteamtrap.com

67

Connections: 1/2" – 1" NPT

TYPE DUA

ORIFICE UNION

ASSEMBLY

SPECIFICATION

Orifice Union shall consist of 1/4" 304 stainless steel plate fixed

inside a gasketed union housing. Seal shall be provided by spiral

wound gaskets whose inlet shall be modified with a stainless

steel dome mesh strainer fixed across the inside diameter. Orifice

shall be sized for the application to a minimum of 0.020 inches.

MAXIMUM

OPERA TING CONDITIONS

PMO: Max. Operating Pressure see Chart

TMO: Max. Operating Temperature see Chart

MATERIALS OF CONSTRUCTION

Body: …………………………………Forged Carbon Steel

Inlet Gasket:Spiral-wound S.S./Graphite w/S.S. 60 mesh

dome strainer insert

Orifice Plate: …………………………304 S.S., 1/4" thick

Outlet Gasket: ………………Spiral-wound S.S./Graphite

S

IZING*

Consult Factory–required information:

Condensate Load ______

Inlet Pressure ______

Outlet Pressure ______

Elevation of return line over trap (if any) ______

* Specify orifice size when ordering.

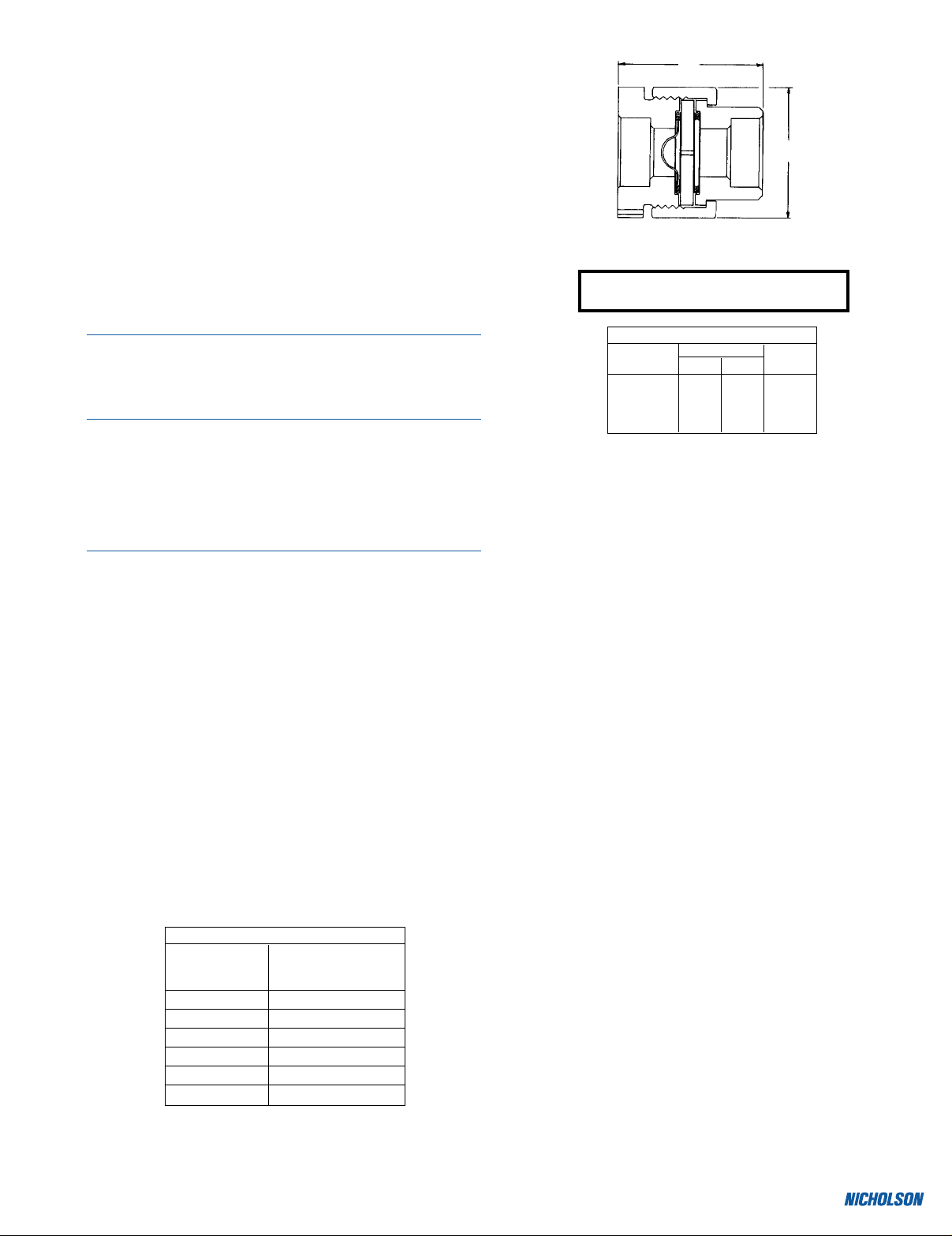

DUA

Dimensions

Pipe Size

Inches Weight

NPT A B Lbs.*

1/2 2.42 1.8 1.2

3/4 2.73 2.20 1.8

1 2.94 2.57 2.6

*Average weight-actual weights

may vary slightly.

*Minimum recommended temperature is -20°F.

Temperature/Pressure Ratings

Temperature* Pressure (PSIG)

°F Carbon Steel

100 3000

200 2735

300 2655

400 2565

500 2425

600 2220

700 2155

A

B

Loading...

Loading...