Page 1

8

845.778.5566 ● Fax: 845.778.7123 ●

www.nicholsonsteamtrap.com

Thermal actuator is filled at its free length with a

liquid having a lower boiling point than water. On

start-up, valve is normally open to discharge air,

non-condensibles and condensate. When steam

enters trap, thermal actuator fill vaporizes to a

pressure higher than line pressure. This forces

valve into seat orifice to prevent any further flow. As condensate collects, it takes heat from thermal actuator, lowering internal pressure. Line pressure will then compress thermal actuator to open valve and discharge condensate.

Valve opening automatically adjusts to load conditions from

minimum on very light loads to full lift at maximum load.

DS100/DS110

THERMOSTATIC

STEAM TRAPS

Pressures To 150 PSIG (10.3 barg)

Temperatures to 366°F (186°C)

Stainless Steel Body—Body materials of all models are

Type 316L Stainless Steel.

Self Centering Valve—Leak tight shut off. Assembly of

actuator and valve to impingement plate allows valve to

self-align with center of valve seat orifice. Provides long

lasting valve and seat.

Temperature Sensitive Actuator—316L Stainless welded

actuator for maximum corrosion, thermal and hydraulic

shock resistance. One moving part.

Thermal and Hydraulic Shock Resistant—Impingement

plate plus welded construction prevents damage to actuator.

Long Life Valve and Seat—Stainless steel valve and seat

matched together for water tight seal.

Maintenance—All models are sealed and maintenance

free.

Directional Discharge—Erosion prevented by directing

discharge into the center of pipe or tubing.

Best Air Handling Capacity—Fast start up and operation.

Fast Response—Quickly adjusts to condensate load or

temperature changes.

One Size Suits Most Services—Universal hygienic clamp

fits both 1/2" and 3/4" piping.

Two Year Guarantee—Trap guaranteed for two years

against defects in material or workmanship.

M

ODELS

● DS100–Hygienic Clamp end 1

7

⁄

8" OAL

● DS100TE–Tube end

● DS110–Hygienic Clamp end 2

5

⁄8" OAL

NOTE: Please specify if Material Test Reports (MTR) or Certificates of

Conformance (COC) are required.

A

PPLICATIONS

● CIP/SIP System Condensate Drainage

● Sterilization of Process Vessels

● Culinary Steam

● Humidifiers

● WFI System Sterilization

● Main Drips

A

PPLICABLE CODES

● ASME BPE

Canadian Registration # 0E0591.9C

O

PERATION

Page 2

845.778.5566 ● Fax: 845.778.7123 ●

www.nicholsonsteamtrap.com

9

Connections: 1/2" – 3/4" Tube

1/2" / 3/4" Hygienic Clamp

DS100/DS110 THERMOSTATIC

STEAM TRAPS

SPECIFICATION

Steam trap shall be thermostatically actuated and maintenance free. Actuator shall be of single piece, fail open design consisting of 1.2" diameter, welded 316L stainless plates capable

of releasing condensate within 5ºC (10ºF) of saturated pressure. Trap shall be constructed

entirely of 316L stainless steel components with wetted body surfaces finished to 20 µ inch

(0.5 µm) Ra or better. Trap shall be self draining when installed vertically in piping systems.

Trap shall have tube or universal hygienic clamps. Ferruled connections shall be Tri-clampcompatible and designed to fit both

1

/

2" and

3

/

4" service. Trap shall be guaranteed against defects

for 2 years.

MAXIMUM O

PERATING CONDITIONS

PMO: Max. Operating Pressure 150 psig (10.3 barg)

TMO: Max. Operating Temperature 366°F (170°C)

PMA: Max. Allowable Pressure 300 psig* (20.7 barg)

TMA: Max. Allowable Temperature 500°F* (260°C)

*May be limited by rating of utilized end connection.

MATERIALS OF CONSTRUCTION

Body– Inlet …………………………………………………………………A276 316L

Actuator ……………………………………………………………………………316L

Body – Outlet ………………………………………………………………A276 316L

Valve…………………………………………………………………………………316L

BODY SURFACE FINISH

Internal <20 µ in. (0.5 µm) Ra SFCI.External <32 µ in. (0.75 µm) Ra. Optional

mechanical polishing to 10 µ in. (0.25 µm) Ra and/or electropolish SFC4

SERVICE

NOTES

Trap is designed to be self draining for vertical installation (discharge down).

1

/2" - 3/4" ferrule service trap should be installed with 3/4" inlet gasket.

SLR ORIFICE

OPTION

Specify when immediate elimination of condensate and improved sensitivity is

desired. An orifice on the valve allows for continuous discharge of condensate.

Trap will nominally pass 50 lb/hr (22.7 kg/hr) of condensate at 50 psi (3.4 barg)

within 0.5ºC (1°F) of saturated temperature.

13⁄4"

(44.5)

13⁄4"

(44.5)

47⁄

8"

(104.8)

17⁄8"

(47.6)

Maximum Capacity—lbs/hr 10°F Below Saturation (Kg/hr 5°C Below Saturation)

Differential PSIG (bar)

Trap Orifice

5 10 20 30 40 50 60 70 80 90 100 125 150

Inches (0.34) (0.7) (1.4) (2.1) (2.8) (3.4) (4.2) (4.9) (5.6) (6.2) (6.9) (8.62) (10.3)

DS100 1/4

550 825 1210 1495 1750 1975 2175 2350 2525 2650 2825 3140 3425

(249) (374) (549) (678) (794) (896) (987) (1066) (1145) (1202) (1281) (1424) (1554)

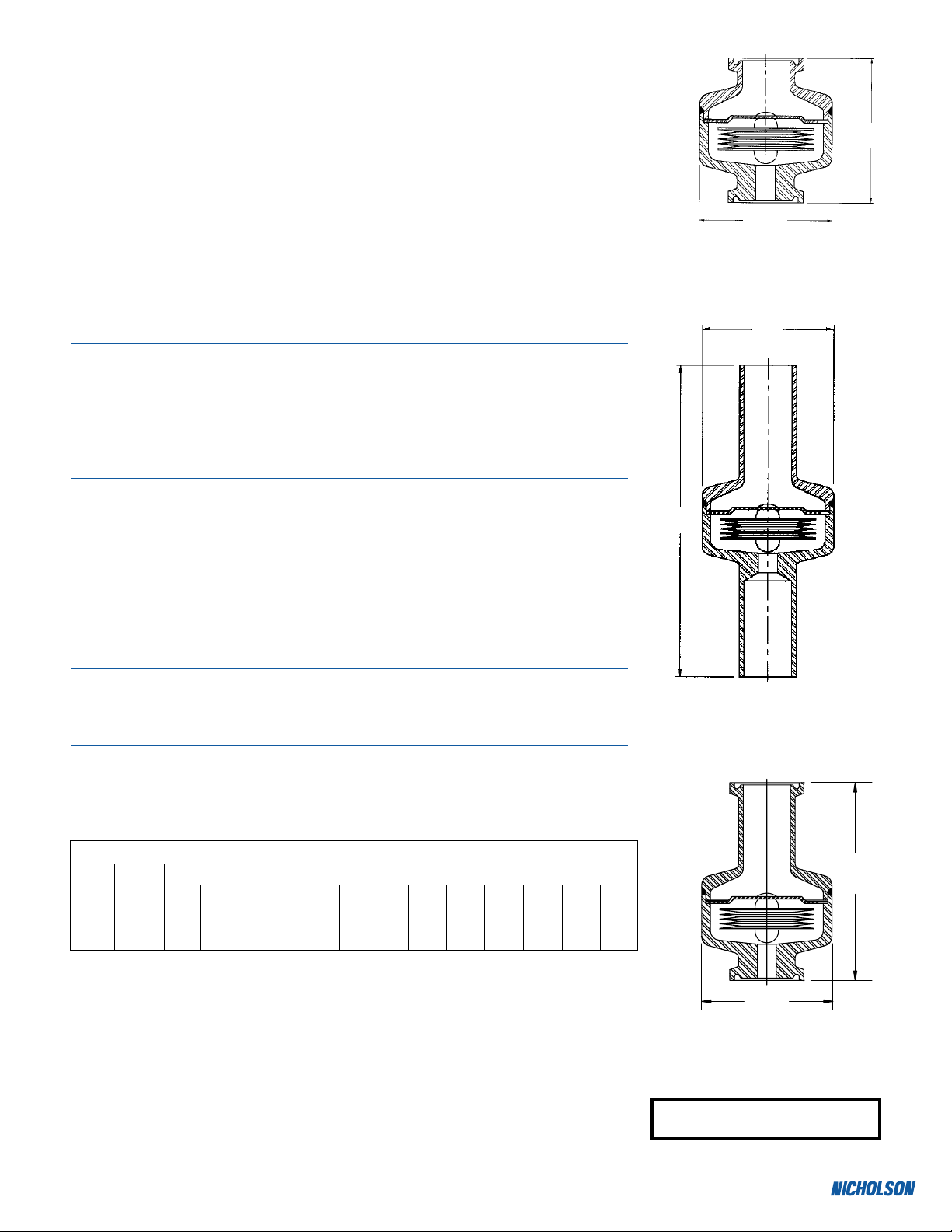

DS100 HYGIENIC CLAMP

CONNECTION

1/2" & 3/4"

Weight .4 lbs (0.18)

DS100TE TUBE CONNECTION

(1/2" & 3/4")

Weight .4 lbs (0.18)

DS110 HYGIENIC CLAMP

CONNECTION

(1/2" & 3/4")

Weight .4 lbs (0.18)

25⁄8"

(66.7)

13⁄

4"

(44.5)

Loading...

Loading...