Page 1

DRAIN-AIR

& MINI-DRAINS

- 350 -

A simple disc is used with no linkage or close fitting

parts to eliminate problems found in ordinary small

float or piston-operated devices used in drip legs on

air lines. Disc will lift off seat on a periodic time

cycle, allowing moisture to be discharged and

atomized through the muffler. Positive action of the

disc assures reliable condensate removal with

minimum loss of air and rapid shutoff on no load condition.

Intermittent discharges atomize condensate to avoid messy

accumulations produced by other devices. Highly effective,

specially designed muffler eliminates noise and diffuses

moisture so that discharge drain piping is usually unnecessary. Freeze proof when mounted in vertical position with

outlet facing down and muffler removed.

DRAIN-AIR &

MINI-DRAINS

Condensate Removal from Air Systems

Pressures To 600 PSIG (41.4 barg)

Temperatures to 220°F (104°C)

Automatic and Positive Drain — Effectively removes

condensate from compressed air systems with minimum

air loss and rapid shutoff on no load conditions.

Reliable — Only one moving part.

Low Maintenance Cost — No adjustments necessary.

Replaceable cartridge for in line repair and/or cleaning.

Long Service Life — Stainless Steel internals.

Freezeproof — Will not freeze when installed in vertical

position with muffler removed.

Quiet Operation — Meets OSHA noise standards.

Simplifies Startup — No need to drain air lines through

manual valves or petcocks. Top performance is reached

without waiting for system to purge.

Sized for Most Applications — Drain-Air available in 3/8"

and 1/2"; Mini-Drain available in 1/8" and 3/8".

MODELS

●

Drain Air–Forged body w/SS internal mechanism & nylon

muffler

●Mini Drain–All SS integral body w/nylon muffler

Note: Pneumatic mufflers are available separately.

A

PPLICATIONS

Drain-Air

●Air Header Drainage (pocket risers, end of line)

●Air Station or Location where petcock is used

for blowdown, collecting wells, separators.

Mini-Drain

●Pneumatic Tools

●Air Filters

●Pneumatic Valves

Canadian Registration # OE0591.9C

OPERA TION

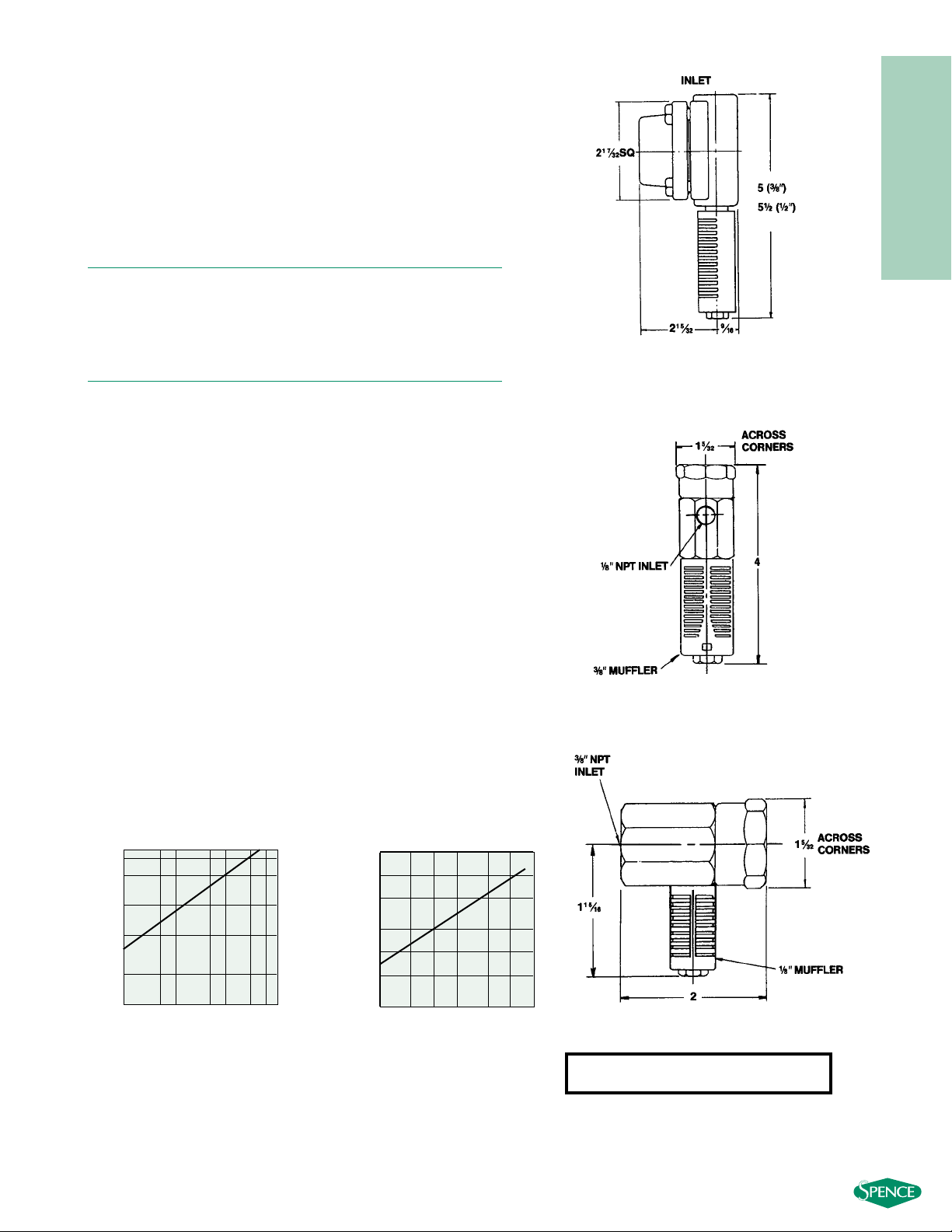

Page 2

Connections: 1/8"-3/8" NPT

The liquid drain trap shall be of thermodynamic design with screwed

NPT connections. Internal mechanism shall be stainless steel with

hardened working surfaces. A pneumatic muffler shall be employed

to reduce exhaust sound pressure level.

MAXIMUM OPERATING

CONDITIONS

PMO: Max. Operating Pressure 600 psig (41.4 barg)

TMO: Max. Operating Temperature 220°F (104°C)

PMA: Max. Allowable Pressure 600 psig (41.4 barg)

TMA: Max. Allowable Temperature 800°F (426°C)

MATERIALS OF

CONSTRUCTION

DRAIN-AIR

Body & Cover: . . . . . . . . . . . . . . .ASTM A105 Forged Steel

Celtron® Cartridge: . . . . . . . . . . . . . . . .416 Stainless Steel

w/hardened disc & seat

Bolts: . . . . . . . . . . . . . . . . . . . . . . . .High temperature alloy

Cover Gasket: . . . . . . . . . . . . . .347 Stainless Spiral-wound

w/graphite filler

Integral Strainer: . . . . . . . . . . . . . . . . . . .304 Stainless Steel

Muffler: . . . . . . . . . . . . . . .Nylon Housing, Aluminum Screen

Connections: . . . . . . . . . . . . . . . . . . . . . . . .3/8"-1/2" NPT

MINI-DRAIN

Cap, Seat & Disc: . . . . . . . . . . . . .416 Stainless, Hardened

Muffler: . . . . . . . . . . . . . . .Nylon Housing, Aluminum Screen

DRAIN-AIR &

MINI-DRAINS

S

PECIFICATION

10 .02

.04

.1

.2

.4

.6

.7

20

1 5 10 50 100 300 600

.0025 .005 .01 .025 .05 .1

50

100

200

300

10

25

.001

50

100

250

500

1000

LBS. PER HOUR

PSIG

GAL. PER MINUTE

PSIG

DISCHARGE

CAPACITY

AIR LOSS–NO

LOAD CONDITION

CFM

3/8" & 1/2" DRAIN-AIR

2.3 LBS.

1/8" MINI-DRAIN

.9 LBS.

3/8" MINI-DRAIN

.9 LBS.

- 351 -

DRAIN-AIR

& MINI-DRAINS

Loading...

Loading...