Page 1

CV80-0912

®

TITAN

f

SINGLE DISC

STAINLESS STEEL BODY

TITAN FLOW CONTROL, INC.

SILENT CHECK VALVE

ANSI CLASS 300

f

MODEL: CV 80-SS

STAINLESS STEEL BODY

TEFLON (PTFE) SEAT

FEATURES

F

s

q u i c k c l o s u r e t o r e d u c e w a t e r h a m m e r

s i l e n t s h u t - o f f is a c h i e v e d v i a t h e f u l l y a u t o m a t i c , s p r i n g a s s i s t ed

d i s c t h a t c l o s e s n e a r z e r o f l o w v e l o c i t y . t h e l i g h t w e i g h t , c e n t e r

g u i d e d d i s c d e s i g n c r e a t e s a p o s i t i v e s h u t o f f p r i o r t o f l o w r e v e r s a l

a n d h e l p s t o k e e p s l a m m i n g a n d s u r g e s t o a m i n i m u m .

s

m i n i m a l h e a d l o s s

t h e c o n t o u r o f b o d y p r o v i d e s a s h o r t a n d s t r a i g h t f l o w p a t h t h a t

g e n e r a t e s v e r y l i t t l e t u r b u l e n c e . a d d i t i o n a l l y , t h e s p r i n g -l o a d e d ,

c e n t e r g u i d e d d i s c i s d e s i g n e d w i t h v e r y l o w c r a c k i n g p r e s s u r e

w h i c h r e d u c e s t h e a m o u n t o f e n e r g y r e q u i r e d t o o p e n t h e v a l v e .

s

b u b b l e t i g h t s e a l

b y uti liz ing a t e f l o n s e a t a n d g a s k e t i n c o n j u n c t i o n w i t h p rec isi o n

m a c h i n e d s e a l i n g s u r f a c e s , t h e c v 80-s s m a i n t a i n s a b u b b l e t i g h t s e a l

t h a t m e e t s o r e x c e e d s a p i 598 l e a k a g e r e q u i r e m e n t s .

s

d e s i g n e d f o r l o n g s e r v i c e l i f e

t h e c v 80- s s ut i li z es a h i g h l y r e l i a b l e i n v e s t m e n t c a s t i n g , s ta i n l es s

s t e e l c o n s t r u c t i o n , a n d a si mpl ifi e d d e s i g n (o n l y s i x p a r t s ) t h a t c a n

p r o v i d e a l o n g s e r v i c e l i f e f o r a w i d e v a r i e t y o f a p p l i c a t i o n s .

s

v e r s a t i l e a n d e c o n o m i c a l d e s i g n

t h e c v 80- s s c a n b e i n s t a l l e d in a n y p o s i t i o n ( h o r i z o n t a l o r v e r t i c a l

w i t h u p w a r d f l o w ) - c o n s u l t f a c t o r y f o r v e r t i c a l w i t h d o w n w a r d

f l o w . h e x e n d s a r e p r o v i d e d f o r q u i c k a n d e a s y i n s t a l l a t i o n s

size range:

3/8" t h r o u g h 3 "

f

THREADED ENDS

TECHNICAL

T

PRESSURE/ TEMPERATURE RATING

SS - ASTM A351 GR. CF8M - CLASS 300

WOG

(Non-shock): 720 PSI @ 100 °F

Max Liquid: Consult Factory

Max Steam: Not Recommended

SEAT MATERIAL

TEMPERATURE RANGE

PTFE: - 2 ~ 248 °F

SPRING MATERIAL

MAXIMUM TEMPERATURE

Type 316 SS: 450 °F

A

m a r k e t s : o i l & g a s p r o d u c t i o n , g e n e r a l i n d u s t r y , c h e m i c a l i n d u s t r y , p e t r o c h e m i c a l i n d u s t r y , p o w e r ,

f o o d & b e v e r a g e i n d u s t r i e s .

s e r v i c e : c h e m i c a l / s t e a m / n i t r o g e n l i n e s , g a s i nj e ct i on , c o n d e n s a t e r e c o v e r y , p u m p & c o m p r e s s o r

d i s c h a r g e , p u m p j a c k f l o w l i n e s , c h i l l e r & b o i l e r f e e d

: r e c o m m e n d e d f o r m o s t c h e m i c a l e n v i r o n m e n t s i n c l u d i n g a c i d s , b a s e , o i l s , s t e a m a n d

p t f e

o t h e r p r o c e s s f l u i d s . o f f e r s e x c e l l e n t t e a r , a b r a s i v e , c h e m i c a l , a c i d , a n d a l k a l i r e s is ta n c e . n o t

r e c o m m e n d e d f o r h i g h p r e s s u r e s t e a m o r l a r g e t e m p e r a t u r e v a r i a t i o n a p p l i c a t i o n s

Th e ab ov e da ta re pre se nt s co mmo n ma rke t an d se rvi ce a pp lic atio ns . N o re pr es en tat ion or g ua ran tee , e xp res sed or im pl ied , is gi ve n due to th e nu mer ous v ar ia tio ns

APPLICATIONS

of concentrations, temperatures and flow conditions that may occur during actual service .

TITAN FLOW CONTROL, INC.

YOUR PIPELINE TO THE FUTURE!

s

Tel: 910-735-0000

290 Corporate Drive

Fax: 910-738-3848

s

s

titan@titanfci.com

PO Box 7408

s

s

Lumberton, NC 28358

www.titanfci.com

Page 2

CV80-0912

®

TITAN

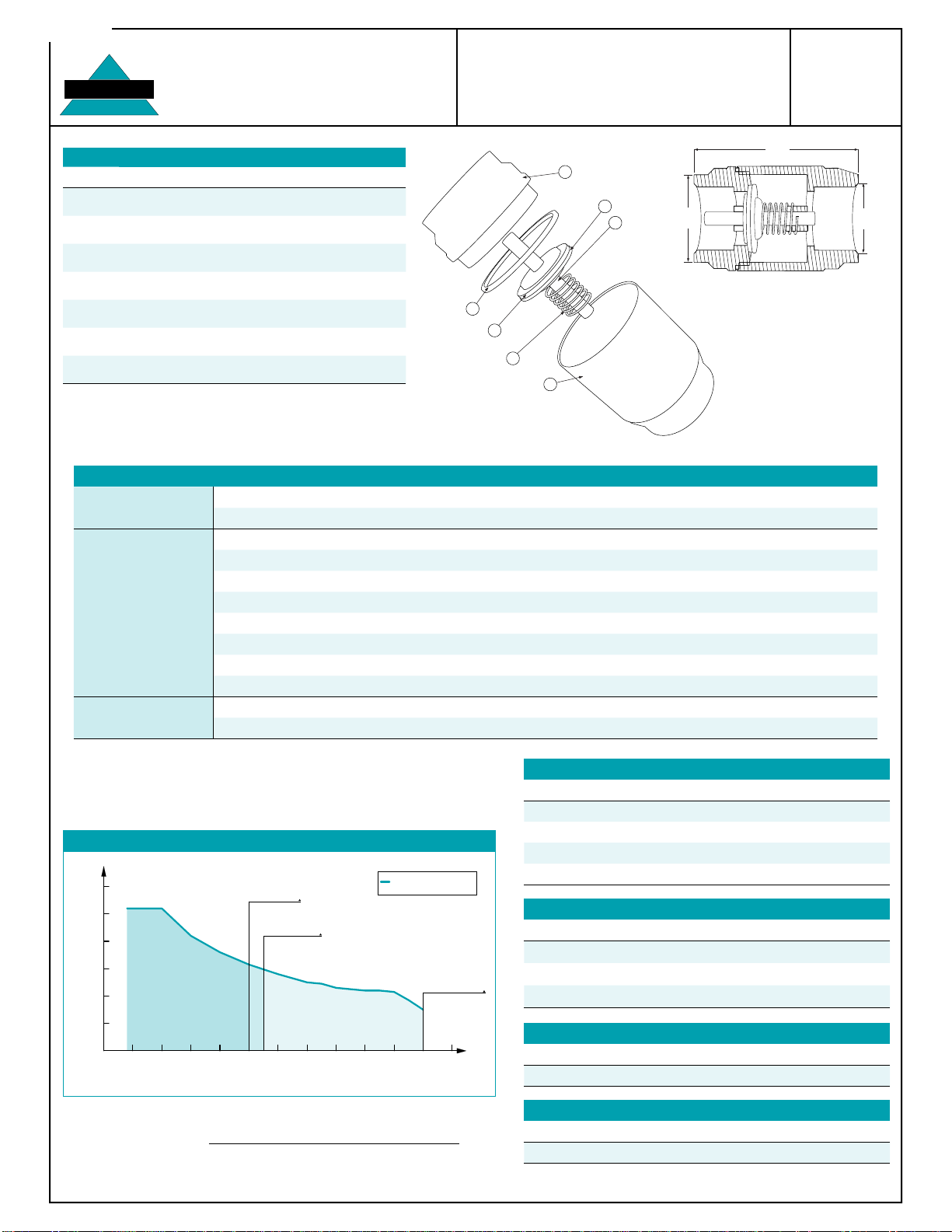

Stainless Steel

A351 Gr. CF8MANSI Class 300

Temperature(

°F)

Pressure (PSI)

Source: ASME B16.34-1996

-100 0 100 200 300 400 500 600 700 800 900 1000 1100

200

300

400

500

600

700

800

400 °F MaxTemp

PTFESeat

450 °F MaxTemp

T - 316 SS Springs

1000 °F Max Temp

Stainless Steel Body

ØC

ØB

ØA

3

2

1

4

5

6

7

TITAN FLOW CONTROL, Inc.

290 Corporate Drive E-mail: titan@titanfci.com

Lumberton, NC 28358 Web: www.titanfci.com

Tel: 910.735.0000

Fax: 910.738.3848

IN-LINE • SILENT CHECK VALVE

CENTER GUIDED • THREADED ENDS

MODEL: CV 80-SS

Stainless Steel Body • PTFE Seat and Gasket

ANSI Class

300

BILL OF MATERIALS

(1)

No. PART MATERIAL

1 CAP ASTM A351 Gr. CF8M Stainless Steel

2 DISC Stainless Steel 18-8

3 STEM ASTM A351 Gr. CF8M Stainless Steel

4 GASKET

(2)

PTFE

5 SEAT PTFE

6 SPRING Type 316 Stainless Steel

7 BODY ASTM A351 Gr. CF8M Stainless Steel

Notes:

1. Bill of Materials represents standard materials. Equivalent

materials may be substituted at the manufacturer's discretion.

2. Denotes recommended spare parts.

DIMENSIONS AND PERFORMANCE DATA

SIZE

A DIMENSION

FACE TO FACE

ØB DIMENSION

OUTSIDE DIAMETER

ØC DIMENSION

INSIDE DIAMETER

ASSEMBLED

WEIGHT

Flow Coefcient

Cracking Pressure

(2)

in 3/8 1/2 3/4 1

mm 10 15 20 25 32 40 50 65 80

in 2.086 2.204 2.480 2.913 3.188 3.582 3.818 4.660 5.500

mm 53 56 63 74 81 91 97 118 140

in 0.905 1.181 1.620 1.878 2.165 2.775 3.228 4.312 4.900

mm 23 30 41 48 55 70 82 110 125

in 0.669 .826 1.023 1.259 1.614 1.850 2.322 2.625 3.250

mm 17 21 26 32 41 47 59 67 83

lb 0.3 0.4 0.5 1.0 1.5 2.5 3.5 6.0 8.5

kg 0.1 0.2 0.2 0.5 0.7 1.1 1.6 2.7 3.9

C

psi

v

6 7 14 20 40 40 80 110 162

≤ .5 ≤ .5 ≤ .5 ≤ .5 ≤ .5 ≤ .5 ≤ .5 ≤ .5 ≤ .5

(1)

1

1

/4 1 1/2

Design Notes:

1. Size range: 3/8" ~ 3"

2. ANSI Class 300

3. Low cracking pressure

4. Minimal head loss

5. Low pressure drop

6. Spring assisted design

7. Long stem for smooth

closure

8. PTFE Seat for long

service life

2

1

2

/2

3

1. Dimensions, weights, and ow coefcients are provided for reference only.

When required, always request certied drawings.

2. The listed valve cracking pressure only applies to horizontal installations.

For vertical installations, cracking pressure is higher. Please consult factory.

PRESSURE-TEMPERATURE RATINGS FOR CF8M

1. The above chart displays the pressure-temperature ratings for the valve's body material per

ASME/ANSI B16.34-1996. For reference, maximum temperature limits have been added

for seat and spring materials. PTFE seat limits the maximum temperature for this valve.

Stainless Steel not recommended for prolonged use above 1000 °F

Titan FCI makes every effort to ensure the information presented on our literature accurately reects exact product specications. However, as product changes occur, there may be short-term differences between actual product

specications and the information contained within our literature. Titan FCI reserves the right to make design and specication changes to improve our products without prior notication. When required, request certied drawings.

(1)

CLASS 300

REFERENCED STANDARDS & CODES

CODE DESCRIPTION

ANSI B1.1 Unied Inch Screw Threads

ANSI B1.20.1 Pipe Threads - General Purpose

ANSI B16.34 Valves - Flanged, Threaded & Welding Ends

ASTM A351 GR CF8M Austenitic Steel Castings

pressure - temperature rating

Body Material - ASTM A351 GR. CF8M - CLASS 300

WOG

(Non-shock): 720 PSI @ 100 °F

Max Liquid: Consult Factory

Max Steam: Not Recommended

seat and gasket temperature rating

Seat Material Temperature Range

Teon (PTFE): - 2 ~ 248 °F

spring temperature rating

Spring Material Maximum Temperature

T-316 Stainless Steel 450 °F

Loading...

Loading...