Page 1

6

845.778.5566 ● Fax: 845.778.7123 ●

www.nicholsonsteamtrap.com

Thermal actuator is filled at its free length with a liquid having a lower boiling point than water. On

start-up, valve is normally open to discharge air,

non-condensibles and condensate. When steam

enters trap, thermal actuator fill vaporizes to a

pressure higher than line pressure. This forces

valve into seat orifice to prevent any further flow. As condensate collects, it takes heat from the actuator, lowering

internal pressure. Line pressure will then compress thermal

actuator to open valve and discharge condensate. Valve

opening automatically adjusts to load conditions from minimum on very light loads to full lift at maximum load.

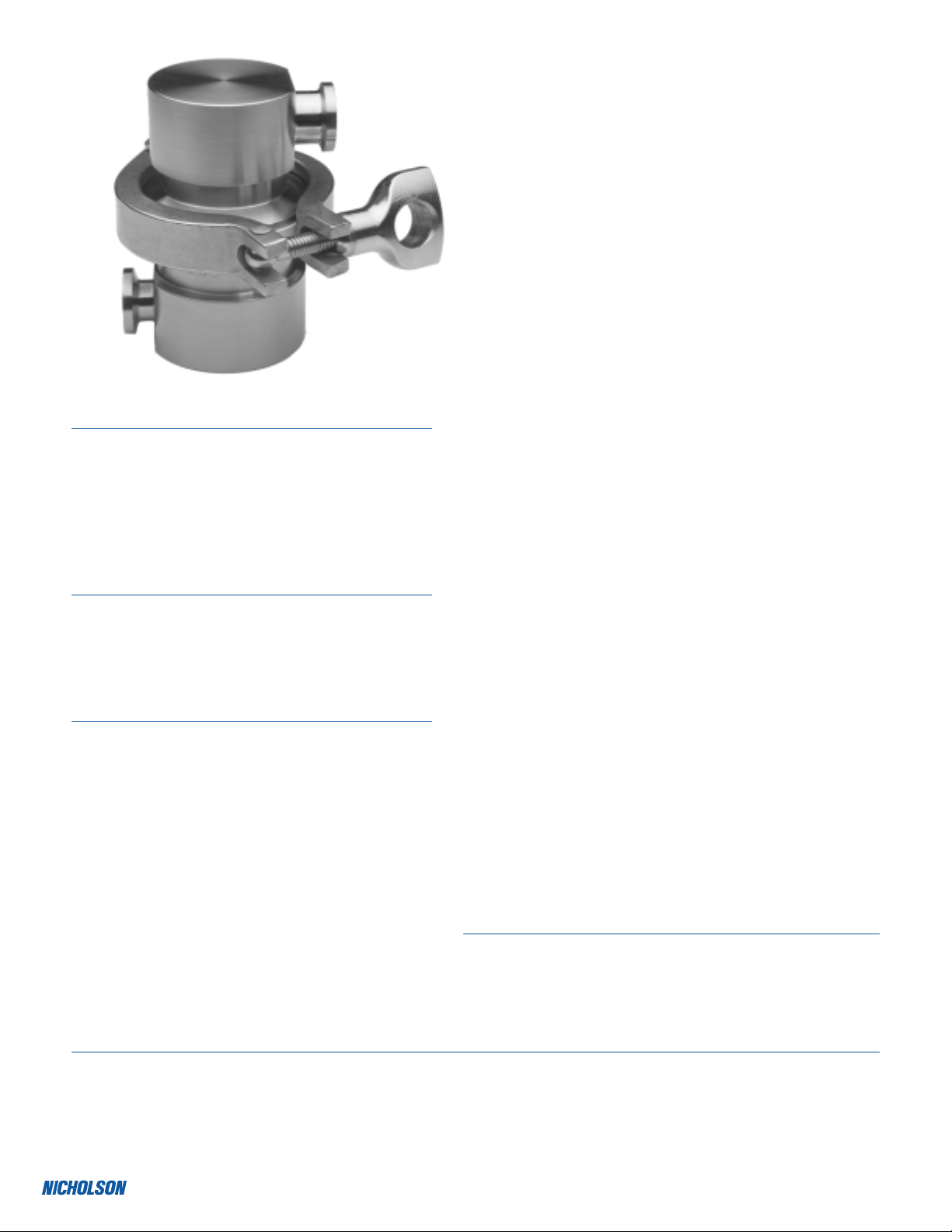

CDH SANITARY

THERMOSTATIC

STEAM TRAPS

Pressures To 100 PSIG (6.9 barg)

Temperatures to 338°F (170°C)

Universally Configurable—Horizontal connections from

any direction on standard model; AI and AO models feature

one multi-directional horizontal and one vertical connection.

Steepest Interior Surfaces—Designed to completely drain

without puddling, even in significantly sloped lines.

Stainless Steel Body—Body Material is 316L Stainless

Steel with 20 µ in. (0.5 µm) Ra internal finish and 32 µ in.

(0.75 µm) Ra external finish. Available with mechanical polishing to 10 µ in. (0.25 µm) Ra and/or electropolish.

Self centering Valve—Leak tight shut off. Assembly of

actuator and valve to impingement plate allows the valve to

self align with center of the orifice.

Temperature Sensitive Actuator—One moving part. 316L

Stainless Steel, fail open, welded actuator for maximum

corrosion, thermal and hydraulic shock resistance.

One Size Suits Most Services—Universal hygienic clamp

fits both 1/2" and 3/4" piping.

Maintenance—Can be easily removed and disassembled

for sterilization and/or repair.

Four Year Guarantee—Guaranteed for four years against

defects in material or workmanship.

Inventory Standard Food Grade Gasket—White Viton

food grade gasket offers superior performance for higher

pressure steam applications.

Superior Air Handling—Best air handling capability pro-

vides for fast startup.

Unique SLR Orifice Option—Specify when immediate

elimination of condensate and improved sensitivity is

desired. An orifice on the valve allows for continuous discharge of condensate. Trap will nominally pass 50 lb/hr

(22.7 k g /h r ) o f condensate at 50 psi (3.4 barg) within 0.5ºC

(1°F) of saturated temperature.

Bar Stock—Connectiion fittings are not welded onto inlet

and outlet pieces.

M

ODELS

● CDH-AI-AO–Horizontal inlet and outlet

● CDH-AI–Horizontal inlet, vertical outlet

● CDH-AO–Vertical inlet, horizontal outlet

NOTE: Please specify if Material Test Reports (MTR) or Certificates of

Conformance (COC) are required.

APPLICA TIONS

● CIP/SIP System Condensate Drainage

● Sterilization of Process Vessels

● Culinary Steam

● Humidifiers

● WFI System Sterilization

● Fermenter Sterilization

O

PTIONS

● MP - Mechanical Polish to 10 µ in. (0.25 µm) Ra

● EP - Electropolish

● SLR - SLR Orifice

● Tef-Steel, PTFE, Teflon®, E.P.D.M., and other

gasket materials available

APPLICABLE CODES

● ASME BPE

Canadian Registration # 0E0591.9C

OPERA TION

Page 2

845.778.5566 ● Fax: 845.778.7123 ●

www.nicholsonsteamtrap.com

7

Connections:

1/2/3/4" Hygienic Clamp

CDH

SANITARY THERMOSTATIC

STEAM TRAPS

SPECIFICATION

Steam trap shall be of balanced pressure design with 316L welded bellows capable of releasing condensate within 5ºC (10°F) of saturated pressure. All other interior wetted components

shall be of 316L stainless. It shall have interior body finish of at least 20 µ in. (0.5 µm) Ra and

exterior body finish of at least 32 µ in. (0.75 µm) Ra. Trap shall utilize hygienic body clamp allowing disassembly for inspection or cleaning and be entirely self draining in horizontal or angle piping configuration. Trap end connections shall be standard hygienic clamp. Thermostatic actuator shall employ a conical valve lapped to the seat. Traps shall have SLR orifice where drainage

at saturated temperatures is required. Traps shall be guaranteed against defects for four years.

MAXIMUM

OPERA TING CONDITIONS

PMO: Max. Operating Pressure 100 psig (6.9 barg)

TMO: Max. Operating Temperature 338°F (170°C)

PMA: Max. Allowable Pressure 150 psig (10.3 barg)

TMA: Max. Allowable Temperature 366°F (186°C)

MATERIALS OF CONSTRUCTION

Part # Part Name Material

1 Body – Inlet ................................................................................A276 316L

2 Clamp ....................................................................................................304

3 Gasket ........................................................................................Viton 3227

4 Body – Outlet..............................................................................A276 316L

5 Actuator Nut ........................................................................................316L

6 Impingement Plate ..............................................................................316L

7 Actuator..........................................................................................316L SS

8 Valve ....................................................................................................316L

C

ONNECTION

Sanitary Ferrule accommodates 1/2" and 3/4" service

BODY SURFACE FINISH:

Internal <20 µ in. (0.5 µm) Ra SFCI.External <32 µ in. (0.75 µm) Ra. Optional

mechanical polishing to 10 µ in. (0.25 µm) Ra and/or electropolish SFC4

GASKET APPROVALS:

FDA, USDA, USP Class VI, 3A Sanitary Standard, NSF

SLR ORIFICE OPTION

Specify when immediate elimination of condensate and improved sensitivity is

desired. An orifice on the valve allows for continuous discharge of condensate.

Trap will nominally pass 50 lb/hr (22.7 kg/hr) of condensate at 50 psi (3.4 barg)

within 0.5ºC (1°F) of saturated temperature.

POLISHING PROCEDURE

All surface finishes are achieved without the use of additional buffing,

compounds or grit.

Maximum Capacity

—lbs/hr 10°F Below Saturation (Kg/hr 5°C Below Saturation

Differential PSIG (bar)

Trap Orifice

5 102030405060708090100

Inches (0.34) (0.7) (1.4) (2.1) (2.8) (3.4) (4.2) (4.9) (5.6) (6.2) (6.9)

CDH 1/4

550 825 1210 1495 1750 1975 2175 2350 2525 2650 2825

(249) (374) (549) (678) (794) (896) (987) (1066) (1145) (1202) (1281)

CDH-AI-AO – 3.9 LB.(1.8 kg)

CDH-AI – 2.6 LB. (1.2 kg)

CDH-AO – 3.1 LB. (1.4 kg)

For Kg/Hr Multiply by .454

U.S. PATENT NO. 6,220,519

3"

3"

4"

313⁄16"

11⁄

2"

31⁄4"

3"

23⁄4

"

3"

31⁄4"

23⁄

4"

11⁄2"

7

8

6

5

4

3

2

1

Loading...

Loading...