Page 1

SERIES C

CRYOGENIC BALL VALVES

Page 2

SHARPE

®

HIGH PERFORMANCE CRYOGENIC BALL VALVES

Sharpe® Cryogenic Series Ball Valves offer as standard features advantages that other

valve manufacturers offer only as costly extras. This is the Sharpe® advantage.

STANDARD FEATURES

Valves meet test specications of BS6364 for

Cryogenic Valves

Pressure relief hole in side of ball

Permanent Attached Flow Arrow

Relief hole in stem slot

Live load stem packing (Belleville)

Visual position indicator

Special cleaning

Packing

Extended stem and bonnet

ADVANTAGES

Insures proper construction and testing.

Upstream vent for excessive valve cavity pressure in closed

position.

Reduce possibility of incorrect valve installation.

Equalizes valve cavity pressure and line pressure in open

position.

Provides long intervals between stem packing adjustments,

decreasing emissions through the packing.

Provides easy identication of valve position

Ready to use in critical applications

Keeps the valve in Factory-new condition until it is to be

installed.

Positions stem and stem packing away from cryogenic uid

to prevent stem seal freeze-up and to ensure emission-free

service.

Size Ranges and Pressure Classes Available

Series C84/C99/CD84

Bottom Entry Stem

High Cycle Stem Packing

Fully Encapsulated Body Seals

(Series C84/C99/CD84)

Integral Mounting Pad

ISO 5211

Lockable Handle

1/2” - 2-1/2” Standard Port, 1/2” - 2” Full Port, Meet wall

thickness requirement of ANSI B 16.34 for class 600, 3” - 4”

Standard Port Class 300, and 2-1/2” - 3” Full Port Class

300.

In-line serviceable swing-out center section allows easy

access to internal valve components without disturbing

alignment of pipe.

Prevents accidental removal of stem under pressure.

Self adjusts with pressure and temperature uctuations.

Bottom entry system helps prevent accidents and injuries.

PEEK and Nova* thrust bearings and stem seals extend valve

cycle life and are the best choice for actuation.

Allows valve ends to be welded in line without disassembly,

saving costly labor time. Also prevents seal ruptures in high

pressure and eliminates cold ow.

Ide a l for ac t u a t i o n . Centering li p feature assures

precise alignment of bracket, stem and coupler. Allows

for secondary containment unit to be added when

necessary.

All Sharpe® Series C Valves meet OSHA standards with

locking device. Keeps valves from being opened or closed

accidentally.

Traceability

* Carbon and Graphite Filled TFE

Heat numbers are provided on all valve bodies and ends.

CMTR’s ( certied mill test reports ) are available upon

request.

Page 3

7

8

4

25

6

2

22

7

21

1

5

6

2

19

A

8A

3

26

23

11

21A

9A

16A

16B

16C

14

13

7A

12

12

24

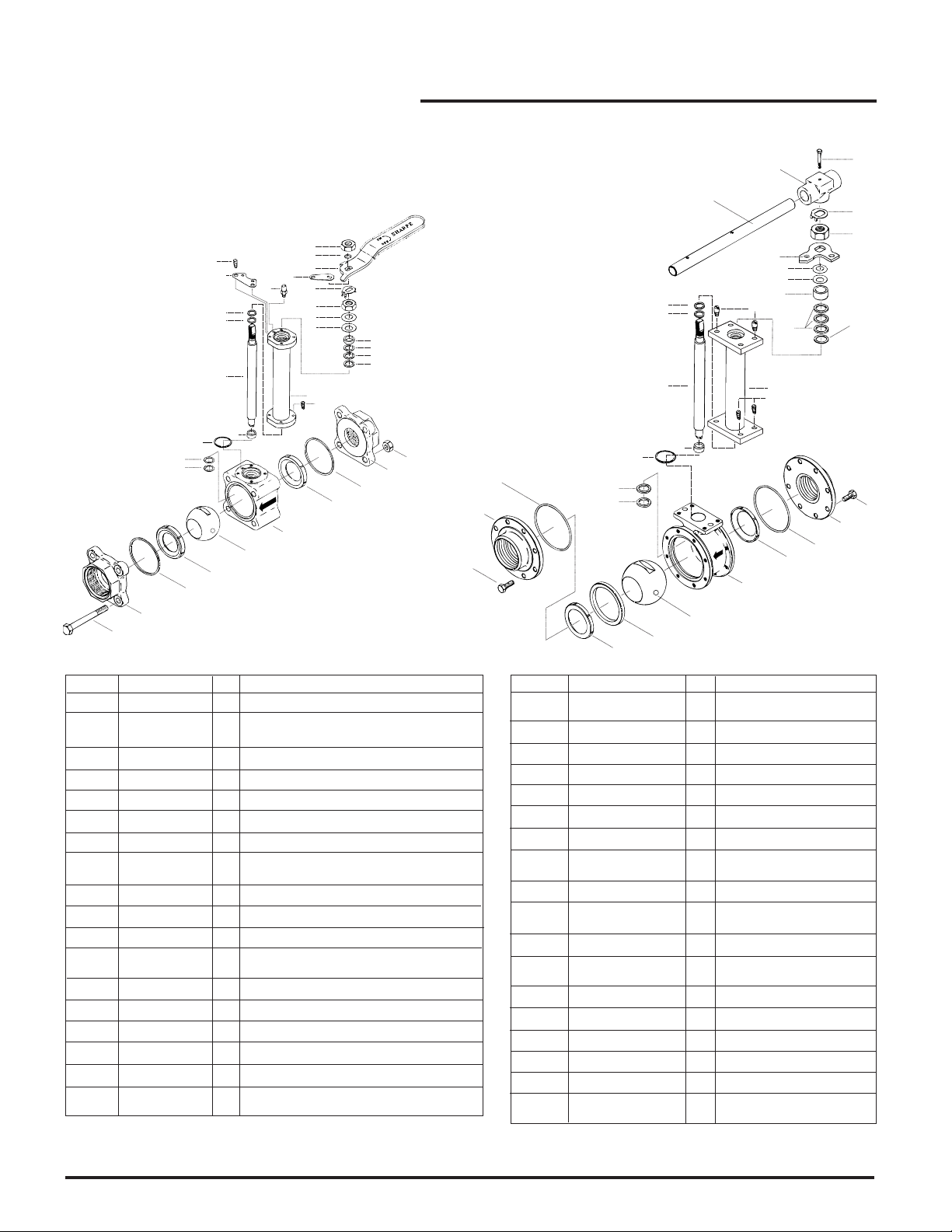

SERIES C84/C99

7

8

4

25

26

23

24

15C

15

21

18

17

16

15B

14

13

12

12

11

10

9

9

5

1

3

5

6

2

19

6

2

20

7

8

VALVE PARTS AND IDENTIFICATION

C84 1/2” - 2-1/2”

C99 1/2”- 2”

C84 3” - 4”

C99 2-1/2” - 3”

PART NO. PART QTY. MATERIAL

1 Body 1 Stainless Steel 316 ASTM A351 CF8M

2 Pipe Ends 2 Stainless Steel 316L ASTM A351 CF3M

Bronze ASTM B62/B584 C83600

3 Ball 1 Stainless Steel 316

4 Stem 1 Stainless Steel 316 / 17-4PH

5 Valve Seat 2 PCTFE - KEL-F

6 Body Seal 2 TFM / RTFE

7 Thrust Bearing 1 Nova*

7A Stem Location 1 Stainless Steel

Ring (3” & 4”)

8 Thrust Bearing 1 PEEK

8A Thrust Bearing 1 Nova*

9 Stem Packing 2 Nova*

9A Stem Packing 3 Nova*

(3” & 4”)

10 Seal Protector 1 PEEK

®**

/ Reinforced TFE

11 Gland Packing 1 Stainless Steel

12 Belleville Washer 2 Stainless Steel

13 Packing Nut 1 Stainless Steel

14 Lock Tab 1 Stainless Steel

15 Lower

Lock Latch 1 Stainless Steel

* Nova: Carbon and Graphite Filled TFE

** Kel-F® is registed trade mark of 3M Company.

*** TFM is registered trade mark of Dyneon,LLC

PART NO. PART QTY. MATERIAL

15B Upper Lock

Latch 1 Stainless Steel

15C Latch Bolt 1 Stainless Steel

16 Handle (1/4”-2”) 1 Stainless Steel

16A Wrench (3” & 4”) 1 Cad Plate Carbon Steel

16B Wrench Block 1 Stainless Steel

16C Hex Head Bolt 1 Stainless Steel

17 Lock Washer 1 Stainless Steel

18 Handle Nut

(1/4”-2”) 1 Stainless Steel

19 Body Bolts 4 Stainless Steel

19A Body

Connector Bolts 16 Stainless Steel

20 Nuts 4 Stainless Steel

21 Stop Pin 1 Stainless Steel

(1/4”-1/2”) 2 Stainless Steel

21A Stopper 1 Stainless Steel

22 Seat Retainer 1 Stainless Steel

23 Cryo Extension 1 Stainless Steel 316

24 Cryo Extension Bolts 4 Stainless Steel 304

25 Bonnet Seal 1 TFM / TFE

26 Cryo Extension

Bushing 1 TFM

Page 4

19A

20A

7

3

8A

6

2

19A

5

22

1

5

6

2

19A

180º

90º

14

13

7

8

4

25

26

23

24

11

21A

9A

16A

16B

7A

7

8A

21

16C

12

12

180º

90º

3

5

6

2

19

19A

7

8

13

12

12

11

10

9

9

18

17

16

14

15B

1

6

20

20

2

6

5

7

8

4

26

23

24

15C

15

21

25

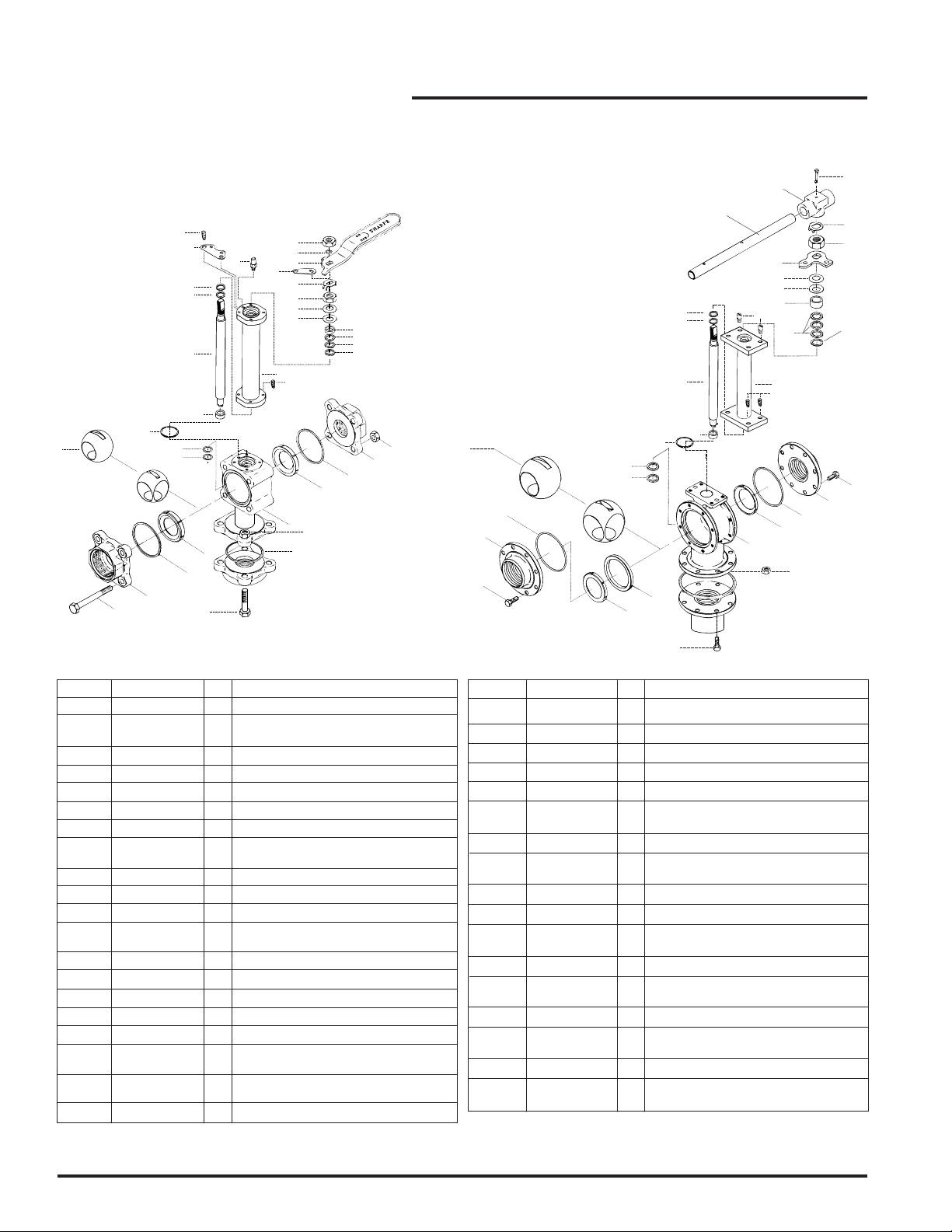

SERIES CD84

VALVE PARTS AND IDENTIFICATION

1/2” - 2-1/2”

3” - 4”

PART NO. PART QTY. MATERIAL

1 Body 1 Stainless Steel 316 ASTM A351 CF8M

2 Pipe Ends 3 Stainless Steel 316L ASTM A351 CF3M

Bronze ASTM B62/B584 C83600

3 Ball 1 Stainless Steel 316

4 Stem 1 Stainless Steel 316 / 17-4PH

5 Valve Seat 2 PCTFE - KEL-F

®

/ Reinforced TFE

6 Body Seal 3 TFM / TFE

7 Thrust Bearing 1 Nova*

7A Stem Location

Ring (3” & 4”) 1 Stainless Steel

8 Thrust Bearing 1 PEEK

8A Thrust Bearing 1 Nova*

9 Stem Packing 2 Nova*

9A Stem Packing 3 Nova*

(3” & 4”)

10 Seal Protector 1 PEEK

11 Gland Packing 1 Stainless Steel

12 Belleville Washer 2 Stainless Steel

13 Packing Nut 1 Stainless Steel

14 Lock Tab 1 Stainless Steel

15 Lower

Lock Latch 1 Stainless Steel

15B Upper Lock

Latch 1 Stainless Steel

15C Latch Bolt 1 Stainless Steel

PART NO. PART QTY. MATERIAL

16 Handle (1/4”-2”) 1 Stainless Steel

16A Wrench (3” & 4”) 1 Cad Plate Carbon Steel

16B Wrench Block 1 Stainless Steel

16C Hex Head Bolt 1 Stainless Steel

17 Lock Washer 1 Stainless Steel

18 Handle Nut

(1/4”-2”) 1 Stainless Steel

19 Body Bolts 4 Stainless Steel

19A Body

Connector Bolts 4/24 Stainless Steel

20 Nuts 8 Stainless Steel

20A Nuts 16 Stainless Steel

21 Stop Pin 1 Stainless Steel

(1/4”-1/2”) 2 Stainless Steel

21A Stopper 1 Stainless Steel

22 Seat 1 Stainless Steel

Retainer

23 Cryo Extension 1 Stainless Steel 316

24 Cryo Extension

Bolts 4 Stainless Steel 304

25 Bonnet Seal 1 TFM / TFE

26 Cryo Extension

Bushing 1 TFM

Page 5

1

16

17

4

3

4

5

7

11B

11C

11A

11

10

10

9

13

15

14

8

8

8

7

8

6

23

24

21

22

20

23

7

8

6

24

21

22

13

17

7

16

1

4

3

4

5

2

11B

13A

11A

11

12

10

10

9

8

8

8

8

15

20

20

SERIES C50

VALVE PARTS AND IDENTIFICATION

CLASS 150

BLOW OUT PROOF STEM

LOCKING DEVICE

1/2 - 2”

APPLICABLE STANDARDS

Shell Wall Thickness ASME B 16.34

Face to Face Dimensions ASME B 16.10

Flange Dimensions ASME B 16.5

Tests ASME B 16.34 API 598

Basic Design API 608

2-1/2” - 4”

PART NO. PART QTY. MATERIAL

1 Body 1 Stainless Steel 316 ASTM A351 CF8M

2 End Connector 1 Stainless Steel 316 ASTM A351 CF8M

3 Ball 1 Stainless Steel 316

4 Seat 2 PCTFE - KEL-F® / Reinforced TFE

5 Body Seal 1 TFE

6 Stem 1 Stainless Steel 316 / 17-4PH

7 Thrust Bearing 2 Reinforced TFE

8 Stem Packing 3/4 Reinforced TFE

9 Gland Packing 1 304 Stainless Steel

10 Belleville Washer 2 304 Stainless Steel

11 Packing Nut 1 304 Stainless Steel

11A Lock Tab 1 Stainless Steel

11B Handle Nut 1 304 Stainless Steel

11C Lock Washer 1 304 Stainless Steel (1/2”-2”)

12 Stopper 1 304 Stainless Steel

*See Dimensions

PART NO. PART QTY. MATERIAL

13 Handle 1 304 Stainless Steel (1/2”-2”)

Galvanized Steel (2-1/2”-4”)

13A Wrench Block 1 Stainless Steel

13B Hex Head Bolt 1 304 Stainless Steel

14 Locking Device 1 304 Stainless Steel

(1/2”-2”)

15 Sleeve 1 Vinyl

16 Body Stud SEE* A193 B8M

N

17 Nut SEE* A194 B8M

N

20 Stop Pin (1/2”-2”) 1 304 Stainless Steel

(2-1/2”-4”) 2 304 Stainless Steel

21 Cryo Extension 1 Stainless Steel 316

22 Cryo Extension

Bolts 4 Stainless Steel

23 Bonnet Seal 1 TFM / TFE

24 Cryo Extension

Bushing 1 TFM

Page 6

SERIES C84

A

N

G

D

B

R

L

DIMENSIONS

1/2” - 2” 2-1/2”

SIZE A B C D E F G L M N Q R T V

150# 300#

THRD.

SW / BW

FLOW

COEFF.

Cv

APPROX.

WEIGHT

PORT

SIZE

1/2” 2.78 4.25 5.50 .969 1.50 6.25 1.00 2.05 6.59 3/8”-24 UNF .22 6.87 1.00 4.50 M5 .28 8 3.90 .44

3/4” 2.78 4.62 6.00 .969 1.50 6.25 1.00 2.05 6.59 3/8”-24 UNF .22 6.87 1.00 4.50 M5 .28 12 3.90 .56

1” 3.68 5.00 6.50 1.25 1.75 7.50 1.18 2.42 8.19 7/16”-20 UNF .30 8.40 1.18 5.75 M5 .30 32 6.70 .81

1-1/4” 4.22 5.50 7.00 1.63 2.00 7.65 1.18 2.70 8.38 7/16”-20 UNF .30 8.70 1.18 5.75 M5 .30 46 7.60 1.00

1-1/2” 4.55 6.50 7.50 1.91 2.25 9.70 1.38 3.16 10.88 9/16”-18 UNF .35 11.16 1.38 7.00 M6 .42 80 12.00 1.25

2” 5.00 7.00 8.50 2.22 2.62 9.90 1.38 3.56 11.06 9/16”-18 UNF .35 11.35 1.38 7.00 M6 .42 120 14.00 1.50

2-1/2” 5.86 7.50 9.50 2.86 3.35 10.90 2.75 4.57 16.56 M20 .55 17.58 1.25 10.00 M8 .55 240 41.00 2.00

3” - 4”

FLOW

SIZE A B C D E F G L M N Q R T V

150# 300#

THRD.

SW / BW

COEFF.

Cv

APPROX.

WEIGHT

PORT

SIZE

3” 6.66 8.00 11.12 3.28 5.50 16.09 3.38 6.44 19.44 1-14 UNS .745 19.69 1.75 13.80 M10 .66 350 50.00 2.50

4” 8.40 9.00 12.00 4.28 6.97 16.65 3.38 8.12 20.00 1-14 UNS .745 20.24 1.75 22.00 M10 .66 720 71.00 3.25

Page 7

A

R

B

L

N

G

D

SERIES C99

DIMENSIONS

1/2” - 1-1/2”

SIZE A B C D E F G L M N Q R T V

150# 300#

THRD.

SW / BW

2”

FLOW

COEFF.

Cv

APPROX.

WEIGHT

PORT

SIZE

1/2” 2.78 4.25 5.50 .969 1.50 6.25 1.00 2.05 6.59 3/8”-24 UNF .22 6.87 1.00 4.50 M5 .28 38 3.90 .56

3/4” 3.68 4.62 6.00 1.25 1.75 7.50 1.18 2.42 8.19 7/16”-20 UNF .30 8.40 1.18 5.75 M5 .30 71 6.70 .81

1” 4.22 5.00 6.50 1.63 2.00 7.65 1.18 2.70 8.38 7/16”-20 UNF .30 8.70 1.18 5.75 M5 .30 110 7.60 1.00

1-1/4” 4.55 5.50 7.00 1.91 2.25 9.70 1.38 3.16 10.88 9/16”-18 UNF .35 11.16 1.38 7.00 M6 .42 230 12.00 1.25

1-1/2” 5.00 6.50 7.50 2.22 2.62 9.90 1.38 3.56 11.06 9/16”-18 UNF .35 11.35 1.38 7.00 M6 .42 350 14.00 1.50

2” 5.86 7.00 8.50 2.86 3.35 10.90 2.75 4.57 16.56 M-20 .55 17.58 1.25 10.00 M8 .55 600 41.0 2.00

2-1/2” - 3”

SIZE A B C D E F G L M N Q R T V

150# 300#

2-1/2” 6.66 7.50 9.50 3.28 5.50 16.09 3.38 6.44 19.44 1-14 UNS .745 19.69 1.75 13.80 M10 .66 780 50.0 2.50

3” 8.40 8.00 11.12 4.28 6.97 16.65 3.38 8.12 20.00 1-14 UNS .745 20.24 1.75 22.00 M10 .66 1200 71.0 3.25

THRD.

SW / BW

FLOW

COEFF.

Cv

APPROX.

WEIGHT

PORT

SIZE

Page 8

SERIES CD84

DIMENSIONS

1/2” -2”

2-1/2”

3’ - 4”

SIZE A B C D E F G L M N Q R T V

150# 300#

1/2” 2.78 4.25 5.50 2.75 1.50 6.25 1.00 2.05 6.59 3/8”-24 UNF .22 6.87 1.00 4.50 M5 .28 0.47 5

3/4” 2.78 4.62 6.00 2.75 1.50 6.25 1.00 2.05 6.59 3/8”-24 UNF .22 6.87 1.00 4.50 M5 .28 0.47 5

1” 3.68 5.00 6.50 3.45 1.75 7.50 1.18 2.42 8.19 7/16”-20 UNF .30 8.40 1.18 5.75 M5 .30 0.63 13

1-1/2” 4.55 6.50 7.50 4.15 2.25 9.70 1.38 3.16 10.88 9/16”-18 UNF .35 11.16 1.38 7.00 M6 .42 1.05 31

2” 5.00 7.00 8.50 4.50 2.62 9.90 1.38 3.56 11.06 9/16”-18 UNF .35 11.35 1.38 7.00 M6 .42 1.40 48

2-1/2” 5.86 7.50 9.50 6.00 3.35 10.90 2.92 4.57 16.56 M20 .55 17.58 1.25 10.00 M8 .55 1.84 82

3” 6.66 8.00 11.12 7.25 5.50 15.90 3.38 6.44 19.25 1”-14 UNS .745 19.50 1.75 13.80 M10 .66 2.00 120

4” 8.40 9.00 12.00 8.60 6.97 16.50 3.38 8.12 19.84 1”-14 UNS .745 20.09 1.75 22.00 M10 .66 2.50 155

THRD.

SW / BW

BOTTOM

PORT

CV*

US GAL.

GPM

Page 9

B

E F

C G

D

A

D

N

E F

C

G

B

0.06

SERIES C50

DIMENSIONS

1/2” - 2”

2-1/2” - 4”

SIZE A B C D E F

CLASS 150# 300# 150# 300# 150# 300# 150# 300# 150# 300# 150# 300#

1/2” 4.25 5.50 4.75 4.75 9.70 9.70 1.80 2.64 2.38 2.62 3.50 3.75

3/4” 4.62 6.00 4.75 4.75 9.90 9.90 2.00 2.94 2.75 3.25 3.85 4.60

1” 5.00 6.50 6.22 6.22 11.90 11.90 2.12 3.19 3.13 3.50 4.25 4.90

1-1/2” 6.50 7.50 9.00 9.00 12.70 12.70 2.76 3.63 3.56 4.50 5.00 6.15

2” 7.00 8.50 9.00 9.00 17.00 17.00 3.08 4.30 4.75 5.00 6.00 6.50

2-1/2” 7.50 9.50 13.75 13.75 18.70 18.70 3.09 4.90 5.50 5.86 7.00 7.48

3” 8.00 11.12 13.75 13.75 19.00 19.00 3.74 5.40 6.00 6.62 7.48 8.26

4” 9.00 12.00 13.75 13.75 19.70 19.70 4.46 5.94 7.50 7.88 9.01 10.00

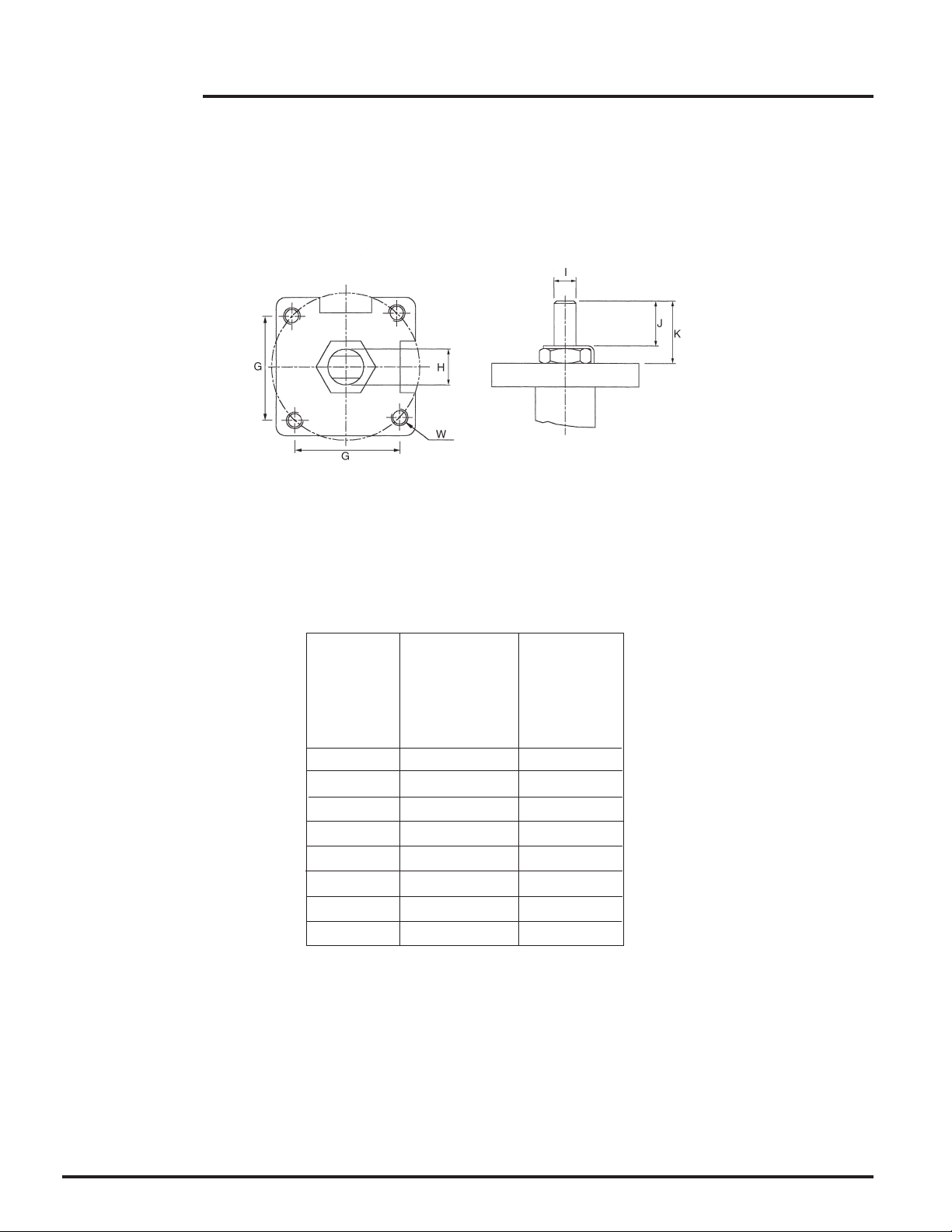

SIZE N G H I J K W

CLASS 150# 300# 150# 300# 150# 300# 150# 300# 150# 300# 150# 300# 150# 300#

1/2” 4 4 9.60 9.60 3/8-24 UNF 0.22 0.22 0.28 0.28 0.63 0.63 M5 M5

3/4” 4 4 9.75 9.75 3/8-24 UNF 0.22 0.22 0.28 0.28 0.63 0.63 M5 M5

1” 4 4 11.75 11.75 7/16-20 UNF 0.30 0.30 0.30 0.30 0.90 0.90 M6 M6

1-1/2” 4 4 12.50 12.50 9/16-18 UNF 0.35 0.35 0.42 0.42 1.18 1.18 M8 M8

2” 4 8 16.80 16.80 9/16-18 UNF 0.35 0.35 0.42 0.42 1.18 1.18 M8 M8

2-1/2” 4 8 18.45 18.45 M20 0.55 0.55 0.55 0.55 1.83 1.83 M10 M10

3” 4 8 18.75 18.75 1”-14 UNS 0.745 0.745 0.66 0.66 1.83 1.83 M10 M10

4” 8 8 19.45 19.45 1”-14 UNS 0.745 0.745 0.66 0.66 1.83 1.83 M10 M10

Page 10

SERIES C50

DIMENSIONS

1/2” - 4”

PERFORMANCE DATA

APPROX.

VALVE FLOW PORT

SIZE COEFF. SIZE

US GPM

1/2” 26 .59

3/4” 50 .78

1” 94 1.00

1-1/2” 260 1.50

2” 480 2.00

2-1/2” 750 2.55

3” 1300 3.00

4” 2300 4.00

Due to ongoing development of our product line, specications subject to change without notice.

Page 11

OPERATING DATA

C84/C99/CD84

PRESSURE TEMPERATURE DATA

1600

1/2”-2-1/2” C84 1/2”-2” C99

1400

800

720

700

C50

SEAT PRESSURE

TEMPERATURE DATA

CL150#

1200

1000

800

3”-4” C84 2-1/2”-3” C99

720

600

Maximum Pressure PSIG

400

200

0

-425 -300 -100 0 100 200 250 300 400 450 500

KEL-F

600

500

400

RTFE

275

300

Maximum Pressure PSIG

200

100

0

-425 -300 -100 0 100 200 250 300 400 450 500

BREAKAWAY TORQUE*

CL300#

Kel-F

RTFE

SIZE C84/CD84 C99 C50-150# C50-300#

1/2” 55 80 150 160

3/4” 80 195 170 215

1” 195 395 215 310

1-1/4” 395 700 - 1-1/2” 700 1050 400 600

2” 1050 1750 560 850

2-1/2” 1750 2190 875 1310

3” 2190 3500 1560 2250

4” 3500 - 3125 3690

* BASED ON MAXIMUM LINE PRESSURE, AT MINIMUM TEMPERATURE.

Page 12

HOW TO ORDER

VALVE VALVE BODY, STEM

SIZE SERIES & BALL ENDS SEATS SEALS ENDS OPTIONS

1/2” C84 Standard Port 6 = 316 Stainless Steel 6 = 316L Stainless Steel K = KEL-F® M = TFM IPS GO = Gear Operator

3/4” C99 Full Port 1 = Bronze R= RTFE T = TFE TE = Threaded NB = Non Extended Bonnet**

1” TEB = Threaded BSPT SB = Special Extended Length

1-1/4” R= BW = Butt Weld SCH 5,10,40,80 OH = Oval Handle

1-1/2” SW = Socket Weld OH = Oval Handle

2” 1 = 150# Flanged

2-1/2” 3 = 300# Flanged

3” TUBE ENDS

4”* IE = Instrumentation Ends ** Valves available without

(*C84 Only) BE = Tube Buttweld Bonnet Extension, for intermittent

BTE = Tube Extended Buttweld Cryogenic service.

3/4” C84 6 6 K M TE FS

HOW TO ORDER

VALVE VALVE BODY, STEM ENDS BALL

SIZE SERIES & BALL SIDE & BOTTOM SEATS SEALS ENDS CONFIGURATIONS OPTIONS

1/2” CD84 6 = 316 Stainless Steel 6 = 316L Stainless Steel K = KEL-F® M = TFM IPS P1 GO = Gear Operator

3/4” (DIVERTERS) 1 = Bronze R = RTFE T = TFE TE = Threaded P2 NB = Non Extended Bonnet**

1” R= RTFE TEB = Threaded BSPT SB = Special Extended Length

1-1/2” R= BW = Butt Weld OH = Oval Handle

2” SCH 5,10,40,80 OH = Oval Handle

2-1/2” SW = Socket Weld

3” 1 = 150# Flanged

4” 3 = 300# Flanged

TUBE ENDS

IE = Instrumentation Ends

BE = Tube Buttweld ** Valves available without

BTE = Tube Extended Bonnet Extension, for intermittent

BButtweld Cryogenic service.

T

3/4” CD84 6 6 K M TE P1 FS

HOW TO ORDER

VALVE VALVE

SIZE SERIES CLASS ALLOY SEATS OPTIONS

1/2” 2” C50 11 = 150# 6 = 316 Stainless Steel K = KEL-F® GO = Gear Operator

3/4” 2-1/2” 33 = 300# K R = RTFE NB = Non Extended Bonnet**

1” 3” SB = Special Extended Length

1-1/4” 4” R = OH = Oval HandleNB =

1-1/2” ** Valves available without Bonnet Extension, for

intermittent Cryogenic service.

3/4” C50 11 6 K FS

Toll-Free 1-877-7SHARPE

E-Mail: info@sharpevalves.com

A Division of Smith-Cooper International, LLC

Northlake, Illinois 60164 U.S.A.

Due to continuous development of our product range we reserve the right to change the dimensions and information contained in the leaet as required. Rev. 1/09

TFE is a registered trademark of Dyneon, LLC.

(877) 774-2773

Fax: (708) 562-9250

www.sharpevalves.com

1260 Garnet Drive

Loading...

Loading...