Page 1

CONNECTORS

- 242 -

SERIES AUM

NEOPRENE NPT END CONNECTION

DOUBLE SPHERE CONNECTORS

Pressures to 150 PSIG (10.34 barg)

Temperatures to 230ºF (110ºC)

● For connection pipes and equipment where

threaded union ends are preferred

● Accommodates thermal movement and

misalignment

● Four way greater movements provide high level

of installation flexibility.

● Precision molded of synthetic rubber reinforced

with nylon cord.

● Excellent ability to absorb vibrations, sounds and

withstand high pressures.

● Easy to install.

M

ODELS

● AUM – NPT Connection

APPLICABLE CODES

● ASME/ANSI B1-20.1

APPLICA TIONS

● Process Industry

● Weak Acids

● Alkalies

● Compressed Air

● Pulp & Paper

● Oil & Gas

● Water & Waste

● Pump suction & discharge

● Chemical lines

0 2 0 0 - A U M

12345678

Inlet Size

Model

Dash

Series AUM Ordering Code

Dash - Position 5

Model - Position 6 -8

AUM - Twin Sphere,

NPT, CI, Neoprene

Inlet Size* - Position 1 - 4

0050 - 1/2"

0075 - 3/4"

0100 - 1"

0125 - 11⁄4"

0150 - 11⁄2"

0200 - 2"

PRESSURE/TEMPERATURE RATINGS

Pressure (psi)

Temperature (F)

Page 2

CONNECTORS

- 243 -

Connections: 1/2" to 2"

Dimensions are subject to change. Consult

factory for certified drawings when required.

SERIES AUM

NEOPRENE NPT END CONNECTION

DOUBLE SPHERE CONNECTORS

SPECIFICATION

Union End Connector body material shall be neoprene cover and

tube elastomer with nylon cord fabric reinforcement. The twin sphere

connector will have Cast Ductile Iron threaded union ends. The twin

sphere connector shall be SSI AUM Series.

M

ATERIALS OF CONSTRUCTION

Body ......................................................................Neoprene

Reinforcing Fabric ......................................Nylon Cord Fabric

Wire ..............................................................Hard Steel Wire

Threaded Union Ends ..................................Cast Ductile Iron

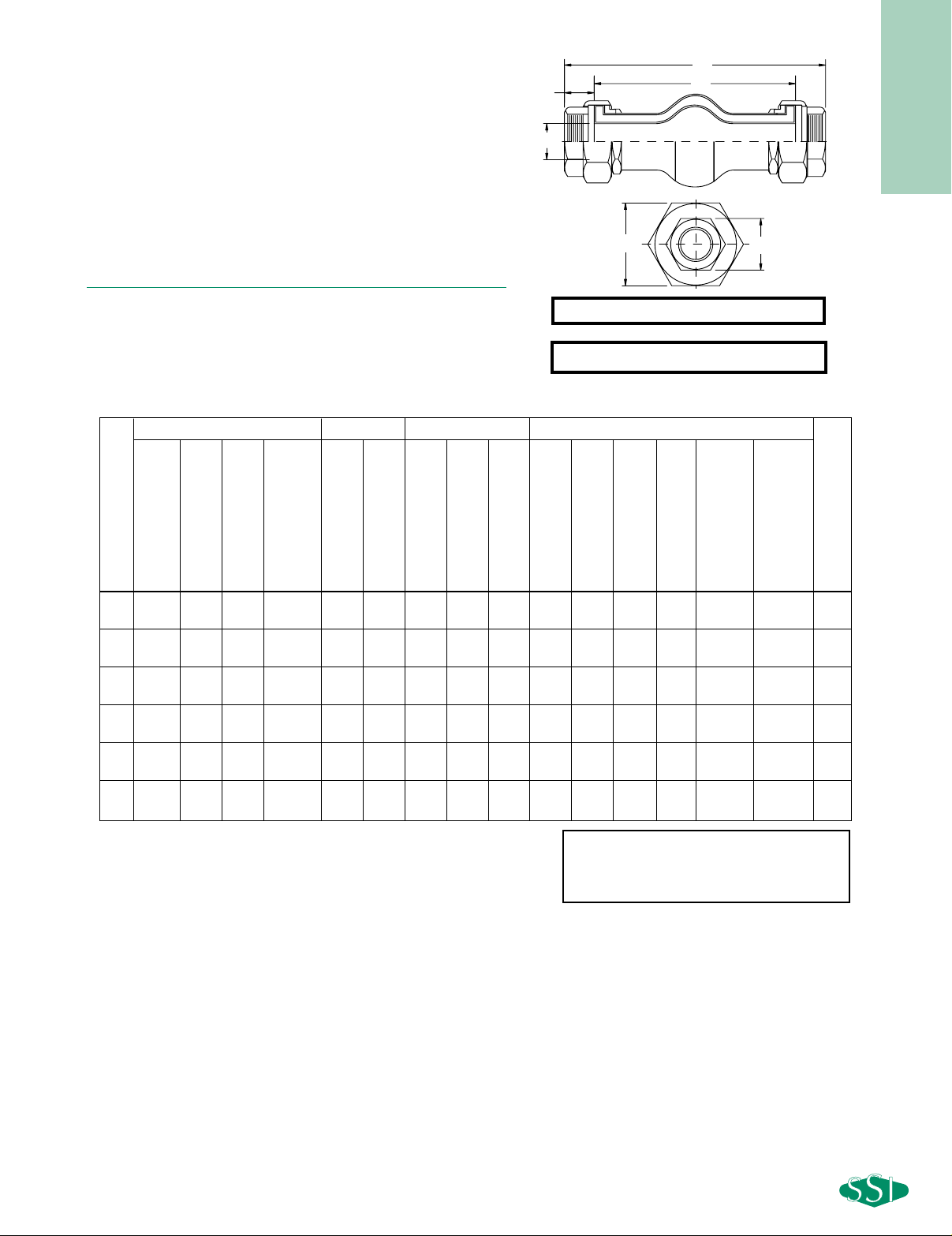

Installed Length Travel Allowable Movement Dimensions

1/2 8 711⁄32 81⁄8 75⁄16 71⁄8 87⁄32 7/8 1/4 7/8

32

29/32 63⁄32 17/32 11⁄16 111⁄16 1

(13) (203) (187) (206) (186) (181) (209) (22) (6) (22) (23) (155) (13) (27) (43) (0.5)

3/4 8 711⁄32 81⁄8 67⁄8 71⁄8 87⁄32 7/8 1/4 7/8

32

1529⁄32 3/4 111⁄32 131⁄32 1

(19) (203) (187) (206) (175) (181) (209) (22) (6) (22) (25) (150) (19) (34) (50) (0.5)

18711⁄32 81⁄8 65⁄8 71⁄8 87⁄32 7/8 1/4 7/8

25

13⁄16 517⁄32 1 1 5/8 21⁄2 2

(25) (203) (187) (206) (168) (181) (209) (22) (6) (22) (30) (140) (25) (41) (64) (0.9)

11⁄4 8711⁄32 81⁄8 65⁄8 71⁄8 87⁄32 7/8 1/4 7/8

25

13⁄16 517⁄32 11⁄4 131⁄32 227⁄32 3

(32) (203) (187) (206) (168) (181) (209) (22) (6) (22) (30) (140) (32) (50) (72) (1.5)

11⁄2 8711⁄32 81⁄8 65⁄8 71⁄8 87⁄32 7/8 1/4 7/8

20

13⁄8 51⁄8 117⁄32 21⁄4 323⁄32 4

(38) (203) (187) (206) (168) (181) (209) (22) (6) (22) (35) (130) (39) (57) (94) (2.0)

28711⁄32 81⁄8 65⁄8 71⁄8 87⁄32 7/8 1/4 7/8

15

2423⁄32 127⁄32 2 3/4 323⁄32 6

(51) (203) (187) (206) (168) (181) (209) (22) (6) (22) (40) (120) (47) (70) (94) (2.6)

DIMENSIONS inches (mm) AND WEIGHTS pounds (kg)

F

E

D

C

A

B

A

C

B

Size

Neutral Length

Minimum Installed

Maximum Installed

Recommended

Pipe Opening

Total Compressed

Total Extended

Axial Compression

Lateral Deflection

Angular Deflections

“B” Length of Fittings

“C” Length of Rubber

“D” Connector

Inner Diameter

“E” Width of Fitting

Hex Head

“F” Width of

Union Hex Head

Weight

D

F

E

Burst Pressure 570 PSIG

Installation Note:

For correct Installation & Maintenance

instructions

see page 244

Loading...

Loading...