Page 1

RUSSELL PUMP

Model A915

End Suction, Close Coupled, Bronze Fitted,

Centrigal Pump

Typical Applications

General Purpose, OEM, Boosters,

Cooling Towers, Boiler Feed,

Process Fluids, HVAC, Irrigation,

Hot and Chilled Water Circulation

Russell Pump and Engineering Inc.

102 W. Chicago Street

Albion, IA 50005

641-488-2319

Page 2

Design Features

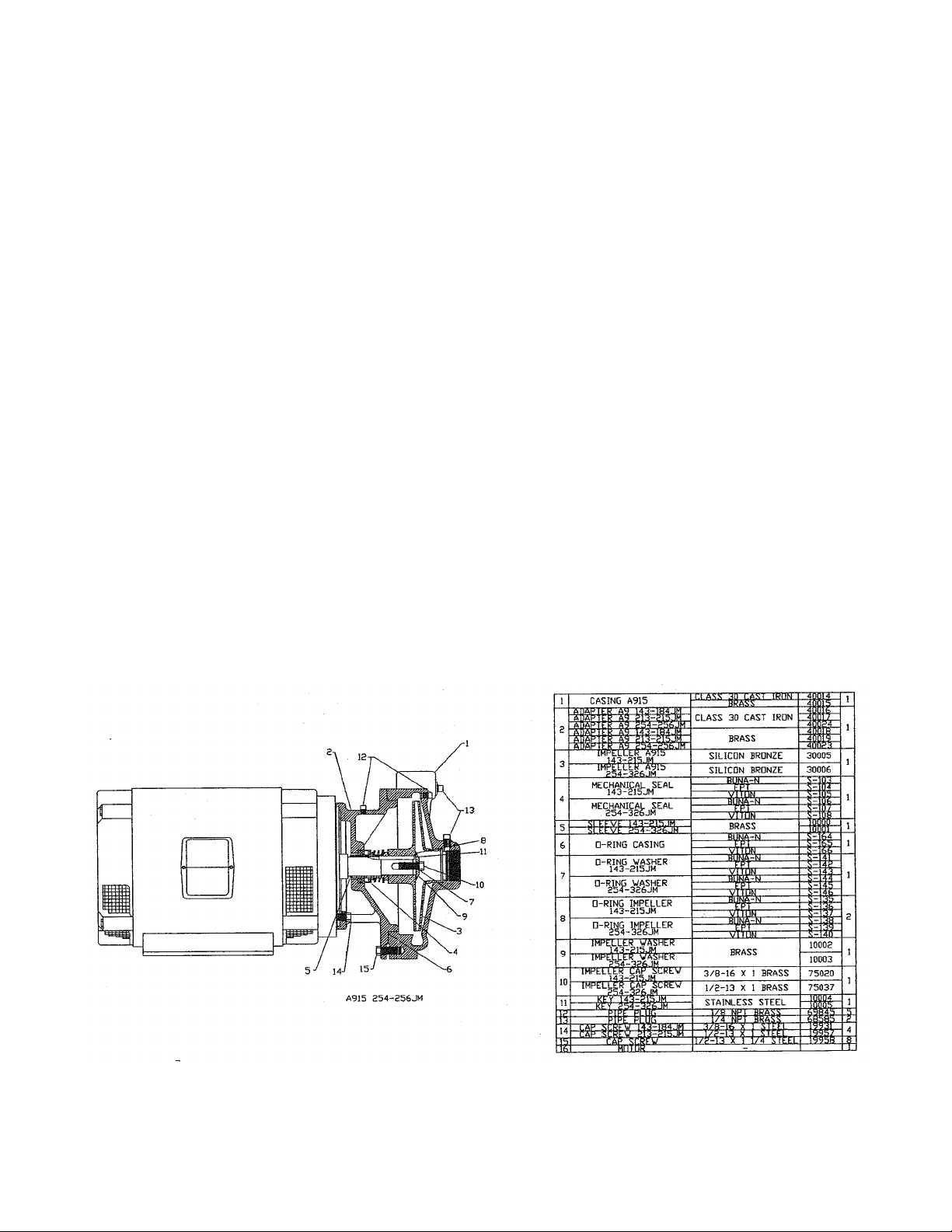

CASING Constructed as ASTM A48 class 30 cast iron. The discharge can be mounted in

any 90° position. Drain and air ports are also positioned every 90°, 1/4 npt suction and discharge tappings are standard. Back pull out design allows the pump to

be serviced without disturbing the piping. The volute was designed to maximize

hydraulic efciency.

MECHANICAL SEAL Type 21 buna-n seal is rated to 225°F and pressures to 175PSI. Carbon seal face

mates with the ceramic seat providing years of trouble free service. Alternate seals

available upon request.

IMPELLER The hydraulic design of the impeller maximizes pressure and gpm while minimiz-

ing horsepower. The enclosed impeller is made of cast bronze.

ADAPTER The precise machining of the adapter allows for easy assembly of the pump. A 1/8

npt hole is provided if a seal ush line is added. Construction consists of ASTM

A48 class 30 cast iron.

MOTOR The NEMA JM frame motor utilizes a high carbon steel shaft. The motor’s heavy

duty ball bearings withstand axial and radial thrust loads with no problem. Standard enclosure type is dripproof but alternates are available.

Page 3

LIMITATIONS

MAXIMUM WORKING PRESSURE - 175PSI

MAXIMUM GALLONS PER MINUTE - 225

MAXIMUM HEAD PRODUCED - 360 FT.

RPM - 3500

MAXIMUM SEAL TEMP BUNA-N - 225°F

EPT - 300°F

VITON - 400°F

MAXIMUM HORSEPOWER - 25

Page 4

SPECIFICATIONS

The contractor shall furnish (and install as shown on the plans) a Russell Series A915 close coupled, centrifugal, bronze tted pump.

Each 11⁄2” x 2” pump shall have the capacity of ____ GPM when operated at a total head of ____ feet.

The pump casing shall be radially split, end suction with 1/4 npt suction and discharge gauge tappings included. The casing should be

able to accommodate any 90° mounting position. There shall be four drain/air ports drilled and tapped 90° apart. The casing design

should be of a back pull-out type.

The pump is to be furnished with a mechanical seal which incorporates stainless steel parts. Buna-N elastomers, ceramic seat, and

carbon seal face shall be standard.

The adapter shall be drilled and tapped to allow for the possible addition of a seal ush line.

The pump shall be close coupled to a NEMA C face _____HP _____PHASE _____HERTZ _____VOLTAGE _____RPM drip-

proof motor. The motor shall be sized to prevent overloading at the duty point. The motor shall have a stainless steel shaft and sealed

bearings.

All external cast parts shall have at least one coat of a high grade baked on powder coat paint. Each unit shall be checked by the contractor to regulate the correct pressure, voltage, and amp draw.

Loading...

Loading...