Page 1

For optimal performance, the service

conditions (medium, flow, temperature,

inlet and outlet pressures) of the

application must be considered when

selecting a valve. Please refer to the

Valve Selection Section of this catalog.

Consult the Valve Selection tables

for the capabilities of a particular

valve/actuator assembly. Improper

application may cause failure of the

valve, resulting in possible personal

injury or property damage.

For replacement or service parts please

see Accessories and Replacement Parts

in the Regulators and Control Valves

section of the list price sheet.

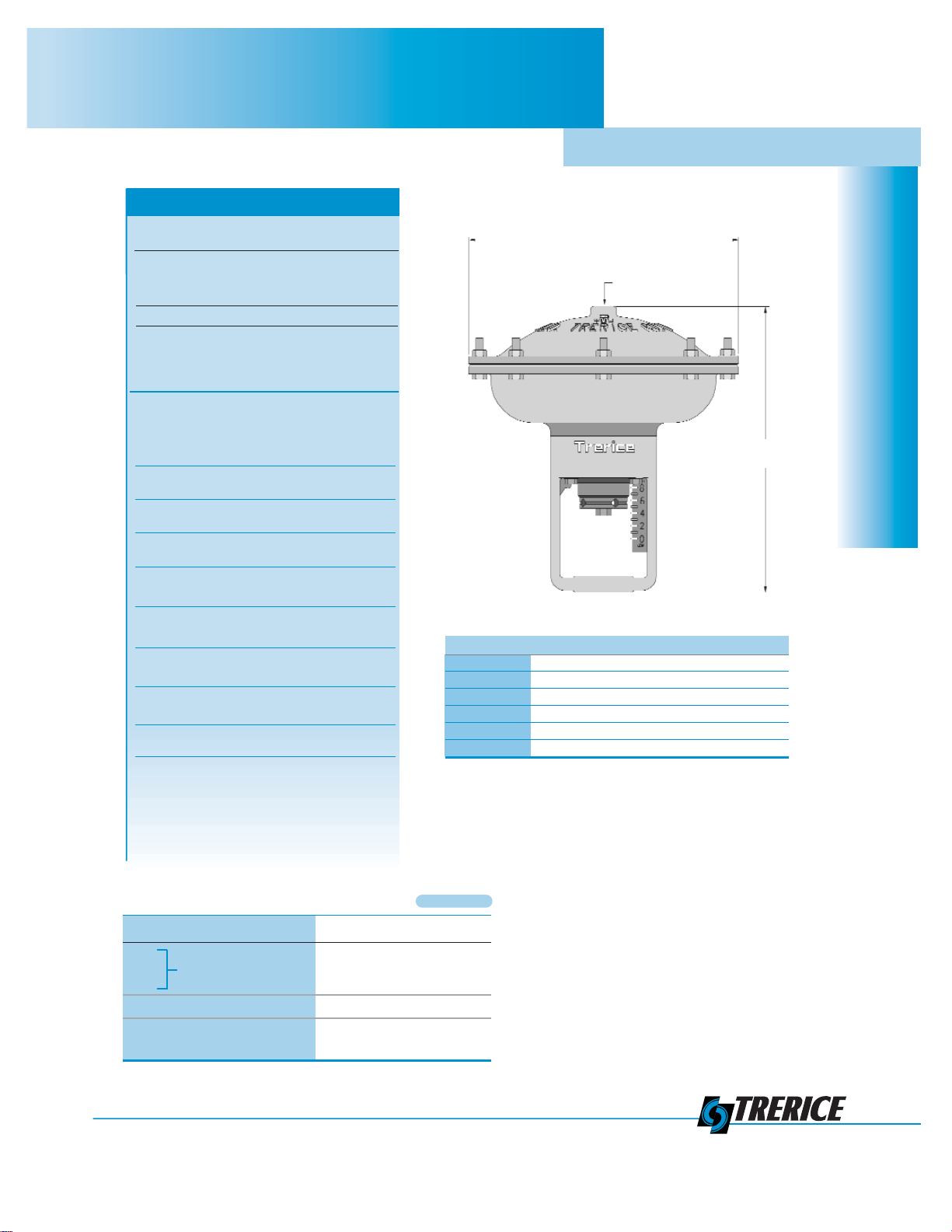

910B shown

910 Series Compact Control Valve

CONTROL VALVES

Diaphragm Actuated

7", 9", & 12" Actuator Sizes

Heavy Duty Die CastHousing

1

/2" – 6" Valve Sizes

The Trerice 910 Series Pneumatic

Control Valve offers high quality

at an economical price, incorporating

many features found only on more

expensive units. Models are available

to provide the proper flow response

required by the application.

The 910A, 910B & 910C are

used for On/Off control applications,

providing a quick-opening flow response

when used with single or double

seated valves.

The 910TB is used for proportional

or PID control applications, providing

a throttling flow response when used

with double seated or 3-way valves.

The 910EPA & 910EPC is used for

proportional or PID control applications,

providing an equal percentage flow

response when used with single

seated valves.

Valve

Body

Actuator

12950 W. Eight Mile Road • Oak Park, MI 48237-3288 • TEL:248/399-8000 • FAX: 248/399-7246 • www.TRERICE.com

228

Page 2

A

1/8 NPT

HOW TO ORDER Sample Order Number: 910TB - A56

Actuator Model (Control Action) Valve Body Number

910A

910B On/Off Refer to pages 230–234

910C

910TB Throttling Refer to pages 235–238

910EPA

Equal Percentage Refer to page 239

910EPC

Housing

Die cast aluminum, epoxy powder

coated blue finish

Setting Scale

Integral to housing

Adjustment Screw

Brass

Adjustment Screw Bushing

Lubricant impregnated sintered bronze

Range Adjustment Spring

Cadmium plated

Pressure Plate

Aluminum

Diaphragm

Nylon reinforced EDPM

Air Pressure to Diaphragm

30 psig maximum

Air Pressure Connection

1

/8NPT Female

Operating Temperature

Ambient:

-40°F (-40°C) to 180°F (82°C)

Process Flow:

-40°F (-40°C) to 410°F (210°C)

Specifications

910

Series

Compact Control Valve

CONTROL VALVES

All dimensions are nominal. Dimensions in [ ] are in millimeters

Actuator

Diaphragm

Control Input

Model Size Action Signal

910A 7" On/Off 15 psi

910B 10" On/Off 15 psi

910C 12" On/Off 15 psi

910TB 10" Throttling* 3-15 psi

910EPA 7" Equal 3-15 psi

Percentage

910EPC 12" Equal 3-15 psi

Percentage

*Includes 3-Way

Actuator Number A B Approx. Shipping Weight

910A 7.0 [178] 9.8 [249] 6.6 lbs [2.97 kg]

910B 9.3 [236] 9.8 [249] 8.5 lbs [3.83 kg]

910C 11.4 [290] 9.8 [249] 12.0 lbs [5.41 kg]

910TB 9.3 [236] 9.8 [249] 9.6 lbs [4.32 kg]

910EPA 7.0 [178] 9.8 [249] 7.6 lbs [3.42 kg]

910EPC 11.4 [290] 9.8 [249] 13.1 lbs [5.90 kg]

B

1. Determine the Actuator Model ( 910A, 910B, 910C, 910TB,

910EPA or 910EPC) required. Note: Refer to the maximum

close-off pressure columns in the Valve Body Selection tables

to determine the Actuator size required by your application.

2. Determine the Valve Size, style and material required

by the application. Note: Consult the Valve Selection Table

to determine the required Valve Body Number.

12950 W. Eight Mile Road • Oak Park, MI 48237-3288 • TEL:248/399-8000 • FAX: 248/399-7246 • www.TRERICE.com

229

Loading...

Loading...