Page 1

- 408 -

600Y SERIES

STRAINERS

600Y SERIES

CARBON STEEL, STAINLESS STEEL, LOW

CARBON STEEL, ALLOY 20 Y STRAINERS

NPT, FLANGED, RING JOINT,

SOCKETWELD, BUTTWELD

PRESSURES TO 1480 PSIG (102

BARG)

T

EMPERATURES TO 800°F (427°C)

●ANSI 600 PSIG rated strainers

● NPT, RF or RTJ Flanges, Socketweld and Buttweld in

accordance with ANSI 16.34 and 16.5

● SSI Exclusive – Body blow down flange and cover

flange dimensions are in dimensional accordance with

ANSI B16.5

● All Flanged connections complete with Bolted Cover

● One piece cast body

● Upper and lower machined seats

● Generous screen area and properly proportioned

straining chamber to minimize initial pressure drop

while maximizing time between cleanings

● Drain/Blow-off connection furnished with plug

MODELS

●600Y1T* – NPT with Threaded Cover

● 600Y1W* – Socketweld with Threaded Cover

● 600Y2F* – Flanged with Bolted Cover

● 600Y2J* – Ring Joint with Bolted Cover

● 600Y2B* – Buttweld with Bolted Cover

*Carbon Steel, Stainless Steel, Low Carbon Steel or Alloy 20

APPLICA TIONS

●Steam, liquid, gas and oil service

●Power industry

●Pulp and paper

●Chemical industry

●Process Equipment

●Metal & Mining

●Water & Waste

OPTIONS

●Low Carbon Steel and Alloy 20 bodies

available on Y1T and Y1W models

● Other perforated screens and mesh liners

● Other drain connections and gasket materials

● Oxygen cleaning

● Special internal / external coatings and linings

● Contact Factory for other Options

APPLICABLE CODES

●ANSI B16.5

● ANSI B16.34

Canadian Registration

OEO447.902517 - 600Y1

OE1972.2987 - 600Y2

0300-600Y1WC-B____

12345678910111213141516

Add’l

Inlet Size Model Body Dash Perf Mesh Require-

ments

600Y Series Ordering Code

Dash - Position 5

Model - Position 6 - 11

600Y1T

600Y1W

600Y2F

1

600Y2J

1

600Y2B

1, 2

Body - Position 12

C - CS

T - SS

L - LCS

A - A20

Dash - Position 13

Perf3- Position 14

304SS Material

4

A - No Perf

1 - 1/32"

B - 3/64"

4 - 1/8"

2 - 1/16"

3 - 3/32"

5 - 5/32"

6 - 3/16"

7 - 7/32"

8 - 1/4"

9 - 3/8"

Mesh4- Position 15

Leave Blank

If not Required

(std ALL)

1 - 10

2 - 20

3 - 30

4 - 40

5 - 50

6 - 60

7 - 80

8 - 100

9 - 120

Add’l Requirements -

Position 16

Leave Blank

If not Required

D - Special Drain Size

F - Silicon Free

G - Special Gaskets

N - Nace MR01-75

T - Special Testing

X - Oxygen Cleaning

Y - Other and / or

Multiple Specials

Indicate Specials

Clearly On the Order

Inlet Size -

Position 1 - 4

0050 -

1

⁄2"

0075 -

3

⁄4

"

0100 - 1"

0125 - 11⁄4"

0150 - 1

1

⁄2

"

0200 - 2"

0250 - 21⁄2"

0300 - 3"

0400 - 4"

0500 - 5"

0600 - 6"

0800 - 8"

1000 - 10"

1200 - 12"

4. For other screen

material, contact factory.

3. Standard Screens:

All

1

⁄2"-11⁄2"—1/32" perf,

All 2"-3"—3/64" perf,

All >3"—1/8" perf.

1. CS available 2" - 12",

SS available 2" - 6".

2. For Buttweld connec-

tions please specify

mating pipe schedule.

Page 2

- 409 -

600Y1 SERIES

STRAINERS

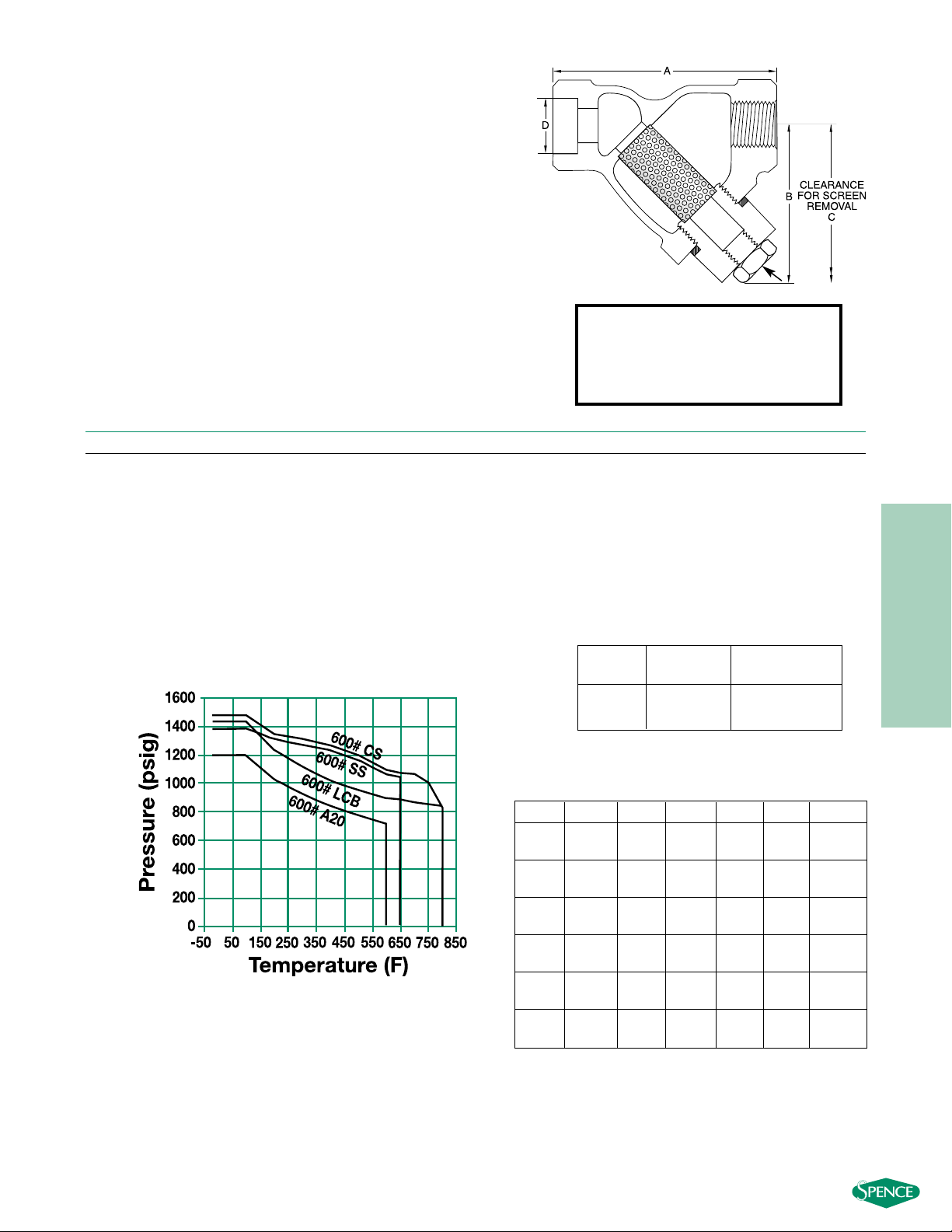

PRESSURE/TEMPERATURE CHART

ANSI B16.34

Connections:

CS – 1⁄2" to 2" NPT or SW

SS – 1⁄2" to 2" NPT or SW

LCS – 1⁄2" to 2" NPT or SW

A20 – 1⁄2" to 2" NPT or SW

SCREEN OPENINGS

STANDARD

SIZE SCREEN MATERIALS

1

⁄

2" – 1

1

⁄

2" 1/32" Perf 304 SS/Alloy 20

2" 3/64" Perf 304 SS/Alloy 20

600Y1 SERIES

CARBON STEEL, STAINLESS STEEL,

LOW CARBON STEEL, ALLOY 20

Y STRAINERS NPT, SOCKETWELD

SPECIFICATION

Y Strainer shall be straight flow design with NPT or Socketweld inlet/outlet

connections. The strainer shall be rated to ANSI 600 PSIG . The Strainer

shall be Cast Carbon Steel, Stainless Steel Low Carbon Steel or Alloy 20

body and the screen shall be size ______ perf 304 SS or Alloy 20. The

strainer shall be have an inlet size of ______ and Open Area Ratio of

_______. The Y Strainer shall be SSI 600Y1 Series

SIZE A B C D E WEIGHT

1

⁄2 32

7

⁄16 31⁄8 0.855

1

⁄4 1.4

(15) (76) (62) (80) (21.72) (8) (0.6

3

⁄4 33⁄4 215⁄16 39⁄16 1.065

3

⁄8 2.2

(20) (95) (75) (90) (27.05) (10) (1.0)

14

5

⁄8 33⁄4 315⁄16 1.330

3

⁄8 4.1

(25) (118) (95) (100) (33.78) (10) (1.9)

11⁄4 544

1

⁄4 1.675

3

⁄4 5.3

(32) (127) (102) (108) (42.55) (20) (2.4)

11⁄2 55⁄8 413⁄16 45⁄8 1.915

3

⁄4 8.4

(40) (143) (122) (118) (48.64) (20) (3.8)

276

1

⁄

8 6

3

⁄

4 2.406 1 12.6

(50) (178) (156) (171) (61.11) (25) (5.7)

DIMENSIONS inches (mm)

AND WEIGHTS pounds (kg)

Dimensions shown are subject to change.

Consult factory for certified drawings when required.

MATERIALS OF CONSTRUCTION

Part Carbon Steel Stainless Steel Low Carbon Steel Alloy 20

Body A216-WCB A351-CF8M A352-LCB A351-CN7M

Cap

2

A216-WCB A351-CF8M A351-CF8M A351-CN7M

Screen

1

304 SS 304 SS 304 SS 304 SS

Plug

2

A105 304 SS 304 SS B462

Gasket

1

304 SS Spiral Wound 304 SS Spiral Wound 304 SS Spiral Wound 304 SS Spiral Wound

1. Recommended Spare Parts

2. Materials of equivalent strength may be substituted

E N.P.T.

Page 3

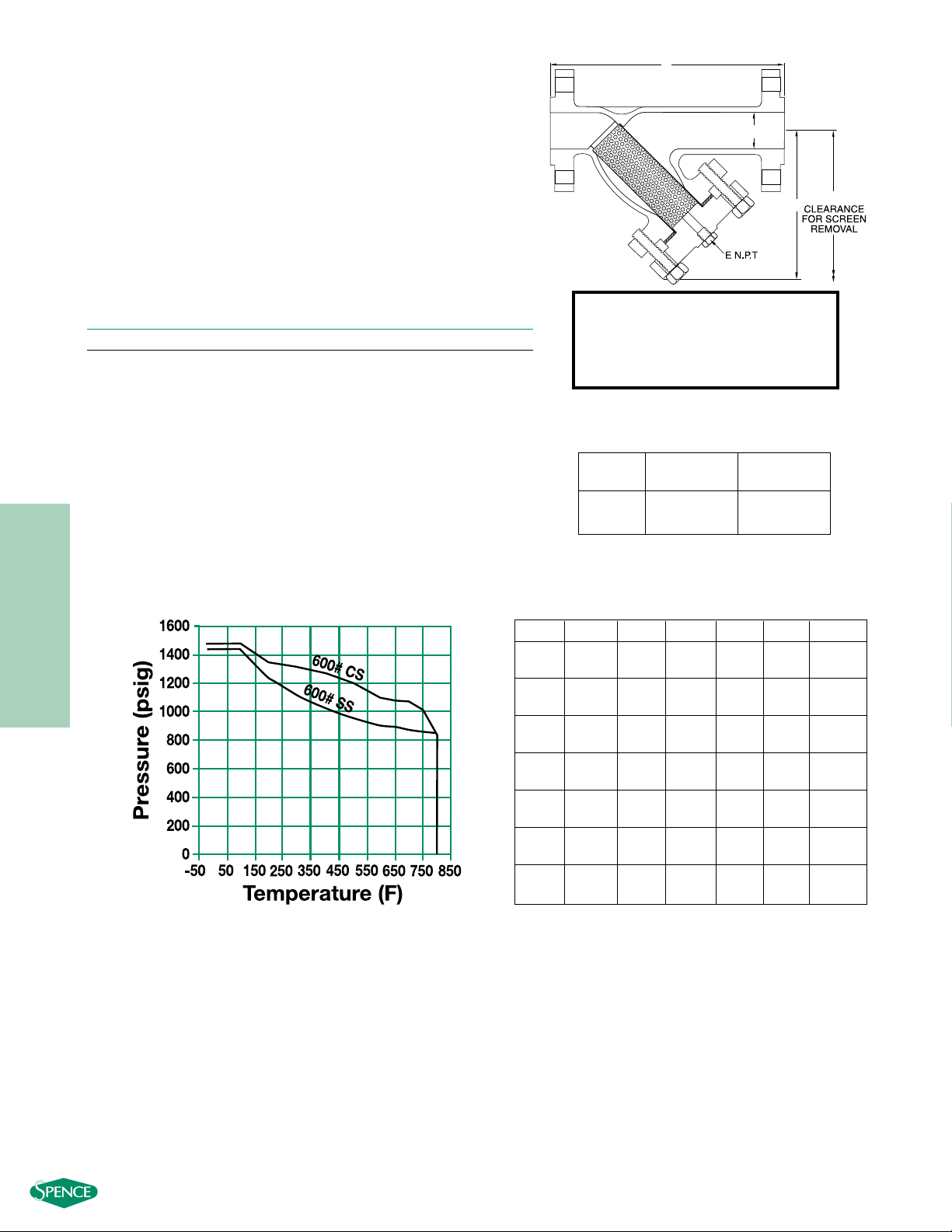

- 410 -

600Y2 SERIES

STRAINERS

Connections:

CS - 2" to 12" RF Flanged,

RTJ or Buttweld

3

SS – 2" to 6" RF Flanged,

RTJ or Buttweld

3

SCREEN OPENINGS

STANDARD

SIZE SCREEN MATERIALS

2"- 3" 3/64" Perf 304 SS

4" – 12" 1/8" Perf 304 SS

600Y2 SERIES

CARBON STEEL, STAINLESS STEEL

Y STRAINERS

FLANGED, RING JOINT, BUTTWELD

SPECIFICATION

Y Strainer shall be straight flow design with RF Flanged, Ring Joint or

Buttweld inlet/outlet connections. The strainer shall be rated to ANSI 600

PSIG rating in accordance with ANSI B16.5 or B16.34. The Strainer shall

be Cast Carbon Steel or Stainless Steel body and the screen shall be size

______ perf 304 SS. The strainer shall be have an inlet size of ______ and

Open Area Ratio of _______. The Y Strainer shall be SSI 600Y2 Series.

M

ATERIALS OF

C

ONSTRUCTION

Part Carbon Steel Stainless Steel

Body A216-WCB A351-CF8M

Cover A216-WCB A351-CF8M

Screen

1

304 SS 304 SS

Plug

2

A105 304 SS

Gasket

1

304 SS Spiral Wound 304 SS Spiral Wound

Stud A193-B7 A320-B8

Nut

2

A194-2H A194-8

1. Recommended Spare Parts

2. Materials of equivalent strength may be substituted

SIZE

4

A B C D E WEIGHT

212

1

⁄

2 89

1

⁄

4 2

1

⁄

2 46

(50) (318) (203) (235) (51) (15) (20.9)

315

5

⁄

8 10

1

⁄

8 11

3

⁄

8 31

1

⁄

4 93

(80) (397) (257) (289) (76) (32) (42.2)

4201314

1

⁄

4 41

1

⁄

2 187

(100) (508) (330) (362) (102) (40) (85.0)

625

1

⁄2 17 181⁄4 6 2 403

(150) (648) (432) (463) (152) (50) (183.2)

83021

3

⁄8 2211⁄16 8 2 660

(200) (330) (543) (576) ( 203) (50) (300.0)

10 375⁄8 243⁄4 26 10 2 1428

(250) (956) (629) (660) (254) (50) (649.1)

12 42 30 311⁄4 12 2 1608

(300) (1067) (762) (794) (305) (50) (730.9)

DIMENSIONS inches (mm)

AND WEIGHTS pounds (kg)

Dimensions shown are subject to change.

Consult factory for certified drawings when required.

PRESSURE/TEMPERATURE CHART

ANSI B16.34

C

A

D

B

4. CS available 2" - 12",

SS available 2" - 6".

3. For Buttweld connections please specify

mating pipe schedule.

Page 4

- 411 -

600Y SERIES

STRAINERS

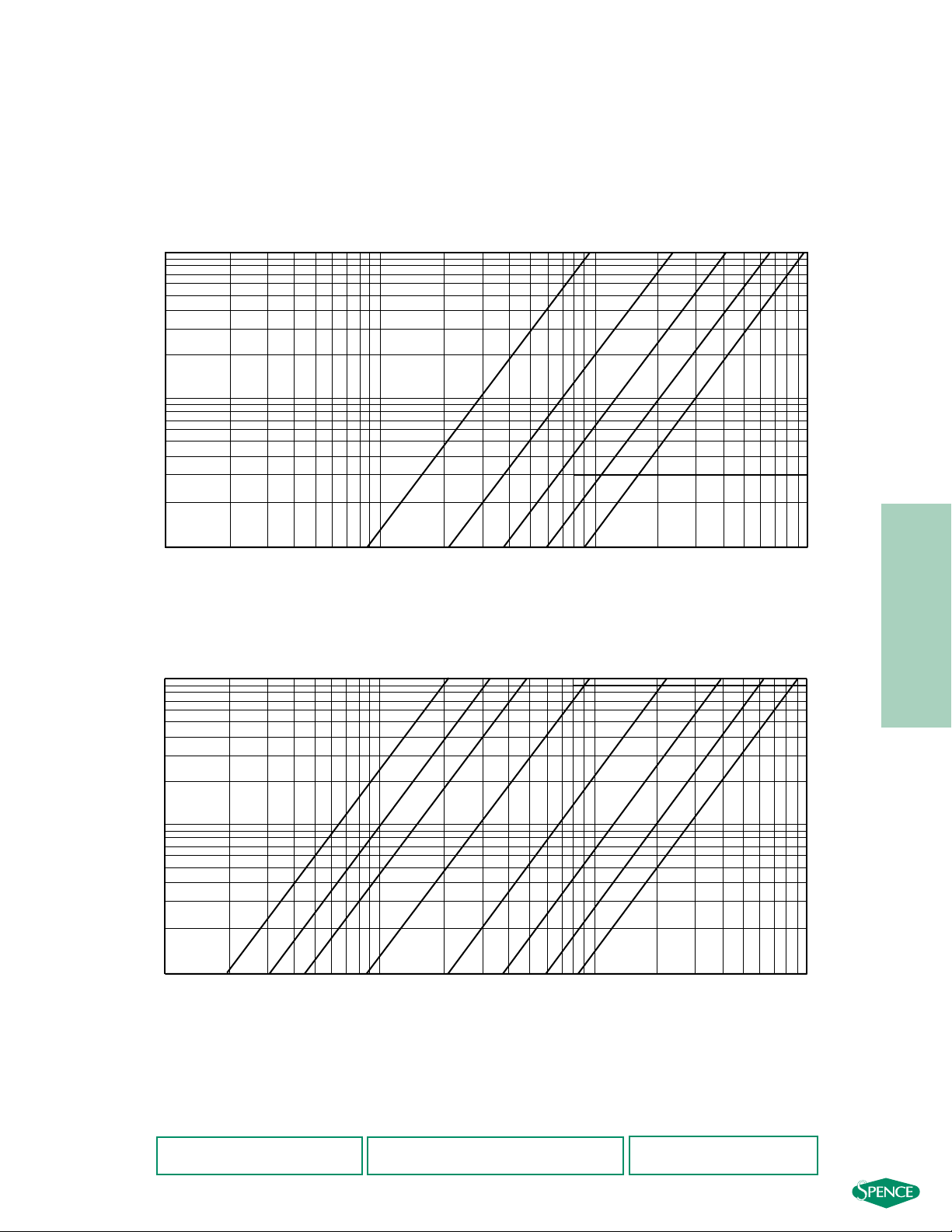

600Y SERIES

CARBON STEEL, STAINLESS STEEL, LOW CARBON STEEL, ALLOY 20

PRESSURE DROP VS FLOW RATE

Water Service, Clean Basket, 1/32" - 1/4" Perforated Screen*

(Sizes 1⁄2" - 11⁄2")

(Sizes 2" - 12")

* For Gas, Steam or Air service, consult factory.

Steam Service Pressure Drop

Page 433

Correction Factors for Other Viscous

Liquids and/or Mesh Liners Page 432

Correction Factors for

Clogged Screens Page 432

10

1

PRESSURE DROP (PSIG)

0.1

0.1 1 10 100

1/2”

FLOW RATE (GPM)

3/4”

1”

”

1-1/4

1-1/2”

10

10

”

12”

1

2-1/2”

3”

4”

6”

8”

2”

PRESSURE DROP (PSIG)

0.1

10 100 1000 10000

FLOW RATE (GPM)

Page 5

- 412 -

600Y SERIES

STRAINERS

Flange Gross Free Open

Perf. Inlet Screen Screen Area

Size Diameter Opening Area Area Area Ratio

(inches) % (in2) (in2) (in2) (OAR)

2 3/64 36 3.14 38.4 13.82 4.4

3 3/64 36 7.07 74.2 26.72 3.8

4 1/8 40 12.57 127.6 51.06 4.1

6 1/8 40 28.27 261.2 104.49 3.7

8 1/8 40 50.27 408.5 163.42 3.3

10 1/8 40 78.54 598.9 239.57 3.1

12 1/8 40 113.10 817.7 327.08 2.9

600Y2 - Flanged, Ring Joint Flanged

& Buttweld

XH Pipe Gross Free Open

Perf. Inlet Screen Screen Area

Size Diameter Opening Area Area Area Ratio

(inches) % (in2) (in2) (in2) (OAR)

1

⁄2 1/32 28 0.23 2.7 0.76 3.3

3

⁄4 1/32 28 0.43 4.6 1.28 3.0

1 1/32 28 0.72 8.5 2.38 3.3

11⁄4 1/32 28 1.28 12.8 3.58 2.8

11⁄2 1/32 28 1.77 16.5 4.61 2.6

2 3/64 36 2.95 27.8 19 3.4

600Y1 - Threaded & Socketweld

600Y SERIES

CARBON STEEL, STAINLESS STEEL, LOW CARBON STEEL, ALLOY 20

OPEN AREA RATIOS

with Standard Perforated Screen

Basket Burst Pressure

Page 435

OAR = Free Screen Area / Inlet Area

Free Screen Area = Opening % x Gross Screen Area

Values shown are approximate. Consult factory for exact ratios.

Other Screen Openings

Page 430

Loading...

Loading...