Page 1

- 315 -

DURA-FLO

FEATURES

Applications

● Steam Lines ● Unit Heaters

● Process Equipment ● Oil Preheaters

● Steam Cookers ● Converters

● Steam Heated Vats ● Coils

● Pressing Machinery ● Rotating Drum

DURA-FLO

Inverted

Bucket

Steam Trap

Pressures To 250 PSIG

Temperatures to 450°F

Withstands Severe Conditions

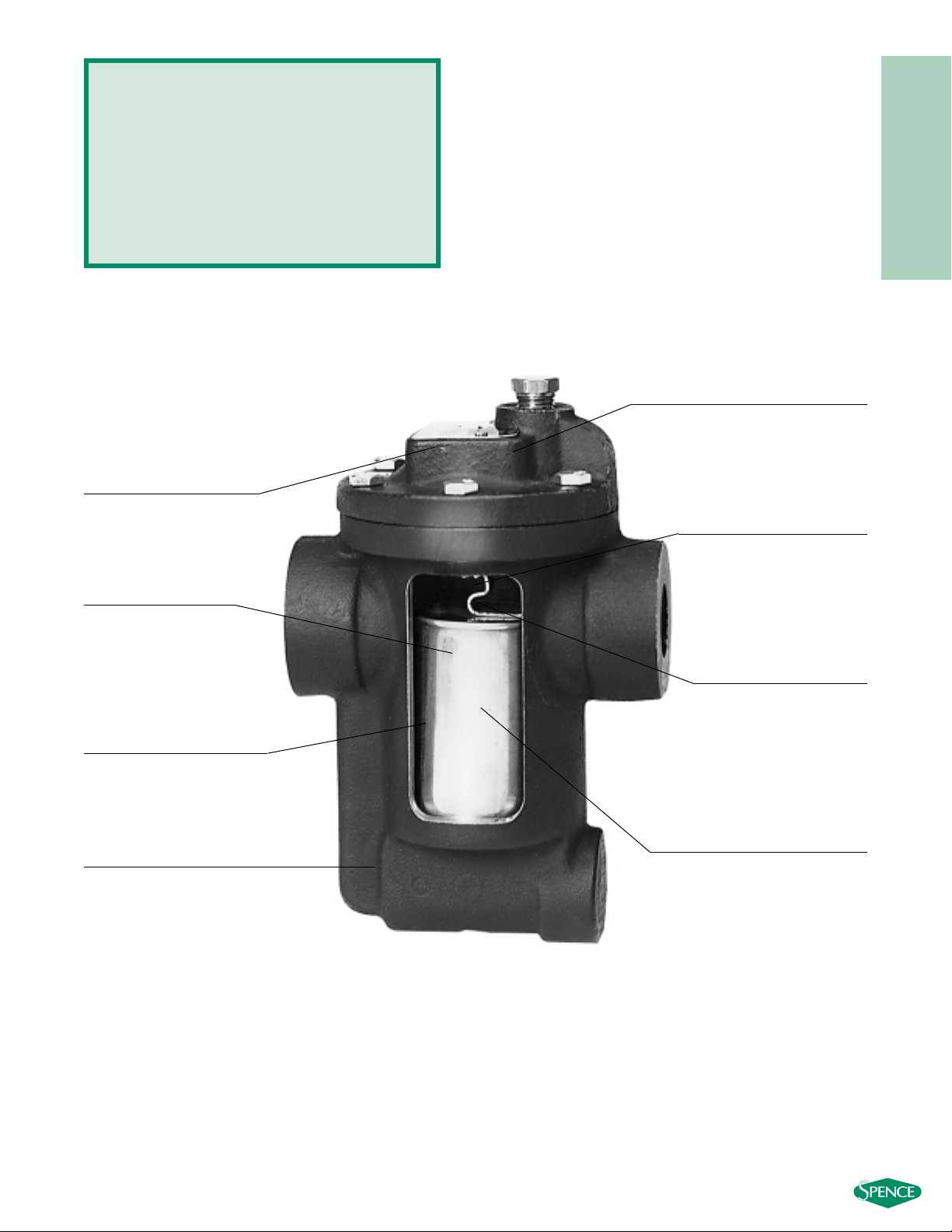

Heavy wall cast iron cover and

body provide many years of

trouble free service.

Smooth Action and

Tight Shutoff

Stainless steel linkage, valve

and seats are precision

manufactured to insure

optimal performance.

Ideal for

“Dirty” Systems

Valve and seat located at

top of trap and stainless

steel strainers available on

most horizontal models

ensure long service.

Maximum Compatibility

with Existing Installations

Pressure change assemblies

are interchangeable with

Armstrong which guarantees

maximum flexibility when

stocking repair parts.

Easy to Maintain

Working parts lift out with

top for quick inspection

and maintenance.

Resists Corrosion

Stainless steel bucket

provides maximum

service life with

minimum deterioration.

Minimizes Effects of

Water Hammer

Open bucket design avoids

collapse typical of sealed floats.

Suitable for Wide Variety

of Loads/Applications

Horizontal and vertical models in

thirteen body sizes are one of the

most comprehensive inverted

bucket trap lines available.

Page 2

DURA-FLO INVERTED

BUCKET TRAP

- 326 -

DURA-FLO

INVERTED BUCKET

STEAM TRAPS

Pressures To 250 PSIG (17.2 barg)

Temperatures to 450°F (232°C)

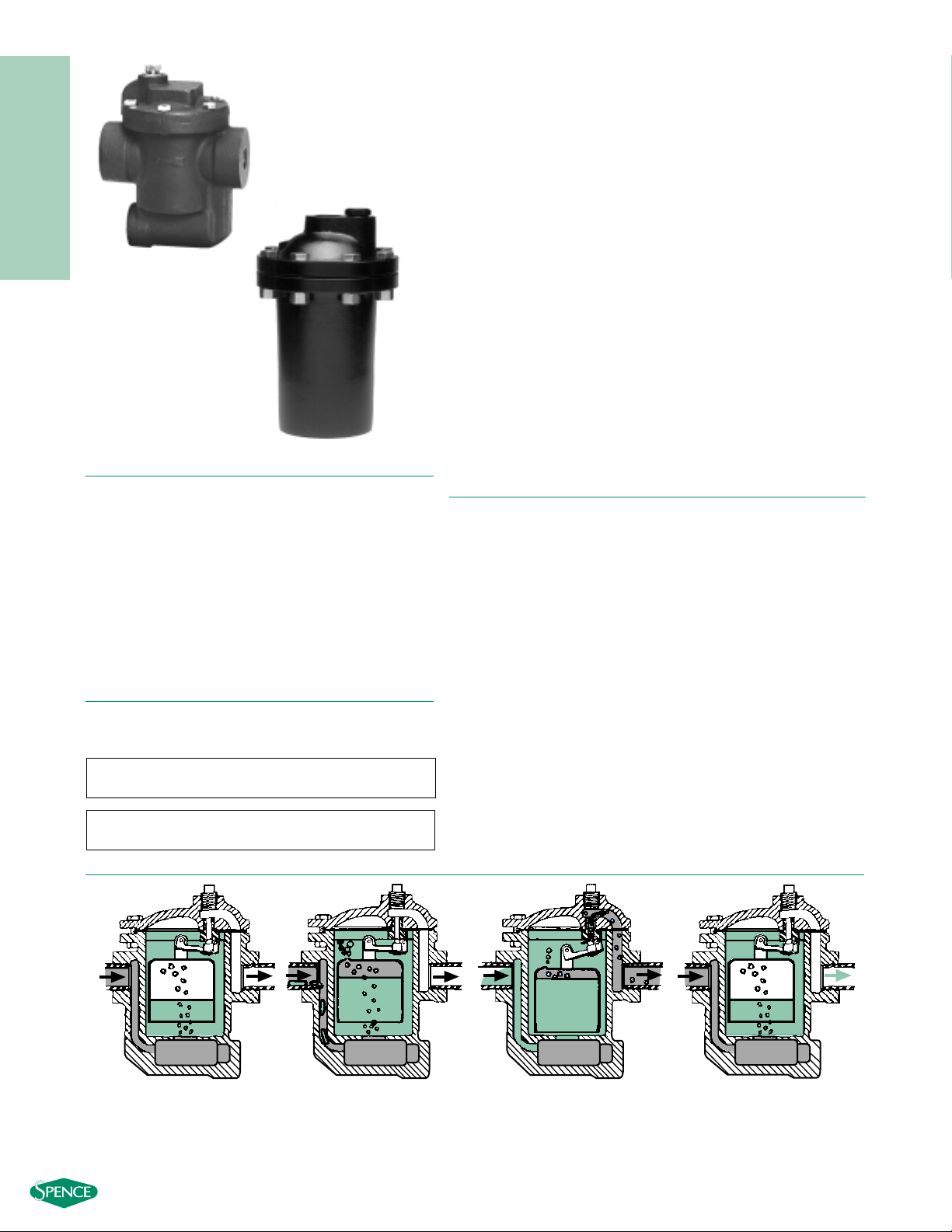

Trap Closed – After trap is installed

and primed, steam entering the

trap collects in the top of the

bucket, floating the bucket and

forcing the valve into its seat.

Trap Begins to Open – As

condensate begins to flow into the

trap, steam and air are forced from

the bucket. This causes the bucket

to begin losing buoyancy, tending

to pull the valve from its seat.

Trap Discharges – When enough

condensate has entered the trap,

displacing the steam and air, the

bucket drops, pulling the valve

from the seat and allowing

condensate and air to discharge.

Trap Closes – As the flow of

condensate stops, steam enters

the trap and refloats the bucket,

forcing the valve into its seat. The

cycle then repeats as more

condensate reaches the trap.

OPERA TION

Hardened Stainless Steel Valve and Seat — Long life and

maximum corrosion resistance.

Stainless Steel Bucket — Long lasting, rugged and

naturally resistant to water hammer.

Inexpensive — Low maintenance and initial cost.

Repairable in-line — All working parts lift out of top of trap.

Cast Iron Body — Durable heavy wall construction

provides years of reliable service.

Suitable for Wide Variety of Loads/Applications — Hori-

zontal and vertical models in thirteen body sizes.

Resists Dirt and Scale — Valve and seats positioned at

top of traps and internal stainless strainer available on

most horizontal models ensure long service.

MODELS

●

80S–Low capacity horizontal w/integral strainer

●81S–Medium low capacity horizontal w/integral strainer

●82S–Medium capacity horizontal w/integral strainer

●83S–Medium high capacity horizontal w/integral strainer

●84–High capacity horizontal

●85–Super high capacity horizontal

●86–Ultra high capacity horizontal

●21–Medium low capacity vertical

●22–Medium capacity vertical

●23–Medium high capacity vertical

●24–High capacity vertical

●25–Super high capacity vertical

●26–Ultra high capacity vertical

APPLICA TIONS

●

Steam Lines

●Process Equipment

●Steam Cookers

●Steam Heated Vats

●Pressing Machinery

●Unit Heaters

●Oil Preheaters

●Converters

●Coils

●Rotating Drum

O

PTIONS

●

Repair Kits

Canadian Registration # OE 0591.1C

See page 329

Installation Tip: Always install STV Test & Block Valve

as part of trap station – SEE PAGE 354

Installation Tip: Add Uniflex Pipe Coupling for ease of

maintenance – SEE PAGE 374

Page 3

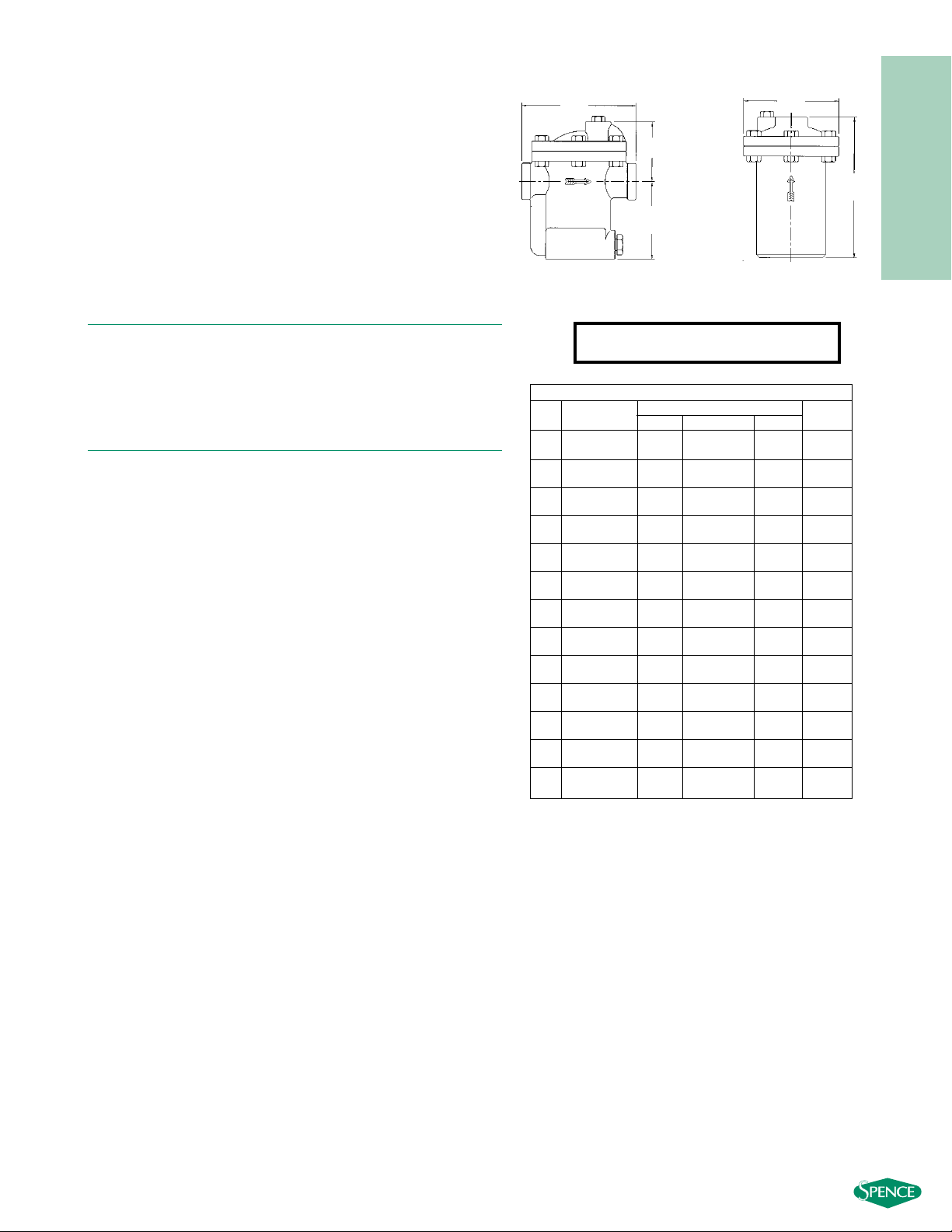

Connections: 1⁄2" – 21⁄2" NPT

Furnish and install as shown on the plans, inverted bucket

traps capable of discharging condensate, air and other noncondensible gases without loss of steam. These traps shall have

a heavy cast iron body, hardened stainless steel valve and seat,

all stainless steel linkage and bucket, and an asbestos free

fiber cover gasket.

MAXIMUM OPERATING

CONDITIONS

PMO: Max. Operating Pressure see orifice selection

TMO: Max. Operating Temperature saturated at pressure

PMA: Max. Allowable Pressure 250 psig (17.2 barg)

TMA: Max. Allowable Temperature 450°F (232°C)

MATERIALS OF CONSTRUCTION

Body & Cover ……………………Cast Iron ASTM-A-126/A48

Bucket & Linkage ………………………………Stainless Steel

Valve & Seat …………………………Hardened Chrome Steel

Standpipe ……………………………………………Steel Pipe

Cover Gasket ……………………………Asbestos Free Fiber

DURA-FLO

INVERTED BUCKET

STEAM TRAPS

SPECIFICATION

A

C

B

B

A

DURA-FLO Dimension Table

Trap End Inches (mm) Weight

Connections A B C Lbs (kg)

80S

1

⁄2, 3⁄4 51⁄16 211⁄16 31⁄2 7

(129) (69) (89) (3.2)

81S1⁄2, 3⁄4, 1 51⁄16 211⁄16 47⁄16 8

(129) (69) (113) (3.6)

82S

1

⁄2, 3⁄4 73

7

⁄8 57⁄16 22

(178) (98) (138) (10.0)

83S

3

⁄4

, 1 8

1

⁄8

57

5

⁄8

32

(206) (127) (194) (14.5)

84 1, 11⁄4

95

3

⁄4

7

13

⁄16

47

(229) (146) (199) (21.3)

85 11⁄

2, 2 10

1

⁄

4 88

3

⁄

8 74

(260) (203) (213) (33.6)

86 2, 21⁄2 13 93⁄4 11 140

(330) (248) (279) (63.5)

21

1

⁄2 63⁄8 41⁄4 — 6.5

(162) (108) (2.9)

22

1

⁄2, 3⁄4 85

5

⁄8 —16

(203) (143) (7.3)

23

3

⁄4, 1 101⁄2 67⁄8 —28

(267) (175) (12.7)

24 1, 11⁄4 121⁄2 71⁄2 —35

(318) (190) (15.9)

25 1, 11⁄2 143⁄8 91⁄16 —60

(365) (230) (27.2)

26 11⁄2, 2 1611⁄16 101⁄4 —90

(424) (260) (40.8)

80 SERIES,

HORIZONTAL

20 SERIES,

VERTICAL

- 327 -

DURA-FLO INVERTED

BUCKET TRAP

Page 4

- 328 -

DURA-FLO

CAPACITY TABLES

DURA-FLO CAPACITY TABLES

Trap Orifice 0.50 1 5 10 15 20 25 30 40 60 70 80 100 125 130 150 180 200 225 250

Size Max ∆P (.034) (.069) (.345) (.690) (1.03) (1.38) (1.72) (2.07) (2.76) (4.14) (4.83) (5.52) (6.90) (8.62) (8.97) (10.3) (12.4) (13.8) (15.5) (17.2)

3/16 20 200 270 450 560 640 690

80S

1/8 80 80 110 200 300 360 420 460 500 540 620 660 690

7/64 125 - 55 90 145 195 260 305 345 400 485 525 565 640 680

3/32 150 - - 70 110 150 200 240 270 310 380 410 440 480 540 545 570

1/4 15 300 450 830 950 1060

81S

3/16 30 190 300 540 670 770 880 950 1000

&

5/32 70 100 165 180 430 495 585 655 710 770 900 950

21 1/8 125 70 130 220 340 390 460 515 560 610 710 760 800 860 950

7/64 200 - 65 150 230 275 335 375 405 455 545 580 610 665 735 780 810 850 860

3/32 250 - - 100 150 190 240 270 290 340 420 450 470 520 575 585 620 670 700 730 760

5/16 15 570 850 1600 1900 2100

82S

1/4 30 350 500 950 1380 1630 1800 1900 2050

&

3/16 70 250 420 785 950 1120 1260 1395 1500 1700 2000 2200

22 5/32 125 180 300 560 680 800 900 995 1070 1220 1440 1550 1650 1800 2000

1/8 200 100 180 325 465 505 575 650 710 805 980 1050 1105 1225 1375 1410 1500 1560 1600

7/64 250 75 130 240 340 370 420 480 520 590 720 770 810 900 1010 1020 1100 1170 1230 1280 1300

1/2 15 1410 1880 2900 3500 3900

3/8 30 990 1400 2300 2700 3300 3500 3800 4000

83S

5/16 60 600 940 1730 2045 2510 2825 2995 3135 3800 4400

& 9/32 80 510 735 1350 1595 1960 2205 2340 2450 2880 3490 3800 4000

23

1/4 125 385 600 1100 1300 1600 1800 1910 2000 2350 2850 3100 3300 3600 3900

7/32 180 300 490 860 1165 1350 1595 1865 2085 2205 2510 2695 2820 3065 3185 3300 3500 3700

3/16 250 255 400 700 950 1100 1300 1520 1700 1800 2050 2200 2300 2500 2600 2700 2800 3020 3200 3400 3500

5/8 15 2160 2900 4800 5800 6500

1/2 30 1450 2250 3700 4750 5200 6000 6500 6800

84

3/8 60 1050 1750 2950 3550 4000 4700 5000 5400 5800 6800

& 11/32 80 800 1560 2500 2900 3200 3500 4000 4400 4850 5750 6000 6400

24

5/16 125 660 1200 1950 2450 2750 3100 3250 3500 4000 4800 5250 5600 6200 6700

9/32 180 550 950 1500 1900 2200 2350 2700 2900 3250 3800 4250 4500 4800 5500 5600 5700 6000

1/4 250 350 580 1000 1250 1450 1800 2000 2200 2600 3150 3350 3500 3800 4300 4450 4700 5000 5300 5500 5700

3/4 15 3100 4160 7600 9000 10000

9/16 30 1800 2900 5200 6400 7700 8500 9200 9800

85

7/16 60 1400 2200 3800 5000 6000 6600 7100 7600 8300 9500

&

3/8 100 1100 1700 3000 3600 4500 5200 5800 6100 7000 8500 9200 9700 10400

25 11/32 130 900 1500 2600 3200 3900 4500 5000 5400 6200 7500 8050 8500 9600 10900 11000

5/16 180 750 1200 2100 2600 3200 3700 4100 4500 5400 6600 7000 7257 8118 8979 9040.5 9500 10000

9/32 225 600 970 1700 2100 2600 2950 3300 3600 4500 5400 5700 5900 6600 7300 7350 7850 8400 9200 9800

1/4 250 400 700 1200 1500 1900 2100 2400 2600 3200 3800 4000 4150 4600 5100 5150 5500 5950 6350 6650 7000

1-1/16 15 6240 8400 14500 17300 19200

7/8 25 4100 5490 10000 12930 15620 18500 20000

86

3/4 40 2900 4500 8200 10600 12800 15000 16700 18000 20000

&

5/8 60 2100 3500 6900 8700 10600 12100 13300 14250 16300 19800

26 9/16 80 1900 3095 6000 7600 9300 10600 11700 12500 14300 17300 18300 19000

1/2 125 1600 2600 5000 6400 7800 8900 9800 10500 12000 14500 15400 16300 18000 20000

7/16 180 1400 2210 4180 5530 6640 7500 8490 9230 10450 12420 13300 14150 15750 17400 17900 18500 20000

3/8 250 1000 1800 3400 4500 5400 6100 6900 7500 8500 10100 10800 11500 12800 14200 14300 15600 16900 17500 18500 19000

For Kg/Hr Multiply by .454

Page 5

DURA-FLO

INVERTED BUCKET

STEAM TRAPS

PCA REPAIR KITS

FTN SERIES FLOAT

& THERMOSTATIC

STEAM TRAPS

REPAIR KITS

Quick, easy and economical

Simplifies and standardizes inventory

All stainless steel corrosion resistant internal parts

Hardened stainless steel condensate valves and seats

for extra long life

MODELS

●

80S–Orifice ratings 20, 80, 125, 150

●81S & 21–Orifice ratings 15, 30, 70, 125, 200, 250

●82S & 22–Orifice ratings 15, 30, 70, 125, 200, 250

●83S & 23–Orifice ratings 15, 30, 60, 80, 125, 180, 250

●84 & 24–Orifice ratings 15, 30, 60, 80, 125, 180, 250

●85 & 25–Orifice ratings 15, 30, 60, 100, 130, 180, 225, 250

●86 & 26–Orifice ratings 15, 25, 40, 60, 80, 125, 180, 250

High quality replacement kits

Rebuild existing F & T Traps far more economically than

replacement

Quick, easy and economical

Simplifies and standardizes inventory

All stainless steel corrosion resistant internal parts

Hardened stainless steel condensate valves and seats

for extra long life

Repairs other leading manufacturers’ F & T Traps

MODELS

●

FTN-15 available in 3⁄4", 1", 11⁄4", 11⁄2" and 2"

●FTN-30 available in

3

⁄4", 1", 11⁄4", 11⁄2" and 2"

●FTN-75 available in

3

⁄4", 1", 11⁄4", 11⁄2" and 2"

●FTN-125 available in

3

⁄4", 1", 11⁄4", 11⁄2" and 2"

All 3⁄4" and 1" kits as well as 11⁄4" FTN-15 and FTN-30 kits

supplied with cover assembly.

All 11⁄4" FTN-75 and FTN-125 kits as well as all 11⁄2" and 2"

kits supplied as mechanism complete.

SEAT RING

VALVE LINKAGE ASS’Y

PIVOT BRACKET

Supplied in a labeled, clear plastic bag.

Consult factory for latest crossover fitments.

CAP SCREWS

(2 req’d)

NAMEPLATES

(2 req’d)

See page 323 for Capacity Charts

- 329 -

DURA-FLO/FTN

REPAIR KITS

Page 6

- 330 -

THREADED DURA-FLO

STEAM TRAP

THREADED

STAINLESS STEEL

DURA-FLO

INVERTED BUCKET STEAM TRAPS

Pressures to 650 PSIG (45 barg)

Temperatures to 800ºF (425ºC)

Hardened Chrome Steel Valve and Seat — Long life and

maximum corrosion resistance.

Stainless Steel Bucket — Long lasting, rugged and

naturally resistant to water hammer.

Inexpensive — Low maintenance and initial cost.

Stainless Steel Body — Durable heavy wall construction

provides years of reliable service and resists corrosion and

freezing.

Suitable for Wide Variety of Loads/Applications —

Horizontal models in three body sizes.

Resists Dirt and Scale — Valve and seats positioned at

top of traps ensure long service.

Maintenance Free (TSBT-_S) — Sealed design prevents

unnecessary tampering.

Repairable Model (TSBT-_R)— Removable cover allows

pressure change or repair with existing Dura-Flo PCA kits.

MODELS

NPT CONNECTION

● TSBT-LS – Low Capacity, 400 PSIG

● TSBT-MS – Medium Capacity, 400 PSIG

● TSBT-HS – High Capacity, 650 PSIG

NPT CONNECTION, REPAIRABLE

● TSBT-LR – Low Capacity, 400 PSIG

● TSBT-MR – Medium Capacity, 400 PSIG

● TSBT-HR – High Capacity, 650 PSIG

APPLICA TIONS

●

Steam Lines

● Process Equipment

● Steam Cookers

● Steam Heated Vats

● Pressing Machinery

● Unit Heaters

● Oil Preheaters

● Converters

● Coils

● Rotating Drum

After trap is installed and primed, steam entering the trap collects in the top of the bucket,

floating the bucket and forcing the valve into its

seat. As condensate begins to flow into the trap,

steam and air are forced from the bucket. This

causes the bucket to begin losing buoyancy,

tending to pull the valve from its seat. When

O

PERATION

enough condensate has entered the trap, displacing the

steam and air, the bucket drops, pulling the valve from the

seat and allowing condensate and air to discharge. As the

flow of condensate stops, steam enters the trap and refloats the bucket, forcing the valve into its seat. The cycle

then repeats as more condensate reaches the trap.

Page 7

- 331 -

THREADED DURA-FLO

STEAM TRAP

THREADED

STAINLESS STEEL

DURA-FLO

INVERTED BUCKET STEAM TRAPS

SPECIFICATION

Furnish and install as shown on the plans, inverted bucket traps

capable of discharging condensate, air and other non-condensable

gases without loss of steam. These traps shall have a stainless

steel sealed body, hardened chrome steel valve and seat and an

all stainless steel linkage and bucket. The repairable model traps

shall have a removable cover to allow repair or pressure change.

M

AXIMUM OPERATING CONDITIONS

PMO:Max. Operating Pressure See Orifice Selection

TMO: Max. Operating Temperature Saturated at PMO

PMA: Max. Allowable Pressure 400 psig (28 barg)

or 650 psig (45 barg)

TMA: Max. Allowable Temperature 800ºF (425ºC)

M

ATERIALS OF CONSTRUCTION

Body ……………………………………………AISI 304 SS

Cover (Repairable only)…………………………AISI 304 SS

Bucket …………………………………………AISI 304 SS

Bucket Clip………………………………………AISI 304 SS

Lever ……………………………………………AISI 304 SS

Inlet Tube ………………………………………AISI 304 SS

Valve………………………Hardened Chrome Steel AISI D3

Valve Seat ………………Hardened Chrome Steel AISI D3

Connector ………………………………………AISI 304 SS

Cover Gasket (Repairable only) Spiral Wound 304 SS w/Grafoil

Connections:

3/8" – 1" NPT

A

B

C

D

A

B

C

D

TBST SEALED SERIES

TSBT REPAIRABLE SERIES

Differential Pressure

Trap

Orifice

5 10 15 30 40 70 80 125 200 250 300 400 650

Size MOP (0.34) (0.69) (1.03) (2.07) (2.76) (4.83) (5.52) (8.62) (13.79) (17.24) (20.69) (27.59) (44.83)

TSBT-LS & LR 3/32 200 85 120 145 200 230 300 325 400 500

1/4 15 800 920 1040

3/16 30 540 690 800 1000

5/32 70 390 490 560 700 790 940

TSBT-MS

1/8 125 260 325 400 530 600 750 800 970

& MR

7/64 200 200 265 315 410 470 580 610 720 900

3/32 250 155 200 240 315 360 440 480 560 690 750

5/64 400 100 130 155 210 235 280 310 360 440 460 510 580

1/4 40 1040 1350 1580 2000 2350

3/16 80 680 930 1120 1550 1775 2400 2300

TSBT-HS

1/8 250 320 42 510 700 790 1020 1090 1300 1650 1800

& HR

7/64 300 220 280 325 430 500 630 685 800 1000 1100 1200

3/32 650 175 225 270 370 400 510 540 650 800 870 930 1050 1300

For Kg/Hr Multiply by .454

Maximum Capacity—(lbs/hr)

Inches (mm)

Weight

Model

AB CD

lbs(kg)

TSBT-LR

27⁄

8 6

1

⁄

4 4

5

⁄

16 5

9

⁄

16 6.6

(73) (159) (110) (141) (3.0)

TSBT-MR

27⁄8 71⁄4 45⁄16 69⁄16 7.2

(73) (184) (110) (166) (3.2)

TSBT-HR

41⁄8 91⁄2 58

1

⁄2 22

(104.8) (241.3) (127) (215.9) (10)

DIMENSIONS inches (mm)

AND WEIGHTS pounds (kg)

Inches (mm)

Weight

Model

AB CD

lbs(kg)

TSBT-LS

23⁄

4 5

9

⁄

16 4

5

⁄

16 4

9

⁄

16 2.25

(70) (142) (110) (116) (1)

TSBT-MS

23⁄

4 6

9

⁄

16 4

5

⁄

16 5

9

⁄

16 2.5

(70) (167) (110) (141) (1.1)

TSBT-HS

37⁄

8 8

9

⁄

16 57

3

⁄

8 7

(99) (218) (127) (187) (3.2)

DIMENSIONS inches (mm)

AND WEIGHTS pounds (kg)

CAT ADD A/0403

Page 8

- 332 -

UNIVERSAL MOUNT

DURA-FLO TRAP

UNIVERSAL MOUNT

STAINLESS STEEL

DURA-FLO

INVERTED BUCKET STEAM TRAPS

Pressures to 650 PSIG (45 barg)

Temperatures to 800ºF (425ºC)

Easy Trap Replacement — Universal two bolt swivel

mounting simplifies removal from system.

Simple Installation — Stainless mounting Block

mounts permanently into system. Trap installs via two

bolt universal mount connection.

Hardened Chrome Steel Valve and Seat — Long life

and maximum corrosion resistance.

Stainless Steel Bucket — Long lasting, rugged and

naturally resistant to water hammer.

Inexpensive — Low maintenance and initial cost.

Stainless Steel Body — Durable heavy wall

construction provides years of reliable service and

resists corrosion and freezing.

Suitable for Wide Variety of Loads/Applications —

Horizontal models in three body sizes.

Resists Dirt and Scale — Valve and seats positioned at

top of traps ensure long service.

Maintenance Free (USBT-_S) — Sealed design

prevents unnecessary tampering. Trap can be

inspected and replaced without breaking pipe.

Repairable Model (USBT-_R) — Removable cover

allows pressure change or repair with existing Dura-Flo

PCA kits.

M

ODELS

UMT CONNECTION

● USBT-LS – Low Capacity, 400 PSIG

● USBT-MS – Medium Capacity, 400 PSIG

● USBT-HS – High Capacity, 650 PSIG

UMT CONNECTION, REPAIRABLE

● USBT-LR – Low Capacity, 400 PSIG

● USBT-MR – Medium Capacity, 400 PSIG

● USBT-HR – High Capacity, 650 PSIG

UMT CONNECTOR BLOCKS

● UMTC–Standard connector (1/2" & 3/4" only)

● UMTCY-RH–Right Hand Connector w/Y strainer*

● UMTCY-LH–Left Hand Connector w/Y strainer*

● UMTVS-BB–Connector with Isolation Valves, Strainer,

Blowdown Valve and Test Port

APPLICA TIONS

●

Steam Lines

● Process Equipment

● Steam Cookers

● Steam Heated Vats

● Pressing Machinery

● Unit Heaters

● Oil Preheaters

● Converters

● Coils

● Rotating Drum

After trap is installed and primed, steam entering the

trap collects in the top of the bucket, floating the

bucket and forcing the valve into its seat. As

condensate begins to flow into the trap, steam and

air are forced from the bucket. This causes the

bucket to begin losing buoyancy, tending to pull the

valve from its seat. When enough condensate has

OPERA TION

entered the trap, displacing the steam and air, the bucket

drops, pulling the valve from the seat and allowing

condensate and air to discharge. As the flow of

condensate stops, steam enters the trap and re-floats the

bucket, forcing the valve into its seat. The cycle then

repeats as more condensate reaches the trap.

For information on Big Block UMTVS-BB Connector

See Page 344

Page 9

- 333 -

UNIVERSAL MOUNT

DURA-FLO TRAP

UNIVERSAL MOUNT

STAINLESS STEEL

DURA-FLO

INVERTED BUCKET STEAM TRAPS

SPECIFICATION

Furnish and install as shown on the plans, inverted bucket traps

capable of discharging condensate, air and other non-condensable gases without loss of steam. These traps shall have a stainless steel sealed body, hardened chrome steel valve and seat and

an all stainless steel linkage and bucket. It shall also have a universal mount connection. The optional repairable traps shall have a

removable cover to allow repair or pressure change.

MAXIMUM OPERATING

CONDITIONS

PMO:Max. Operating Pressure See Orifice Selection

TMO: Max. Operating Temperature Saturated at PMO

PMA: Max. Allowable Pressure 400 psig (28 barg)

or 650 psig (45 barg)

TMA: Max. Allowable Temperature 800ºF (425ºC)

MATERIALS OF CONSTRUCTION

Body ……………………………………………AISI 304 SS

Shaft (Sealed only)………………………………AISI 304 SS

Bucket……………………………………………AISI 304 SS

Bucket Clip ………………………………………AISI 304 SS

Lever ……………………………………………AISI 304 SS

Inlet Tube ………………………………………AISI 304 SS

Valve ……………………Hardened Chrome Steel AISI D3

Valve Seat ………………Hardened Chrome Steel AISI D3

Swivel Connector ………………………………AISI 304 SS

Cover Gasket (Repairable only)Spiral Wound 304 SS w/Grafoil

Connections:

Universal Mount Two Bolt Swivel Connection

For Kg/Hr Multiply by .454

Inches (mm)

Weight

Model

AB CDE

lbs(kg)

USBT- 23⁄4 62

3

⁄4 45⁄8 4 4.25

LS

(70) (152) (70) (117) (101.6) (2)

USBT- 23⁄4 73⁄16 23⁄4 513⁄16 4 4.75

MS

(70) (183) (70) (148) (101.6) (2.2)

USBT- 37⁄8 83⁄4 23⁄4 73⁄8 57

HS

(99) (222) (70) (187) (127) (3.2)

B

C

D

E

A

B

C

D

E

Differential Pressure

Trap

Orifice

5 10 15 30 40 70 80 125 200 250 300 400 650

Size MOP (0.34) (0.69) (1.03) (2.07) (2.76) (4.83) (5.52) (8.62) (13.79) (17.24) (20.69) (27.59) (44.83)

USBT-LS & LR 3/32 200 85 120 145 200 230 300 325 400 500

1/4 15 800 920 1040

3/16 30 540 690 800 1000

5/32 70 390 490 560 700 790 940

USBT-MS

1/8 125 260 325 400 530 600 750 800 970

& MR

7/64 200 200 265 315 410 470 580 610 720 900

3/32 250 155 200 240 315 360 440 480 560 690 750

5/64 400 100 130 155 210 235 280 310 360 440 460 510 580

1/4 40 1040 1350 1580 2000 2350

3/16 80 680 930 1120 1550 1775 2400 2300

USBT-HS

1/8 250 320 42 510 700 790 1020 1090 1300 1650 1800

& HR

7/64 300 220 280 325 430 500 630 685 800 1000 1100 1200

3/32 650 175 225 270 370 400 510 540 650 800 870 930 1050 1300

Maximum Capacity—(lbs/hr)

USBT SEALED SERIES

USBT REPAIRABLE SERIES

Inches (mm)

Weight

Model

AB CDE

lbs(kg)

USBT- 27⁄8 63⁄8 23⁄4 55⁄8 41⁄4 7.25

LR

(73) (161) (70) (143) (108) (3.3)

USBT- 27⁄8 73⁄8 23⁄4 65⁄8 41⁄4 8

MR

(73) (186) (70) (168) (108) (3.6)

USBT- 41⁄8 93⁄4 23⁄4 83⁄4 61⁄4 25

HR

(104.8) (247.7) (70) (222.3) (158.8) (11.33)

DIMENSIONS inches (mm) AND WEIGHTS pounds (kg)

DIMENSIONS inches (mm) AND WEIGHTS pounds (kg)

A

E

C

B

D

A

Loading...

Loading...