Page 1

THE PARKER DESIGN

S

The Parker liquid tube design offers an

extremely efficient, reliable heater built for

the long term with ease of maintenance.

The Parker design offers many advantages.

Compare ours to the competition.

ADVANTAGES

• Sealed combustion chamber offers high

efficiencies with low excess air levels.

• Less heat loss due to liquid tube furnace

and sealed combustion chamber design.

• Flexible tubes, no thermal shock prob-

lems.

• Extra heavy boiler tubes

1-5/16” OD, minimum 0.12” (11GA) heavy

thickness steel, built for long term service

life.

• Doube welded tube bundle. No rolled,

ferrell fit, or gasket type connections.

Tube bundle is baffled/designed to match

system flow requirements.

• Factory set tube bundle pass baffling to

match system flow

• Units can go through a 35” door.

• Modular cabinet construction.

• Lighter weight. No refractory.

• Multiple burner options including Ultra

Low NOx

Safety

Our ASME tube bundle is extremely flexible

and offers a long life with a 25 year warranty

against thermal shock. No Parker Boiler has

ever been known to experience an internal

explosion.

POWER BURNER THERMAL LIQUID HEATER

G---RHT Models, Bent Steel Liquid Tube Furnace

500,000 - 2,500,000 BTUH

Power Gas Fired, Light Oil or Combination

207WW Thermal

Liquid Heater

Temperatures to 600°F

Pressures to 125 PSI

Low Cost Operation

The staggered tubing design provides

a 10-pass self-baffled heating surface to

increase efficiency

Codes / Approvals

All Parker Heater Boilers are manufactured

in accordance with the ASME Power Boiler

Code, and registered with the National Board

of Boiler and Pressure Vessel inspectors. The

boiler, burner and controls are prewired, factory tested. The burner is Listed by a Nationally Recognized Testing Laboratory as Gas,

Oil or Combination Gas/Oil fired and complies

with ASME CSD-1.

Liquid Tube

Furnace

Heavy Insulated Cabinet

The cabinet is durably constructed with heavy

steel, insulated with high temperature ther-

mal fiber insulation to effectively reduce heat

losses to a minimum.

207WW Power Burner Thermal Liquid Heater

A

S

M

E

PARKER BOILER CO.

5930 Bandini Boulevard

Los Angeles, CA 90040

Tel (323) 727-9800

Fax (323) 722-2848

www.parkerboiler.com

BROCHURE 207WW 1D0

"Never a Compromise for Quality or Safety"

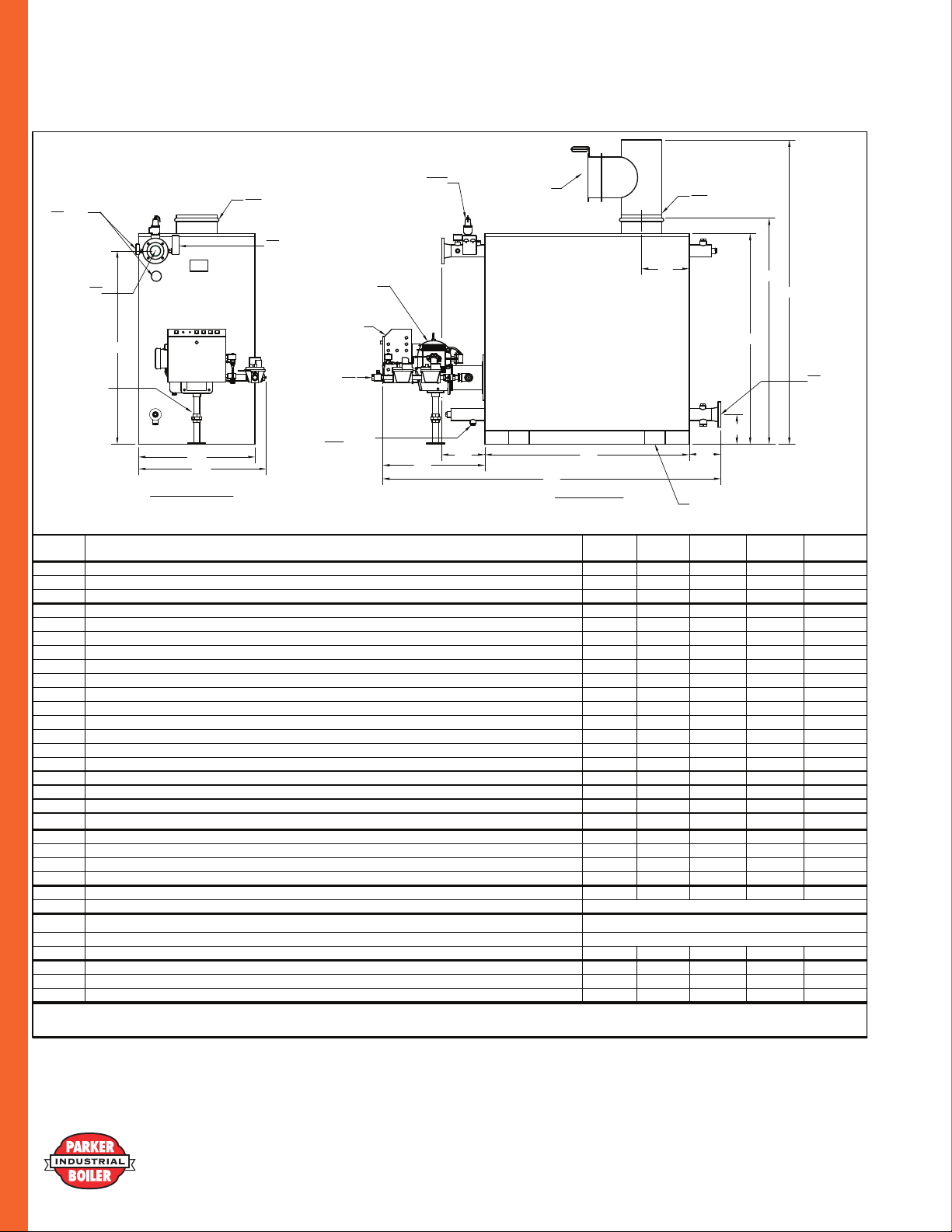

Page 2

PARKER BOILER THERMAL LIQUID HEATER

POWER GAS, OIL, COMBINATION OR LOW NOx FIRED

SPEC. SHEET D-207WW

1E0

MODELS G672R TO G3120R

18A.

RELIEF

4A.

22. T & P

GAUGE

15.

FLANGED

OUTLET

15H

207WW Power Burner Thermal Liquid Heater

BURNER

SUPPORT

VENT COLLAR

23. HIGH LIMIT &

OPERATING TEMP.

CONTROL

POWER

BURNER

ELECT.

CONTROL

PANEL

7A.

GAS INLET

VALVE

BARO. DAMPER

4B.

4A.

VENT COLLAR

3HA

3HB

3HC

16.

FLANGED

INLET

17D. DRAIN

1WA

1WB

2LD

2LE

FRONT VIEW

NO.

ITEM

A

B

C

1WA

1WB

2LA

2LB

2LC

2LD

2LE

3HA

3HB

3HC

4A.

7A

7B 1-1/2

8A

8B

15 & 16

15H

16H

17D

18AHP

BTU Input

BTU Output

Heating Surface

Width of Cabinet

Width Overall Including Controls (controls can be removed)

Length of Cabinet

Lenght Overall

Length of Back Header Flange Beyon Cabinet

Length of Burner Beyond Cabinet

Lenght of Front Header Beyond Cabinet

Height of Cabinet

Height with Vent Collar

Height Overall Including Barometric Damper

Vent Collar Diameter

Std. Nat. Gas Inlet Size, @ Inlet Supply Pressure; Min: 7" W.C.; Max: 14" W.C.

Hi Pressure Natural Gas or LP Gas Inlet Size, Supply Pressure 1-5 PSI

Oil Input Required @ Manuf.'s Capacity Rating (#2 Oil)

Oil Supply Line Size - Minimum for up to 30'

Inlet & Outlet Size

Outlet Height from Floor

Inlet height from Floor

Drain Line Size Required

Safety Relief Valve Size - 125 PSI

" * " = G(gas), O (oil), GO (gas oil comb)

MODEL NO.

1000's BTU/HR.

1000's BTU/HR.

(CL. 150 Flanged)

OUTLET IN.

C

L

2LA

2LB

SIDE VIEW

SQ. FT.

GPH.

400 807 1229

93 234140

IN.

IN.

32

IN.IN.

IN.

IN.

31 31

IN. 34-1/2

IN.

62

IN.

IN.IN.

IN.IN.

IN.IN.

IN.4B. Vent Stack Location - From Rear of Boiler Cabinet

12

IN.

1

IN.

3.5

3/8 1/2

IN.

3

IN.

57 57 57

IN.

IN.

IN.

4040

47

7-1/29-1/2

108

17-1/2

11

7

8-3/48-3/4

11

1-1/21-1/2

ww2000_sv.dwg

2LC

FORK LIFT SLOTS

*1536RHT*1008RHT*672RHT

15361008500

353535

42

68

111-1/272-1/2 85-1/2 126-1/2

9

131313

6262

66-1/266-1/266-1/2

908481 92 96

14

23

1-1/21-1/4

14.5

3/4

33

8-3/4

1

1-1/2

16H

*2304RHT

2000

1600

294

35

44

83

9

34-1/2

14 14

62

66-1/2

16

26

2

1-1/2

17.5

3/4

3

57

8-3/4

1

1-1/2

*2640RHT

2500

2000

358

35

44

101

144

8-1/2

34-1/2

62

66-1/2

18

30

2

2

22

3

57

8-3/4

1

1-1/2

20A

20B

21

POWER SPECIFICATIONS

Controls ( 115V-1Ph-60Hz)

Blower HP - *G (gas)

Liquid Capacity

Net Weight of Heater

Crated Shipping Weight of Boiler- Approximate

VOLTAGE/Ph

AMPS

HP

GAL.

LBS.

LBS.

16

1640

Recommended Clearances 48" around all sides. Inspection Doors 18"; Controls 24"; Electrical Panel 30"; 3Ph (36") ;

Additional space may be required by Local Codes.

Notes: Due to continuous improvement, specifications are subject to change without notice.

"Never a Compromise for Quality or Safety"

22

16851440

1935

115V/1Ph

5 AMPS

1/21/31/3

35

2350

2650

1/2

43

2800

3130

D-207WW.DWG

PARKER BOILER CO.

5930 Bandini Boulevard

Los Angeles, CA 90040

Tel (323) 727-9800

Fax (323) 722-2848

www.parkerboiler.com

BROCHURE 207WW 1D0

3/4

56

3450

3900

Loading...

Loading...