Page 1

DYNA-WAVE

®

CENTRIFUGAL PUMP

WITH INTEGRAL TRAP

O W N E R’ S M A N U A L

INSTALLATION, OPERATION & PARTS

Pentair Water Pool and Spa, Inc.

© 2009 Pentair Water Pool and Spa, Inc. All rights reserved.

1620 Hawkins Ave., Sanford, NC 27330 • (919) 566-8000

10951 West Los Angeles Ave., Moorpark, CA 93021 • (805) 553-5000

Dyna-Wave®, Sta-Rite® and Pentair Water Pool and Spa® are registered trademarks of Pentair Water Pool and Spa, Inc. and/or its affiliated

companies in the United States and/or other countries. Plasto-Joint Stik® is a registered trademark of La-Co Industries, Inc. and Teflon® is a

registered trademark of E.I. Du Pont De Nemours and Company Corporation. Unless noted, names and brands of others that may be used in this

document are not used to indicate an affiliation or endorsement between the proprietors of these names and brands and Pentair Water Pool and Spa,

Inc. Those names and brands may be the trademarks or registered trademarks of those parties or others.

S752 Rev B (10/07/09)

This manual should be given to the end user of this pump;

its use will reduce service calls and chance of injury and will

lengthen pump life.

Page 2

2

‘MPRA’, SERIES PUMP

WITH TRAP

To avoid unneeded service calls, prevent possible

injuries, and get the most out of your pump, READ THIS

MANUAL CAREFULLY!

The Sta-Rite ‘MPRA’ Series Self-priming Centrifugal

pump:

• Is designed for use with water features or as a

centrifugal pump.

• Is an excellent performer; durable, reliable.

Table of Contents

Safety Instructions ......................................................2

Installation ...................................................................3

Pool Pump Suction Requirements ............................4-5

Electrical...................................................................5-6

Operation.....................................................................7

Storage/Winterizing ..................................................7-8

Pump Service .........................................................8-10

Repair Parts List ........................................................10

Troubleshooting Guide...............................................11

Warranty ....................................................................12

READ AND FOLLOW

SAFETY INSTRUCTIONS!

This is the safety alert symbol. When you see this

symbol on your system or in this manual, look for

one of the following signal words and be alert to the

potential for personal injury.

warns about hazards that will cause death,

serious personal

injury, or major property damage if ignored.

warns about hazards that can cause death,

serious personal

injury, or major property damage if ignored.

warns about hazards that will or can cause

minor personal injury or property damage if ignored.

NOTICE indicates special instructions not related to

hazards.

Carefully read and follow all safety instructions in this

manual and on equipment. Keep safety labels in good

condition; replace if missing or damaged.

Incorrectly installed or tested equipment

may fail, causing severe injury or property

damage.

Read and follow instructions in owner's

manual when installing and operating equipment. Have

a trained pool professional perform all pressure tests.

1. Do not connect system to a high pressure or city

water system.

2. Use equipment only in a pool or water feature

installation.

3. Trapped air in system can cause explosion. BE SURE

all air is out of system before operating or testing

equipment.

Before pressure testing, make the following safety

checks:

• Check all clamps, bolts, lids, and system accessories

before testing.

• Release all air in system before testing.

• Water pressure for test must be less than 25 PSI

(7.5 kg/cm

2

).

• Water Temperature for test must be less than 100° F.

(38° C).

• Limit test to 24 hours. After test, visually check

system to be sure it is ready for operation. Remove

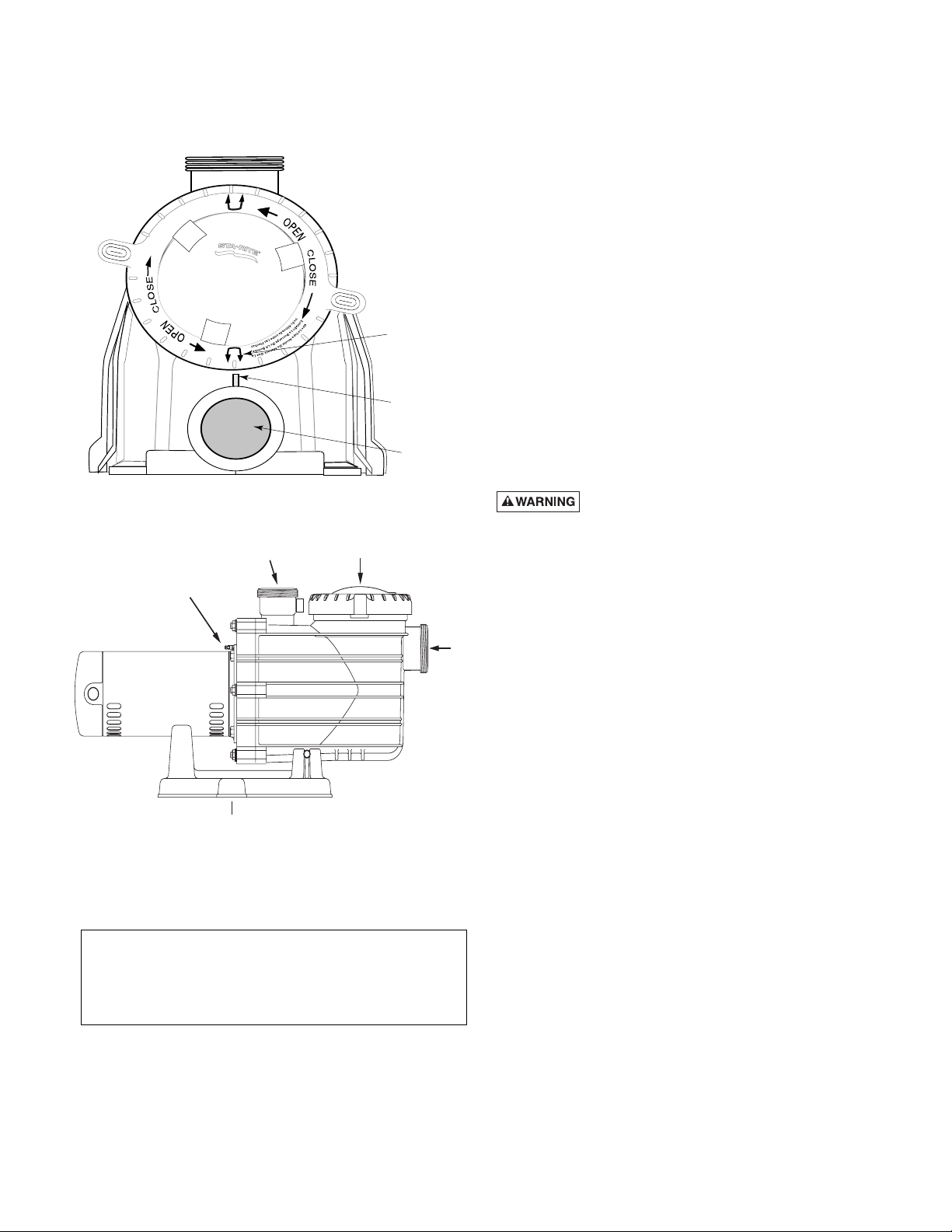

trap lid and retighten hand tight only, see Figure 1.

NOTICE: These parameters apply to Sta-Rite®

equipment only. For non-Sta-Rite equipment, consult

manufacturer.

NOTICE: Do not start the pump until the strainer basket

cover is on and the tab, or rib, on the discharge port

aligns between the arrows.

IMPORTANT SAFETY

INSTRUCTIONS

Always follow basic safety precautions with this

equipment, including the following.

To reduce the risk of injury, do not

permit children to use this product unless they are

closely supervised at all times.

This pump is for use with permanently

installed pools and may also be used with hot tubs

and spas if so marked. Do not use with storable

pools. A permanently installed pool is constructed in

or on the ground or in a building such that it cannot

be readily disassembled for storage. A storable pool

is constructed so that it may be readily disassembled

for storage and reassembled to its original integrity.

SAVE THESE INSTRUCTIONS

Page 3

3

NOTICE: These parameters apply to Sta-Rite equipment

only. For non-Sta-Rite equipment, consult manufacturer.

INSTALLATION

(See Figure 2)

Only qualified, licensed personnel should install pump

and wiring.

Pump mount must:

Be located away from corrosive or flammable liquids.

Have enough ventilation to maintain air temperature at less

than the maximum ambient temperature rating (Max.

Amb.) listed on the motor model plate. If this pump is

installed in an enclosure/pump house, the enclosure must

have adequate ventilation and air circulation to keep the

temperature in the enclosure at or below the motor’s rated

ambient temperature whenever the pump is running.

Be solid - Level - Rigid - Vibration free. (To reduce

vibration and pipe stress, bolt pump to mount.)

Allow pump suction inlet height to be as close to water

level as possible. Pump will not lift water more than

10'(3m).

Allow use of short, direct suction pipe (To reduce friction

losses).

Allow for gate valves in suction and discharge piping.

Have adequate floor drainage to prevent flooding.

Be protected from excess moisture.

Allow adequate access for servicing pump and piping.

Fire and burn hazard. Modern motors run at

high temperatures. To reduce the risk of fire, do not allow

leaves, debris, or foreign matter to collect around the

pump motor. To avoid burns when handling the motor, let

it cool for 20 minutes before trying to work on it.

NOTICE: When connecting threaded pipe directly to pump,

use Teflon® tape or Plasto-Joint Stik® to seal connections.

Do not use pipe dope; pipe dope causes cracking in some

plastics and may damage components in piping system.

When connecting pipe to pump with union half, use

Teflon tape or Plasto-Joint Stik between pipe and union

adapter. Union collar to pump should be assembled dry

and hand-tight.

NOTICE: Pump suction and discharge connections have

molded in thread stops. DO NOT try to screw pipe in

beyond these stops.

Teflon Taping Instructions:

Use only new or clean PVC pipe fittings.

Wrap male pipe threads with one to two layers of Teflon

tape. Cover entire threaded portion of pipe.

Do not overtighten or tighten past thread stop in pump

port!

If leaks occur, remove pipe, clean off old tape, rewrap

with one to two additional layers of tape and remake the

connection.

NOTICE: Support all piping connected with pump!

Piping:

Use at least 2" (51mm) pipe. Increase size if a long run

is needed.

To avoid strains on the pump, support both suction and

discharge pipes independently. Place these supports

near the pump.

NOTICE: Port threads are: Internal - 2" NPT for direct

connection to pipe. External - 3-1/4" Buttress. Fits Sta-Rite

U11-200P Union Collar for quick disconnect pipe

connection. See Page 10 for Union Kits.

Figure 1 – Strainer basket cover alignment.

Figure 2.

P

P

M

M

U

U

P

P

N

N

S

O

W

O

O

S

R

B

B

R

I

W

I

A

O

R

R

R

N

R

E

O

O

E

A

S

S

W

N

T

E

G

E

G

E

B

N

N

W

I

I

S

T

R

R

E

N

-

-

B

G

I

D

D

S

I

L

I

A

L

N

L

G

E

I

E

E

G

L

T

T

R

A

A

A

A

T

E

T

H

G

O

O

C

R

R

R

S

A

I

H

D

C

S

I

D

Arrows

Ta b

Discharge

Por t

Discharge Port

to Filter or Pool

Strainer Basket

Cover

Bonding Lug

Pump may be bolted to level

foundation or mounting bracket.

Suction

Port

from

Pool or

Vacuum

Filters

5138 0905

Page 4

4

To avoid a strain left by a gap at the last connection,

start all piping at the pump and run pipe away from the

pump. To avoid airlocking, slope suction pipe slightly

upward toward the pump.

NOTICE: To prevent flooding when removing pump for

service, all flooded suction systems must have gate

valves in suction and discharge pipes.

PUMP SUCTION

REQUIREMENTS

Pump suction is hazardous and can trap and drown

or disembowel bathers. Do not use or operate

swimming pools, spas, hot tubs or water features if a

suction outlet cover is missing, broken, or loose. Follow

the guidelines below for a pump installation which

minimizes risk to users of pools, spas, hot tubs and water

features.

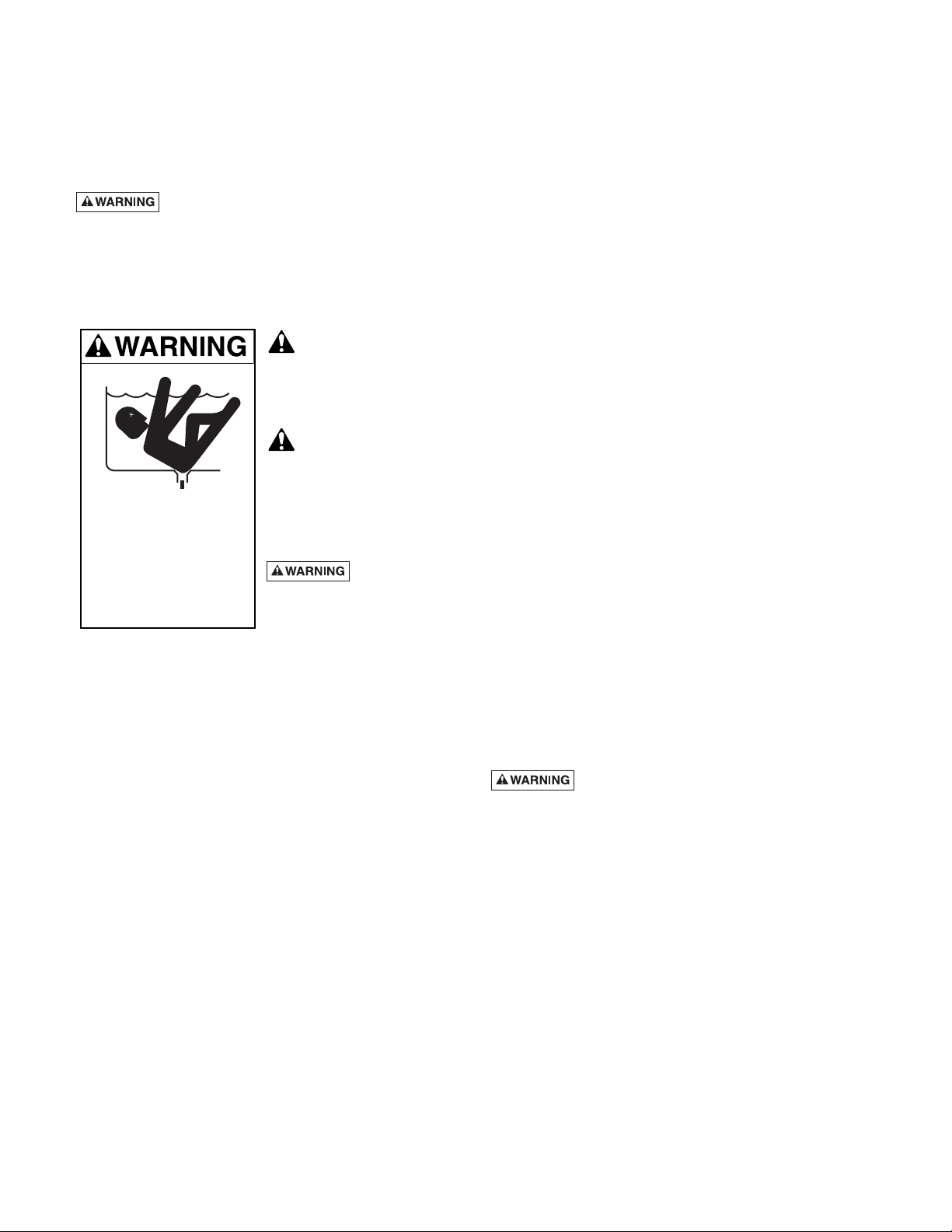

Entrapment Protection

The pump suction system

must provide protection

against the hazard of

suction entrapment or hair

entrapment/entanglement.

Suction Outlet Covers

All suction outlet covers

must be maintained. They

must be replaced if

cracked, broken, or

missing.

See Page 5 for outlet cover

certification requirements.

All suction outlets must have

correctly installed, screwfastened covers in place.

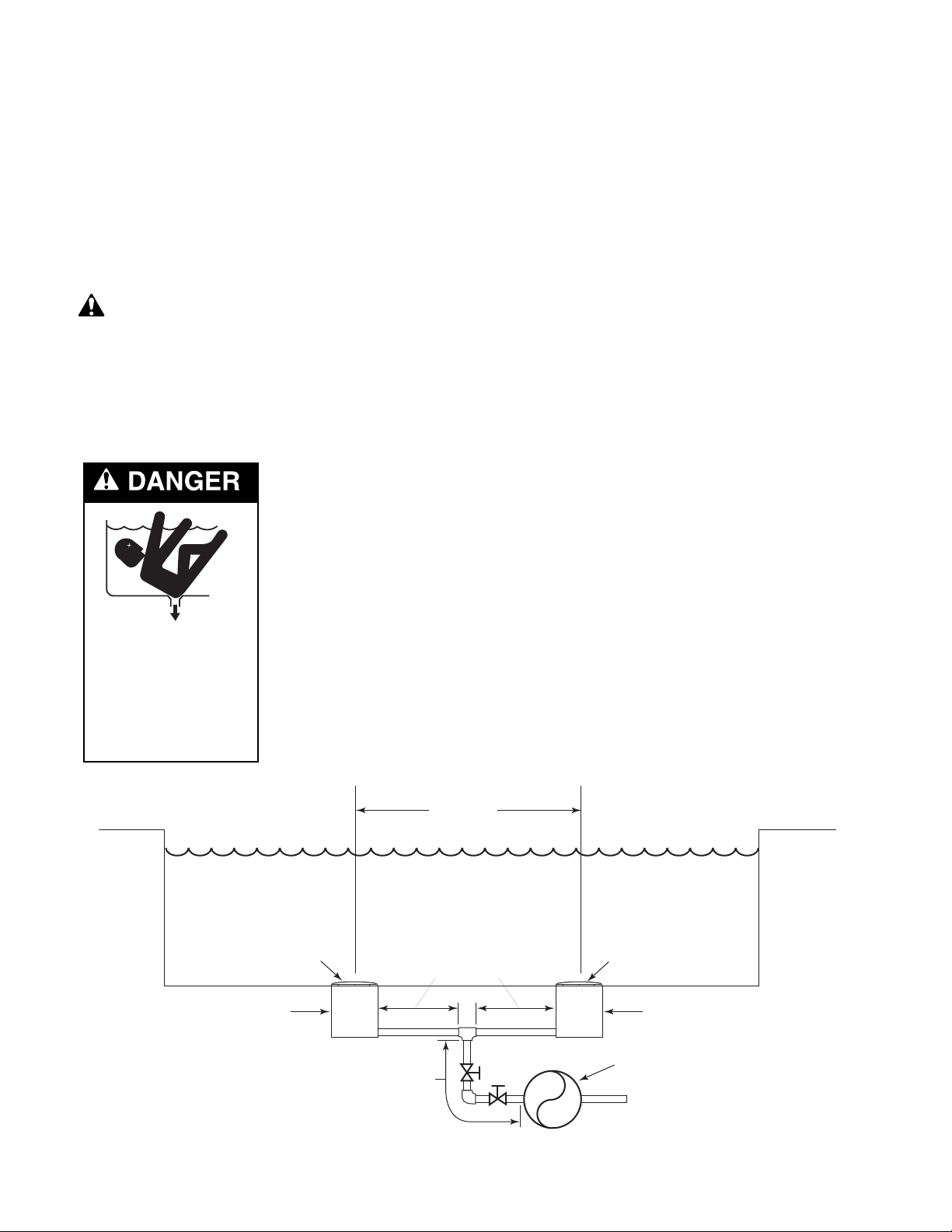

Suction Outlets Per Pump (Figure 2)

Provide at least two hydraulically balanced main drains,

with covers, as suction outlets for each circulating pump

suction line. The centers of the main drains (suction

outlets) on any one suction line must be at least three feet

apart.

The system must be built so that it cannot operate with

the pump drawing water from only one main drain (that is,

there must be at least two main drains connected to the

pump whenever it is running – see Figure 2). However, if

two main drains run into a single suction line, the single

suction line may be equipped with a valve which will shut

off both main drains from the pump (see Figure 2).

More than one pump can be connected to a single

suction line as long as the requirements above are met.

Water Velocity

The maximum water velocity through the suction fitting

or cover for any suction outlet must be 1.5 feet per

second unless the outlet complies with the latest

ASME/ANSI Specification for Suction Fittings For Use in

Swimming Pools, Spas, Hot Tubs, and Whirlpool

Bathtub Applications. In any case, do not exceed the

suction fitting’s maximum designed flow rate.

If 100% of the pump’s flow comes from the main drain

system, the maximum water velocity in the pump

suction hydraulic system must be six feet per second or

less even if one main drain (suction outlet) is completely

blocked. The flow through the remaining main drain(s)

must comply with the latest ASME/ANSI Specification

for Suction Fittings For Use in Swimming Pools, Spas,

Hot Tubs, and Whirlpool Bathtub Applications.

Hazardous suction.

Can trap hair or

body parts, causing

severe injury

or death.

Do not block

suction.

Figure 2 – Recommended pump suction layout.

IAPMO Certified

Anti-entrapment

Cover or Suction Fitting,

screw-fastened to

Main Drain Sump

Suction Outlet

(Main Drain)

Valves OK between

pump and Tee

At Least

3 Feet

No valves between

Tee and Main Drains

IAPMO Certified

Anti-entrapment

Cover or Suction Fitting,

screw-fastened to

Main Drain Sump

Suction Outlet

(Main Drain)

Pump

2762 0197

Page 5

5

Testing and Certification

Suction outlet covers must have been tested by a

nationally recognized testing laboratory and found to

comply with the latest ASME/ANSI Specifications for

Suction Fittings For Use in Swimming Pools, Spas, Hot

Tubs, and Whirlpool Bathtub Applications.

Fittings:

Fittings restrict flow; for best efficiency use fewest

possible fittings (but at least two suction outlets).

Avoid fittings which could cause an air trap.

Pool fittings must conform to International Association

of Plumbing and Mechanical Officials (IAPMO)

standards.

Use only non-entrapping suction fitting or double suction.

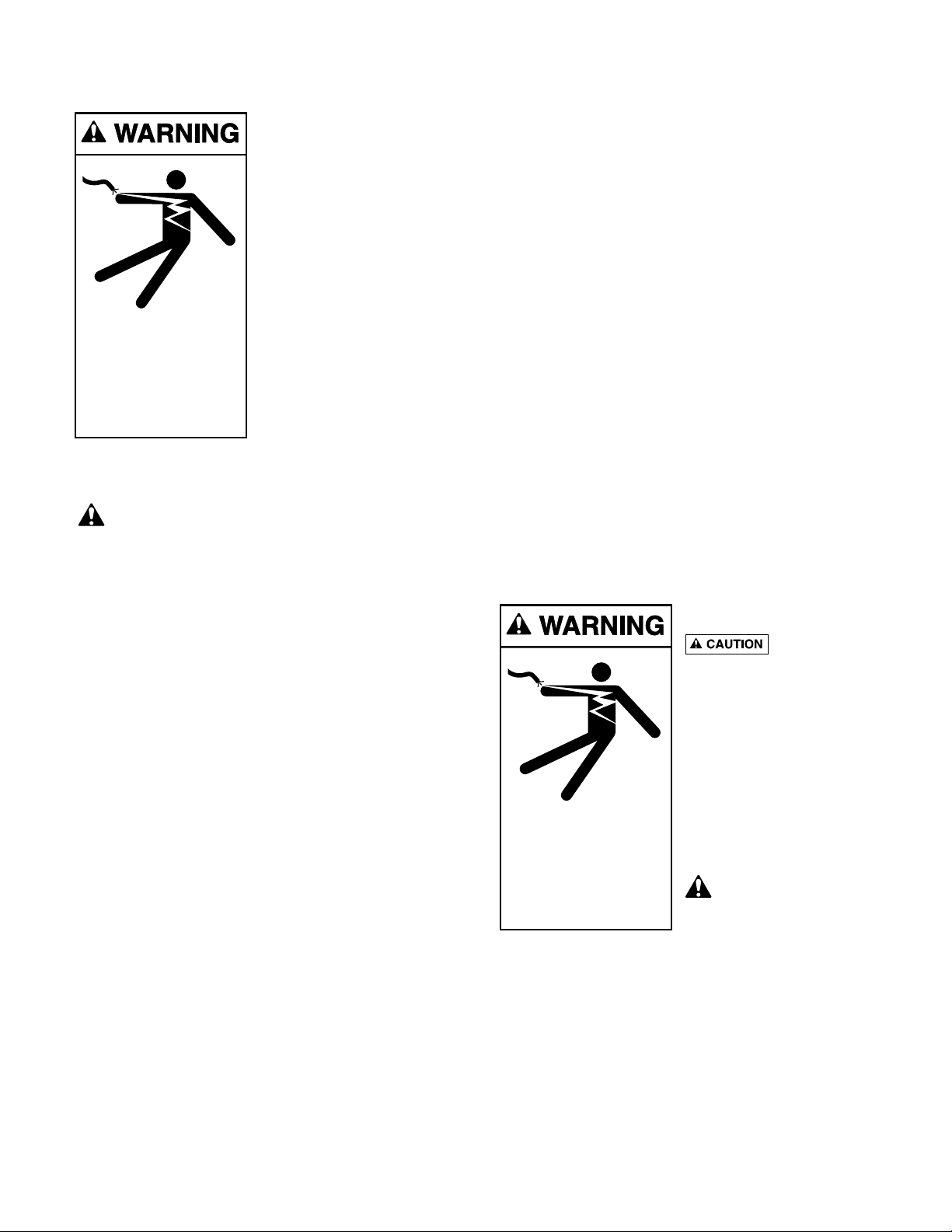

ELECTRICAL

Ground motor before connecting to electrical

power supply. Failure to ground motor can cause

severe or fatal electrical shock hazard.

Do not ground to a gas supply line.

To avoid dangerous or fatal electrical shock, turn

OFF power to motor before working on electrical

connections.

Ground Fault Circuit Interrupter (GFCI) tripping

indicates an electrical problem. If GFCI trips and

will not reset, have a qualified electrician inspect and

repair electrical system.

Exactly match supply voltage to nameplate

voltage. Incorrect voltage can cause fire or

seriously damage motor and voids warranty. If in doubt

consult a licensed electrician.

Voltage

Voltage at motor must be not more than 10% above or

below motor nameplate rated voltage or motor may

overheat, causing overload tripping and reduced

component life. If voltage is less than 90% or more than

110% of rated voltage when motor is running at full

load, consult power company.

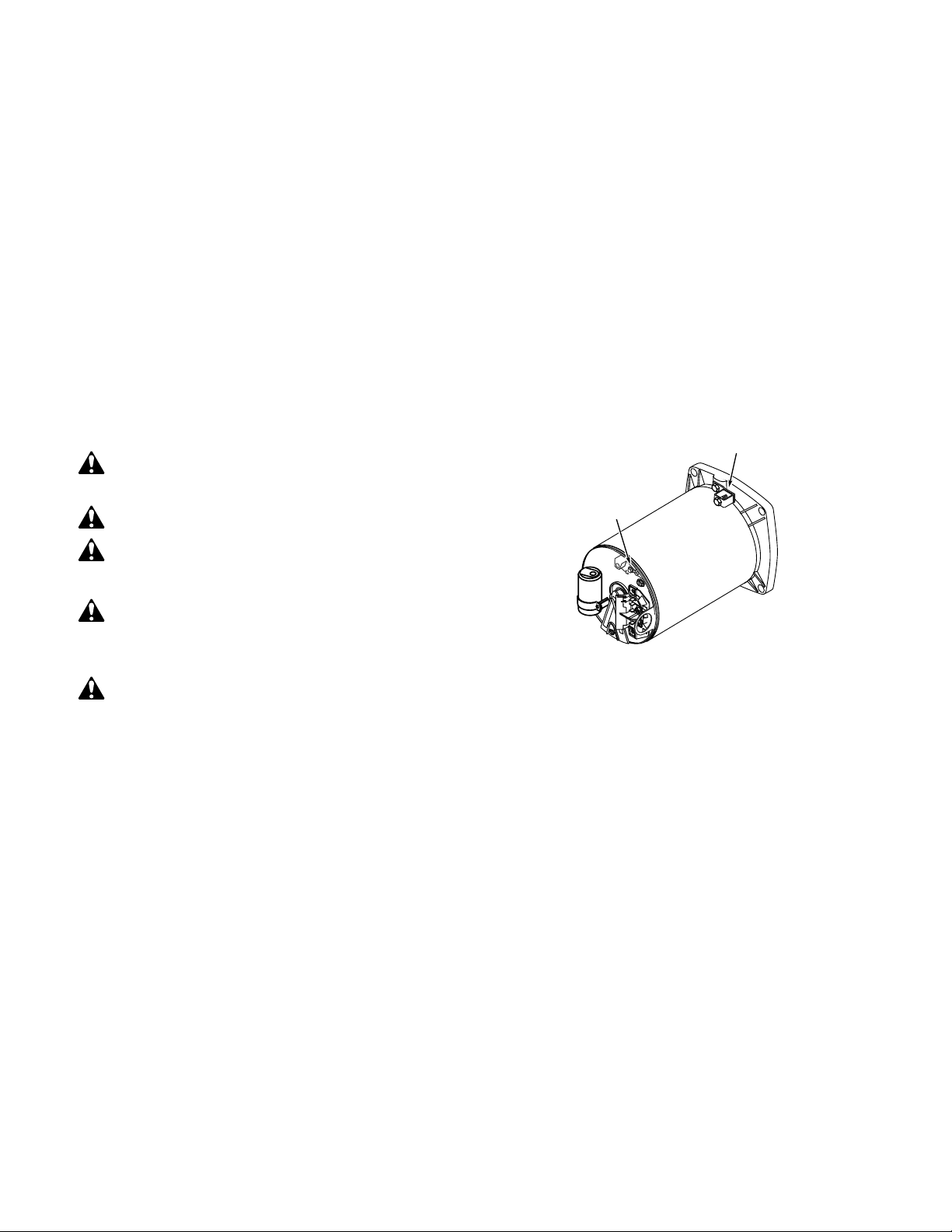

Grounding/Bonding

Install, ground, bond and wire motor according to local

or National Electrical Code requirements.

Permanently ground motor. Use green ground terminal

provided under motor canopy or access plate (See

Figure 3); use size and type wire required by code.

Connect motor ground terminal to electrical service

ground.

Bond motor to pool structure. Use a solid copper

conductor, size No. 8 AWG (8.4 sq.mm) or larger. Run

wire from external bonding lug (see Figure 3) to reinforcing

rod or mesh.

Connect a No. 8 AWG (8.4 sq.mm) solid copper

bonding wire to the pressure wire connector provided

on the motor housing and to all metal parts of the

swimming pool, spa, or hot tub and to all electrical

equipment, metal piping or conduit within 5 feet (1.5 m)

of the inside walls of swimming pool, spa, or hot tub.

Wiring

NOTICE: 3 phase models require magnetic motor

starters and external overload protection. If in doubt

about the procedure, consult a licensed electrician.

Pump must be permanently connected to circuit. Table

I, Page 6, give correct wire and circuit breaker sizes for

the pump alone. If other lights or appliances are also on

the same circuit, be sure to add their amp loads to

pump amp load before figuring wire and circuit breaker

sizes. (If unsure how to do this or if this is confusing,

consult a licensed electrician.) Use the load circuit

breaker as the master on-off switch.

Figure 3 – Typical ground screw and bonding lug

locations.

Bonding

Lug

Green

Ground

Screw

A

A

230V

115V

L2

L2

L1

L1

Page 6

6

Install a Ground Fault Circuit Interrupter (GFCI) in

circuit; it will sense a short-circuit to ground and

disconnect power before it becomes dangerous to pool

users. For size of GFCI required and test procedures for

GFCI, see manufacturer’s instruction.

In case of power outage, check GFCI for tripping (which

will prevent normal pump operation). Reset if

necessary.

NOTICE: If you do not use conduit when wiring motor,

be sure to seal wire opening on end of motor to prevent

dirt, bugs, etc., from entering.

Risk of dangerous or fatal electrical shock.

Be sure that power to the motor circuit is off before

working on wiring, wiring connections, or motor. Reinstall the motor end cover and all other wiring covers

before turning on the power.

1. Turn off power.

2. Remove the motor end cover.

To Wire a Single Speed, Single Voltage Motor

There are two terminals labeled L1 and L2. Attach the

power leads to these terminals. Either wire may attach to

either terminal.

To Wire a Dual-Voltage Motor

Dual voltage motors have a plug to change from 230

volts (factory setting) to 115 volts.

1. If you have 230 volts motor supply voltage, confirm

that the plug is set for 230 volts. The arrow on the

plug will point to the 230 volt position. Note that plug

only connects with one prong in this position.

2. If you have 115 volt supply, pull the plug straight up

and place it on the two brass prongs as shown.

NOTE: Arrow is highlighted for clarity.

Figure 4B Voltage Change

Plug Set for 115 Volts.

Figure 4A -Voltage Change

Plug Set for 230 Volts.

TABLE I - RECOMMENDED FUSING AND WIRING DATA

Serv. to Motor - Dist. in Ft. (M)

AWG Wire Size (mm2)

Motor Branch Fuse Max Load Voltage/ 0-100' 101-200' 201-300'

Model HP Rating Amps* Amps Hz/Phase (0-30) (30-60) (60-90)

MPRA6B-202L

1/3 15/15 4.2/2.1 115/230/60/1 14/14(2/2) 14/14(2/2) 12/14(3/2)

1750 RPM

* Time delay fuses are recommended instead of standard fuses in any motor circuit.

Page 7

7

OPERATION

NOTICE: NEVER run pump dry. Running pump dry may

damage seals, causing leakage and flooding. Fill pump

with water before starting motor.

Before removing trap cover:

1. STOP PUMP before proceeding.

2. CLOSE GATE VALVES in suction and discharge

pipes.

3. RELEASE ALL PRESSURE from pump and piping

system.

If pump is being

pressure tested, be

sure pressure has been

released before removing

trap cover.

Do not block pump

suction. To do so with

body may cause severe or

fatal injury. Small children

using pool must ALWAYS

have close adult

supervision.

Fire and burn

hazard. Modern motors run

at high temperatures. To

reduce the risk of fire, do not

allow leaves, debris, or foreign matter to collect around

the pump motor. To avoid burns when handling the

motor, let it cool for 20 minutes before trying to work on

it. An automatic internal cutoff switch protects the motor

from heat damage during operation.

Priming Pump

Release all pressure from filter, pump, and piping

system; see the filter owner’s manual.

In a flooded suction system (water source higher than

pump), pump will prime itself when suction and

discharge valves are opened.

If pump is not in a flooded suction system, unscrew and

remove trap cover; fill trap and pump with water.

Clean and inspect O-Ring; reinstall on trap groove.

Do not lubricate the trap cover O-Ring. The original

equipment O-Ring contains a permanent internal

lubricant.

NOTICE: If you replace the O-Ring with a non-internally

lubricated O-Ring, you may need to apply a silicone

based lubricant. Replace trap cover on trap; turn

clockwise to tighten cover.

NOTICE: Tighten trap cover handle ring by hand only

(no wrenches)! See Figure 1, Page 3.

Pump should prime now. Priming time will depend on

vertical length of suction lift and horizontal length of

suction piping.

If pump does not prime, make sure that all valves are

open, suction pipe end is under water, pump is not trying

to lift water more than 10'(3m), and that there are no leaks

in suction pipe. See Troubleshooting Guide, Page 11.

Storage/Winterizing:

NOTICE: Allowing pump to freeze will damage pump

and void warranty!

NOTICE: Do not use anti-freeze solutions (except

propylene glycol) in your pool/spa system. Propylene

glycol, “RV antifreeze”, is non-toxic and will not damage

plastic system components; other anti-freezes are

highly toxic and may damage plastic components in the

system.

Drain all water from pump and piping when expecting

freezing temperatures or when storing pump for a long

time (see instructions below).

Keep motor dry and covered during storage.

To avoid condensation/corrosion problems, do not

cover pump with plastic.

For outdoor/unprotected installations:

1. Enclose entire system in a weatherproof enclosure.

2. To avoid condensation/corrosion damage, allow

ventilation; do not wrap system in plastic.

3. Use a 40% propylene glycol/60% water solution to

protect pump to -50° F (-46° C).

Draining Pump

Explosion hazard. Purging the system with

compressed air can cause components to explode, with

risk of severe injury or death to anyone nearby. Use only

a low pressure (below 5 PSI), high volume blower when

air purging the pump, filter, or piping.

Hazardous suction.

Can trap hair or

body parts, causing

severe injury

or death.

Do not block

suction.

Page 8

8

1. Pump down water level below all inlets to the pool.

To avoid dangerous or fatal electrical shock

hazard, turn OFF power to motor before draining

pump.

2. Remove trap cover and use low pressure air to blow

accumulated water from the piping system. Use a pry

bar or board to remove trap covers that have been

overtightened or have taken a set and cannot be

removed by hand. Lugs have been provided on the

trap lid to use a lever or pry bar for loosening (see

Figure 6).

3. Cap inlet piping after draining to keep water out of

the pipes.

4. To prevent pump from freezing, remove trap cover and

drain the tank body through the two drain plugs

provided.

A. Gravity drain system as far as possible.

B. Protect areas which retain water with non-toxic

propylene glycol antifreeze (“RV” antifreeze).

5. Clean pump thoroughly; replace trap cover.

NOTICE: Tighten trap cover by hand only (no

wrenches)! If pump is not anchored, use caution to

not break attached piping!

6. Be sure motor is kept dry and covered.

Startup For Winterized Equipment

1. Remove any temporary weather protection placed

around system for shutdown.

2. Follow filter manufacturer’s instructions for

reactivation of the filter.

3. Inspect all electrical wiring for damage or

deterioration over the shutdown period. Have a

qualified serviceman repair wiring as needed.

4. Inspect and tighten all watertight connections.

5. Open all valves in suction and return piping.

6. Remove any winterizing plugs in piping system.

7. Drain all antifreeze from system.

8. Close all drain valves and replace all drain plugs in

piping system.

9. Prime pump according to instructions on Page 7.

PUMP SERVICE

Pump should only be serviced by qualified personnel.

For best results, use only genuine Sta-Rite factory

parts.

Be sure to prime pump

(Page 7) before starting.

Before

removing trap cover:

1. STOP PUMP before

proceeding.

2. CLOSE GATE VALVES

insuction and discharge

pipes.

3.RELEASE ALL

PRESSURE from pump

and piping

system.

To avoid dangerous or

fatal electrical shock

hazard, turn OFF power to

motor before working on

pump or motor.

Aside from lubricating trap cover O-Ring, no lubrication

or regular maintenance is needed beyond reasonable

care and periodic cleaning of strainer basket.

If shaft seal is worn or damaged, repair as follows:

Hazardous voltage.

Can shock, burn,

or cause death.

Disconnect power

before working

on pump or motor.

Hazardous voltage.

Can shock, burn,

or cause death.

Disconnect power

before working

on pump or motor.

Page 9

9

Pump Dissasembly/Removing Old Seal

Disconnect power to pump motor.

Be sure valves on suction and return piping are

closed before starting work.

Release all pressure by opening all vents before

starting work.

1. Drain pump by removing drain plugs on bottom of

pump body and trap body.

2. Be sure there is no pressure in trap body; remove

cover (unscrew by turning counterclockwise).

3. Remove 6 nuts, lockwashers and flat washers holding

seal plate to pump body. Pull seal plate and motor

away from pump body. (You may have to

CAREFULLY use a screwdriver to separate body

from seal plate.)

4. Remove seven screws and washers holding diffuser

to seal plate. Remove diffuser.

5. Remove motor canopy. Being careful not to touch

capacitor terminals, loosen capacitor clamp and

move capacitor to one side.

6. Hold shaft with 7/16" open-end wrench on motor

shaft flats.

7. Unscrew impeller from shaft (turn counterclockwise

when facing it).

NOTICE: On 2 HP model, remove impeller

screw (left hand thread - turn clockwise) and

gasket before removing impeller. Inspect gasket

for damage, cracks, etc. Replace if damaged.

8. Remove four screws holding seal plate to motor.

9. Place seal plate face down on flat surface and tap

out ceramic seat (Figure 5).

10. Remove slinger from motor shaft and inspect for

damage or abrasion.

11. Clean seal cavity in seal plate and clean motor

shaft.

Pump Reassembly/Installing New Seal

1. Ceramic seat must be clean and free of dirt, grease,

dust, etc. Wet outer edge with small amount of

liquid detergent; press ceramic seat into seal plate

cavity firmly and squarely with finger pressure (see

Figure 8).

2. If ceramic seat will not locate properly, remove it,

place face up on bench and reclean cavity.

Ceramic seat should now locate.

3. If seat still will not locate properly, place a

cardboard washer over the polished face and use a

piece of 3/4" (19mm) standard pipe for pressing

purposes.

NOTICE: Be sure not to scratch or mar polished

surface or seal will leak.

4. Replace slinger on end of motor shaft so that

impeller sleeve will push it into position. If slinger

shows signs of wear or damage, replace it.

5. Remount seal plate on motor. Tighten bolts to 6080 inch-lbs. (69-92 kg/cm) torque.

6. Apply a small amount of liquid detergent to inside

diameter of rotating half of seal.

7. Slide rotating seal member, polished carbon face

out, over impeller sleeve until rubber drive ring hits

back of impeller.

NOTICE: Be sure not to nick or scratch polished

seal face; seal will leak if face is damaged.

8. Screw impeller onto shaft (clockwise); this will

automatically locate seal in seal plate. NOTICE: On

2 and 2-1/2 HP models; install impeller gasket

and lock screw (left-hand thread - turn

counterclockwise). Torque lock screw to 50-55

inch-lbs. (57.6-63 kg/cm).

9. Mount diffuser on seal plate; tighten screws to 1014 inch-lbs. (11.2-16.1 kg/cm) torque.

10. Assemble motor and seal plate to pump body with

nuts, flat washers and lock washers. Torque nuts to

120-130 in-lbs. (138-150 kg/cm).

11. Prime pump according to instructions on Page 7.

Figure 5

Figure 8

Mechanical seal

ceramic seat

Polished

surface

Rubber

surface

Page 10

10

24

Key Part MPRA6B-143L

No. Description Qty. 1/3 HP

1 Motor, 115/230V 1750 RPM 1 62003-2088

2 Screw #10-32x1/2" 1 U30-692SS

3 Bonding Lug 1 U17-568

4 Slinger 1 17351-0009

5 Seal Plate 1 C3-184P

6 Seal Plate Cord Ring 1 U9-373

7 Shaft Seal 1 37400-0027S

8 Impeller 1 C105-236PDA

8A O-Ring Gasket 1 33455-1047

8B Impeller Screw 1 37337-6080

9 Diffuser 1 C1-270P

10 Diffuser “O” Ring 1 U9-374

11 Tank and Trap Body (Only) 1 C76-71P

12 Trap Cover 1 17307-01111

13 Trap Cover “O” Ring 1 35505-1440

14 Trap Basket 1 C8-58P

15A Drain Plug 2 U178-920P

15B Mounting Screw 5/16-14x5/8" 2 U30-919SS

16 Base 1 C4-77P

17 Motor Pad 1 C35-45

18 Screw #8-32x7/8" Rd. Hd. 7 U30-542SS

19 Lock Washer #8 Ext. Tooth 7 U43-21SS

20 Flat Washer 3/8" 6 U43-62SS

21 Lock Washer 3/8" 6 U43-12SS

22 Nut 3/8-16 Hex. nickel-plated brass 6 71403

23 Cap Screws 3/8-16x1" Hex. 4 U30-74SS

• Nameplate 1 32155-4071

• Tag, “CAUTION This pump equipped with 1 U63-13

mechanical shaft seal…”

• Voltage Sticker 1 U27-153

• Decal “Overtight trap lid…” 1 U27-644

• Tag, “WARNING/CAUTION/Instructions...” 1 C63-12

• Not illustrated.

REPAIR PARTS LIST

Pkg. 188 2" Slip 1/2 Union Kit.

Note that this kit includes both

inlet and outlet connections.

Includes:

U11-200PS Union Collar - Qty 2

U9-362 O-Ring - Qty 2

U11-196P 2" Slip Adapter - Qty 2

Box A

23

1

22

21

2

3

20

4

5

6

7

19

15B

8

16

18

8A

17

See

Box A

8B

9

10

11

12

13

14

15A

See

Box A

5136 0905

Page 11

11

TROUBLESHOOTING

Read and understand safety and

operating instruc-tions in this manual

before doing any work onpump!

Only qualified personnel should electrically test pump motor!

FAILURE TO PUMP; REDUCED CAPACITY OR

DISCHARGE PRESSURE

Suction leaks/lost prime:

1. Pump must be primed; make sure that pump

voluteand trap are full of water. See priming

instructions, Page 7.

2. Make sure there are no leaks in suction piping.

3. Make sure suction pipe inlet is well below the

waterlevel to prevent pump from sucking air.

4. If suction trap gasket is defective, replace it.

5. Make sure pump is not trying to lift water more

than10' (3m).

6. Make sure suction pipe is at least 2" (51mm) in

diameter.

CLOGGED PIPE/TRAPPED IMPELLAR/WORN

IMPLELLAR

7. Make sure suction trap is not clogged; if it is, cleantrap

and strainer.

8. Make sure impeller is not clogged (follow steps 1

through 7 under “Removing Old Seal”, Page 9; check

impeller for clogging; follow steps 7 through 11under

“Installing New Seal”, Page 9, for reassembly).

9. Impeller and diffuser may be worn. If so, order

replacement parts from Repair Parts List, Page 10.

ELECTRICAL

10. Pump may be running too

slowly; check voltage at motor

terminals and at meter while

pump is running. If low, see wiring

instructions or consult power

company. Check for loose

connections.

11. Pump may be too hot.

(A)Check line voltage; if less than

90% or morethan 110% of rated

voltage consult a licensed

electrician.

(B) Increase ventilation.

(C) Reduce ambient temperature.

(D)Tighten any loose

connections.

MECHANICAL

12. If suction and discharge piping

are not adequately supported,

pump assembly will be strained. See “Installation”, Page 3.

13. Do not mount pump on a wooden platform! Securely mount on

concrete platform for quietest performance.

Hazardous voltage.

Can shock, burn,

or cause death.

Disconnect power

before working

on pump or motor.

Page 12

For customer support or technical information about

this product, contact the installer or call:

Phone: (800) 831-7133 Fax: (800) 284-4151

Visit www.pentairwater.com and staritepool.com

S752 Rev B (10-09-09)

Page 13

DYNA-WAVE

BOMBA CENTRÍFUGA

CON COLECTOR INTEGRAL

MANUAL DEL PROPIETARIO

INSTALACIÓN, OPERACIÓN Y PIEZAS

© 2009 Pentair Water Pool and Spa, Inc. Todos los derechos reservados.

1620 Hawkins Ave., Sanford, NC 27330 (919) 566-8000

10951 West Los Angeles Ave., Moorpark, CA 93021 (805) 553-5000

Starite®, Dyna-Wave®, Pentair Water Pool and Spa® es marca comercial y/o marca registrada de Pentair Water Pool and

Spa, Inc. y/o de sus compañías afiliadas en Los Estados Unidos y/o en otros países. Plasto-Joint Stik® es marca comercial y/o

marca registrada de La-Co Industries, Inc. and Teflon® es marca comercial y/o marca registrada de E.I. Du Pont De Nemours and

Company Corporation. A menos que sea indicado, los nombres y marcas de otras compañias pueden ser utilizados en este

documento pero no son utilizados para indicar una afiliación o endorse entre los propietarios de estos nombres y marcas y

Pentair Water Pool and Spa, Inc. Esos nombres y marcas pueden ser las marcas comerciales o registradas de esas

entidades u otros.

S752 Rev B (10-07-09)

Este manual se debe entregar al usuario final de esta bomba; su uso

reducirá las llamadas de servicio y las posibilidades de lesiones, y

alargará la vida útil de la bomba.

®

5137 0905

Page 14

2

BOMBA DE LA SERIE

‘MPRA’, CON COLECTOR

Para evitar llamadas innecesarias de servicio, evitar

posibles lesiones y obtener el máximo de su bomba,

¡LEA ESTE MANUAL CON ATENCIÓN!

La bomba centrífuga autocebadora de la Serie

‘MPRA’ de Sta-Rite:

• Ha sido diseñada para usar con agua o como

bomba centrífuga.

• Tiene un desempeño excelente, es duradera y

fiable.

Îndice

Instrucciones de seguridad............................................2

Instalación .....................................................................3

Requerimientos de aspiración

para bombas de albercas...........................................4-5

Información eléctrica ..................................................5-6

Operación......................................................................7

Almacenamiento/Preparación para el invierno...........7-8

Servicio de la bomba................................................8-10

Lista de piezas para reparaciones...............................10

Guía para la localización de fallas...............................11

Garantía ......................................................................12

¡LEA Y SIGA LAS

INSTRUCCIONES

DE SEGURIDAD!

Este es el símbolo de alerta de seguridad. Cuando usted

vea este símbolo en su sistema o en este manual,

busque alguna de las siguientes palabras de advertencia y

esté alerta a la posibilidad de lesiones personales:

advierte acerca de los peligros que

provocarán muerte, lesiones personales graves, o daños

materiales considerables si se ignoran.

advierte acerca de los peligros que

pueden provocar muerte, lesiones personales graves, o daños

materiales considerables si se ignoran.

advierte acerca de los peligros que

provocará o pueden provocar lesiones personales o daños

materiales menores si se ignoran.

La etiqueta AVISO indica instrucciones especiales que no están

relacionadas con los peligros.

Lea y siga cuidadosamente todas las instrucciones de seguridad

en este manual y en la máquina. Mantenga las etiquetas de

seguridad en buen estado; reemplace las que falten o estén

dañadas.

Las máquinas que se instalan o se

prueban en forma incorrecta pueden fallar,

provocando lesiones graves o daños

materiales considerables.

Cuando instale y opere la máquina, es importante que lea y

siga las instrucciones del manual del propietario. Haga que un

profesional capacitado en instalaciones en albercas realice

todas las pruebas de presión.

1. No conecte el sistema a un sistema de alta presión o de

aguas públicas.

2. Use la máquina sólo en instalaciones de agua o en

albercas.

3. El aire atrapado en el sistema puede provocar explosiones.

VERIFIQUE que todo el aire haya salido del sistema antes

de operar la máquina o de hacer una prueba.

Antes de realizar la prueba de presión, verifique lo siguiente:

• Inspeccione todas las abrazaderas, los pernos, las tapas y

los accesorios del sistema antes de realizar una prueba.

• Libere todo el aire en el sistema antes de realizar una

prueba.

• Ajuste las tapas del colector Sta-Rite a una torsión de 30 ft.

lbs. (4.1 kg-m) para hacer la prueba.

• La presión del agua para la prueba debe ser inferior a 25

PSI (7.5 kg/cm

2

).

• La temperatura del agua para la prueba debe ser inferior a

100Þ F (38Þ C).

• Limite la prueba a 24 horas. Después de realizarla,

inspeccione el sistema visualmente, para verificar que esté

listo para funcionar. Saque la tapa del colector y vuelva a

ajustarlo a mano solamente.

INSTRUCCIONES

IMPORTANTES DE

SEGURIDAD

Siempre observe las precauciones básicas de seguridad

con esta máquina, que incluyen lo siguiente:

Para reducir el peligro de lesiones,

no permita que los niños usen este producto a menos que

estén bajo supervisión estricta en todo momento.

Esta bomba se debe usar en albercas

de instalación permanente y se puede usar con baños

termales y jacuzzis si así se indica. No la use con albercas

desmontables. Una alberca de instalación permanente

está construida dentro o sobre el suelo o en un edificio, y

no se puede desarmar fácilmente para guardarla. Una

alberca desmontable se ha construido de manera que se

pueda desarmar fácilmente para guardarle y se pueda

volver a armar para obtener su integridad inicial.

CONSERVE ESTAS

INSTRUCCIONES

PELIGRO

ADVERTENCIA

PRECAUCIÓN

ADVERTENCIA

PRECAUCIÓN

Page 15

3

AVISO: Estos parámetros corresponden sólo a máquinas

Sta-Rite. Para máquinas que no son de la marca Sta-Rite,

consulte con el fabricante.

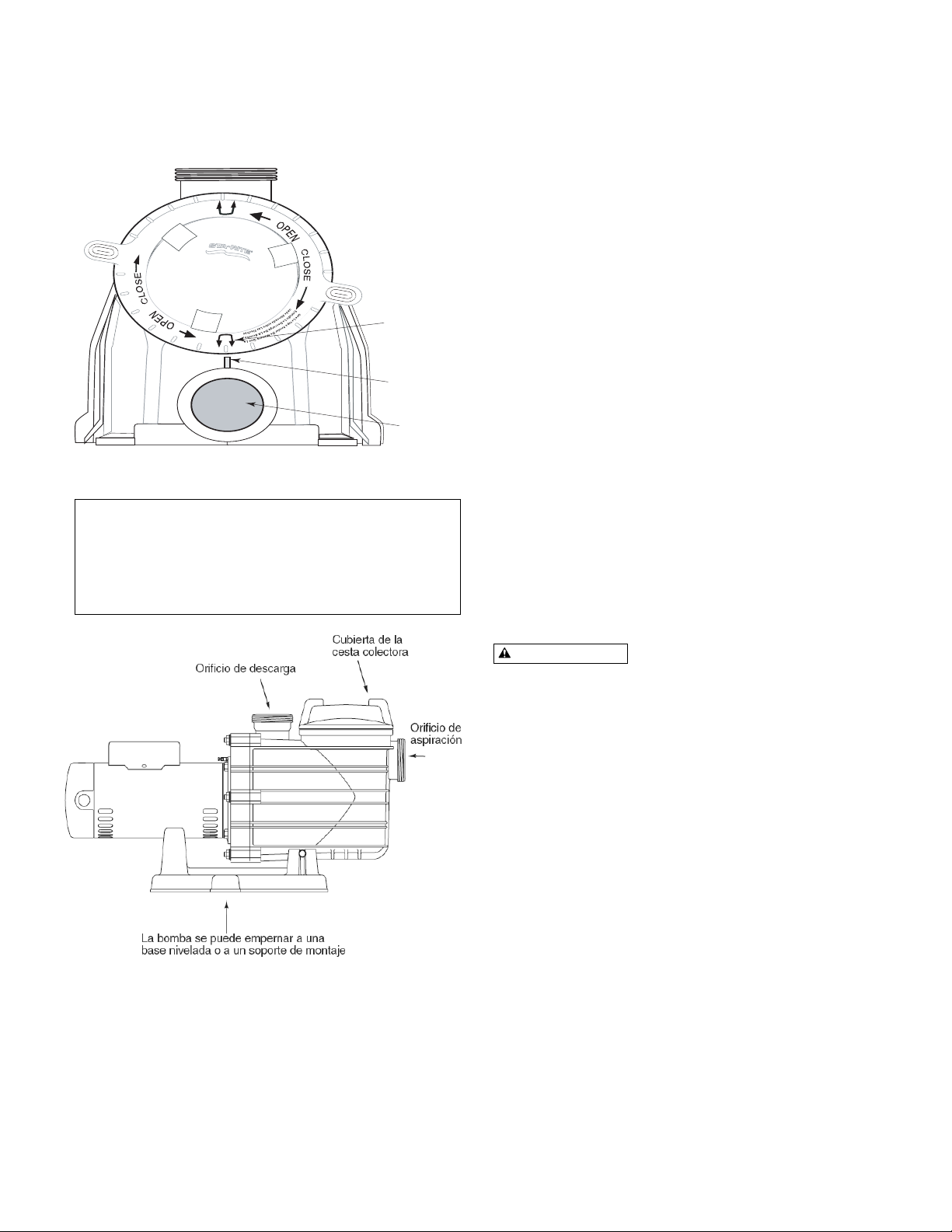

INSTALACIÓN (Figura 2)

La bomba y los cables deben ser instalados sólo por personas

competentes y autorizadas.

La instalación de la bomba debe:

Estar ubicada lejos de líquidos corrosivos o inflamables.

Tener suficiente ventilación para mantener la temperatura del

aire por debajo de la clasificación máxima de temperatura

ambiente (Máx. Amb.) indicada en la placa del modelo del

motor. Si esta bomba está instalada en un recinto/estación de

la bomba, el recinto deberá tener una ventilación y una

circulación de aire adecuadas para mantener la temperatura

dentro del mismo a la temperatura ambiente nominal del motor

o por debajo de la misma, siempre que la bomba esté

funcionando.

Ser firme - nivelada - rígida - sin vibraciones. (Para reducir las

vibraciones y la tensión en las tuberías, emperne la bomba al

dispositivo de montaje)

Permitir que la altura de la admisión de aspiración de la bomba

esté lo más cerca posible del nivel del agua. La bomba no

levantará agua a más de 10 pies de altura (3 m).

Permitir el uso de tubos de aspiración cortos y directos (Para

reducir las pérdidas por fricción).

Permitir la instalación de válvulas de compuerta en los tubos

de aspiración y de descarga.

Tener un desagüe adecuado en el suelo para evitar

inundaciones.

Estar protegida contra una humedad excesiva.

Permitir el acceso adecuado para los trabajos de servicio de la

bomba y de las tuberías

.

Peligro de incendio y de quemaduras.

Los motores modernos funcionan a altas temperaturas. Para

reducir el peligro de incendio, no permita que hojas, escombros o

partículas extrañas se acumulen alrededor del motor de la

bomba. Para evitar quemaduras cuando se trabaje con el motor,

deje que éste se enfríe durante unos 20 minutos antes de

manipularlo.

AVISO: Cuando conecte un tubo fileteado directamente a la

bomba, use cinta de Teflón o Plasto-Joint Stik

1

para sellar las

conexiones. No use compuesto para tubos, ya que éste

provoca rajaduras en ciertos plásticos y puede dañar los

componentes del sistema de tubos.

Cuando conecte el tubo a la bomba con una mitad de unión,

use cinta de Teflón o Plasto-Joint Stik entre el tubo y el

adaptador de la unión. El collarín de unión a la bomba se debe

ensamblar en seco y apretar a mano.

AVISO: Las conexiones de aspiración y de descarga tienen

topes de rosca moldeados. NO trate de atornillar una tubería

más allá de estos topes.

AVISO: Las roscas de los orificios son: Internos - 2” NPT

para conexión directa a la tubería. Externas - 3-1/4”

Trapezoidal. Se adapta al collarín de unión Sta-Rite U11200P para una conexión a tubos de desconexión rápida.

Consulte la página 10 para los juegos de uniones.

Figura 1. Alineanto del cesto colador

Figura 2

P

P

M

M

U

U

P

P

N

N

S

O

W

O

O

S

R

B

B

R

I

W

I

A

O

R

R

R

N

R

E

O

O

E

A

S

S

W

N

T

E

G

E

G

E

B

N

N

W

I

I

S

T

R

R

E

N

-

-

B

G

I

D

D

S

I

L

I

A

L

N

L

G

E

I

E

E

G

L

T

T

R

A

A

A

A

T

E

T

H

G

O

O

C

R

R

R

S

A

I

H

D

C

S

I

D

Flechas

Etiqueta

Orificio de

descarga

ADVERTENCIA

Page 16

4

Instrucciones para la

aplicación de cinta de Teflón:

Use sólo accesorios para tubos de PVC nuevos o limpios.

Envuelva las roscas macho de

los tubos con una o dos capas

de cinta de Teflón. Cubra toda la

porción fileteada del tubo.

¡No apriete demasiado ni más

allá del tope de rosca en el

orificio de la bomba!

Si observa fugas, saque el tubo,

limpie la cinta vieja, vuelva a

envolverlo con una o dos capas

adicionales de cinta y vuelva a

establecer la conexión.

AVISO: ¡Soporte todos los

caños conectados a la bomba!

Tuberías:

Use un tubo de al menos 2” (51

mm). Aumente el tamaño si

necesita un trayecto largo.

Para evitar demasiado esfuerzo

sobre la bomba, soporte la tubería de aspiración y de

descarga en forma independiente. Coloque estos soportes

cerca de la bomba.

Para evitar el esfuerzo debido a una brecha en la última

conexión, comience toda la tubería en la bomba y haga correr

los caños alejándose de la misma.

Para evitar la creación de bolsas de aire, incline el tubo de

aspiración ligeramente hacia arriba y hacia la bomba.

AVISO: Para impedir inundaciones cuando saque la bomba

para realizar trabajos de mantenimiento o de reparación, todos

los sistemas de aspiración inundados deberán tener válvulas

de compuerta en las tuberías de aspiración y de descarga.

1

Lake Chemical Co., Chicago, Illinois

REQUERIMIENTOS PARA

LA ASPIRACIÓN DE LA

BOMBA

La aspiración de la bomba es peligrosa y puede atrapar,

ahogar o desentrañar a los bañistas. No use ni opere

albercas, jacuzzis, baños termales ni otros sistemas acuáticos,

si observa que las cubiertas de las salidas de aspiración faltan,

están rotas o flojas.

Siga los lineamientos que aparecen a continuación para la

instalación de una bomba, para reducir los peligros a los

usuarios de albercas, jacuzzis, baños termales y otros

sistemas acuáticos.

Protección para no quedar atrapado

El sistema de aspiración de la bomba debe ofrecer protección

contra el peligro de que una persona o su cabello queden

atrapados o enredados debido a la aspiración.

Cubiertas para la salida de aspiración

Es necesario mantener todas las cubiertas de las salidas de

aspiración. Se deberán reemplazar en caso de que estén

rajadas, rotas o ausentes.

Consulte la página 5 para obtener información sobre los

requerimientos de certificación de las cubiertas para las

salidas.

Todas las salidas de aspiración deben contar con cubiertas

debidamente instaladas, y atornilladas en su lugar.

Aspiración peligrosa.

Puede atrapar el cabello

o partes del cuerpo,

provocando lesiones

graves o muerte.

No bloquee

la aspiración.

Figura 2 – Configuración recomendada de la aspiración de la bomba.

Mínimo

3 pies

No hay válvulas entre el Te

y los Drenajes principales

Salida de aspiración

(Drenaje principal)

Bomba

Salida de aspiración

(Drenaje principal)

Válvulas OK entre la

bomba y el Te

Cubierta o Accesorio de

Aspiración anti-enredos,

certificado por IAPMO,

atornillado al colector

del drenaje principal.

Cubierta o Accesorio de

Aspiración anti-enredos,

certificado por IAPMO,

atornillado al colector

del drenaje principal.

PELIGRO

At Least

3 Feet

IAPMO Certified

Anti-entrapment

Cover or Suction Fitting,

screw-fastened to

Main Drain Sump

Suction Outlet

(Main Drain)

Valves OK between

pump and Tee

No valves between

Tee and Main Drains

IAPMO Certified

Anti-entrapment

Cover or Suction Fitting,

screw-fastened to

Main Drain Sump

Suction Outlet

(Main Drain)

Pump

2762 0197

Page 17

5

Salidas de aspiración por bomba (Figura 2)

Proporcione al menos dos drenajes principales hidráulicamente

equilibrados, con cubiertas, como salidas de aspiración para

cada línea de aspiración de la bomba de circulación. Los centros

de los drenajes principales (salidas de aspiración) en cualquiera

de las líneas de aspiración deben estar al menos a tres pies de

distancia entre sí.

Es necesario construir el sistema de manera que no pueda

funcionar si la bomba extrae agua solamente de un drenaje

principal (es decir, que deben haber al menos dos drenajes

principales conectados a la bomba siempre que esté

funcionando – consulte la Figura 2). Sin embargo, si dos

drenajes principales corren hacia una sola línea de aspiración, la

línea de aspiración singular puede estar equipada con una

válvula que cierre ambos drenajes principales desde la bomba

(consulte la Figura 2).

Se puede conectar más de una bomba a una sola línea de

aspiración siempre que se cumplan los requerimientos indicados

en el párrafo que precede.

Velocidad del agua

La máxima velocidad del agua a través del accesorio de

aspiración o de la cubierta para cualquier salida de aspiración

debe ser de 1.5 pies por segundo, a menos que la salida

cumpla con la versión más reciente de la Especificación de

ASME/ANSI para Accesorios de Aspiración que se usen en

Albercas, Jacuzzis, Baños termales, y Piscinas de

Hidromasaje. En todo caso, no sobrepase el caudal máximo

designado para el accesorio de aspiración.

Si el 100% del flujo de la bomba se origina en el sistema de

drenaje principal, la máxima velocidad del agua en el sistema

hidráulico de aspiración de la bomba debe ser de seis pies por

segundo o menos, aún en el caso en que uno de los drenajes

principales (salidas de aspiración) esté completamente

bloqueado.

El flujo a través del (de los) desagüe(s) principal(es)

restante(s) deberá cumplir con la versión más reciente de la

Especificación de ASME/ANSI para Accesorios de Aspiración

que se usen en Albercas, Jacuzzis, Baños termales, y

Piscinas de Hidromasaje.

Pruebas y certificación

Las cubiertas de la salida de aspiración deben haber sido

verificadas por un laboratorio de pruebas reconocido a nivel

nacional, conforme a la versión más reciente de las

Especificaciones de ASME/ANSI para Accesorios de Aspiración

que se usen en Albercas, Jacuzzis, Baños termales, y Piscinas

de Hidromasaje.

Accesorios:

Los accesorios limitan el flujo; para mayor eficacia, use la

mínima cantidad posible de accesorios (pero al menos dos

salidas de aspiración).

Evite accesorios que puedan provocar una trampa de aire.

Los accesorios para albercas deben cumplir con las normas

de la “International Association of Plumbing and Mechanical

Officials (IAPMO)”.

Use solamente accesorios de aspiración que no provoquen

enredos o de doble aspiración.

INFORMACIÓN

ELÉCTRICA

Conecte el motor a tierra antes de conectarlo a la fuente

de corriente eléctrica, de lo contrario existe el peligro de

choque eléctrico grave o fatal.

No haga la conexión a tierra mediante una línea de

suministro de gas.

Para evitar choques eléctricos peligrosos o fatales,

desconecte la alimentación eléctrica al motor antes de

trabajar en las conexiones eléctricas.

El disparo del disyuntor de escape a tierra (“GFCI”

según sus siglas en inglés) indica un problema eléctrico.

Si el GFCI se dispara y no se reposiciona, haga que un

electricista competente inspeccione y repare el sistema

eléctrico. La tensión de suministro debe corresponder

exactamente a la tensión indicada en la placa de fábrica.

Una tensión incorrecta puede provocar incendios o

causar daños considerables al motor y anular la

garantía. En caso de duda, consulte a un electricista

certificado.

Figura 3 – Ubicaciones típicas del tornillo de puesta a

tierra y de la saliente de empalme.

Tornillo

verde de

puesta a

tierra

Saliente de

empalme

Bonding

Lug

Green

Ground

Screw

A

A

230V

115V

L2

L2

L1

L1

Page 18

6

Tensión (voltaje)

La tensión en el motor no debe ser más del 10% superior o

inferior a la tensión nominal indicada en la placa de fábrica, ó

el motor se recalentará, provocando un disparo de la

sobrecarga y reduciendo la vida útil del componente. Si la

tensión es menor del 90% o mayor del 110% de la tensión

nominal cuando el motor esté marchando a toda carga,

consulte con la empresa de energía.

Conexión a tierra/Metalización eléctrica

Instale, conecte a tierra, empalme y conecte los cables del

motor conforme a los requerimientos locales o del “National

Electrical Code”.

Motor con conexión permanente a tierra. Use el borne verde a

tierra suministrado debajo de la cubierta del motor o de la

plancha de acceso (Consulte la Figura 3); use los cables del

tamaño y del tipo requeridos por el código. Conecte el borne

de conexión a tierra del motor a la tierra del servicio eléctrico.

La metalización eléctrica del motor se debe hacer a la

estructura de la alberca. Use un conductor de cobre macizo,

tamaño No. 8 AWG (8.4 mm

2

) o mayor. Haga correr el cable

desde la saliente externa de empalme (consulte la Figura 3) a

la vara o malla de refuerzo.

Figura 4B - Ficha de

cambio de voltaje

configurada para 115

Voltios.

Figura 4A - Ficha de

cambio de voltaje

configurada para 230

Voltios.

TABLA I - INFORMACIÓN SOBRE LOS FUSIBLES Y LOS CABLES RECOMENDADOS

Servicio al motor - distancia en pies (metros)

Tamaño AWG del cable (mm2)

HP Branch fuse Max Load Voltaje/ 0-100' 101-200' 201-300'

Modelo del motor rating amps* Amps Hz/Fase (0-30) (30-60) (60-90)

MPRA6B-202L

1/3 15/15 4.2/2.1 115/230/60/1 14/14(2/2) 14/14(2/2) 12/14(3/2)

1750 RPM

* Se recomienda usar fusibles temporizados en lugar de fusibles estándar en cualquier circuito de motor.

Page 19

7

Conecte un cable de empalme de cobre macizo No. 8 AWG

(8.4 mm

2

) al conector del cable de presión suministrado en la

caja del motor y a todas las partes metálicas de la alberca, el

jacuzzi o el baño termal, y a todo equipo eléctrico, tubería

metálica o conducto dentro de una distancia de 5 pies (1.5 m)

de los muros interiores de la alberca, el jacuzzi o el baño

termal.

Cableado

AVISO: Los modelos trifásicos requieren arranques de motor

magnéticos y protección externa contra sobrecarga. En caso de

duda sobre el procedimiento, consulte a un electricista

certificado.

La bomba debe estar permanentemente conectada al circuito.

La Tabla 1, página 6, indica los tamaños correctos de los

cables y disyuntores para la

bomba sola. Si se conectan

otras luces o aparatos

electrodomésticos al mismo

circuito, asegúrese de agregar

las cargas de amperaje a la

carga de amperaje de la bomba

antes de determinar los tamaños

correctos para los cables y

disyuntores.

(Si no está seguro o está

confundido, consulte a un

electricista certificado.) Use el

disyuntor de carga como

interruptor maestro de

encendido y apagado.

Instale un disyuntor de escape a

tierra (“GFCI”) en el circuito; éste detectará un cortocircuito a

tierra y desconectará la corriente eléctrica antes de que resulte

peligroso para los usuarios de la alberca. Consulte las

instrucciones del fabricante para determinar el tamaño del

GFCI requerido y los procedimientos de verificación del GFCI.

En caso de un corte de corriente, verifique que el GFCI no se

haya disparado (lo cual impediría un funcionamiento normal de

la bomba). Reposicione de ser necesario.

AVISO: Si no usa un conducto para cablear el motor, verifique

que la abertura del cable en el extremo del motor esté cerrada

herméticamente para impedir la entrada de suciedad, insectos,

etc.

Riesgo de choque eléctrico peligroso o

fatal. Verifique que la alimentación eléctrica al circuito del

motor esté desconectada antes de trabajar con los cables, las

conexiones de los cables o con el motor. Vuelva a colocar la

cubierta del motor y las cubiertas de los otros cables antes de

activar la alimentación eléctrica.

1. Desconecte la alimentación eléctrica.

2. Saque la cubierta del motor.

Cómo cablear un motor de una sola velocidad

y un sólo voltaje

Hay dos bornes marcados L1 y L2. Conecte los conductores

de alimentación a estos bornes. Cualquiera de los cables se

puede conectar a cualquier de los bornes.

Cómo cablear un motor de doble voltaje

Los motores de doble voltaje tienen una ficha para cambiar de

230 voltios (graduación de fábrica) a 115 voltios.

1. Si usted tiene una tensión de suministro del motor de 230

voltios, verifique que la ficha esté configurada para 230

voltios. La flecha en la ficha indicará a la posición de 230

voltios. Observe que la ficha sólo se puede conectar con

una de las puntas en esta posición.

2. Si tiene un suministro de 115 voltios, empuje la ficha

directamente hacia arriba y colóquela en las dos puntas de

latón según se ilustra.

NOTA: La flecha está realzada para mayor claridad.

ADVERTENCIA

Aspiración peligrosa.

Puede atrapar el

cabello o partes del

cuerpo, provocando

lesiones graves o

muerte.

No bloquee la

aspiración.

ADVERTENCIA

Page 20

8

OPERACIÓN

AVISO: NUNCA haga marchar la

bomba en seco, ya que eso

puede dañar los sellos,

provocando fugas e

inundaciones. Llene la bomba

con agua antes de encender el

motor.

Antes de

retirar la cubierta del colector:

1. DETENGA LA BOMBA antes

de continuar.

2. CIERRE LAS VÁLVULAS DE

COMPUERTA en las tuberías

de aspiración y de descarga.

3. LIBERE TODA LA PRESIÓN

de la bomba y del sistema de

tubería.

Si la bomba está pasando una prueba de presión,

verifique que se haya liberado la presión antes de retirar

la cubierta del sifón.

No bloquee la aspiración de la bomba. Si se bloquea con

el cuerpo, puede provocar lesiones graves o fatales.

Cuando niños pequeños usen la alberca, es importante que

SIEMPRE estén bajo la estricta supervisión de un adulto.

Peligro de incendio y quemaduras. Los

motores modernos funcionan a altas temperaturas. Para

reducir el peligro de incendio, no permita que hojas,

escombros o partículas extrañas se acumulen alrededor del

motor de la bomba. Para evitar quemaduras cuando se trabaje

con el motor, deje que éste se enfríe durante unos 20 minutos

antes de manipularlo. Un interruptor interno de corte

automático protege al motor contra daños térmicos durante su

funcionamiento.

Cebado de la bomba

Libere toda la presión del filtro, de la bomba y del sistema de

tubería; consulte el manual del propietario.

En un sistema de aspiración inundado (la fuente de agua está

a un nivel más alto que la bomba), la bomba se cebará por sí

misma cuando se abran las válvulas de aspiración y de

descarga.

Si la bomba no está en un sistema de aspiración inundado,

destornille y retire la cubierta del colector (consulte la Figura

5); llene el colector y la bomba con agua.

Limpie e inspeccione el aro tórico, vuelva a colocar la cubierta

del colector.

No lubrique el aro tórico de la cubierta del sifón. El aro tórico

original de la máquina contiene un lubricante interno

permanente.

AVISO: Si reemplaza el aro tórico con uno sin lubricación interna,

es posible que necesite aplicar un lubricante a base de silicona.

Vuelva a colocar la cubierta del colector en el colector; gire hacia

la derecha para apretar la cubierta.

AVISO: ¡Apriete la cubierta del colector a mano solamente (sin

llaves de tuerca)!

Ahora la bomba se deberá cebar. El tiempo de cebado

dependerá del largo vertical de la altura de aspiración y del largo

horizontal de la tubería de aspiración.

Si la bomba no ceba, verifique que todas las válvulas estén

abiertas, que el extremo de la tubería de aspiración se encuentre

debajo del agua, que la bomba no esté tratando de levantar agua

a más de 5 pies (1.5 m) de altura, y que no haya fugas en la

tubería de aspiración. Consulte la Guía para la Localización de

Fallas, Página 11.

Almacenamiento/Preparación para el invierno:

AVISO: ¡Si permite que la bomba se congele, la bomba sufrirá

daños y la garantía quedará anulada!

AVISO: No use soluciones anticongelantes (excepto

propilenglicol) en su sistema de alberca/jacuzzi. El

propilenglicol, “anticongelante RV” no es tóxico y no dañará los

componentes plásticos del sistema, otros anticongelantes son

muy tóxicos y pueden dañar los componentes plásticos en el

sistema.

Drene toda el agua de la bomba y de la tubería cuando espere

temperaturas heladas o cuando guarde la bomba por un

tiempo prolongado (consulte las instrucciones a continuación).

Mantenga el motor seco y cubierto durante el almacenamiento.

Para evitar problemas de

condensación / corrosión, no

cubra la bomba con plástico.

Para instalaciones no protegidas

/ al exterior:

1. Encierre todo el sistema en un

recinto a prueba de la

intemperie.

2. Para evitar daños debido a

condensación / corrosión,

asegúrese de que haya

ventilación; no envuelva el

sistema en plástico.

3. Use una solución de 40%

propilenglicol/60% agua,

para proteger la bomba a

temperaturas de -50° F

(-46° C).

Drenaje de la bomba

Peligro de explosión. La purga del

sistema con aire comprimido puede hacer que explote, con el

peligro de lesiones graves o muerte a cualquiera que se

encuentre cerca. Use sólo un soplador de gran volumen a baja

presión (debajo de 5 PSI), cuando purgue el aire de la bomba,

del filtro o de la tubería.1. Baje el nivel del agua por debajo de

todos los orificios de admisión a la alberca.

Para evitar el riesgo de choques eléctricos peligrosos o

fatales, desconecte la alimentación eléctrica al motor

antes de drenar la bomba.

ADVERTENCIA

Tensión peligrosa.

Puede provocar choques

eléctricos, quemaduras o

muerte.

Desconecte la alimentación

eléctrica antes de trabajar

con la bomba o con el

motor.

Figura 6 – Use una barra o una tabla de apalancar

según se ilustra, para sacar una tapa apretada. No use

una barra de apalancar para apretar la tapa.

ADVERTENCIA

Tensión peligrosa.

Puede provocar choques

eléctricos, quemaduras o

muerte.

Desconecte la alimentación

eléctrica antes de trabajar

con la bomba o con el

motor.

ADVERTENCIA

ADVERTENCIA

ADVERTENCIA

Page 21

9

2. Saque la cubierta del sifón y use aire a baja presión para

soplar el agua acumulada del sistema de tubería. Use una

barra o una tabla de apalancar para sacar las cubiertas del

colectorque estén demasiado apretadas o se hayan

atascado y no se puedan sacar con la mano. La tapa del

colector tiene salientes para poder usar una palanca o una

barra de apalancar (consulte la Figura 6).

3. Tape la tubería de admisión después de drenar para

mantener el agua fuera de los caños.

4. Para impedir que la bomba se congele, saque la cubierta

del colector y drene la unidad del tanque a través de los

dos tapones de drenaje provistos.

A. Drene el sistema lo más posible por gravedad.

B. Proteja las áreas que retienen agua con un

anticongelante de propilenglicol que no sea tóxico

(anticongelante “RV”).

5. Limpie la bomba a fondo y vuelva a colocar la cubierta del

colector.

AVISO: Apriete la cubierta del colector a mano solamente

(¡sin llaves de tuerca)! Si la bomba no está anclada, ¡tenga

cuidado de no romper los caños sujetos a la misma!

6. Asegúrese de que el motor se mantenga seco y cubierto.

Arranque para máquinas preparadas para el

invierno

1. Retire toda protección provisoria contra la intemperie que

se haya colocado alrededor del sistema para el período de

inactividad.

2. Siga las instrucciones del fabricante del filtro para reactivar

el filtro.

3. Inspeccione todos los cables eléctricos y verifique que no

se hayan dañado o deteriorado durante el período de

inactividad. Haga que un técnico de servicio competente

repare todos los cables que así lo requieran.

4. Inspeccione y ajuste todas las conexiones herméticas.

5. Abra todas las válvulas en las tuberías de aspiración y de

regreso.

6. Saque todos los tapones de preparación para el invierno

del sistema de tuberías.

7. Drene todo el anticongelante del sistema.

8. Cierre todas las válvulas de drenaje y reemplace todos los

tapones de drenaje en el sistema de tuberías.

9. Cebe la bomba según las instrucciones que aparecen en

la página 7.

SERVICIO DE LA BOMBA

El servicio de la bomba debe ser realizado solamente por

personas competentes.

Para obtener los mejores resultados, use sólo repuestos

genuinos de fábrica de Sta-Rite.

Asegúrese de cebar la bomba (página 7) antes de encenderla.

Antes de

retirar la cubierta del sifón:

1. DETENGA LA BOMBA

antes de continuar.

2. CIERRE LAS VÁLVULAS DE COMPUERTA en las

tuberías de aspiración y de descarga.

3. LIBERE TODA LA PRESIÓN de la bomba y del sistema de

tuberías.

Para evitar el riesgo de choques eléctricos peligrosos o

fatales, desconecte la alimentación eléctrica al motor

antes de drenar la bomba.

Exceptuando la lubricación del aro tórico de la cubierta del

colector, no se necesita realizar ningún tipo de lubricación y

mantenimiento habitual fuera del cuidado razonable y de la

limpieza periódica de la cesta colectora.Si el sello del eje está

gastado o averiado, repárelo de la siguiente manera:

Desensamblaje de la bomba /

Remoción del sello viejo

Desconecte la alimentación eléctrica al motor de la bomba.

Asegúrese de que las válvulas en las tuberías de

aspiración y de regreso estén cerradas antes de

comenzar a trabajar.

Libere toda la presión abriendo todos los orificios de

ventilación antes de comenzar a trabajar.

1. Drene la bomba, sacando los tapones de drenaje en la parte

inferior de la unidad de la bomba y de la unidad del colector.

2. Verifique que no haya presión en la unidad del colector;

saque la cubierta (destornille girando hacia la izquierda).

3. Saque las 6 tuercas, las arandelas de fijación y las

arandelas planas, sujetando la plancha de estanqueidad a

la unidad de la bomba. Jale y saque la plancha de

estanqueidad y el motor de la unidad de la bomba. (Puede

ser necesario usar un destornillador CUIDADOSAMENTE

para separar la unidad de la plancha de estanqueidad).

4. Saque los siete tornillos y arandelas que sujetan el difusor

a la plancha de estanqueidad. Saque el difusor.

Polished

Figura 8

Superficie pulida

Superficie

de caucho

Figura 7

Sello mecánico asiento de cerámica

Mechanical seal

ceramic seat

surface

PRECAUCIÓN

Rubber

surface

Page 22

10

Clave Descripción MPRA6B-143L

No. de la pieza Cantidad 1/3 HP

1 Motor, 115/230V 1750 RPM 1 62003-2088

2 Tornillo #10-32 x 1/2” 1 U30-692SS

3 Saliente de empalme 1 U17-568

4 Deflector 1 17351-0009

5 Plancha de estanqueidad 1 C3-184P

6 Cordón anular de la plancha de estanqueidad 1 U9-373

7 Sello del eje 1 37400-0027S

8 Impulsor 1 C105-236PDA

8A O-Ring Gasket 1 33455-1047

8B Impeller Screw 1 37337-6080

9 Difusor 1 C1-270P

10 Aro tórico del difusor 1 U9-374

11 Unidad de tanque y colector (solamente) 1 C76-71P

12 Cubierta del colector 1 17307-01111

13 Aro tórico de la cubierta del colector 1 35505-1440

14 Cesta del colector 1 C8-58P

15A Tapón de drenaje 2 U178-920P

15B Tornillo de montaje de 5/16-14 x 5/8” 2 U30-919SS

16 Base 1 C4-77P

17 Cojinete del motor 1 C35-45

18 Tornillo #8-32 x 7/8” cabeza redonda 7 U30-542SS

19 Arandela de fijación #8 diente alargado 7 U43-21SS

20 Arandela plana de 3/8” 6 U43-62SS

21 Arandela de fijación 3/8” 6 U43-12SS

22 Tuerca de 3/8-16 Hexagonal. Latón chapado en níquel 6 71403

23 Tornillos prisioneros de 3/8-16 x 1” Hexagonales 4 U30-74SS

• Placa de fábrica 1 32155-4071

• Etiqueta, “PRECAUCIÓN Esta bomba viene 1 U63-13

equipada con un sello de eje mecánico …”

• Etiqueta de tensión (voltaje) 1 U27-153

• Calcomanía “tapa de sifón demasiado apretada …” 1 U27-644

• Etiqueta, “ADVERTENCIA/PRECAUCIÓN/Instrucciones...” 1 C63-12

• No se ilustra.

LISTA DE PIEZAS PARA REPARACIONES

Paquete 188 con juego de unión de

1/2 corredizo de 2”

Note that this kit includes both inlet

and outlet connections.

Incluye:

Collarín de unión U11-200PS - Qty 2

Aro tórico U9-362 - Qty 2

Adaptador U11-196PS

corredizo de 2” - Qty 2

Cuadro A

24

23

1

2

3

4

22

21

5

20

6

19

15B

Ver Cuadro A

7

8

8A

8B

18

17

16

9

10

11

12

13

14

15A

Ver Cuadro A

Page 23

11

5. Saque el techo del motor. Teniendo cuidado de no tocar los

bornes del capacitor, afloje la abrazadera del capacitor y

muévalo a un lado.

6. Sostenga el eje con una llave abierta de 7/16” en los filos del

eje del motor.

7. Destornille el impulsor del eje (gire hacia la izquierda frente al

mismo).

AVISO: En el modelo de 2 HP, saque el tornillo del impulsor

(rosca izquierda - gire hacia la derecha) y la empaquetadura

antes de sacar el impulsor. Verifique que la empaquetadura

no esté averiada, que no tenga rajaduras, etc. Cámbiela si

está averiada.

8. Saque los cuatro tornillos que sostienen la plancha de

estanqueidad al motor.

9. Coloque la plancha de estanqueidad boca abajo sobre una

superficie plana y golpetee el asiento de cerámica para

sacarlo (Figura 7).

10. Saque el deflector del eje del motor y verifique que no esté

averiado ni tenga abrasión.

11. Limpie la cavidad del sello en la plancha de estanqueidad y

limpie el eje del motor.

Re-ensamblaje de la bomba /

Instalación de un sello nuevo

1. El asiento de cerámica debe estar limpio y sin suciedad,

grasa, polvo, etc. Humedezca el borde exterior con una

pequeña cantidad de detergente líquido, oprima el asiento de

cerámica en la cavidad de la plancha de estanqueidad

firmemente haciendo presión con el dedo (Figura 8).

2. Si el asiento de cerámica no encaja debidamente, sáquelo,

colóquelo boca arriba sobre un banco y vuelva a limpiar la

cavidad. El asiento de cerámica ahora deberá encajar

debidamente.

3. Si el asiento aún no encaja debidamente, coloque una

arandela de cartón sobre la superficie pulida y use un trozo

de caño estándar de 3/4” (19 mm) para hacer presión.

AVISO: Asegúrese de no rayar ni estropear la superficie o el

sello goteará.

4. Reemplace el deflector en el extremo del eje del motor de

manera que el manguito del impulsor lo empuje en posición.

Si se observan señales de desgaste o avería en el deflector,

cámbielo.

5. Vuelva a instalar la plancha de estanqueidad en el motor.

Apriete los pernos a una torsión de 60-80 pulgada/libra

(69-92 kg/cm).

6. Aplique una pequeña cantidad de detergente líquido en el

diámetro interior de la mitad giratoria del sello.

7. Deslice la unidad giratoria del sello, con la superficie de carbón

hacia afuera, sobre el manguito del impulsor hasta que el aro

accionador de caucho toque la parte posterior del impulsor.

AVISO: Asegúrese de no cortar ni rayar la superficie pulida

del sello, ya que el sello goteará con una superficie dañada.

8. Atornille el impulsor en el eje (hacia la derecha); esto colocará

el sello automáticamente en la plancha de estanqueidad.

AVISO: En los modelos de 2 y 2-1/2 HP, instale la

empaquetadura del impulsor y el tornillo de sujeción (rosca

izquierda - gire hacia la izquierda). La torsión del tornillo de

sujeción debe ser de 50-55 pulgada/libra (57.6-63 kg/cm).

9. Monte el difusor sobre la plancha de estanqueidad;

apriete los tornillos a una torsión de 10-14 pulgada/libra

(11.2-16.1 kg/cm).

10. Ensamble el motor y la plancha

de estanqueidad a la unidad de la

bomba con tuercas, arandelas

planas y arandelas de

fijación. La torsión de las tuercas

debe ser de 120-130

pulgada/libra (138-150 kg/cm).

11. Cebe la bomba según las

instrucciones que aparecen en la

página 7.

GUÍA DE

LOCALIZACIÓN

DE FALLAS

¡Es importante leer y

comprender las instrucciones

de seguridad y de operación en este

manual antes de realizar trabajos en

la bomba!

¡Las pruebas eléctricas del

motor de esta bomba deben ser

realizadas solamente por personas competentes!

NO BOMBEA; CAPACIDAD O PRESIÓN DE DESCARGA

REDUCIDA

Fugas en la aspiración / pérdida de cebadura:

1. Es necesario cebar la bomba; verifique que la voluta y el

colector de la bomba estén llenos de agua. Consulte las

instrucciones de cebadura, Página 7.

2. Verifique que no haya fugas en la tubería de aspiración.

3. Verifique que la admisión de la tubería de aspiración esté

bien por debajo del nivel del agua para impedir que la bomba

aspire aire.

4. Si la empaquetadura del colector de aspiración es

defectuosa, cámbiela.

5. Verifique que la bomba no esté tratando de levantar agua a

una altura mayor de 10’ (3 m).

6. Verifique que la tubería de aspiración tenga un diámetro

mínimo de 2” (51 mm).

Tubería/colector/impulsor tapado, impulsor gastado:

7. Verifique que el colector de aspiración no esté tapado, de lo

contrario, limpie el colector y el colador.

8. Verifique que impulsor no esté tapado (siga los pasos 1 al 7

en la sección “Remoción del sello viejo”, Página 9; verifique

que el impulsor no esté tapado; siga los pasos 7 al 11 en la

sección de “Instalación del nuevo sello”, Página 9, para reensamblar).

9. Es posible que el Impulsor y el difusor estén gastados. De

ser así, encargue piezas de repuesto de la Lista de Piezas

para Reparaciones, página 10.

ADVERTENCIA

Tensión peligrosa.

Puede provocar choques

eléctricos, quemaduras o

muerte.

Desconecte la alimentación

eléctrica antes de trabajar

con la bomba o con el

motor.

Page 24

Soporte Técnico

Sanford, North Carolina (8 A.M. a las 5 P.M. Horario del Este y Pacifico)

Moorpark, California (8 A.M. a las 5 P.M. Horario del Este y Pacifico)

Phone: (800) 831-7133

Fax (800) 284-4151

Pagina de internet: visite www.pentairpool.com y staritepool.com

S752 Rev B (10-07-09)

Loading...

Loading...