Page 1

125Y SERIES

STRAINERS

125Y SERIES

BRONZE, CAST IRON Y STRAINERS

NPT, SWEAT ENDS, FLANGED

PRESSURES TO 200 PSIG (13.8 BARG)

T

EMPERATURES TO 450°F (232°C)

●ANSI 125# rated strainers

●NPT, SE and FF flanges in accordance with ASME 16.1

and 16.15

●One piece cast body

●Upper and lower machined seats

●Generous screen area and properly proportioned

straining chamber to minimize intial pressure drop

while maximizing time between cleanings.

MODELS

●125Y1T - Bronze, NPT, Threaded Cover

●125Y1E - Bronze, Sweat Ends, Threaded Cover

●125Y2F - Cast Iron, Flanged, Bolted Cover

- 384 -

0100-125Y1TB- A2__

12345678910111213141516

Inlet Size Model

Add’l

Dash

Body Dash Perf

Mesh

Require-

Material ments

125Y Series Ordering Code

Dash - Position 5

Model - Position 6 - 11

125Y1T

125Y1E

125Y2F

Body Material -

Position 12

I - Cast Iron

B - Bronze

Dash - Position 13

Mesh

1, 2

- Position 15

Leave Blank If Not

Required (std Y2F)

1 - 10

2 - 20

3 - 30

4 - 40

5 - 50

6 - 60

7 - 80

8 - 100

9 - 120

Add’l Requirements -

Position 16

Leave Blank

If not Required

D - Special Drain Size

F - Silicon Free

G - Special Gaskets

T - Special Testing

X - Oxygen Cleaning

Y - Other and / or

Multiple Specials

Indicate Specials

Clearly On the Order

1. Standard Screens: Y1T, Y1E—20 mesh,

Y2F< 3"—3/64" perf, Y2F>3"—1/8" perf

2. For other screen materials contact factory.

APPLICA TIONS

●Steam, liquid, gas and oil service

●Power industry

●Pulp and paper

●Chemical industry

●Metal & Mining

●Water & Waste

OPTIONS

●Other perforated screens and mesh liners

●Other drain connections and gasket materials

●Oxygen cleaning

●Special internal/external coatings and linings

●Contact factory for other options

APPLICABLE CODES

●ANSI B16.1

● ANSI B16.15

Canadian Registration OEO591.9C for CI 125Y2F

Inlet Size -

Position 1 - 4

0038 -

3

⁄8"

0050 - 1⁄2"

0075 -

3

⁄

4"

0100 - 1"

0125 - 1

1

⁄4"

0150 - 11⁄2"

0200 - 2"

0250 - 2

1

⁄

2"

0300 - 3"

0400 - 4"

0500 - 5"

0600 - 6"

0800 - 8"

1000 - 10"

1200 - 12"

1400 - 14"

1600 - 16"

Perf1- Position 14

304 SS Material

2

A -No Perf

1 - 1/32"

B -3/64"

4 - 1/8"

5 - 3/32"

6 - 3/16"

7 - 7/32"

8 - 1/4"

9 - 3/8"

Page 2

- 385 -

125Y SERIES

STRAINERS

Connections:

3/8" – 3" NPT or Sweat Ends

SCREEN OPENINGS

STANDARD

SIZE SCREEN MATERIALS

3/8" – 3" 20 Mesh 304 SS

125Y1 SERIES

BRONZE Y STRAINERS

NPT, SWEAT ENDS

S

PECIFICATION

Y Strainer shall be straight flow design with NPT or Sweat Ends inlet/outlet

connections. The strainer shall be rated to ANSI 125 PSIG rating in

accordance with ANSI B16.15. The Strainer shall be bronze body and the

screen shall be size ______ mesh 304 SS. The strainer shall be have an

inlet size of ______ and Open Area Ratio of _______. The Y Strainer shall

be SSI 125Y1 Series.

MATERIALS OF

CONSTRUCTION

Body ……………………………………………………Bronze B584

Cover ……………………………………………………Bronze B584

Screen1…………………………………………………304 SS Mesh

Plug………………………………………………………Bronze B584

Gasket1…………………………………………………Garlock 2900

1. Recommended Spare Parts

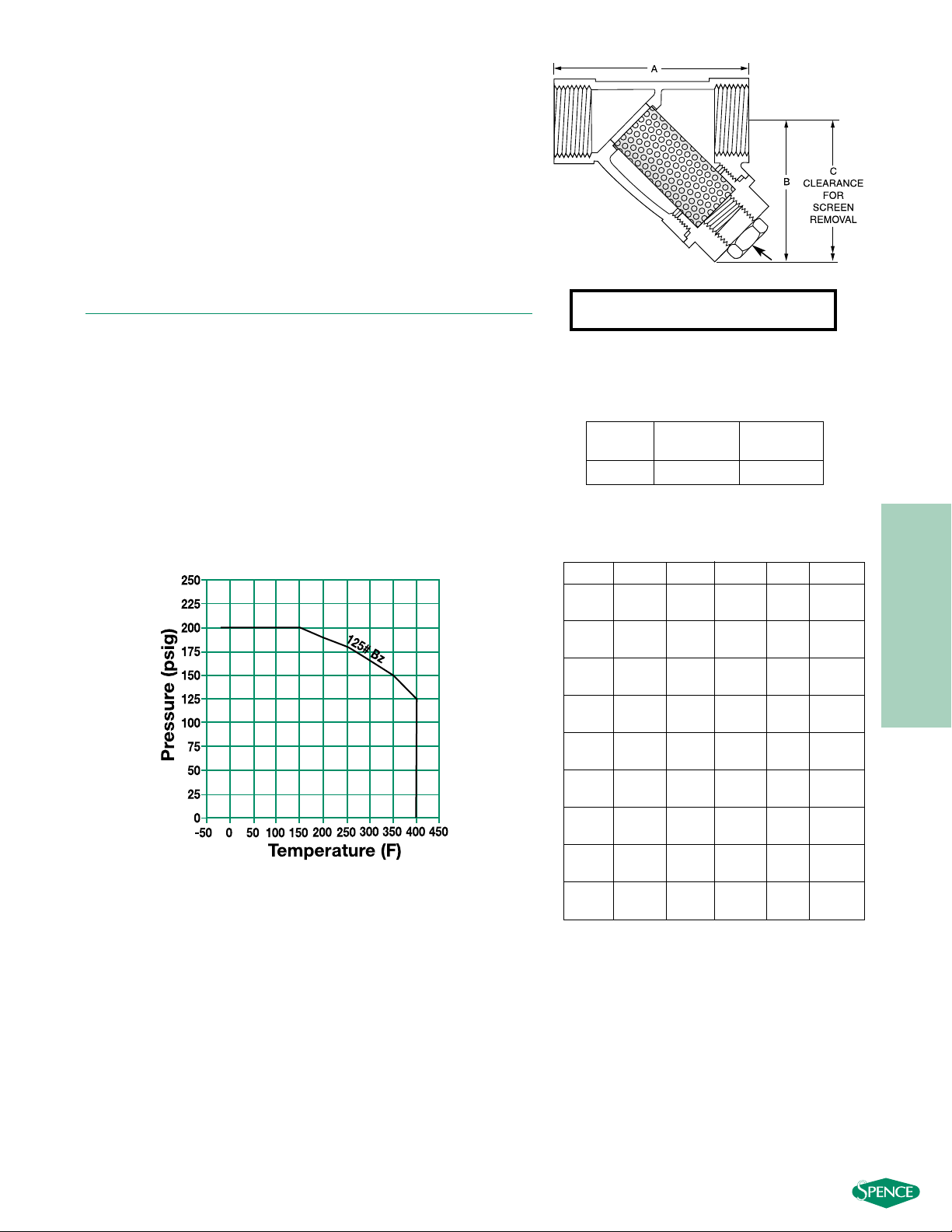

SIZE A B C E WEIGHT

3

⁄

8 3

1

⁄

4 2

1

⁄

8 3

1

⁄

2

3

⁄

8 .8

(10) (82) (55) (89) (10) (.36)

1

⁄

2 3

1

⁄

4 2

1

⁄

8 3

1

⁄

2

3

⁄

8 1.0

(15) (82) (55) (89) (10) (.25)

3

⁄

4 42

3

⁄

4 4

1

⁄

2

3

⁄

8 1.2

(20) (100) (70) (114) (10) (.60)

14

1

⁄

2 35

1

⁄

2 1.6

(25) (115) (75) (127) (15) (.73)

11⁄4 53⁄8 39⁄16 53⁄4

1

⁄2 2.5

(32) (136) (90) (146) (15) (1.1)

11⁄2 65⁄16 37⁄8 63⁄8

1

⁄2 3.4

(40) (160) (98) (162) (15) (1.6)

27

1

⁄2 57⁄16 91⁄16

1

⁄2 5.8

(50) (191) (138) (230) (15) (2.6)

21⁄2 91⁄16 515⁄16 10

1

⁄2 10.2

(65) (230) (151) (254) (15) (4.6)

310

3

⁄16 65⁄16 103⁄8

1

⁄2 13.7

(80) (259) (160) (264) (15) (6.2)

DIMENSIONS inches (mm)

AND WEIGHTS pounds (kg)

Dimensions shown are subject to change. Consult

factory for certified drawings when required.

PRESSURE/TEMPERATURE CHART

ANSI B16.15

E-NPT

Note: For Buttweld sizes please indicate pipe

schedule on the order.

Page 3

- 386 -

125Y SERIES

STRAINERS

Connections:

2" – 16" FF Flanged

SCREEN OPENINGS

STANDARD

SIZE SCREEN MATERIALS

2" – 3" 3/64" Perf 304 SS

4" – 16" 1/8" Perf 304 SS

125Y2 SERIES

CAST IRON Y STRAINERS FLANGED

SPECIFICATION

Y Strainer shall be straight flow design with FF Flanged inlet/outlet

connections. The strainer shall be rated to ANSI 125 PSIG rating in

accordance with ANSI B16.1. The Strainer shall be Cast Iron body and

the screen shall be size ______ perforated 304 SS. The strainer shall be

have an inlet size of ______ and Open Area Ratio of _______. The Y

Strainer shall be SSI 125Y2 Series.

MATERIALS OF

CONSTRUCTION

Body ………………………………………………Cast Iron A126-B

Cover ………………………………………………Cast Iron A126-B

Screen1…………………………………………………………304 SS

Plug …………………………………………………Cast Iron A126-B

Gasket1………………………………………………………Graphite

Bolt/Stud2………………………………………………………A307-B

Nut2………………………………………………………………A563

1. Recommended Spare Parts

2. Materials of equivalent strength may be substituted

SIZE A B C D E WEIGHT

28

7

⁄8 61⁄8 81⁄2 2

1

⁄2 22

(50) (226) (156) (216) (51) (15) (10)

21⁄2 103⁄4 81⁄16 111⁄4 21⁄2 135

(65) (273) (205) (286) (64) (25) (16)

311

5

⁄8 81⁄2 121⁄4 3143

(80) (295) (216) (311) (76) (25) (20)

413

7

⁄8 95⁄8 133⁄8 4175

(100) (353) (245) (340) (102) (25) (34)

516

3

⁄8 115⁄8 161⁄8 51

1

⁄4 115

(125) (416) (295) (410) (127) (32) (52)

618

1

⁄2 125⁄8 1711⁄16 61

1

⁄2 154

(150) (470) (321) (449) (152) (40) (70)

821

3

⁄8 163⁄8 23 8 11⁄2 243

(200) (543) (416) (584) (203) (40) (110)

10 26 191⁄8 2611⁄16 10 2 390

(250) (660) (486) (678) (254) (50) (117)

12 30 221⁄16 31 12 2 650

(300) (762) (559) (787) (305) (50) (295)

14 373⁄8 3011⁄16 41 14 2 815

(350) (949) (780) (1041) (356) (50) (370)

16 421⁄2 331⁄16 46 16 2 1224

(400) (1080) (840) (1168) (406) (50) (555)

DIMENSIONS inches (mm)

AND WEIGHTS pounds (kg)

Dimensions shown are subject to change. Consult factory for

certified drawings when required.

PRESSURE/TEMPERATURE CHART

ASME B16.1

C

A

D

B

Page 4

- 387 -

125Y SERIES

STRAINERS

125Y SERIES BRONZE, CAST IRON

PRESSURE DROP VS FLOW RATE

Water Service, Clean Basket, 1/32" - 1/4" Perforated Screen*

(Sizes 3⁄8

" - 1

1

⁄2

")

* For Gas, Steam or Air service, consult factory.

(Sizes 2" - 16")

Steam Service Pressure Drop

Page 433

Correction Factors for Other Viscous

Liquids and/or Mesh Liners Page 432

Correction Factors for

Clogged Screens Page 432

10

1

PRESSURE DROP (PSIG)

0.1

0.1 1 10 100

3/8”

FLOW RATE (GPM)

1/2”

”

1-1/4

1-1/2”

3/4”

1”

10

14”

16

”

1

PRESSURE DROP (PSIG)

0.1

2-1/2”

3”

4”

5”

6”

8”

2”

10

”

12”

10 100 1000 10000

FLOW RATE (GPM)

Loading...

Loading...