Page 1

PUMP

PROTECTION

- 168 -

125T SERIES

CAST IRON TRIPLE DUTY VALVES

Pressures to 200 PSIG (13.8 barg)

Temperatures to 212°F (100°C)

● Triple function includes a spring loaded silent

check valve, balancing valve and shutoff valve

to minimize cost and reduce installation time

● Operates automatically and silently

● Center guided soft seal disc ensures leak

free performance

● Spring loaded Buna N disc provides no impact

shutoff and prevents water hammer upon

closing

●Graduated position indicator provides accurate

visual check of valve position

●Standard handwheel for ease of operation

●Cracking pressure of 1/4 PSI

●Drain and differential connections with plug are

furnished as standard

MODELS

●125TFI – Cast Iron Triple Duty Valve

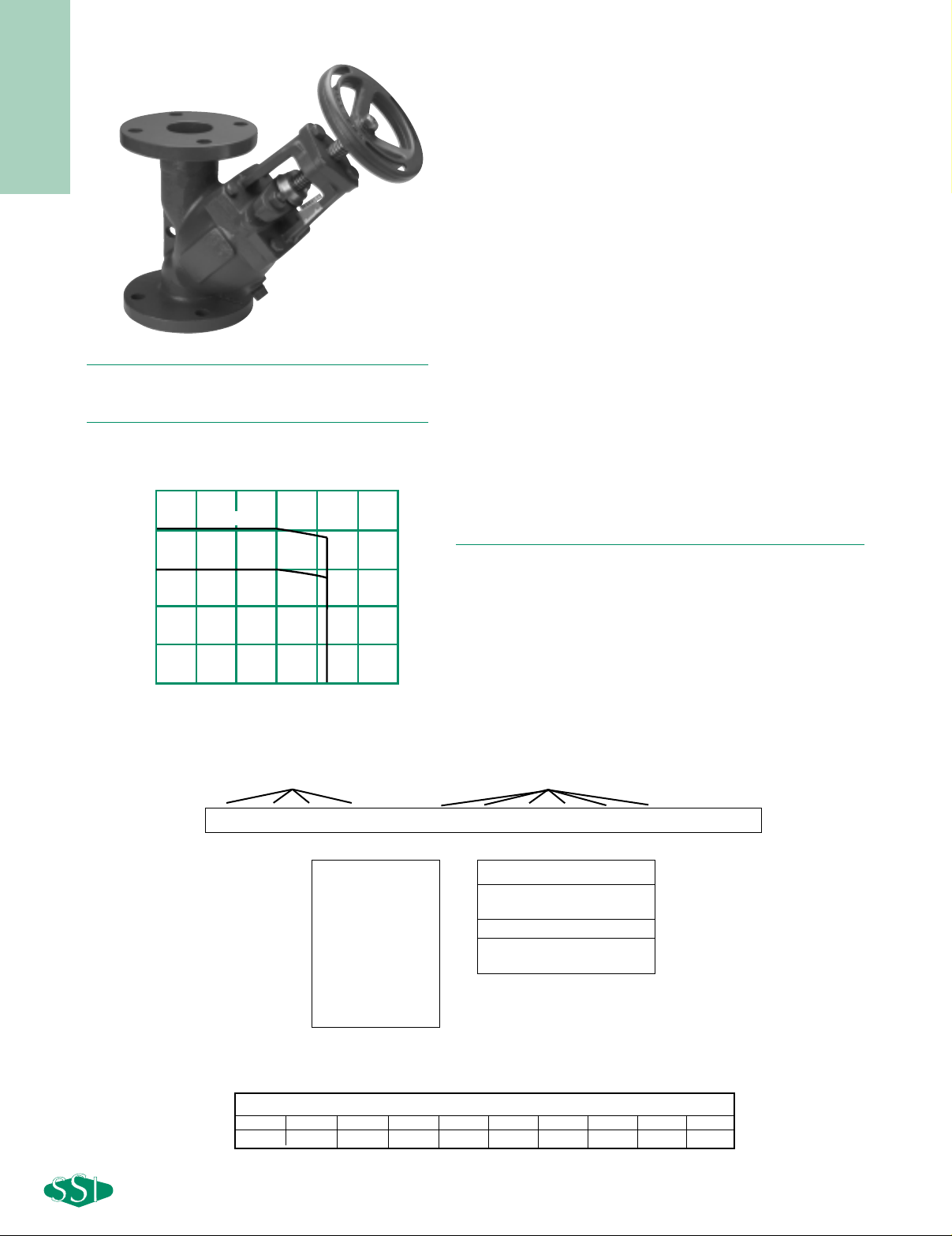

PRESSURE/TEMPERATURE CHART

0400 -125TFI-B

Triple Duty Valve Ordering Code

1 2 3 4 5 6 7 8 9 10 11 12 13

Size Dash Model Dash O-Ring

Size - Position 1-4

0200 - 2”

0250 - 2

1

⁄2”

0300 - 3”

0400 - 4”

0500 - 5”

0600 - 6”

0800 - 8”

1000 - 10”

1200 - 12”

Dash - Position 5

Model - Position 6 -11

125TFI - Triple Duty Valve

Dash - Position 12

O-Ring - Position 13

B - Buna N

For any variations, use the part numbering system above but clearly indicate the additional requirement.

Valve Size

2 2-1/2 3 4 5 6 8 10 12 14

83 129 189 335 529 766 1372 2154 3106 4016

MAXIMUM RATED FLOW COEFFICIENTS (Cv)*

* Maximum Cv rating is at 100% of stem rise.

APPLICA TIONS

●Pump protection

APPLICABLE CODES

(Designed in accordance with)

●ASME B16.1

250

200

150

2"-12"

14"

100

50

Buna N

Pressure (psig)

0

0 50 100 150 200 250 300

Temperature (F)

Page 2

PUMP

PROTECTION

- 169 -

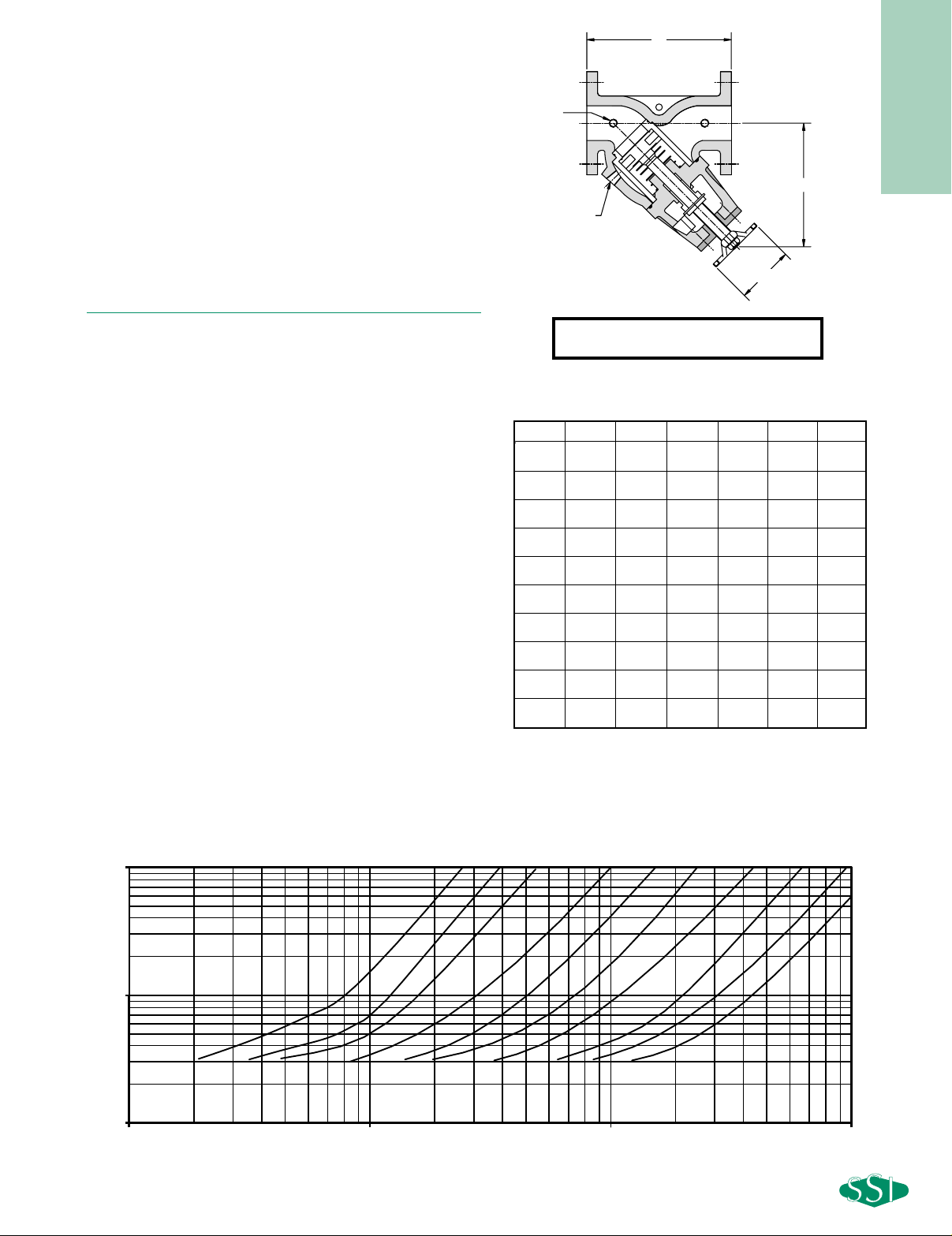

DIMENSIONS inches (mm)

AND WEIGHTS pounds (kg)

Size A B C D E Weight

28

3

⁄

8 9

5

⁄

8 6

5

⁄

16 1/2 1/4 34

(50) (213) (244) (159) (15) (8) (15)

21⁄

2 9

13

⁄

16 10 6

5

⁄

16 1/2 1/4 40

(65) (250) (254) (159) (15) (8) (18)

31010

1

⁄

8 9

3

⁄

8 1/2 1/4 50

(80) (254) (257) (238) (15) (8) (23)

414

1

⁄

2 12

5

⁄

8 9

3

⁄

8 1/2 1/4 100

(100) (368) (321) (238) (15) (8) (45)

51616

3

⁄

8 11 1/2 1/4 155

(125) (407) (416) (279) (15) (8) (70)

61817

1

⁄

2 11 3/4 1/4 200

(150) (457) (444) (279) (20) (8) (91)

821

1

⁄

2 18

1

⁄

2 12

1

⁄

2 3/4 1/4 350

(200) (546) (470) (317) (20) (8) (159)

10 251⁄

2 21

11

⁄

16 12

1

⁄

2 1 1/4 480

(250) (648) (552) (317) (25) (8) (218)

12 30 241⁄

2 12

1

⁄

2 1 1/4 660

(300) (762) (622) (317) (25) (8) (299)

14 303⁄

8 24

1

⁄

2 12

1

⁄

2 1 1/4 790

(350) (771) (622) (317) (25) (8) (359)

Connections:

2" - 14" FF Flanged

125T SERIES

CAST IRON TRIPLE DUTY VALVES

SPECIFICATION

Triple Duty Valve shall install in a straight run of pipe and perform

as a center guided silent check valve, shutoff valve and balancing

valve. The valve shall have ______ psi cracking pressure. The

valve shall have Cast Iron ASME Class 125 FF flanges. The seat

shall have Buna N O-ring seals. The valve shall be an inlet size of

______ and a Cv rating of ______ . The Triple Duty Valve shall be

SSI T Series.

MATERIALS OF C

ONSTRUCTION

Body & Yoke ……………………………Cast Iron A126-B

Disc Guide ………………………Ductile Iron/Nickel Plate

Disc ……………………………………………Ductile Iron

Packing Gland …………………………………Ductile Iron

Packing ……………………………………………Graphite

Spring ………………………………………Stainless Steel

Stem …………………………………………Stainless Steel

Seat Seal ……………………………………………Buna N

Disc Seal ……………………………………………Buna N

Dimensions and Weights are appr oximate. Contact factory for

Certified Drawings.

Dimensions shown are in full open position.

PRESSURE DROP VS FLOW RATE

A

B

C

D

E

(NPT)

(Sizes 2" - 14")

10

1

PRESSURE DROP (PSID)

0.1

10

2"

100

3"

2.5"

FLOW RATE (GPM)

5"4"

1000

10" 12" 14"8"6"

10000

Loading...

Loading...