Page 1

THE PARKER DESIGN

The Parker water tube design

offers an extremely efficient, reliable steam boiler built for the long

term and ease of maintenance.

The Parker design offers many

advantages. Compare ours to the

competition.

ADVANTAGES

1. Safety

Our ASME tube bundle is extremely flexible and offers a long life

with a 25 year warranty against

thermal shock. No Parker Boiler

has ever been known to experience an internal explosion.

LOW NOx PREMIX

INDUSTRIAL PACKAGED STEAM BOILER

Horizontal Drum Sectional Water Tube

7-25 HP Gas Fired

103L Steam Boilers 7-25 HP

Low NOx Premix

Industrial Packaged

Steam Boiler

Pressures to

250 PSI

2. Low NOx System

Parker was the first manufacturer

to achieve SCAQMD Rule 1146.2

NOx Certification. Initial installations began in 1991 and to date

thousands of Low NOx boilers are

on-line providing reliable operation for our customers.

3. Durable Low NOx Burners

Parker heavy duty premix metal

fiber burners not only provide the

lowest emissions possible but also

provide long durable service life.

4. VFD

Variable Speed Blowers for electrical energy savings on 2-Stage

or Modulating units (standard over

15HP).

5. Low Cost, Efficient Operation

The staggered tubing design provides a multi-baffled heating sur-

face to increase efficiency. The

Premix system offers precise fuel

air control for optimum efficiency.

6. Fast Heat-Up

Our boiler requires less than ten

minutes to heat up to 100 PSI from

a cold start which is a considerable time and fuel saver.

7. Accessible Internal

Inspection

Cabinet doors can easily be

removed in a matter of minutes,

making the internal boiler, drum,

tubes, and burners readily accessible. Easy to remove gasketed

access plugs are provided at both

ends of every tube. Boiler inspections can be accomplished quickly

and at low costs.

SCAQMD

Certified

to 1146.2

8. Ease of Inspection and Repair

Any boiler may eventually require

re-tubing depending on care and

operating conditions. Re-tubing

does not require special tools,

skills or welding as is necessary

on most boilers designed with

rolled tubes.

103L Steam Boilers 7-25 HP

PARKER BOILER CO.

5930 Bandini Boulevard

Los Angeles, CA 90040

Tel (323) 727-9800

Fax (323) 722-2848

www.parkerboiler.com

BROCHURE 103L 0E7

"Never a Compromise for Quality or Safety" "Never a Compromise for Quality or Safety"

Page 2

LOW NOx PREMIX

INDUSTRIAL PACKAGED STEAM BOILER

Horizontal Drum Sectional Water Tube

7-25 HP Gas Fired

103L Steam Boilers 7-25 HP

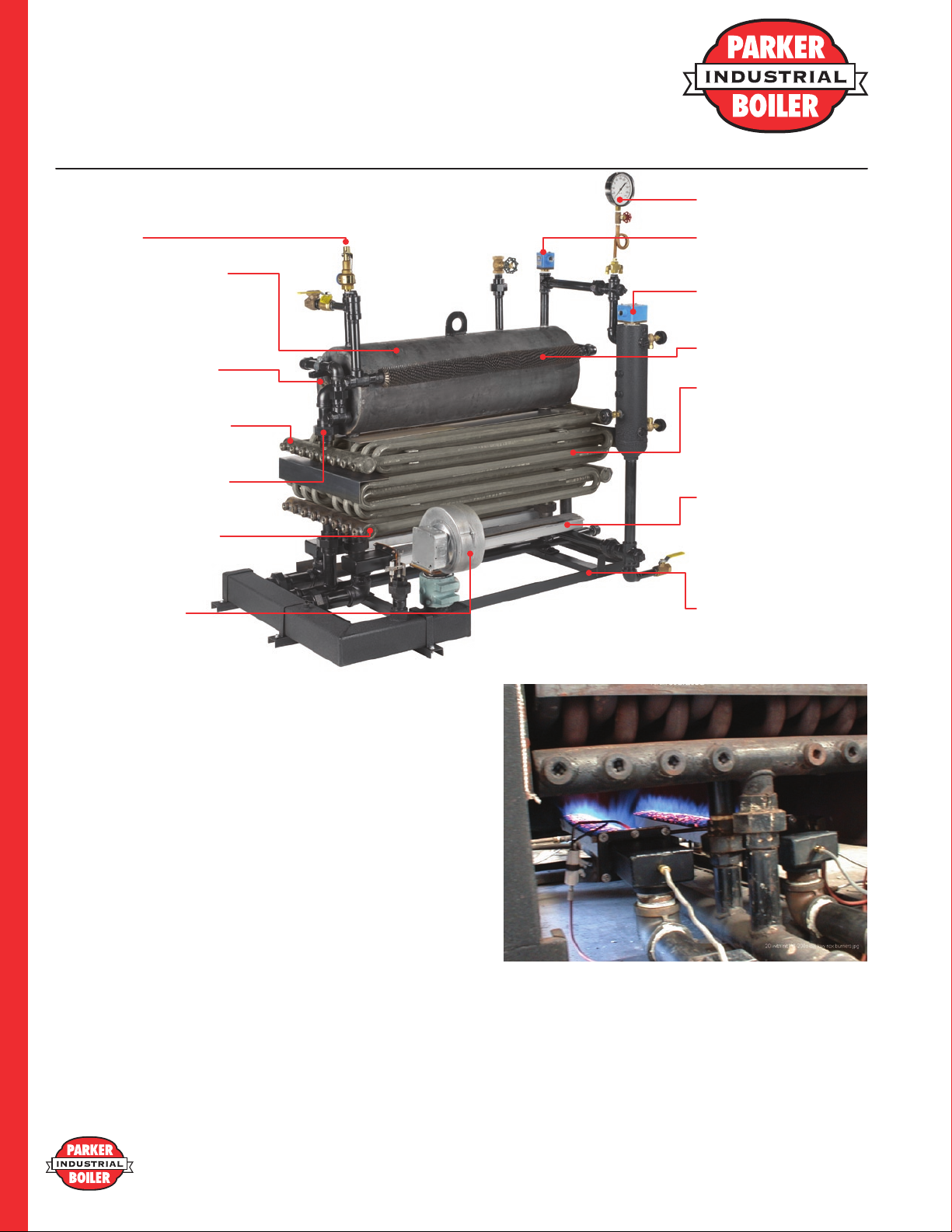

Safety Valve

Horizontal steam drum extra

heavy seamless 1/2” thick

steel, over 60,000 PSI tensile

strength

Drum inspection openings

both heads

Easy to remove access plugs

on each end of the tube

Sectional tubes removable by

disconnecting two unions

Tubes: 1-5/16” OD, heavy 1/8”

thickness, double welded to

headers

Premix blower/mixer

Pressure gauge

Secondary, M.R. probe type

low water cutoff

Water level pump control &

primary low water cutoff

Pre-heater

Staggered tubes flexibly

designed for free expansion

and contraction provide

8-pass self-baffled heating

surface

Efficient Parker premix

metal-fiber gas burners

provide high combustion

efficiency and uniform heat

distribution

Heavy Steel Boiler frame for

setting on concrete floor

THE PARKER DESIGN

A time proven product backed by

one of the largest and most successful manufacturers of packaged steam boilers whose name

is synonymous with quality and

safety. Every boiler is thoroughly

factory fire tested and is required

to meet the highest standards in

all places of mechanical and operating efficiency before shipment.

9. Codes

All boilers are built in accordance

with the ASME Power & Heating Boiler Codes, Sections I & IV.

Boilers above 15 PSI are furnished

with the “S” Stamp and Trim.

Boilers for 15 PSI are normally

furnished with the “H” Stamp and

Trim. All Boilers are inspected

103L Steam Boilers 7-25 HP

and registered with the National

Board of Boiler and Pressure Vessel Inspectors. All individual gas

and electrical controls are Certified or UL Listed. All Low NOx,

outdoor, propane and natural gas

fired models are ETL Listed as

“Industrial and Commercial Gas

Fired Packaged Boilers” and certified to UL795.

All units are provided with trim

and controls to meet ASME CSD-1

standards for “Controls & Safety

Devices for Automatically Fired

Boilers”. In addition, all units also

meet the standards of the International Conference of Building Officials, the International Association

of Mechanical & Plumbing Officials and the Uniform Mechanical

Code.

Parker's Premix Metal Fiber Burner System

Shown burning and achieving better than 12ppm NOx. Standard

units achieve 20-30ppm NOx as required by SCAQMD.

PARKER BOILER CO.

5930 Bandini Boulevard

Los Angeles, CA 90040

Tel (323) 727-9800

Fax (323) 722-2848

www.parkerboiler.com

BROCHURE 103L 0E7

Loading...

Loading...