Page 1

FIGURE 50 SERIES

- 236 -

FIGURE 50 SERIES SAFETY VALVE

APPLICA TION DATA

●Bulk Hauling Truck Tank Trailers

●Bulk Hauling Railroad Tank Cars

●Storage Vessels for Powdered Solids (flour, cement, etc.)

VALVE RATINGS

Pressure Temperature

Model PSIG (bar) °F (°C)

All 10 to 30 -20 to 225

(.7 to 2.1) (-29 to 107)

APPLICABLE CODES

●ASME Section VIII “UV” for Air (Figure 51 & 53 only - 15 PSI

or higher)

●Canadian Registration #0G0591.9C

FIGURE 50 SERIES

SIZES 2"

PRESSURES to 30 PSIG at 225°F

●Air, Gas, Vapors and Powdered Solids

●High Capacity

●Tamper Proof Spring Setting

●Weatherproof

●Spring Chamber Isolated from Process

Fluid

●Soft Seat Seal

●Bronze or Aluminum Body

●“UV” National Board Certified

MODELS

●0050 - Bronze Body, Viton Soft Seat

●0051 - Pull Ring on 0050

●0052 - Aluminum Body, Viton Soft Seat

●0053 - Pull Ring on 0052

0052ZHZ-015

CODE SELECTION CHART

12345678910

Model Orifice Inlet Connec- – Set Pressure

Size tions

Orifice -

Position 5

Z

Inlet Size -

Position 6

H= 2

Connections -

Position 7

Z

Set Pressure -

Position 8, 9 & 10

__ __ __ = Actual Setting

LAS - Loosely Assembled

†

Model -

Position 1, 2, 3 & 4

0050= Bronze Body, Viton Soft Seat

0051= Pull Ring on 0050

0052= Aluminum Body, Viton Soft Seat

0053= Pull Ring on 0052

†Spence Certified Assemblers Only

Page 2

FIGURE 50 SERIES

- 237 -

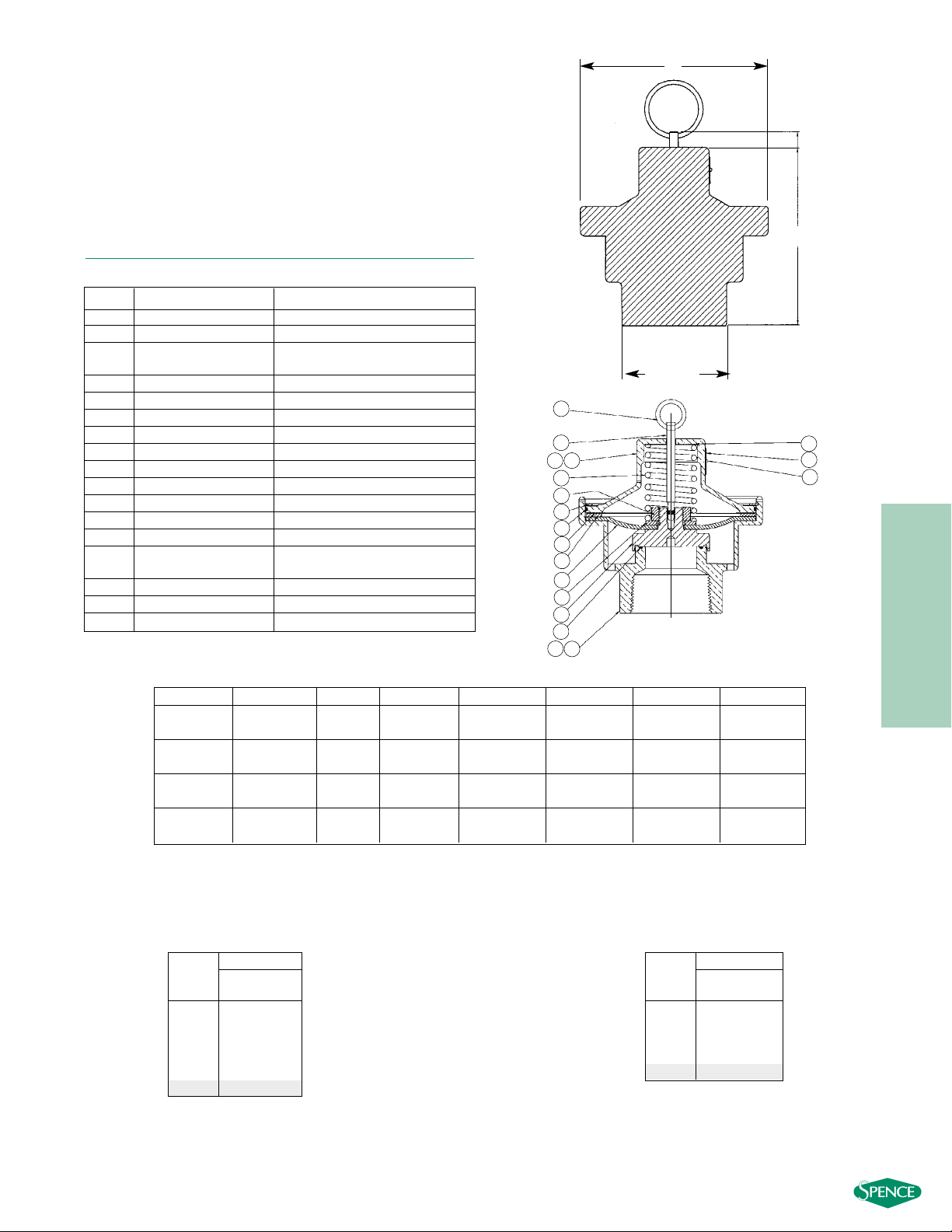

FIGURE 50 SERIES

SPECIFICATION

The valve shall meet the ASME Section VIII Code for air services.

It shall be “UV” National Board Certified. The valve setting shall be

tamper resistant. The valve shall be weatherproof and the

diaphragm shall completely seal the spring chamber from the

process fluid. The valve shall have an O-ring seat seal for tight

shutoff.

MATERIALS OF

CONSTRUCTION

A

AIR CAPACITY CHART –

MODELS 0050, 0051, 0052, 0053

ASME Section VIII “UV” 90% rated at 10% Slope SCFM (NM3/HR)

Set Orifice Area, in

2

Pressure

2.011

PSIG

10* 637

15 752

20 867

25 982

30 1097

1.0 25.3

Set Orifice Area cm

2

Pressure

12.97

Barg

0.6* 1082

0.8* 1278

1.0* 1473

1.2 1669

0.1 43.0

SCFM

NM

3

/HR

Model Inlet Orifice Outlet A B E Weight

0050ZHZ 2 Z Atmosphere 5

3

⁄32 53⁄8 37

(50) (129) (136) (76) (3.2)

0051ZHZ 2 Z Atmosphere 6 53⁄8 37

(50) (152) (136) (76) (3.2)

0052ZHZ 2 Z Atmosphere 53⁄32 53⁄8 33

(50) (129) (136) (76) (1.4)

0053ZHZ 2 Z Atmosphere 6 53⁄8 33

(50) (152) (136) (76) (1.4)

DIMENSIONS* inches (mm) AND WEIGHTS pounds (kg)

Ref Part Name Material

1 Pull Ring SST

3 Spindle (0051/0053) Steel ASTM A108. 12L14

4A Cover Bronze ASTM B62

4B Cover Aluminum ASTM B 26, A03560, T6

5 Spring Steel ASTM A228, Plated

6 Disc Nut Steel, Plated

7 Retaining Ring Steel, Plated

8 Weather Seal Viton

9 Wave Spring Steel, Plated

10 Washer Steel, Plated

11 Diaphragm Nylon Reinforced

12 Disc Washer Plated Steel

13 Disc ASTM B16, C36000, H02

14 Seat Seal Viton

15A Body Bronze ASME SB62

15B Body Aluminum ASTM B26, A03560, T6

16 Fender Washer Steel, Plated

17 Nameplate SST

18 Drive Screw SST

B

E HEX

* Pressure settings below 15 PSIG (1.034 barg) are non code.

Lead seal plus SS wire not shown

1

3

5

6

7

8

9

10

11

12

13

14

15A

16

17

18

4A

4B

15B

Loading...

Loading...