Page 1

FIGURE 10 SERIES

- 230 -

FIGURE 10 SERIES SAFETY VALVE

A

PPLICATION D

ATA

●Industrial Low Pressure Steam Heating Boilers

●Commercial Low Pressure Steam Heating Boilers

V

ALVE R

A TINGS

Pressure Temperature

Model PSIG (bar) °F (°C)

All 5 to 15 -20 to 250

(.3 to 1) (-29 to 121)

A

PPLICABLE CODES

●ASME Section IV “HV” for Low Pressure Steam (when set @

15 PSI)

●Canadian Registration #0G0591.9C

FIGURE 10 SERIES

SIZES 3⁄4" – 3"

PRESSURES to 15 PSIG at 250°F

●Meets ASME Section IV Code for Steam

Service

●“HV” National Board Certified

●Low Cost

●High Capacity

●Dependable

●Tight Shutoff

●Sharp Popping and Closing Action

●High Degree of Repeatability

●Unitized Body

MODELS

●0010 - Cast Iron Body, Bronze Seats

0010ZHA-015

CODE SELECTION CHART

12345678910

Model Orifice Inlet Connec- – Set Pressure

Size tions

Inlet Size -

Position 6

D=

3

⁄4

E= 1

F= 1

1

⁄

4

G= 11⁄2

H= 2

J= 2

1

⁄

2

K= 3

Connections -

Position 7

A = MPT x FPT

Set Pressure -

Position 8, 9 & 10

__ __ __ = Actual Setting

Model -

Position 1, 2, 3 & 4

0010= Cast Iron Body, Bronze Seats

Orifice -

Position 5

Z

Page 2

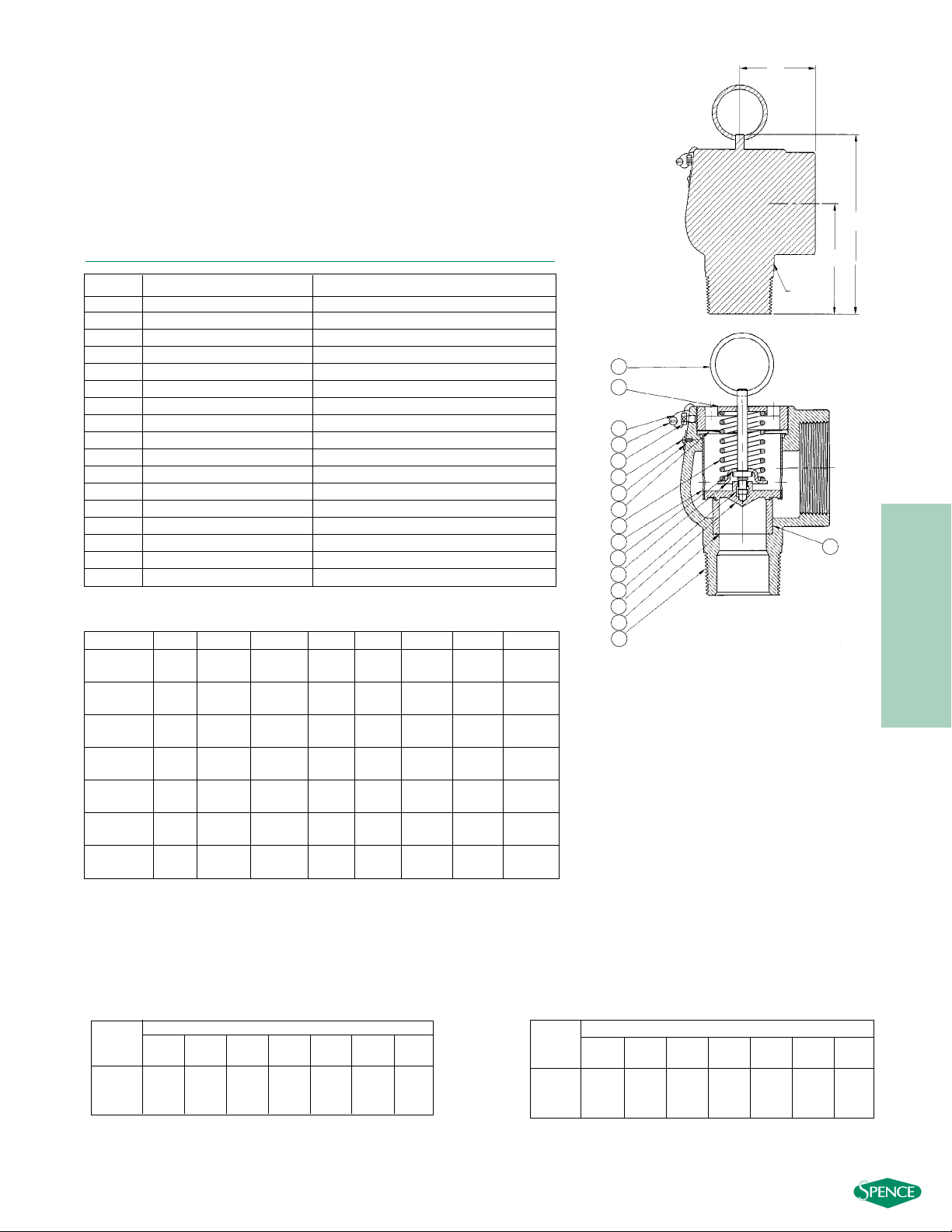

1

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

Model Inlet Orifice Outlet A* B C E Hex Weight

0010ZDA

3

⁄4 Z13

5

⁄16 11⁄2 23⁄16 11⁄4 1

(20) (25) (76) (38) (56) (32) (.4)

0010ZEA 1 Z 1

1

⁄4 422

5

⁄8 11⁄2 2

(25) (32) (95) (51) (67) (38) (.9)

0010ZFA 1

1

⁄4 Z1

1

⁄2 52

1

⁄8 3 17⁄8 3

(32) (40) (108) (54) (76) (48) (1.4)

0010ZGA 1

1

⁄2 Z2 5

1

⁄8 23⁄16 33⁄16 2 4

(40) (50) (117) (56) (81) (51) (1.8)

0010ZHA 2 Z 2

1

⁄2 611⁄16 27⁄8 4 3 8

(50) (65) (156) (73) (102) (76) (3.6)

0010ZJA 2

1

⁄2 Z2

1

⁄2 83⁄8 33⁄8 43⁄8 31⁄4 14

(65) (65) (194) (95) (111) (83) (6.3)

0010ZKA 3 Z 3 9

1

⁄2 37⁄8 51⁄8 4 22

(80) (80) (229) (98) (130) (102) (10)

FIGURE 10 SERIES

- 231 -

FIGURE 10 SERIES

SPECIFICATION

The valve shall meet the ASME Section IV Code for low pressure steam

service. It shall be “HV” National Board Certified. The valve inlet and outlet shall

be one integral casting assuring proper alignment of disc, seat and spindle for

smooth action. The valve shall maintain a high degree of repeatability. The valve

shall be top guided by a disc guide fitted into the body. The valve shall have an

open lever assembly. The valve shall have a non-adjustable blowdown.

MATERIALS OF

CONSTRUCTION

C

A

B

E

HEX

DIMENSIONS inches (mm) AND WEIGHTS pounds (kg)

SATURATED STEAM CAPACITY CHART—

MODEL 0010

ASME Section IV “HV” 90% rated at 33.3% Overpressure** LBS/HR (KGS/HR)

Set Valve & Orifice Area cm

2

Pressure 20 Z 25 25 Z 32 32 Z 40 40 Z 50 50 Z 65 65 Z 65 80 Z 80

Barg 1.78 3.16 4.94 7.14 12.65 19.76 25.58

0.4* 255 452 706 1022 1811 2828 4091

0.7* 321 569 889 1286 2279 3559 5148

1* 387 686 1072 1551 2747 4291 6205

LBS/HR

KGS/HR

* Pressure settings below 15 PSIG (1.034 barg) are non code.

** Pressure settings below 15 PSIG (1 barg) are at 10%

overpressure.

Ref Part Name Material

1 Pull Ring SST

3 Compression Screw Stl. plated CI ASTM A108/A126

4 Seal Wire SST

5 Seal Lead

6 Lock Screw Brass ASTM B16

7 Drive Screw SST

8 Nameplate SST

9 Wave Washer Plated Steel

10 Spring Plated Steel

11 Disc Guide Brass/Bronze ASTM B135/B505

12 Spindle Pin Plated Steel

13 Spring Washer Plated Steel

14 Spindle Steel ASTM A108

15 Disc Brass/Bronze ASTM B16/B62

16 Seat Brass/Bronze ASTM B16/B505

17 Body Cast Iron ASTM A126

18 Sealant Sealant

* Add 1/4" to “A” dimension to allow for lift.

Set Valve & Orifice Area, in

2

Pressure3⁄4 Z 1 1 Z 11⁄4 11⁄4 Z 11⁄2 11⁄2 Z 2 2 Z 21⁄2 21⁄2 Z 21⁄2 3 Z 3

PSIG 0.276 0.49 0.765 1.107 1.961 3.063 4.43

5* 243 431 673 974 1725 2694 3896

10* 318 565 883 1277 2263 3534 5112

15 394 700 1093 1581 2801 4375 6327

Consult Factory for capacities below 5 PSIG

Loading...

Loading...