Page 1

MODEL 860

CAUTION:

• + Power Supply

• - Power Supply

• Signal IN

CONTROLLER

+IN •

COM •

+OUT •

•

+IN

•

COM •

+OUT •

• + Power Supply

• - Power Supply

• - Ctrl Negative

• Ctrl Ground

CONTROLLER

4 to 20 mA Output

TRANSDUCER

INSTALLATION

The Model 860 Pressure Transducer is a

compact instrument for measuring and

controlling the many different media that are

compatible with our sensing element. Positive,

negative, and differential pressures can be

measured in ranges from 0-0.25” WC to 0-15

PSI with 4 standard outputs: 1-5 VDC, 1-6

VDC, 1-10 VDC and 4-20mA. Split ranges and

custom outputs are also available.

INSTALLATION

1. Location- The model 860 pressure

transducer should be placed in as clean, dry and

vibration free a location as possible.

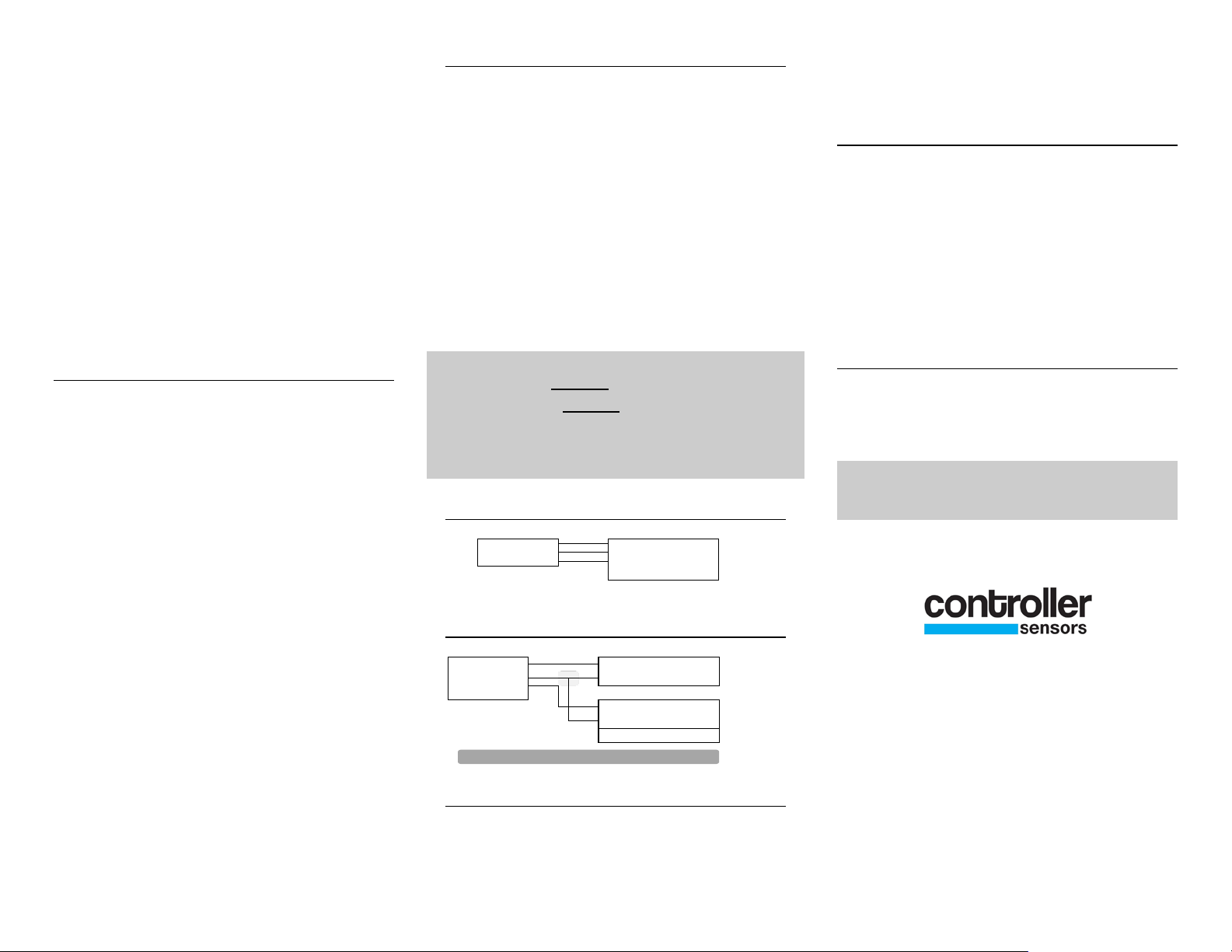

ELECTRICAL CONNECTIONS

All electrical connections to the 860 series

transducer are made to the pluggable screw

terminal block. The block is coded as follows.

1)+IN = Supply Positive, 2)COM = Common

Supply & Signal Negative 3)+OUT = Signal

Out(positive).

An external power supply delivering 12 - 24

VDC/24 VAC with a minimum of 10 mA (or

30mA for a 4-20mA output) is required to drive

the unit. If using a 1-10VDC output, or a 420mA output to drive a 500 ohm load, a

minimum of 18 VDC/24AC is required.

supply voltage. Do not apply voltage to

“+OUT” terminal as permanent damage

will occur.

Do not exceed specified

250 ohm resistor between the “+” and “-”

controller input terminals. This will safely

convert the 4-20mA signal to the desired

voltage.

OFFSET

The offset of the 860 series transducer is factory

set. If it should need adjustment upon arrival,

the offset pot is located next to the ports on the

end of the unit. With the transducer installed

and no pressure applied place a meter in series

with the supply negative (Ground), and the

signal out. Turn offset adjusting pot to desired

reading.

CUSTOMER SERVICE

If any problems are encountered during

installation please call the number below for

assistance.

2. Pressure Connections- The 860 pressure

transducer uses 2 barbed fittings for use with

1/8” ID vinyl or rubber tubing. Attach tubing

3 WIRE CONNECTION

from positive pressure or higher pressure source

to port marked High (P1) and lower or negative

pressure to opposite port (P2). Arrange tubing

to minimize stress on connections. If possible,

mount with ports facing down to aid in moisture

drainage.

3 WIRE TO 2 WIRE CONNECTION

Note: When removing tubing care should be

used to avoid breaking the ports. In some cases

the tubing should be cut off, rather than pulled

off, especially if stiff tubing is being used

3. Mounting- Attach the Model 860

Transducer to the mounting surface using 2

fasteners inserted through the two mounting

holes located on either the side mounting

flanges, or the holes at the top of the case. Do

not overtighten.

CONVERTING 4-20MA TO 1-5 VDC

860 Series Pressure transducers with a 4-20mA

current output can be easily adapted to

controllers requiring 1-5 VDC input. Insert a

Call 1-800-735-8998

7638 Washington Ave S

Eden Prairie, MN 55344

+1.800.735.8998 • +1.952.942.8743

FAX +1.952.942.8753

www.controllersensors.com

IN-860 Rev A

Loading...

Loading...