Page 1

iGAZE® REP KIT

Transceiver System for 10kΩ, or 8.2kΩ

Resistive Safety Edges

Pulsed output

BI-DIRECTIONAL

COMMUNICATION

Movable Device

TCOO900

INSTRUCTION MANUAL

v.05.24.18

Fixed Device

RCOO900P

Page 2

TRANSCEIVER SYSTEM FOR SAFETY EDGES

TECHNICAL SPECIFICATIONS

Movable device name TCOO900

Fixed device name RCOO900P

Frequency 902-928 Mhz

Range of the system in free space 20 m / 60 feet

TCOO900 power supply 2 x 1.5V batteries (AA)

RCOO900P power supply 12/24 Vac-dc

Battery duration 2 years (normal functioning mode).

Minimum battery level (TCOO900) 1.9V

Compatible safety edges (TCOO900) Resistive (8.2 kΩ / 10kΩ)

Number of outputs (RCOO900P) 2

Maximum number of Transmitters for each

RCOO900P

Maximum number of safety edges for each output 8 for each relay.

Power draw on RCOO900P (24Vdc) 15mA (3-wire or 4-wire pulsed)

Resistive Safety Edge (max value) 5kOhm < R < 20KOhm (safety edge OK)

Frequency for alternate current (RCOO900P) 50-60Hz

Operating Temperature -10°C to +55°C / 14°F to 131°F

5 years (Low power mode).

8 for each device.

50mA (2-wire pulsed)

R<5KOhm (safety edge in short circuit)

R>20KOhm (OPEN safety edge)

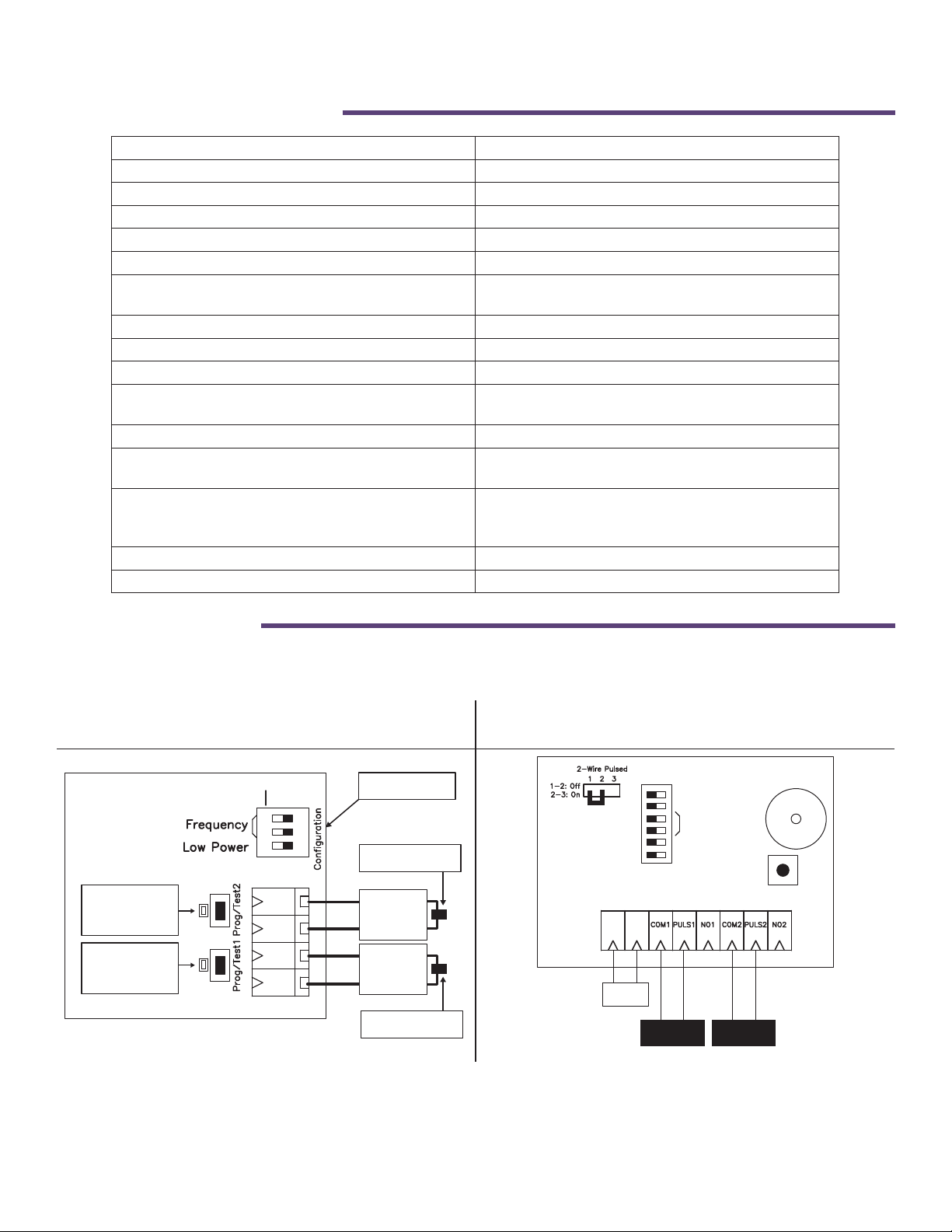

QUICK START GUIDE

BELOW IS THE MOST COMMON INSTALLATION

TCOO900 - Both safety edges are 8.2kΩ or

10kΩ resistive.

Dip switch

OFF

ON

DIP

2 3

Led and

programming /

test key 2

Led and

programming /

test key 1

1

Safety2

Safety1

Resistive edge 2

8.2kΩ / 10kΩ (N.C.)

Resistive

edge 2

Resistive

edge 1

Resistive edge 1

8.2kΩ / 10kΩ (N.C.)

RCOO900P - Pulsed 2 Frequency on both

channels

RCO900P

operator 2

pulsed input

Buzzer

Programming/

Reset key

+

12/24

Vac/Vdc

OFF ON

-

operator 1

pulsed input

2Freq/3Freq

Buzzer OFF

Frequency

Out1 - 10k

Out2 - 10k

2

Page 3

DESCRIPTION

A

The iGAZE® REP transceiver system is intended as a safety device for automated gates and rolling doors. The system is

comprised of 1 fixed device (RC00900P) with 2 pulsed outputs, which is connected to the operator, and up to 8 movable

devices (TC00900) for each relay. The system TCOO900 will accept only resistive safety edge 10kΩ or 8.2kΩ. The

transmission signal is bi-directional and utilizes the frequencies 902-928MHz. Maximum range between the movable and

fixed devices is 60 feet.

TCOO900 is suitable for outdoor use. RCOO900P is suitable for indoor use only (“indoor” means inside the

operator box). The installation of the system must be carried out by a qualified installer.

CONFIGURATION AND ELECTRICAL CONNECTIONS

B

ATTENTION! If external operators or devices are installed, wiring type CL2, CL2P, CL2R or CL2X complying with UL 13 or

other cable with equivalent or better electrical, mechanical, and flammability ratings shall be used.

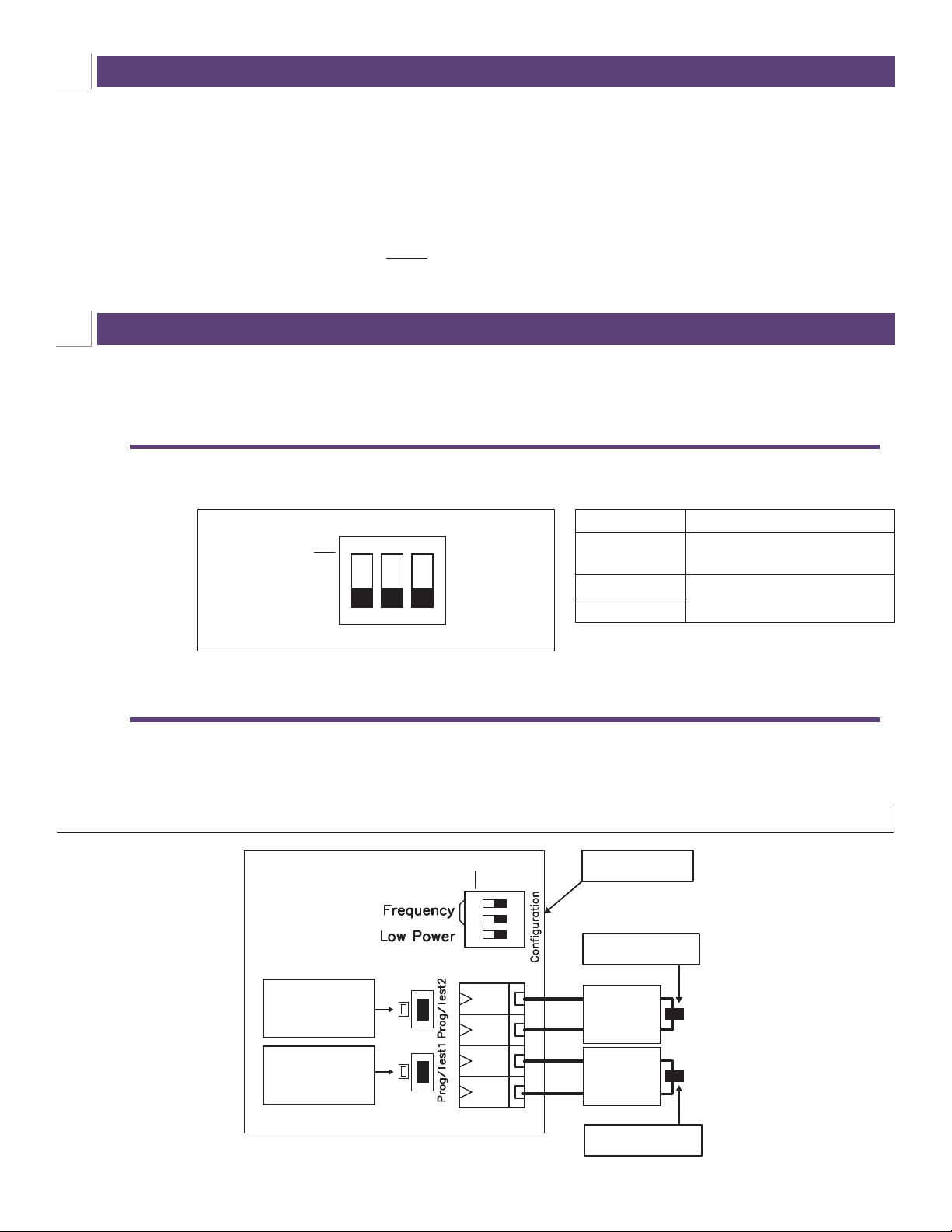

STEP 1

DIP SWITCHES CONFIGURATION OF TCOO900

TCOO900

DIP

ON

OFF

1 2 3

N°DIP Function

Low Power (see section E on

1

page 9)

2

Frequency channel selection

(see page 4)

3

(All switches in example above are set to OFF)

STEP 2

CONNECT THE SAFETY EDGE TO THE SAFETY EDGE MOVABLE DEVICE (TCOO900)

EXAMPLE 1 - Both safety edges are 8.2kΩ or 10kΩ resistive

Dip switch

OFF

ON

DIP

2 3

1

Resistive edge 2

8.2kΩ / 10kΩ (N.C.)

Led and

programming /

test key 2

Led and

programming /

test key 1

Safety2

Safety1

3

Resistive

edge 2

Resistive

edge 1

Resistive edge 1

8.2kΩ / 10kΩ (N.C.)

Page 4

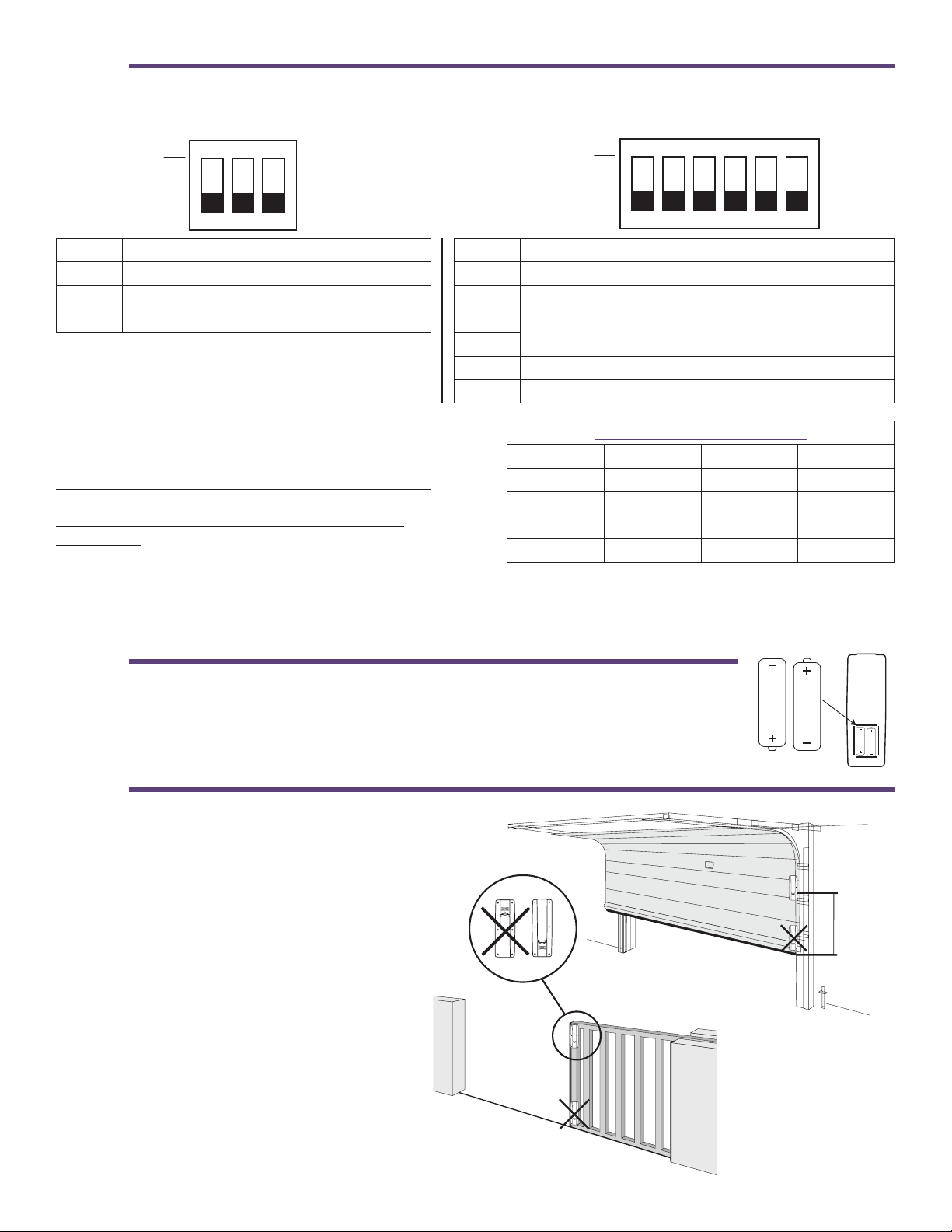

STEP 3

SET DIP SWITCHES 2 AND 3 ON THE TCOO900 AND 3 AND 4 ON THE RCOO900P TO THE SAME SETTINGS.

TCOO900

DIP

ON

OFF

1 2 3

N° DIP Function

1 Low power. (see Section E on page 9)

2

Frequency channel selection

3

It is possible to associate a maximum of 8 TCOO900

to each RCOO900P.

WARNING: for a correct functioning of the system,

every TCOO900 must have the frequency dip

switch set the same way as the corresponding

RCOO900P.

RCOO900P

DIP

ON

OFF

1 2 3

N° DIP Function

1 2 Freq / 3 Freq

2 Buzzer ON / OFF

3

Frequency channel selection

4

5 Out1 type: N.O. contact (OFF) or 10k signal (ON) 1

6 Out2 type: N.O. contact (OFF) or 10k signal (ON) 2

Frequency channel selection

Channel Dip 3 (2) Dip 4 (3) Frequency

1 OFF OFF 912.900

2 OFF ON 914.900

3 ON OFF 916.900

4 ON ON 918.900

4 5 6

On a safety system with more than one Receiver, to avoid interference, we recommend the use of dierent frequency

settings on each set of a RCOO900P and the associated TCOO900.

STEP 4

POWER THE TCOO900 BY INSTALLING THE TWO AA BATTERIES (1.5V) INTO THE

BATTERY HOLDER. PLEASE NOTE THE CORRECT POLARITY.

1.5V

1.5V

STEP 5

MOUNT THE TCOO900 AS HIGH AS POSSIBLE

AND IN SUCH A WAY AS THERE ARE NO

OBSTACLES IN THE DIRECTION OF THE

RCOO900P AND IN SUCH A WAY AS THE

MAXIMUM DISTANCE BETWEEN THE TWO

DEVICES IS LESS THAN 60 FEET (MAX 20

METERS / 60 FEET).

WARNING: install the TCOO900 at a minimum

height of 8” from the ground.

Keep the installation area clean of debris which

can eect the normal operation of the system.

Height

min: 8”

NOTE: Transmitter Solutions is not responsible for

any damage caused by an improper, incorrect, or

unintended use of the product.

Height min: 8”

4

Page 5

STEP 6

MOUNT THE RCOO900P AS CLOSE AS POSSIBLE TO THE TCOO900. IF MOUNTED TO A WALL, USE SUITABLE

SCREWS AND ANCHORS TO SECURE THE RCOO900P.

STEP 7

DEPENDING ON THE TYPE OF SIGNAL REQUIRED, CONNECT THE OUTPUTS AS EXPLAINED IN THE

FOLLOWING EXAMPLES.

WARNING: The power supply for the receiver must be an insulated transformer to protect against short circuits

NOTE: The signals given on the outputs 1 and 2 are a N.O. contact, resistive output (10kΩ) or pulsed output, depending on

the setting of dip switches 5 and 6, and the wiring connection.

NOTE: The level of acoustic noise generated by the device is less than 70 dBA.

EXAMPLE 1 - Pulsed 2 Frequency on both channels EXAMPLE 2 - Pulsed 2-wire on channel 1 and pulsed

4-wire on channel 2

+

12/24

Vac/Vdc

OFF ON

-

operator 1

pulsed input

2Freq/3Freq

Buzzer OFF

Frequency

Out1 - 10k

Out2 - 10k

pulsed input

RCO900P

operator 2

Buzzer

Programming/

Reset key

OFF ON

+

-

12/24Vdc

Power / Signal

Operator 1

2-wire pulsed

2Freq/3Freq

Buzzer OFF

Frequency

Out1 - 10k

Out2 - 10k

RCO900P

Programming/

Reset key

not connected

Signal

Operator 2

4-wire pulsed

Buzzer

Power

5

Page 6

EXAMPLE 3 - Pulsed 4-wire on both channels EXAMPLE 4 - Pulsed 3-wire on both channels

RCO900P

Programming/

Reset key

not connected

Signal

Operator 2

4-wire pulsed

Buzzer

Power

+

-

12/24 Vac/Vdc

Power

Operator 1

4-wire pulsed

OFF ON

2Freq/3Freq

Buzzer OFF

Frequency

Out1 - 10k

Out2 - 10k

Signal

EXAMPLE 5 - Pulsed 2-wire on channel 1 and 10k on

channel 2

RCO900P

COM Signal

POWER

12/24 Vac/Vdc

Operator 2

3-wire pulsed

Buzzer

Programming/

Reset key

+

-

COM Signal

POWER

12/24 Vac/Vdc

Operator 1

3-wire pulsed

OFF ON

2Freq/3Freq

Buzzer OFF

Frequency

Out1 - 10k

Out2 - 10k

EXAMPLE 6 - Pulsed 4-wire on channel 1 and N.O. on

channel 2

OFF ON

+

-

Power / Signal

12/24Vdc

Operator 1

2-wire pulsed

2Freq/3Freq

Buzzer OFF

Frequency

Out1 - 10k

Out2 - 10k

RCO900P

Programming/

Reset key

Resistive input

10k

Operator 2

10k

Buzzer

OFF ON

+

-

Power

12/24

Vdc/Vac

Operator 1

4-wire pulsed

2Freq/3Freq

Buzzer OFF

Frequency

Out1 - 10k

Out2 - 10k

Signal

RCO900P

Buzzer

Programming/

Reset key

N.O. contact

input

Operator 2

N.O.

STEP 8 STEP 9

MOUNT THE IGAZE® REP RCOO900P POWER THE RCOO900P WITH 12-24 VAC/DC

INSULATED POWER SUPPLY (NOT INCLUDED WITH

THE IGAZE® REP KIT).

6

Page 7

PROGRAMMING

C

STEP 10

PROGRAM THE TCOO900 TO THE RCOO900P ACCORDING TO THE FOLLOWING INSTRUCTIONS:

PROGRAMMING OF THE MOVABLE DEVICE ON CHANNEL 1 OUTPUT OF THE FIXED DEVICE

1

2

3

4

5

To enter more TCOO900 in the RCOO900P, repeat the operation from step 2. (on page 3)

(*) If you hear 4 BEEPS, it means that the maximum number of safety edges for the selected channel has been reached

and that no new devices on the same channel output can be memorized.

NOTE: When the TCOO900 is used with two connected safety edges, it is necessary to carry out the learning process

two times, one for each input.

WARNING: The same output of the TCOO900 can be memorized on both output channels. To erase the memorized input it is necessary to perform a complete reset of the RCOO900P (see page 8).

Check that the DIP 2 and 3 of the TCOO900 and DIP 3 and 4 of the RCOO900P

are set the same way.

Press and keep pressed the programming/ reset button on the RCOO900P. RCOO900P emits 1 BEEP.

Release the programming/reset button on the RCOO900P

Press and keep pressed the programming/reset button on the TCOO900 relative to

the used input. Prog./Test1 for safety edge 1, Prog/Test2 for safety edge 2.

Release the programming/reset button on the TCOO900. Programming has succeeded

PROGRAMMING OF THE TRANSMITTER ON CHANNEL 2 OUTPUT OF THE FIXED DEVICE

RCOO900P emits 2 BEEPS. (*)

1

2

3

4

5

To enter more TCOO900 in the RCOO900P, repeat the operation from step 2. (on page 3)

(*) If you hear 4 BEEPS, it means that the maximum number of safety edges for the selected channel has been reached

and that no new devices on the same channel output can be memorized.

NOTE: When the TCOO900 is used with two connected safety edges, it is necessary to carry out the learning process

two times, one for each input.

WARNING: The same output of the TCOO900 can be memorized on both RCOO900P output channels. To erase

the memorized input it is necessary to perform a complete reset of the RCOO900P (see page 8).

Check that the DIP 4 and 5 of the TCOO900 and DIP 3 and 4 of the RCOO900P

are set the same way.

Press and keep pressed the programming/ reset button on the RCOO900P.

Release the programming/reset button on the RCOO900P

Press and keep pressed the programming/reset button on the TCOO900 relative to

the used input. Prog./Test1 for safety edge 1, Prog/Test2 for safety edge 2.

Release the programming/reset button on the TCOO900. Programming has succeeded

7

RCOO900P emits 1 BEEP.

RCOO900P emits 2 BEEPS.

RCOO900P emits 2 BEEPS. (*)

Page 8

STEP 11

TEST THAT THE PROGRAMMING OF THE MOVABLE DEVICE WAS SUCCESSFUL.

On each TCOO900, two buttons, labeled “programming/test key”, and two leds are present. Pushing the programming

button of the edge to test during normal functioning (so not in programming) produces a signal that is sent to the

RCOO900P activates the output channel and responds to this signal with:

Acoustic signaling during the normal functioning

Number of BEEP/

BLINK

1 Regular functioning, no mistake found. -

2 One or more safety edges faulty. Check the safety edge connections

3 One or more 8.2k / 10k resistive edges disconnected. Check the resistive edges connected

4 Battery level low. Substitute the batteries of the indicted device

5 Low battery. Replace the batteries

6 One or more associated devices disconnected Check each associated device

NOTE: If one TCOO900 is in the alarm state and it is necessary to open or close the operating device, press

and keep pressed the programming / test button of the TCOO900 in alarm at the same time the operating

device is activated to open or close.

Meaning What to do

STEP 12

VERIFY THE CORRECT FUNCTION OF EACH SAFETY EDGE, MOVABLE AND FIXED DEVICES WITH

THE OPERATOR INSTALLED.

RECEIVER RESET

D

Using the program/reset key, it is possible to erase all TCOO900 that are programmed into the RCOO900P.

NOTE: This proceedure resets all memory to factory defaults.

1

2

3

4

5

Press and keep pressed the programming / reset button on the RCOO900P. RCOO900P emits 1 BEEP

DO NOT RELEASE the programming/reset button on the RCOO900P. RCOO900P emits 2 BEEPS

DO NOT RELEASE the programming/reset button on the RCOO900P.

DO NOT RELEASE the programming/reset button on the RCOO900P.

Release the programming/reset button on the RCOO900P

RCOO900P emits a series of

rapid BEEPS.

RCOO900P emits a continuous

BEEP

RCOO900P emits 6 BEEPS. The

reset is complete.

8

Page 9

ENERGY SAVING (LOW POWER)

E

With the dip switch set to low power it is important to remember that the TCOO900 will only check in with the

RCOO900P every 15 seconds. If a power failure (dead battery) were to occur during this 15 second interval,

the RCOO900P will only signal an alarm after the 15 second interval has been reached.

TCOO900 Dip switch 1 set ON: (Low power activated) state of the transmitter is checked every 15 seconds.

TCOO900 Dip switch 1 set OFF: (Low power deactivated) state of the transmitter is checked each second.

FCC COMPLIANCE

F

FCC ID: SU7TCO900 and SU7RCOO900P

This device complies with part 15 of the fcc rules. Operation is subject to the following two conditions: (1) this device

may not cause harmful interference, and (2) this device must accept any interference received, including interference that

may cause undesired operation.

IMPORTANT! Any changes or modifications not expressly approved by the party responsible for compliance could void

the user’s authority to operate this equipment.

FCC Radiation Exposure Statement

This equipment complies with FCC RF radiation exposure limits set forth for an uncontrolled environment. This equipment

should be installed and operated with a minimum distance of 20 centimeters between the radiator and your body.

This transmitter must not be co-located or operating in conjunction with any other antenna or transmitter.

The antennas used for this transmitter must be installed to provide a separation distance of at least 20 cm from all persons

and must not be co-located or operating in conjunction with any other antenna or transmitter.

9

Page 10

TROUBLESHOOTING

G

1 – Ensure that wire leads from safety edge are securely attached to the movable device (TCOO900).

NOTE: Wire leads from safety edge have no specific polarity and can be placed in either terminal of Safety

device Input1 or Safety device Input2 on the movable device.

Ensure that wire leads into the fixed device (RCOO900P) are firmly connected and into proper terminals (ie

N.C. or N.O.) for help in wiring RCOO900P inputs see STEP 7 examples.

2 – Make sure that the type of safety edge attached to the TCOO900 is resistive.

How to determine the type of edge if there is no clear label:

A voltmeter can be used to determine the type of edge:

1- Set voltmeter to read Ohms

2- Place a test probe on each of the wire leads from the safety edge

3- If the voltmeter registers resistance (ie 8.2KΩ or 10KΩ) the safety edge is resistive

4- If the voltmeter does not register resistance (ie 1) the safety edge is mechanical

If safety edge is mechanical, the system RCOO900P / TCOO900 is NOT compatible.

Determine what type of output signal the gate operator is looking for:

• Doorking – 10K resistive device

• NICE – 8.2K resistive device

• If 8.2k or 10k (resistive): DIP switch 5 or 6 on the RCOO900P need to be in the ON position (DIP 5 for

Output1 and Safety Device 1 and DIP 6 for Output2 and Safety Device 2)

• If N.O. contact: DIP switch 5 or 6 on the RCOO900P needs to be in the o position (DIP 5 for Output1 and

Safety Device 1 and DIP 6 for Output2 and Safety Device 2)

3 – To ensure that the TCOO900 and RCOO900P are communicating within the same frequency DIP

switch 2 and 3 on the TCOO900 and DIP switch 3 and 4 on the RCOO900P need to be in the same

position.

4 – Check batteries in TCOO900 to ensure correct polarity and sucient power.

5 – If TCOO900 and RCOO900P are still not communicating ensure that obstacles between the devices

are moved and mount devices as high as possible and away from metal objects.

10

Page 11

WARRANTY

The warranty period of this product is 24 months, beginning from the manufacturing date. During this period, if the product

does not operate correctly, due to a defective component, the product will be repaired or replaced at the sole discretion of

Transmitter Solutions. This warranty does not extend to the product casing which can be damaged by conditions outside of

the control of Transmitter Solutions.

EXCEPT AS SET FORTH ABOVE, TRANSMITTER SOLUTIONS MAKES NO WARRANTIES REGARDING THE GOODS, EXPRESS OR IMPLIED,

INCLUDING WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE. BUYER MAKES NO RELIANCE ON ANY

REPRESENTATION OF TRANSMITTER SOLUTIONS, EXPRESS OR IMPLIED, WITH REGARD TO THE GOODS AND ACCEPTS THEM “AS-IS/WHERE-IS”.

TRANSMITTER SOLUTIONS SELLS THE GOODS TO BUYER ON CONDITION THAT TRANSMITTER SOLUTIONS WILL HAVE NO LIABILITY OF ANY KIND

AS A RESULT OF THE SALE. BUYER AGREES THAT TRANSMITTER SOLUTIONS SHALL HAVE NO LIABILITY FOR DAMAGES OF ANY KIND, WHETHER

DIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES, INCLUDING INJURIES TO PERSONS OR PROPERTY, TO BUYER, ITS EMPLOYEES OR AGENTS,

AS A RESULT OF THE SALE. BUYER ALSO AGREES TO HOLD TRANSMITTER SOLUTIONS HARMLESS FROM ANY CLAIMS BUYER, OR ANY THIRD

PARTY, MAY HAVE AS A RESULT OF BUYER’S USE OR DISPOSAL OF THE GOODS. BUYER HAS READ THIS DISCLAIMER AND AGREES WITH ITS TERMS

IN CONSIDERATION OF RECEIVING THE GOODS.

11

Page 12

2 480 South 3850 West, Suite

Salt Lake City, UT 84120

(866) 975-0101 • (866) 975-0404 fa

www.transmittersolutions.com

Loading...

Loading...