Page 1

VARIABLE-FLOW CHEMICAL TRANSFER PUMP

SPECIFICATIONS:

Flow: 120 milliliters to 2.2 liters per minute

Fluid Viscosity: 0 to 200 centipoises

Suction Lift: 3 meters wet, 10 centimeters dry

Acceptable Fluid

Te mperatures: –40 to 93 oC

Acceptable Tubing: All types

Tu bing Size: Inside diameter of nominal 4.8 mm

(3/16 inch)

Wetted Parts: Dupont Delrin, 304 Stainless Steel, Viton, Dupont Teflon

Motor: 12 Volt DC Variable

Adaptor: U.L. 120 VAC, 60 Hz, 47 W

Duty cycle: Intermittent

Size: 20.3 x 12 x 11.5 cm (8 x 4 ¾ x 4 ½ inches)

Weight: 454 grams (1 pound)

CAUTION: Prior to use, a 'Chemical Resistance Chart' should be used to insure

that wetted pump parts will not be affected by chemical being pumped.

MAXIMUM FLOW RATES AT DIFFERENT HEAD PRESSURES

PSI Ft H20 ml/min fluid oz/min

0 0 2,200 78

5 12 2100 75

10 23 1750 63

15 35 1250 45

20 46 350 13

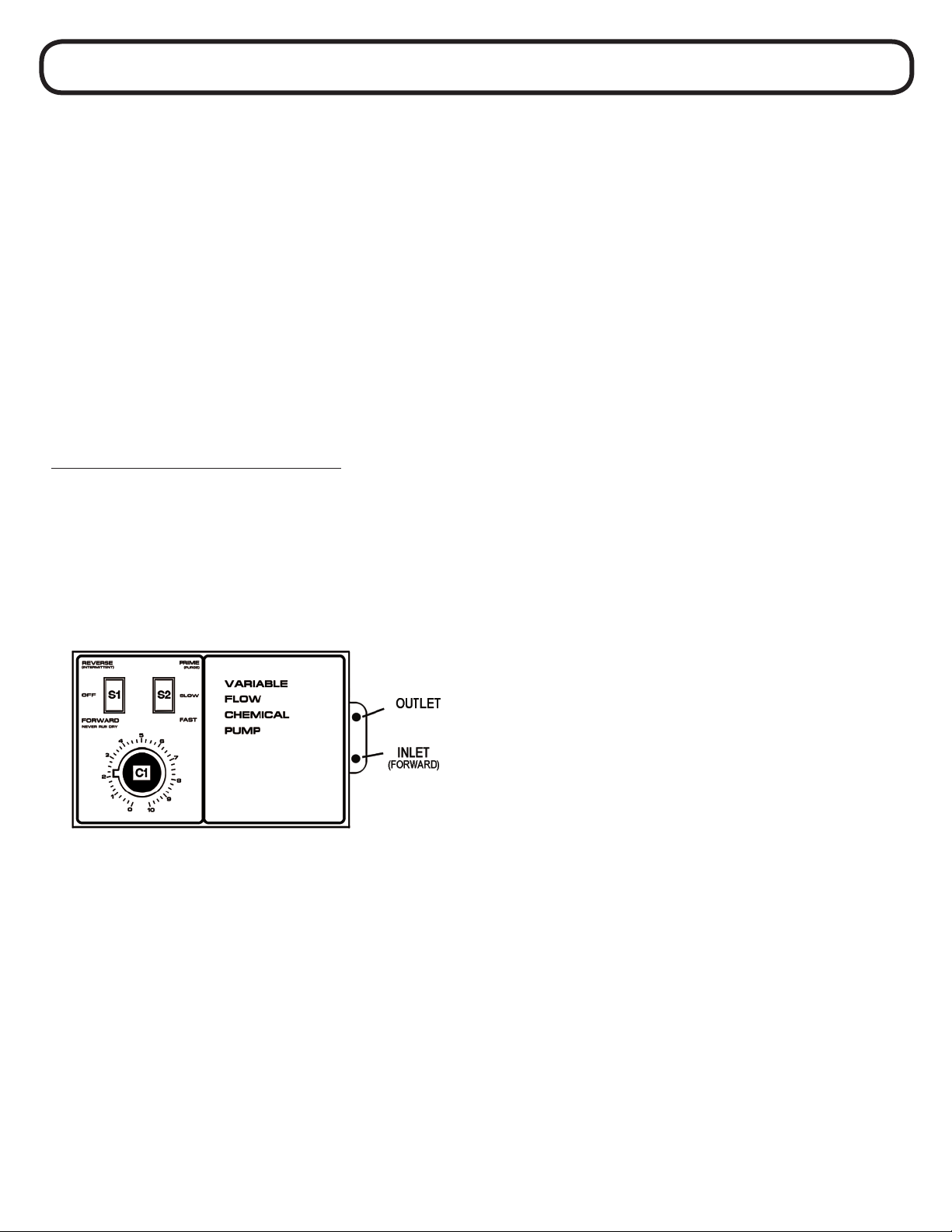

CONTROL PANEL

S1: Power/Direction switch: For selecting FORWARD, REVERSE, & power OFF

S2: Pump Speed switch: For selecting FAST, SLOW, and PRIME (PURGE)

C1: Variable Flow Control: For varying flow rate

barbed fitting. This can be done by squeezing a short piece of tubing

filled with liquid, an eyedropper, a bulb filled with liquid, blowing into

a short piece of tubing filled with liquid, or using a syringe.)

4. Slide one end of a piece of tubing nominal 4.8 mm, inside diameter

(3/16-inch) over the barbed inlet pump fitting. Most users select nominal 4.8 mm (3/16”) inside diameter tubing. Place the other end of the

tubing into the vessel to be emptied.

5. Slide one piece of tubing over the barbed outlet pump fitting. Place

the other end of the tubing into the vessel to be filled.

6. Move Power/Direction switch (S1) to FORWARD to activate

pumping.

7. Move the Pump Speed switch (S2) to Prime (Purge) to quickly fill

the tubing with liquid.

8. Move the Pump Speed switch (S2) to SLOW or FAST.

9. Within each of the two speed ranges (SLOW and FAST), the flow

rate can be varied for precise delivery by rotating the Variable Flow

Control knob (C1). Selecting a higher reference number increases

the flow rate of the pump.

10. Use REVERSE (S1) to empty the liquid in the tubing back to a

vessel.

TROUBLESHOOTING

1. If the pump sounds like it is pumping, but no liquid is moving, do

the following. Prime the pump by placing some liquid into the

barbed inlet fitting. This can be done by squeezing a short piece of

tubing filled with liquid, an eyedropper, a bulb filled with liquid,

blowing into a short piece of tubing filled with liquid, or using a

syringe.

2. If the pump has been pumping at high speed for sometime, the

regulator chip may overheat and shut the unit down. Turn the pump

off and allow it to cool down.

3. If the pump makes no sound when turned on, make certain there is

power to the outlet and the power supply is plugged in.

CAUTION: During operation of the pump, the top panel or the black heat sink

on the back of the pump may be very warm to the touch.

OPERATION

1. Plug the power supply into an electrical outlet.

2. Remove red covers from the inlet and outlet barbed pump fittings.

3. NOTE: To insure instant pumping place some liquid into pump inlet or outlet

fittings so it is wetted. (Prime pump by placing some liquid into the

CONTROL COMPANY

4455 Rex Road Friendswood, Texas 77546 USA

Ph. 281 482-1714 Fax 281 482-9448

E-mail sales@control3.com www.control3.com

Control Company is ISO 9001 Quality-Certified by DNV and ISO 17025 accredited as a Calibration Laboratory by A2LA.

ACCESSORIES

Control Co.

Cat. No. 3280 Tight-SealTM Hose/Tubing Clamp Assortment

Includes 5 each of 13 different sizes. Clamps have an inside diameter

from 6.2 mm to 41 mm (0.246 to 1.61 inches). Clamps securely fasten

tubing on connectors, pumps, glassware, and filtration units. Chemical-corrosion-resistant, rustproof, and nonconducting nylon is ideal for

use in the wide temperature range of 0 to 90oC (32 to 194oF).

Control Co.

Cat. No. 3285 Tight-TiesTM, Cable Ties Assortment

Includes 400 ties with lengths from 4 to 14 inches. One-piece, selflocking, ties are made of chemical-corrosion-resistant, rustproof, and

nonconducting nylon, ideal for use in the wide temperature range of

–40 to 85oC (-40 to 185oF).

WARRANTY OR SERVICE

For warranty or service, contact:

Cat. No. 3388 Variable Flow Chemical Transfer Pump Instructions

92-3388-00

Rev. 5 122707

Tra ceable® is a registered trademark of Control Company.

© 2006 Control Company

Loading...

Loading...