Page 1

SPECIFICATIONS

Photo Tachometer—

Range: 5.0 to 99,999 RPM (revolutions per minute)

Resolution: 0.1 under 1000 RPM

1 over 1000 RPM

Detecting Distance: 2 to 12 inches (50 to 300 mm)

(depending on ambient light)

Contact Tachometer—

Range: 0.5 to 19,999 RPM (revolutions per minute)

Resolution: 0.1 under 1000 RPM

1 over 1000 RPM

Surface Speed Measurement—

Range: 0.05 to 1999.9 m/min

(meters per minute)

Resolution: 0.01 under 100 m/min

0.1 over 100 m/min

Range: 0.2 to 6560 ft/min (feet per minute)

Resolution: 0.1 under 1000 ft/min

1 over 1000 ft/min

Sampling Time: 1 second (over 60 RPM)

Memory Sampling Time: 10 seconds minimum

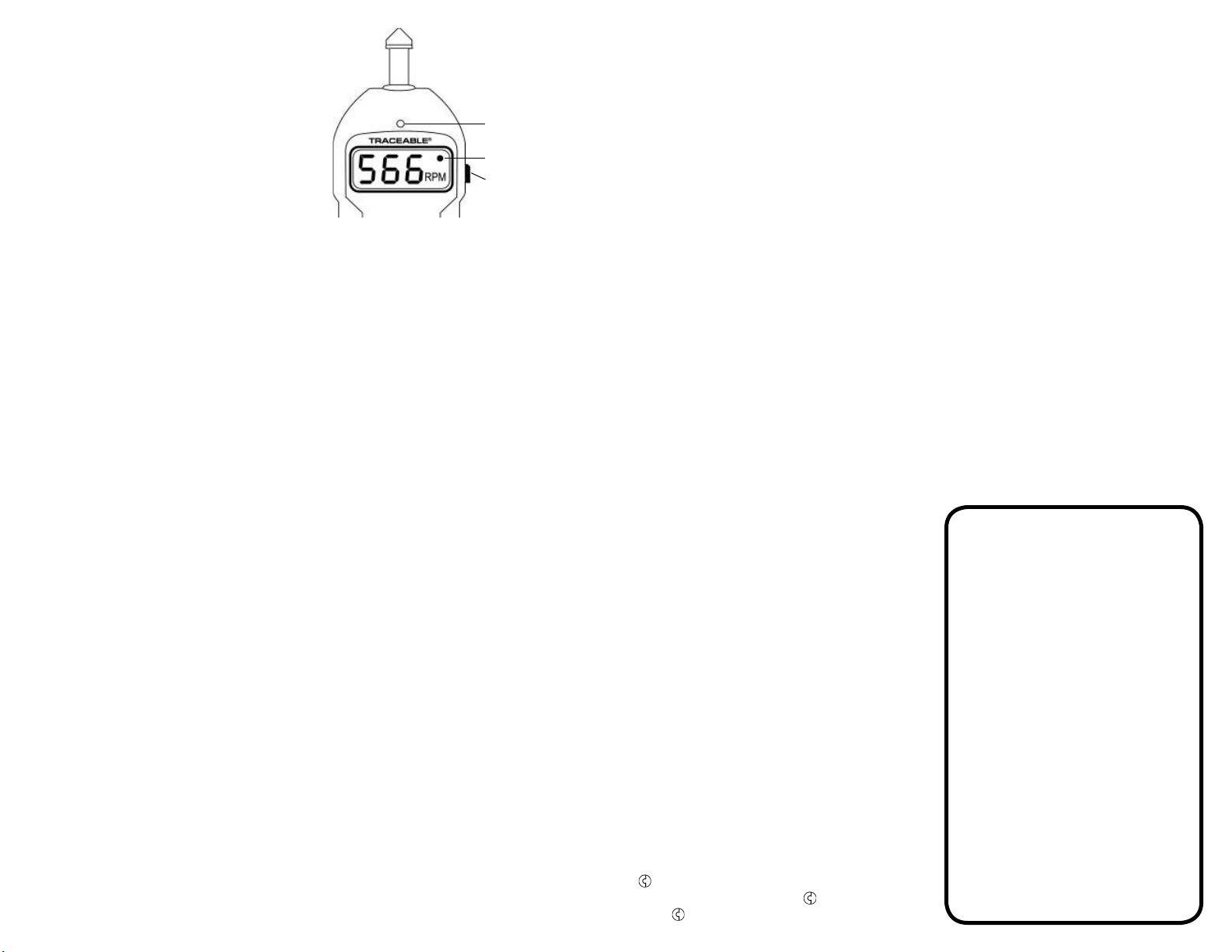

MONITOR INDICATOR (red LED)

MONITOR INDICATOR (LCD)

MEASUREMENT BUTTON

PHOTO TACHOMETER MEASUREMENT

1. Create a refl ective mark by cutting a strip of the

refl ective tape into a 0.5” square.

2. Set the function switch to the RPMé position.

3. Stop the rotating object to be measured and

apply the refl ective mark to the object. Make

certain that the surface of the object is smooth

and clean so that the refl ective mark will adhere.

The non-refl ective area must always be greater than the

refl ective area. If the object being measured is normally

refl ective, then it must be covered with black tape or paint

before applying the refl ective mark.

4. Allow the object to rotate.

5. Press and hold the measurement button and align

the visible light beam with the refl ective mark.

6. Verify that the light beam is properly aligned by

making certain that the monitor indicators blink

each time the refl ective mark passes through

the beam of light.

7. Record the result when the reading stabilizes.

(This will occur in approximately 2 to 10 seconds)

8. Release the measurement button once

measurement is complete.

If the measured rotation is less than 50 RPM,

increase the accuracy of the reading by applying

additional refl ective marks to the object. Place the

additional marks approximately 180 degrees from

each other. To determine the actual RPM, take the

displayed result and divide by the number of marks.

Use special care when measuring the rotation of the

fl at end of the shaft with a relatively small diameter.

Completely cover the fl at end with non-refl ective

black tape. Place the refl ective mark on top of the

black tape, as close to the edge as possible.

CONTACT TACHOMETER MEASUREMENT

1. Set the function switch to the RPMê position.

2. Place the RPM cone or RPM funnel on to the

end of the spindle. Some objects will be more

accurately measured by using the RPM funnel

rather than the RPM cone. To use the RPM

funnel, fi rst remove the RPM cone from the

spindle and replace it with the RPM funnel.

3. Press and hold the measurement button.

4. Place the spindle lightly against the rotating

object. The spindle should be positioned on the

center of the rotating axis of the object that is

being measured.

5. Record the result when the reading stabilizes.

(This will occur in approximately 2 to 10 seconds)

6. Release the measurement button once

measurement is complete.

SURFACE SPEED MEASUREMENT

1. Set the function switch to the M/MIN or

FT/MIN position.

2. Remove the RPM cone/funnel assembly from

the spindle and replace it with the surface speed

wheel assembly. Remove both the cone/funnel

and the sleeve that fi ts over the spindle.

3. Press and hold the measurement button.

4. Place the surface speed wheel in contact with

the moving surface.

5. Record the result when the reading stabilizes.

(This will occur in approximately 2 to 10 seconds)

6. Release the measurement button once

measurement is complete.

MEMORY RECALL

The memory feature will recall the last reading,

highest reading, and lowest reading achieved

during measurement. Readings are normally

retained in memory for several minutes.

After taking a measurement:

The fi rst press of the MEMORY button will display

the last reading (“LA” will appear on the display).

The second press of the MEMORY button will

display the highest reading achieved (“UP” will

appear on the display).

The third press of the MEMORY button will display

the lowest reading achieved (“DN” will appear on

the display).

CONTRAST ADJUSTMENT

The LCD display contrast can be adjusted

using the CONTRAST knob. Simply turn the

knob left or right until the desired LCD contrast

is obtained. If the display shows “88888 ”

when the measurement button is pressed, but no

measurement is being taken, the contrast needs to

be adjusted. Turn the contrast knob to the left until

a single “0 ” appears.

ALL OPERATION DIFFICULTIES

If this meter does not function properly for any

reason, replace the batteries with new, high quality

batteries (see the “Battery Replacement” section).

Low battery power can occasionally cause an

number of “apparent” operational diffi culties.

Replacing the batteries with new fresh batteries will

solve most diffi culties.

BATTERY REPLACEMENT

An erratic display, faint display, no display or “LO”

appearing on the display are all indicators that the

batteries need replacement. Remove the battery

cover located on the back of the unit. Remove the

exhausted batteries and replace them with four

new AA alkaline batteries. Place the batteries in

the proper direction as indicated by the illustration

in the battery compartment. Incorrectly installed

batteries may damage the electronics. Replace

the battery cover.

WARRANTY, SERVICE, OR RECALIBRATION

For warranty, service, or recalibration, contact:

CONTROL COMPANY

4455 Rex Road

Friendswood, Texas 77546 USA

Ph. 281 482-1714 • Fax 281 482-9448

E-mail sales@control3.com • www.control3.com

Control Company is ISO 9001 Quality-Certifi ed by DNV and

ISO 17025 accredited as a Calibration Laboratory by A2LA.

Control Company Cat. No. 4059

Traceable® is a registered trademark of Control Company.

2009 Control Company. 92-4059-20 Rev. 1 100809

©

TRACEABLE

TOUCHLESS/

CONTACT

TACHOMETER

INSTRUCTIONS

®

Loading...

Loading...