Page 1

TRACEABLE® INFRARED THERMOMETER

WITH MEMORIES/ALARM INSTRUCTIONS

SPECIFICATIONS

Range: 0 to 600°F / –20 to 315°C

Resolution: 1°

Accuracy: ±2° C, ±2%

Alarm: Audio

Emissivity: 0.3 to 1.0

Sampling

Features: Backlight, 9 Point Memory,

Laser Targeting,

Programmable Alarm

Included: Lanyard and carrying case

Battery: 9-Volt

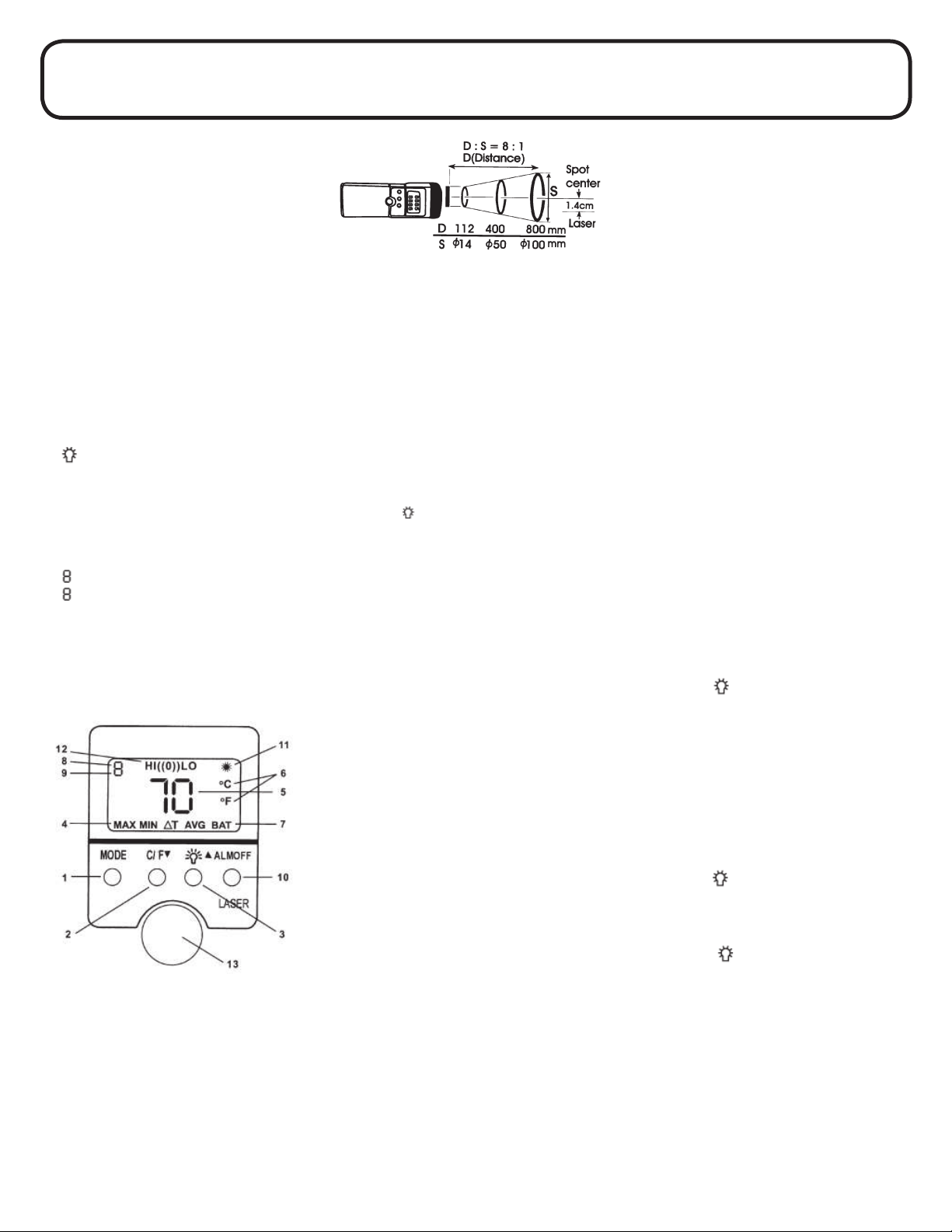

CONTROLS AND INDICATORS

1. MODE key. Temperature display mode se-

2. C/F t key. Fahrenheit/Celsius select button

3.

4. MAX/MIN/▲T/AVG. Temperature display

5. Temperature measurement reading.

6. C/F. Fahrenheit/Celsius scale indicator.

7. BAT. Low battery annunciator.

8. . Memory location annunciator.

9. . Emissivity annunciator.

10. ALMOFF key. Alarm mode indicator button

11.

12. H I ((0))LO. Alarm mode indicators.

13. POWER/HOLD key. Turns unit off/on and

DISTANCE / SPOT RATIO

To take temperature measurements, point the

meter at the surface to be measured and press

the power button.

There are other factors that may effect measurement accuracy - the target must completely

fill the spot diameter seen by the infrared sensor,

otherwise readings will be influ-enced by the

surface surrounding the target.

The ratio of the distance to the size of the spot

being measured is 8:1. For example, an object’s

diameter of 100mm can be measured from

800mm away.

Rate: 0.5 second

lect, memory recall and programming select

button.

and mode down/decrease button.

/▲ key. Backlight button and up/increase

selector.

mode indicator.

and laser on/off.

Y. Laser-on annunciator

holds reading.

POWER KEY

With each press of the power key, five values are

recorded:

1. MAX - Highest temperature measured

2. MIN - Lowest temperature measured.

3. Difference between MAX and MIN

4. Time-weighted average temperature.

5. The value last displayed before releasing

the button.

SELECTING °F OR °C

Pressing the blue “C/F ▼” button will toggle the

temperature in °F or °C.

BACKLIGHT OPERATION

The yellow “ /▲” button will toggle the backlight

off and on. Once the backlight has been turned

on, it will come on each time the power key is

pressed until it is toggled off.

MEASUREMENT MODES

Press and hold down the power button. While

holding down the power button, press the mode

button. Each press of the MODE button will

select one of the 5 temperature modes. You can

cycle through the modes in this order:

1. Real-time temperature - the value is updated

once every 1/2 second (no words or symbols

appear on lower line).

2. “MAX” (Maximum temperature) - press the

MODE button repeatedly until you see the

word MAX displayed on the LCD. In the MAX

mode the highest temperature measurement

taken is displayed on the LCD and will update

each time a higher temperature is measured.

3. “MIN” (Minimum temperature) - Press the

MODE key repeatedly until you see the word

MIN displayed on the LCD. In MIN mode, the

lowest temperature measurement taken is displayed on the LCD and will update each time

a new lower temperature is measured.

4. ▲T “(Temperature differential between MAX

and MIN) - Press and release the mode button repeatedly until “▲T” is displayed on the

LCD.

5. “AVG” (Calculated (time weighted) average

temperature)- Press and release the MODE

button repeatedly until AVG is displayed on

the LCD. Actual surface temperature is not

dis-played while taking measurement in this

mode.

The term “time” in reference to the averaging mode, means all temperature measurements are averaged together from the first

press of the power key. If you were to walk

along a wall for one minute taking readings

that were generally 72 degrees, then walk by

a spot for 1/2 second that was 20 degrees,

no significant change in average temperature

would be displayed.

NOTE: The last mode selected will remain

selected the next time the meter is turned on.

RECALLING MEMORY POINTS

With each press of the power key, values are

recorded in memory:

1. MAX - Highest temperature measured

2. MIN - Lowest temperature measured.

3. Difference between MAX and MIN

4. Time-weighted average temperature.

5. The value last displayed before releasing

the button.

A total of 9 memory sets of four values (MAX,

MIN, ▲T, AVG) are achieved by pressing the

power key nine times. All nine are available for

recall.

To review recorded values, start with the power

off then press and release the MODE button. The

number “1” will appear on the display indicating the last of the 9 sets of values recorded in

memory. Press the yellow button to view 2nd

value, and press it again to view the next reading.

To view the previous value press the blue button.

You may now either cycle through each of

the values recorded during the last power key

presses, or go to one of the values, then select

the number of the power key presses you wish

to review.

For more examples, to select the maximum

temperature measured three power key presses

ago, you may either:

1. Press the MODE button once. The number

“1” and a value appear.

2. Press the ( /▲) button twice. The number

“3” and a value appear.

3. Press the MODE button once again. The

word MAX appears in the lower left of the LCD,

along with the highest temperature recorded

three prior power key presses. OR

1. Press the MODE button once. The number

“1” and a value appears.

2. Press the MODE button once again. The

word MAX appears in the lower left of the LCD,

along with the highest temperature recorded

during the power key press.

3. Press the ( /▲) button twice. The number

“3” and the value of the maximum temperature

recorded from three power key presses ago

appears. To maneuver up and down through

recorded values, press the appropriate

(C/F ▼) or ( /▲) button to view the different

readings on the LCD.

Te m perature Alarm

NOTE: Operate every step in 4 seconds,

otherwise the meter will turn off automatically

to conserve battery life.

An audible alarm will sound at both an upper and

a lower temperature limit. To adjust the alarm

temperatures:

1. Turn the power off.

2. Press and hold the MODE button until “HI” or

“LO” are displayed. (Do not press the power

key). Select the high alarm by pressing the

(continued on next page)

Page 2

TRACEABLE® INFRARED THERMOMETER WITH MEMORIES/ALARM INSTRUCTIONS

(continued from previous page)

To decrease the temperature alarm setting

press the “C/F ▼”. Press the “ /▲” button to

increase the temperature alarm setting. Press-ing

the MODE button will lock in the alarm tem-perature value. “E”, “0.95” (pre-set emissivity) are

shown on the top left of the screen, press MODE

again and the display turns off.

When taking temperatures with power button

pressed down, an alarm will sound when the

tem-perature is above or below preset alarm

values.

EMISSIVITY ADJUSTMENT

Emissivity adjustments are used to provide a

truer temperature reading. Different materials

radiate infrared energy at slightly different temperatures. The emissivity adjustment is used to

compensate for different types of materials.

The factory set emissivity of 0.95 will cover

90% of typical applications. The following instructions indicate how to change the emissivity

setting. The following table provides a guide of

different emissivity values for different materials.

When the emissivity of an object is Unknown

use a non-infrared thermometer, such as a

probe type thermometer to measure the object’s

surface. Then adjust the emissivity until the temperature of the Infrared Thermometer matches

the temperature of the probe type thermometer.

Use this emissivity value to measure similar

materials.

To set emissivity you must pass through

the alarm setting function. Press and hold

the MODE button and the LCD displays the

alarm adjustment function. Go through the key

presses for the alarm setting function. Press

the MODE button again to display the current

emissivity value (preset to 0.95). The emis-sivity

range is 0.3 to 1.0. Press the “C/F ▼” button to

decrease and the “

/▲” button to increase the

emissivity setting. Pressing the MODE button

will lock in the value. This value will become the

unit’s default value until reset.

LASER TARGETING

CAUTION: Eye damage may result from direct

exposure to laser light . To toggle the laser

targeting feature on or off, depress the LASER

button. The laser can be engaged from any

measurement mode.

ALL OPERATIONAL DIFFICULTIES

If this thermometer does not function properly

for any reason, please replace the battery with a

new high-quality battery (see “Battery Replacement” section). Low battery power can occasionally cause any number of “apparent” operational

difficulties. Replacing the battery with a new

battery will solve most difficulties.

CONTROL COMPANY

4455 Rex Road

Friendswood, Texas 77546 USA

Ph. 281-482-1714 Fax 281-482-9448

E-mail sales@control3.com www.control3.com

Control Company is ISO 9001 Quality-Certified by DNV and

ISO 17025 accredited as a Calibration Laboratory by A2LA.

Cat. No. 4472

Traceable® Infrared Thermometer with Memories/Alarm Instructions

Traceable® is a registered trademark of Control Company

© 2005 Control Company

BATTERY REPLACEMENT

Erratic readings, a faint display, no display, or

BAT appearing on the display are all indicators

that the battery must be replaced. Slide the

panel on the back of the unit in the direction

of the arrow. Unplug the old 9-volt battery and

replace with a new 9-volt alkaline battery. Slide

the battery compartment cover back into place.

Replacement battery Cat. No. 1112.

WARRANTY, SERVICE, OR

RECALIBRATION

For warranty, service, or recalibration, contact:

92-4472-00

Rev. 2 060305

METALS

SURFACE EMISSIVITY

Iron and Steel

Cast iron (polished) ...........................................0.2

Cast iron (tumed at 100oC) . .. .. .. .. .. .. . .. .. .. .. .. .. . .. .0.45

Cast iron (tumed at 1000oC) . .. .. .. .. .. . .. .. .. . 0.6 to 0.7

Steel (ground sheet) . .. .. . .. . .. . .. .. . .. . .. . .. .. . .. . .. . .. .. . .. . 0.6

Mild steel . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . 0.3 to 0.5

Steel plate (oxidized) .. ..... ... ..... ... ..... ..... ... ..... ..... 0.9

Iron plate (rusted) ................................. 0.7 to 0.85

Cast iron (rough) rusted...................................0.95

Rough ingot iron .. .. .. ... .. .. ... .. .. ... .. .. ... .. .. ... .. .. ... .. ..0.9

Molten cast iron..................................................0.3

Molten mide steel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.3 to 0.4

Stainless steel (polished) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.1

Stainless steel (various) . . . . . . . . . . . . . . . . . . . . . . . . . . 0.2 to 0.6

Aluminum

Polished aluminum .. ........ ........ ..... ........ ........ ...0.1*

Aluminum (heavily oxidized) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.25

Aluminum oxide at 260oC ... ....... ....... ....... ....... ...0.6

Aluminum oxide at 800oC ... ....... ....... ....... ....... ...0.3

Aluminum Alloys, various . . . . . . . . . . . . . . . . . . . . . . 0.1 to 0.25

Brass

Brass (polished) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.1*

Brass (roughened surface) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.2

Brass (oxide) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . 0.6

Copper

Copper (polished) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.05*

Copper (oxide) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.8

Molten copper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.15

TYPICAL EMISSIVITY VALUES

SURFACE EMISSIVITY

Lead

Leadr (polished) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.1*

Leadr (oxide at 25oC) . . .. . . . . . . .. . . . . . . .. . . . . . . .. . . . . . . .. . . . . . 0.3

Leadr (oxide) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . 0.6

Nickel and Its Alloys

Nickel (pure) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.1*

Nickel plate (oxide) . .. .. .. . .. .. .. . .. .. . .. .. .. . .. .. . . 0.4 to 0.5

Nichrome . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.7

NON-METALS

SURFACE EMISSIVITY

Refractory & Building Materials

Red brick (rough) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.75 to 0.9

Fire clay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.75

Asbestos ..........................................................0.95

Concrete . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.7

Marble .... ....... .... ..... .... ..... .... ..... .... ..... .... ..... .... ....0.9

Carborundum . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.85

Plaster ... ..... ..... ..... ..... ..... ............ ..... ..... ..... ..... ....0.9

Alumina (fine grain) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.25

Alumina (coarse grain) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.45

Silica (fine grain) .. ... ... .... ... .... ... ... .... ... ... .... ... ... ...0.4

Silica (coarse grain) . . .. . . . .. . . . . .. . . . .. . . . . .. . . . .. . . . . .. . . . .0.55

Zirconium silicate up to 500oC . . . . . . . . . . . . . . . . . . . . . . . . . 0.85

Zirconium silicate at 850oC . .. .. . .. .. . .. .. . .. .. . .. .. . .. .. . .0.6

Quartz (rough) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.9

Carbon (graphite) ............................................0.75

Carbon (soot) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.95

Timber (various) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.8 to 0.9

*Emissivity varies with purity

SURFACE EMISSIVITY

Nichrome (oxide) ...... .. .... .. .... .... .. .... .... .. .... .... .. .0.95

Zinc (oxidized)..................................................0.1*

Galvanized iron . .. .. .. . .. .. .. . .. .. .. . .. .. .. . .. .. . .. .. .. . .. .. .. . .. 0.3

Tin-plated steel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.1*

Gold (polished) .. . .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. . .. .. 0.1*

Silver (polished) . .. . .. .. . .. . .. . .. . .. .. . .. . .. . .. . .. . .. .. . .. . .. . .0.1*

Chromium (polished) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . 0.1*

SURFACE EMISSIVITY

Miscellaneous

Enamel (any color) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.9

Oil paint (any color) .........................................0.95

Lacquer .. .. .. .. ... .. .. .. ... .. .. ... .. .. .. ... .. .. .. ... .. .. .. ... .. .. ... .0.9

Matte black paint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.95 to 0.98

Aluminum lacquer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.5

Water . . .. . . . .. . . .. . . .. . . . .. . . .. . . .. . . . .. . . .. . . .. . . . .. . . .. . . .. . . . .. . . .0.98

Rubber (smooth) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.9

Rubber (rough) ... ....... ....... ....... ....... ....... ....... ...0.98

Plastics (various, solid) . .. . . . .. . . . .. . . . .. . . . .. . . 0.8 to 0.95

Plastic films (0.05 mm thick) . . . . . . . . . . . . . . . . . 0.5 to 0.95

Polythene film (0.03 mm thick) . .. .. . .. .. .. . .. 0.2 to 0.3

Rubber (smooth) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.9

Rubber (rough) ... ....... ....... ....... ....... ....... ....... ...0.98

Plastics (various, solid) . .. . . . .. . . . .. . . . .. . . . .. . . 0.8 to 0.95

Plastic films (0.05 mm thick) . . . . . . . . . . . . . . . . . 0.5 to 0.95

Polythene film (0.03 mm thick) . .. .. . .. .. .. . .. 0.2 to 0.3

Paper and cardboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.9

Silicone polish . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.7

Loading...

Loading...