Page 1

SPECIFICATIONS

Range: –50.00 to 70.00 °C

Accuracy: ±0.25°C

Resolution: 0.01°

Temperature

Sampling Rate: 5 seconds

Memory Capacity: 525,600 points

USB Download Rate: 55 readings per second

Backup Battery: 2 AAA (1.5V)

USE SUPPLIED A/C ADAPTOR FOR PRIMARY

SOURCE OF POWER. BATTERIES ARE

INTENDED AS BACK-UP POWER SOURCE

PROBES SUPPLIED:

Model 6430 / 6431-- Supplied with 1 bottle probe (6430) or

2 bottle probes (6431), designed for use in refrigerators and

freezers. Bottle probes are lled with a patented nontoxic glycol solution that is GRAS (Generally Recognized As Safe) by

the FDA (Food and Drug Administration) eliminating concerns

about incidental contact with food or drinking water.

The solution lled bottle simulates the temperature of other

stored liquids. Velcro® and a magnetic strip are provided to

mount the bottle inside a refrigerator/freezer. The included

micro-thin probe cable permits refrigerator/freezer doors to

close on it. (Do not immerse bottle probes in liquid).

Model 6432 / 6433-- Supplied with standard plastic probe

with cable. Designed for use in air and liquids, the sensor and

cable may be completely immersed.

Model 6434– Supplied with 1 bottle probe with cable and 1

standard plastic probe with cable.

Model 6435 / 6436– Supplied with 1 stainless-steel probe

(6435) or 2 stainless-steel probes (6436) triple-purpose probe

for liquids, air/gas, and semisolids. Accurate readings with tip

penetration of

length of 6¼ inches, overall length of 9 inches and a cable

length of 5 feet.

SETTING THE TIME-OF-DAY/DATE

1. Slide the DISPLAY switch to the DATE/TIME position,

the thermometer will display the time-of-day and date.

Adjustable parameters are Year->Month->Day->Hour>Minute->12/24 hour time.

2. Press the SELECT button to enter the setting mode.

1

/

-inch. Probe has a diameter of ⅛-inch, stem

3

3. Subsequently press the SELECT button to select

which parameter to adjust. The selected parameter will

ash once selected.

4. Press the ADVANCE button to increment the selected

parameter.

5. Hold the ADVANCE button to continuously “roll” the

selected parameter.

6. Press the EVENT DISPLAY button to toggle between

Month/Day (M/D) and Day/Month (D/M) display

modes.

If no button is pressed for 15 seconds while in the setting

mode, the thermometer will exit the setting mode.

Changing the position of the DISPLAY switch while in the

setting mode will save the current settings.

VIEWING THE TIME-OF-DAY/DATE

To view the time-of-day/date, slide the DISPLAY switch to

the DATE/TIME position.

SELECTING THE UNIT OF MEASURE

To select the desired unit of temperature measure (°C or

°F), slide the UNITS switch to the corresponding position.

SELECTING THE TEMPERATURE PROBE CHANNEL

Slide the PROBE switch to either position ‘1’ or position ‘2’

to select the corresponding probe channel P1 or P2.

All temperature readings displayed will correspond with

the selected probe channel.

Note: Both probe channels are sampled and monitored

continuously regardless of the selected probe channel.

MINIMUM AND MAXIMUM MEMORY

The minimum temperature stored in memory is the

minimum temperature measured since the last clear of

min/max memory. The maximum temperature stored in

memory is the maximum temperature measured since the

last clear of min/max memory.

MINIMUM AND MAXIMUM TEMPERATURE

VALUES ARE NOT PROGRAMMABLE.

Minimum and maximum temperature values are stored

individually for each probe channel P1 and P2. Both

channels are monitored continuously regardless of the

selected probe channel.

VIEWING MIN/MAX MEMORY

1. Slide the PROBE switch to select temperature probe

channel to be displayed.

2. Slide the DISPLAY switch to the MIN/MAX position.

3. The thermometer will display the current, minimum,

and maximum temperatures for the selected probe

channel.

4. Press the EVENT DISPLAY button to display the

minimum temperature with the corresponding date and

time of occurrence.

5. Press the EVENT DISPLAY button a second time to

display the maximum temperature with the corresponding date and time of occurrence.

6. Press the EVENT DISPLAY button to return to the

current temperature display.

No button press for 15 seconds while viewing the mini-

mum or maximum event data will trigger the thermometer

to return to the current temperature display.

CLEARING THE MIN/MAX MEMORY

1. Slide the PROBE switch to select the temperature

probe channel to be cleared.

2. Slide the DISPLAY switch to the MIN/MAX position.

3. Press the CLEAR SILENCE ALM button to clear the

current minimum and maximum temperature readings.

Alarms

Alarm high and low limits can be set individually for each

probe channel (P1 and P2).

SETTING ALARM LIMITS

1. Slide the PROBE switch to select the probe channel

for which alarms will be set.

Each digit of the alarm value is set individually:

Low Alarm Sign (Positive/Negative) -> Low Alarm

Hundreds/Tens -> Low Alarm Ones -> Low Alarm Tenths

-> High Alarm Sign (Positive/Negative) -> High Alarm

Hundreds/Tens -> High Alarm Ones -> High Alarm Tenths.

2. Press the SELECT button to enter the setting mode.

The LOW ALM symbol will ash.

3. Press the SELECT button to select the digit to adjust.

Each subsequent press of the SELECT button will

move to the next digit. The digit will ash while

selected.

4. Press ADVANCE button to increment the selected

digit.

Note: The negative sign will ash if the sign is negative;

no symbol will ash if the sign is positive. Press the

ADVANCE button to toggle the sign while it is selected.

If no button is pressed for 15 seconds while in the setting

mode, the thermometer will exit the setting mode.

Changing the position of the DISPLAY switch while in the

setting mode will save the current settings.

VIEWING THE ALARM LIMITS

1. Slide the PROBE switch to select the probe channel

alarm limits to be displayed.

2. Slide the DISPLAY switch to the ALARM position.

ENABLING/DISABLING ALARMS

1. Slide the ALARM switch to the ON or OFF position to

enable or disable the alarms.

2. Alarms are enabled for both probe channels P1 and

P2 while the switch is set to ON. Alarms are disabled

for both probe channels P1 and P2 while the switch is

set to OFF.

3. The alarms cannot be congured to enable individual

channels P1 or P2 only.

ALARM EVENT HANDLING

An alarm event will trigger if the alarm is enabled and a

temperature reading is recorded below the low alarm set

point or above the high alarm set point.

When an alarm event triggers, the thermometer buzzer

will sound, and the LED for the alarming temperature

channel will ash (P1 or P2). If the alarming probe channel is selected, the LCD symbol will ash signaling which

set point was breached (HI ALM or LO ALM).

An active alarm may be cleared by either pressing the

CLEAR SILENCE ALM button or disabling the alarm functionality by sliding the ALARM switch to the OFF position.

Once an alarm is cleared, it will not re-trigger until after

the temperature returns to within the alarm limits.

Note: If an alarm event is triggered and returns to within

the alarm limits before being cleared, the alarm event will

remain active until it is cleared.

VIEWING ALARM EVENT MEMORY

1. Slide the PROBE switch to select the probe channel

alarm data to be displayed.

2. Slide the DISPLAY switch to the ALARM position. The

current temperature, low alarm limit, and high alarm

limit will display.

3. Press the EVENT DISPLAY button. The thermometer

will display the alarm limit, date, and time of the most

recent alarm out of range condition. The symbol ALM

OUT will display to signal the date and time displayed

indicate when the temperature when out of tolerance.

4. Press the EVENT DISPLAY button a second time.

The thermometer will display the alarm limit, date, and

time of the most recent alarm event returning to within

the alarm limits. The symbol ALM IN will display to

signal the date and time displayed indicate when the

temperature returned to within tolerance.

5. Press the EVENT DISPLAY button to return to the

current temperature display.

No button press for 15 seconds while viewing the alarm

events will trigger the thermometer to return to the current

temperature display.

Note: If no alarm event has occurred for the selected

probe channel, the thermometer will display “LLL.LL” on

each line.

DATA LOGGING OPERATION

Thermometer will continuously log temperature readings

for both probe channels into permanent memory at

user-specied intervals. The total memory capacity

is 525,600 data points. Each data point contains the

temperature reading for P1, the temperature reading for

P2, and the date and time of occurrence.

Note: All data stored in Celsius (°C) and date format is

MM/DD/YYYY.

The thermometer will also store the most recent 10 alarm

events. Each alarm event data point contains the probe

channel which alarmed, the alarm set point that was

triggered, the date and time the channel reading went

out of range, and the date and time the channel reading

returned to within range.

VIEWING THE MEMORY CAPACITY

Slide the MEM VIEW switch to the ON position.

The rst line will display the current percentage of memory full. The second line will display the number of days

Page 2

remaining before memory is full at the current logging

interval. The third line will display the current logging

interval.

CLEARING THE MEMORY

1. Slide the MEM VIEW switch to the ON position.

2. Press the CLEAR SILENCE ALM button to clear all

recorded data and alarm events.

Note: The MEM symbol will become active on the display

when the memory is full. Once the memory is full, the

oldest data points will be overwritten with new data.

SETTING THE LOGGING INTERVAL

1. Slide the MEM VIEW switch to the ON position. The

rst line will display the current percentage of memory

full. The second line will display the number of days

remaining before memory is full at the current logging

interval. The third line will display the current logging

interval.

2. To increment the logging interval, press the ADVANCE

button. The minimum logging interval is one minute

(0:01). The maximum logging rate is 24 hours (24:00).

Once 24 hours is selected, the next subsequent press

of the ADVANCE button will return to one minute.

VIEWING UNIQUE DEVICE ID NUMBER

1. Slide the MEM VIEW switch to the ON position.

2. Press the EVENT DISPLAY button. The second and

third lines will display the rst eight digits of the ID

number.

3. Press the EVENT DISPLAY button a second time. The

second and third lines will display the last eight digits

of the ID number.

4. Press the EVENT DISPLAY button to return to the

default display.

DOWNLOADING STORED DATA

Note: The USB download will not occur if the battery

LCD symbol is active. Plug the supplied AC adapter

into the thermometer to provide sufcient power for USB

operation.

1. The data can be downloaded directly to a USB Mass

Storage Flash Drive. To begin the download, insert the

USB ash drive into the USB port located on the left

side of the thermometer.

2. The download will begin automatically upon insert.

The P1 LED will turn on to indicate the download

process has begun.

3. Once the download process is complete, the LED

will turn off. Do not remove the USB drive until the

process is complete.

4. The data transfer rate is approximately 55 data points

per second.

REVIEWING STORED DATA

The downloaded data is stored in a comma-delimited

CSV le on the ash drive. The lename naming convention is “D1D2D3D4D5D6D7R1.CSV” where D1 through

D7 are the last seven digits of the thermometer’s unique

ID number and R1 is the revision of the le starting with

the letter “A”.

If more than one le is written from the same thermometer

to the USB ash drive, the revision letter will be incre-

mented in order to preserve the previously downloaded

les.

The data le can be opened in any software package

supporting comma-delimited les including spreadsheet

software (Excel) and text editors.

The le will contain the thermometer unique ID number,

the most recent ten temperature events, and all stored

temperature readings with date and time stamps.

Note: All data stored in Celsius (°C) and date format is

MM/DD/YYYY.

DISPLAY MESSAGES

If no buttons are pressed and LL.LL appears on the display, this indicates that the temperature being measured

is outside of the temperature range of the unit, or that the

probe is disconnected or damaged.

BENCH STAND

The unit is supplied with a bench stand located on the

back. To use the bench stand, locate the small opening at

the bottom back of the unit. Place your ngernail into the

opening and ip the stand out. To close the stand, simply

snap it shut.

POWER

The thermometer should be powered at all times with

supplied AC adapter. In the event of a power failure, the

backup batteries will power the thermometer for one

week. A low battery symbol on the display indicates the

AC adaptor has failed and the thermometer is running on

the backup batteries.

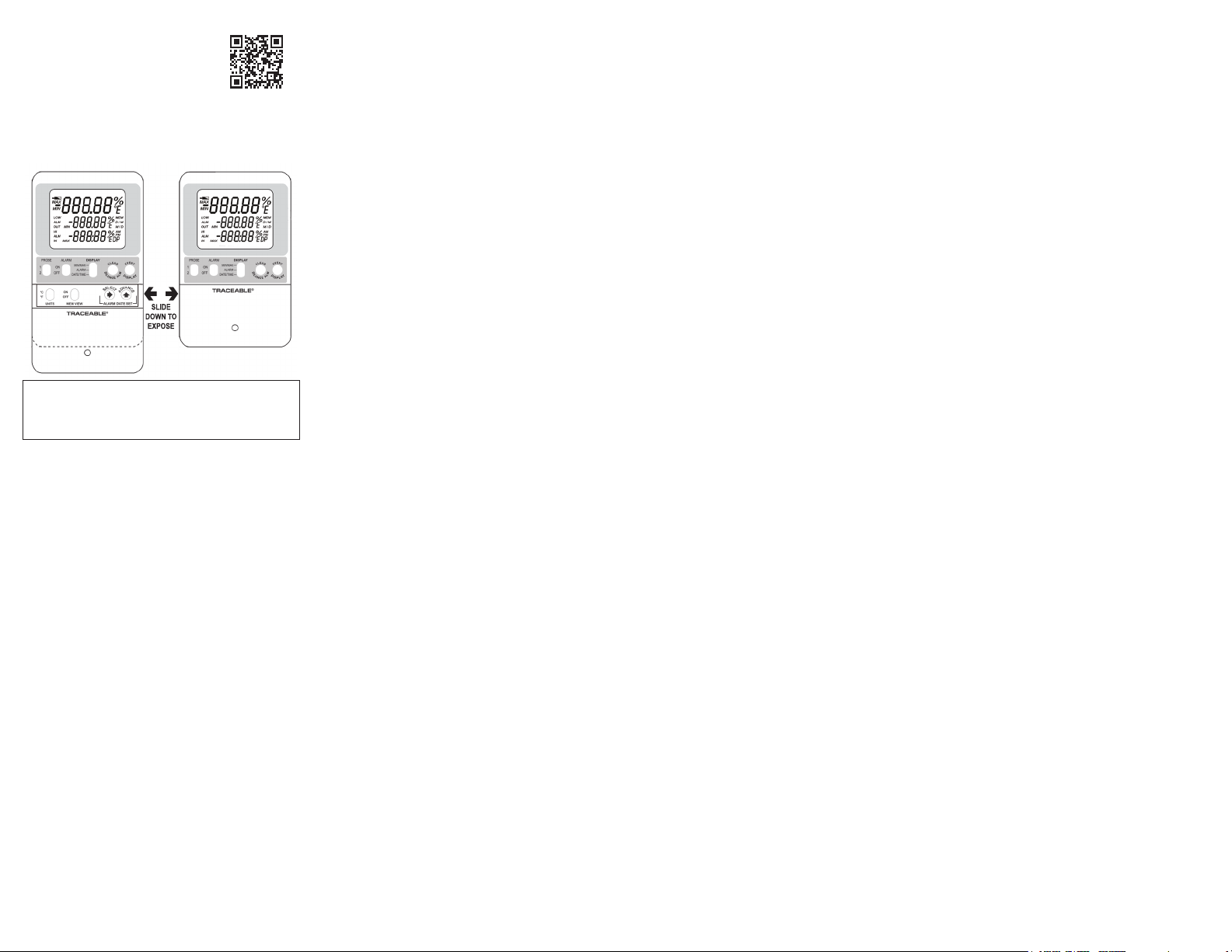

BACKUP BATTERY REPLACEMENT

To replace the Backup Battery, remove the battery cover,

located on the back of the unit by sliding it down. Remove

the exhausted batteries and replace with two (2) new AAA

alkaline batteries. Insert the new batteries with the proper

polarity as indicated by the illustration in the battery

compartment. Replace the battery cover.

Replacing the batteries WILL clear the minimum/maximum memories and high/low alarm settings. However,

replacing the batteries WILL NOT clear the time-of- day/

date settings.

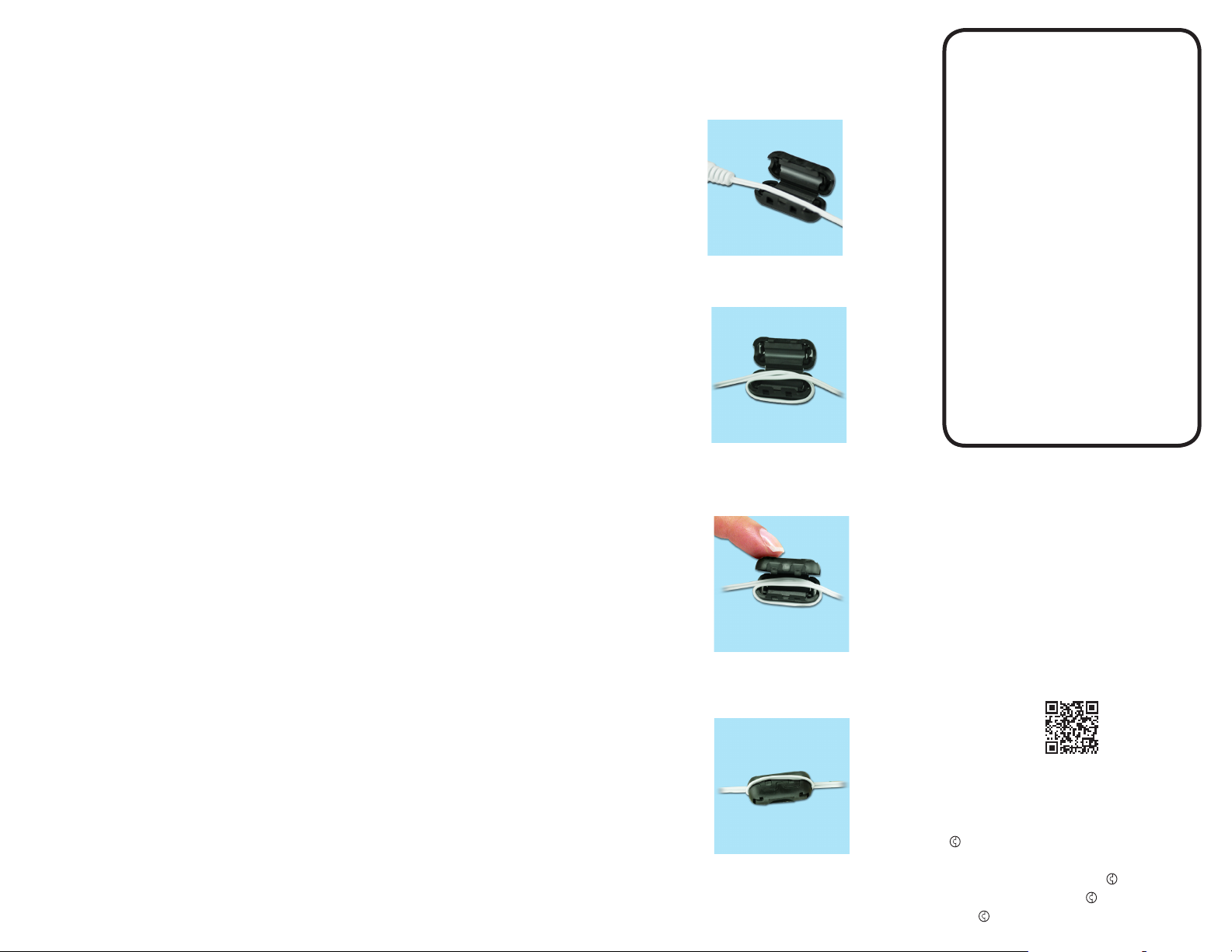

STATIC SUPPRESSOR INSTALLATION

Static generated, radio frequency can affect any cable

through the air or by physical contact. To protect against

radio frequency, install a suppressor onto your thermometers cable to absorb radio frequency as follows:

Lay the cable along the center of the

suppressor with the connector to your left.

Loop the right end of the cable under the

suppressor and back up again laying the cable along

the center of the suppressor.

Carefully, snap the two halves together with the looped

cable routed through the center.

This completes the installation of the suppressor.

TRACEABLE

EXCURSION-TRAC

DATALOGGING

THERMOMETER

INSTRUCTIONS

WARRANTY, SERVICE, OR RECALIBRATION

For warranty, service, or recalibration, contact:

CONTROL COMPANY

4455 Rex Road

Friendswood, Texas 77546 USA

Ph. 281 482-1714 • Fax 281 482-9448

E-mail sales@control3.com • www.control3.com

Control Company is ISO 9001 Quality-Certied by DNV

and ISO 17025 accredited as a Calibration Laboratory

by A2LA.

Control Company Cat. No.

6430 / 6431 / 6432 / 6433 / 6434 / 6435 / 6436

Traceable® is a registered trademark of Control Company.

Excursion-Trac™ is a trademark of Control Company.

©2014 Control Company. 92-6430-00 Rev. 0 040114

®

™

Loading...

Loading...