Page 1

TRACEABLE

®

D

UA

L-CH

ANNEL

THERMOMETER INSTRUC

TI

ONS

SPECIFICATIONS

Circuit Custom one– chip of microprocessor LSI with thermocouple linearity

correction circuit

Display Dual function meter’s display, 13 mm (0.5”), Super large LCD

display with annunciator

Measurement Two channel temperature input (T1, T2), differential temperature

measurement (T1-T2), °C/°F, 0.1°/1° degree

Measurement Range –50 to 1230°C (–58 to 1999°F)

Polarity Automatic switching, ‘—’ indicates negative polarity

Sensor Type Thermocouple K(NiCr—NiAl)

Input Impedance 10 Mega ohm

Sampling Time Approx. 0.8—1.0 second

Memory Recall Records Maximum, Minimum readings with RECALL

Over input indication Indication of “- - - -”

Operating Temperature 0 to 50°C (32 to 122°F)

Operating Humidity Max. 80% RH

Power Supply 006P DC 9V battery (Heavy duty type)

Power Current Approx. DC 6.2 mA

Size 7⅛ x 2⅞ x 11/3 inches

Weight 9¾ ounces

Accessories Temperature probe, carrying case (not included)

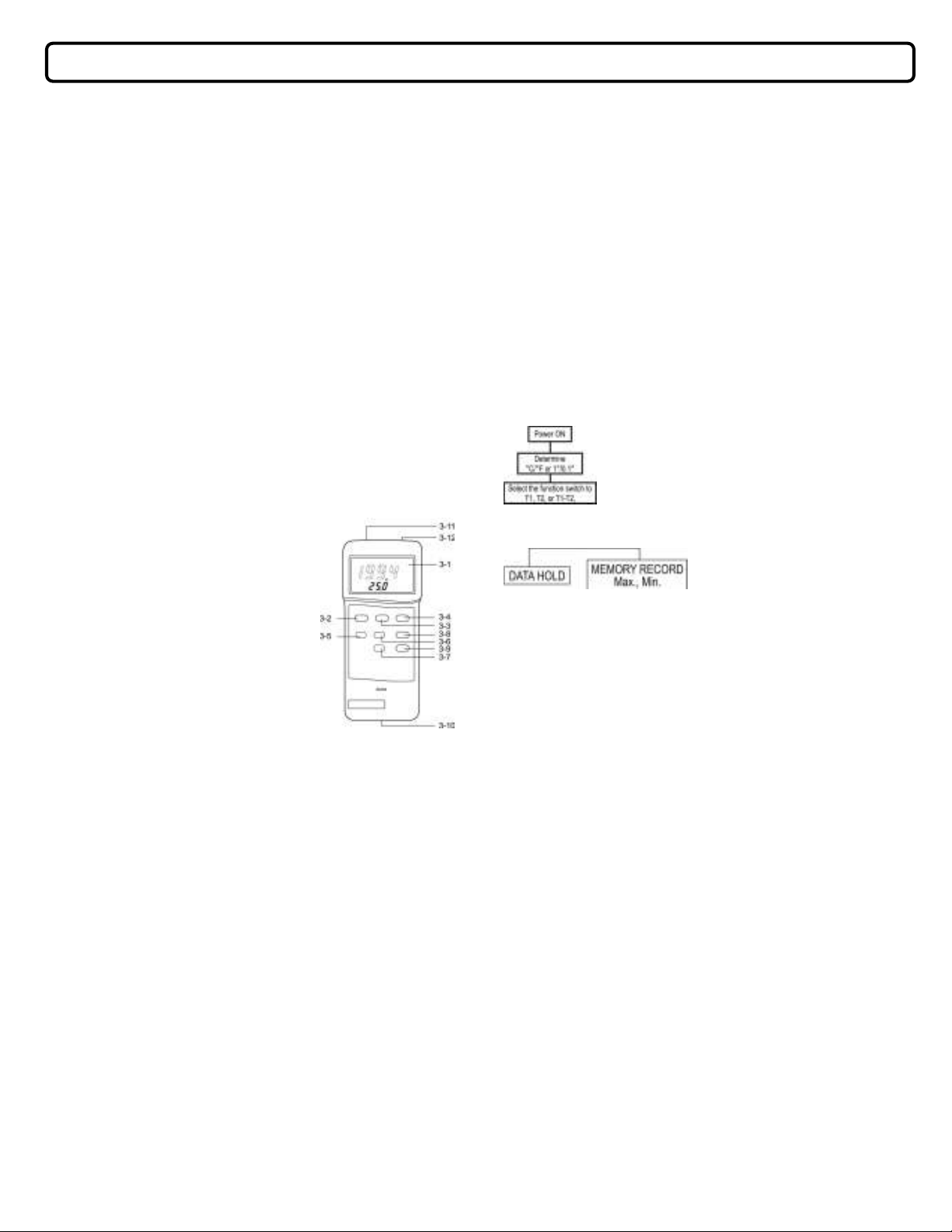

FRONT PANEL DESCRIPTION\

Fig. 1

3-1 Display

3-2 Power On button

3-3 Data Hold button

3-4 °C/°F button

3-5 Power Off button

3-6 Memory “Record” button

3-7 Memory “Call” button

3-8 Function button (T1, T2, T1-T2)

3-9 1°/0.1° button

3-10 Battery Compartment/Cover

3-11 T1 Input Socket

3-12 T2 Input Socket

MEASURING PROCEDURE

1. Push the “power off button” (3-2, Fig. 1) to let the instrument power “ON”.

2. Determine temperature unit to °C or °F by pushing the “ °C/°F Button “ (3-4, Fig.

1) Then the display will show the temperature unit of °C or °F.

3. Determine the display resolution to 0.1° or 1° by pushing the “1°/0.1° Button”.

4. One probe measurement:

Insert one temperature probe plug into the socket T1 (3-11), then push the

“Function Button” (3-8, Fig. 1) until the display show the marker “T1” display will

show the temperature reading that measured from the probe.

5. Two probe (dual channel) & differential measurement:

a. Insert second temperature probe plug into the “T1 Socket” (3-11, Fig. 1).

b. Insert second temperature probe plug into the “T2 Socket” (3-12, Fig. 1).

c. The main display (upper display) will show the temperature reading of the

first probe (T1) & the lower display will show the temperature reading of

second probe (T2), push the “Function Button” (3-8, Fig. 1) until “T1” appears

on the display.

d. The main display (upper display) will show the temperature reading of second

probe (T2) & the lower display will show the temperature reading of the first

probe (T1), push the “Function Button” (3-8, Fig. 1) until “T2” appears on the

display.

e. The main display (upper display) will show the differential temperature

reading of the first and second probe (T1-T2) and the lower display will show

the temperature reading of the first probe (T1), push the “Function Button” (38, Fig. 1) until “T1-T2” appears on the display.

DATA HOLD

1. During the measurement. Push the “Data Hold Button” (3-3, Fig. 1) will hold the

display values & LCD will show the “D.H” marker.

2. Push the “Data Hold Button” again will release the data hold function.

DATA RECORD

1. The DATA RECORD function displays the maximum, and minimum readings. To

start the DATA RECORD function, press the “Record Button” (3-6, Fig. 1) once.

“REC” will appear on the LCD display.

2. With the “REC” appearing on the display.

3. Push the “CALL Button” (3-7, Fig. 1) once, then the “Max” marker along with the

maximum values will appear on the LCD display.

4. Push the “CALL Button” once, then the “Min” marker along with the minimum

values will appear on the LCD display.

5. When running the “Record” function, pushing the “Record Button” once again

will stop the “Record” function.

6. After stopping the “Record” function, the marker of “REC”, “Max”, “Min” will

disappear.

MAIN PROCEDURES

OPTIONAL MEASURING PROCEDURES

MEASURING CONSIDERATION

Insert the probe plug into the temperature input socket T1 (3-11) of T2 (3-12), taking

care to observe the correct polarity. Greatest accuracy is achieved when the probe

plug is first inserted into the thermometer socket (T1,T2), or if the probe is changed,

the plug must be allowed to stabilize at temperature of the socket, which is in thermal

contact with cold junction compensation device. This will take a couple of minutes and

only applies if the probe plug has previously been exposed to an ambient temperature

different to that thermometer.

BATTERY REPLACEMENT

When the left corner of LCD display show “LBT”, it indicates a normal battery output of

less than 6.5V – 7.5V. It is necessary to replace the battery. However, in—spec

measurement may still be made for several hours after low battery indicator appears

before the instrument becomes inaccurate. Slide the Battery Cover (3-10, Fig. 1) away

from the instrument and remove the battery. Replace with 9V battery (heavy duty type)

and replace the cover. Make sure the battery cover is secured after changing the

battery.

WARRANTY, SERVICE, OR RECALIBRATION

For warranty, service, or recalibration, contact:

CONTROL COMPANY

4455 Rex Road

Friendswood, Texas 77546 USA

Ph. 281-482-1714 Fax 281-482-9448

E-mail sales@control3.com

www.control3.com

Control Company is ISO 9001 Quality-

Certified by DNV and ISO 17025 accredited

as a Calibration Laboratory by A2LA.

Traceable® is a registered trademark of Control Company ©2008 Control Company. 92-4029-20 Rev. 3 051908

Loading...

Loading...