Page 1

TRACEABLE

®

BATTER

Y TE

STER

INSTRUCTIONS

The Traceable® Battery Tester is a rugged compact, reliable, and easy-to-

operate instrument. It is used to determine the condition of a battery. It tests

a battery under actual operating load conditions. It is superior to voltmeters

since they only provide misleading no-load values. A battery’s performance

capability can be determined accurately only when a representative load has

been connected across the battery terminals. This battery tester provides a

unique load for each different type of battery under test. It tests batteries for

real-world usage under actual operating conditions.

Gold-plated printed circuit board and silver plated switches provide

●

for accuracy and long life

Unit is self-powered and requires no internal battery

●

Function selector switch provides 13 measuring positions

●

Case is high-impact ABS plastic

●

Size is 3½ x 2½ x 1 inches and weight is 3 ounces

●

TEST PROCEDURE

1. Set the selector switch to the position for the specific type of battery

under test. To avoid damaging the battery or the Traceable Battery

Tester always set the selector switch prior to testing the battery.

2. Disconnect and remove the battery from the equipment in which it is

used.

3. Place the negative terminal of the battery on the metal post probe

located in the lower left corner of the unit near the (–) negative sign.

(Note, the user may, if desired, remove the metal post probe with

fingers or tweezers and replace it by plugging in the supplied black

test probe.)

4. Plug the red probe test lead into the lower right corner receptacle

near the (+) positive sign.

5. Place the metal tip of the red probe test lead on the positive

terminal of the battery.

6. If the pointer on the readout is deflected to the left then the battery

is being tested incorrectly (battery negative terminal is on positive

test probe and positive battery terminal is on negative probe).

Correct this by reversing the position. It is also possible that the

battery has reversed its polarity.

7. Read the meter scale pointer position. There are two scales on the

meter. The upper scale is used to test all batteries except hearing

aid batteries. Do not keep the probes connected to the battery for a

longer time than is needed to make a reading.

8. The reading on the upper scale indicates the following: Green—

battery is in good condition; Red—battery needs to be replaced;

White “?”—battery’s condition is marginal; it may not perform

correctly and should probably be replaced.

9. The reading on the lower scale is for use only with hearing aid

batteries. When testing silver-oxide hearing aid batteries use the

lower scale which says SILVER. When testing mercury hearing aid

batteries use the lower scale, which says MERCURY.

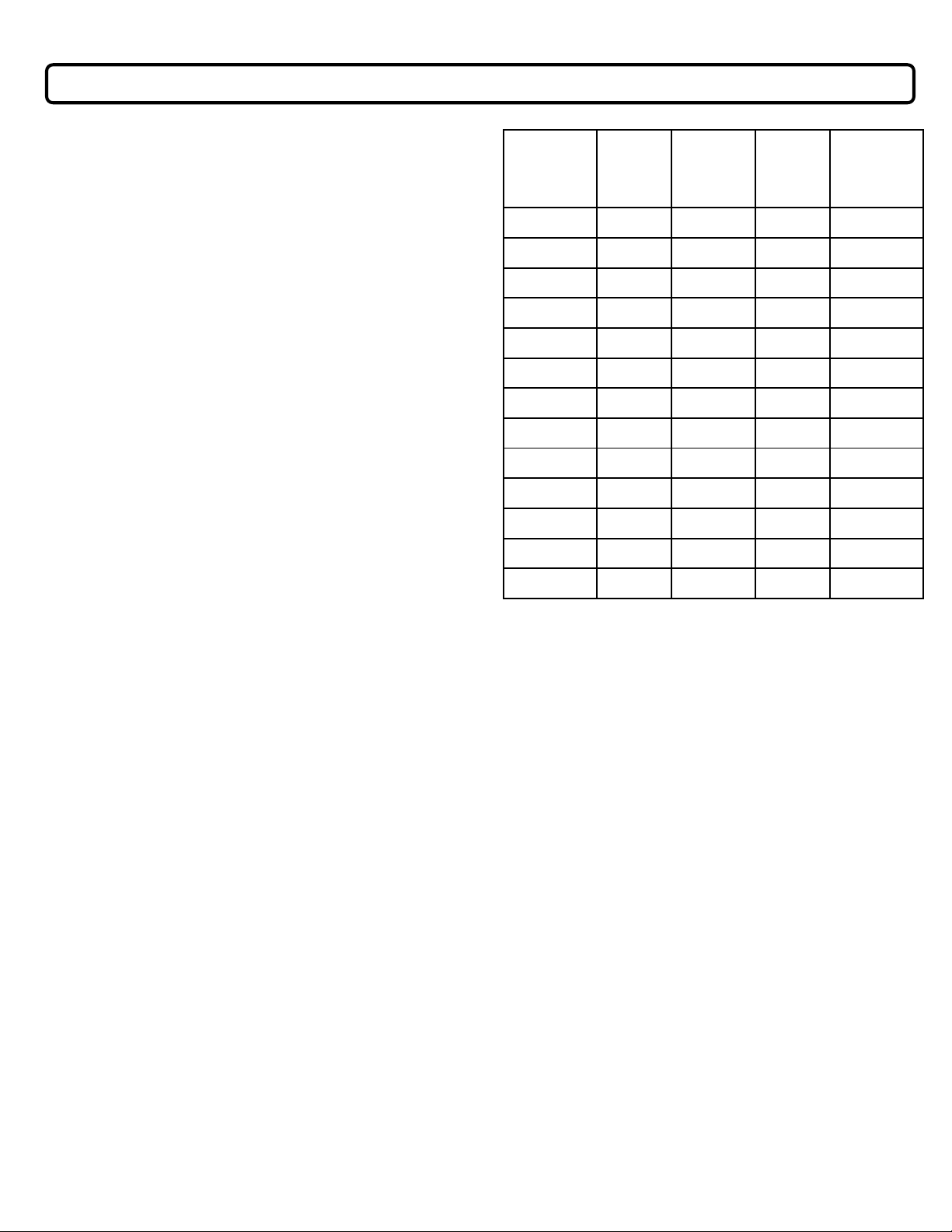

70%

Suggested

Replacement

(Volts)

1.05

1.05

1.05

1.05

1.05

2.1

8.4

6.3

4.2

2.86

1.91

1.08

1.05

Battery Type

1.5 V Button 750

1.5 V "AAA"

1.5 V "AA"

1.5 V "C"

1.5 V "D"

3 V Lithium

12 V

9 V

6 V Lantern

4.0–4.5 V

2.7–3.0 V

1.6–1.7 V

1.35–1.40 V

Test Load

Resistance

(Ohms)

75

36

9.9

4.9

2,870

60

495

14.2

900

600

1,417

280

Test Load

Current

(Milliamps)

2.2

22

46

167

333

1.15

220

20

460

5

5

1.2

5

100% New

Battery

(Volts)

1.65

1.65

1.65

1.65

1.65

3.3

13.2

9.9

6.6

4.5

3.0

1.7

1.4

WARRANTY, SERVICE, OR RECALIBRATION

For warranty, service, or recalibration, contact:

CONTROL COMPANY

4455 Rex Road

Friendswood, Texas 77546 USA

Ph. 281-482-1714

Fax 281-482-9448

E-mail sales@control3.com

www.control3.com

Control Company is ISO 9001 Quality-

Certified by DNV and ISO 17025

accredited as a Calibration Laboratory

by A2LA.

Traceable® is a registered trademark of Control Company ©2009 Control Company. 92-3410-00 Rev. 1 031609

Loading...

Loading...