Page 1

SPST

(single pole single throw)

(single pole double throw)

SPDT

(double pole single throw)

DPST

(double pole double throw)

DPDT

ZigBee IO and Extender

Installation Guide

Package contents

• C4-Z2IO ZigBee IO and Extender

• Four wall mounting screws

• Four plastic dry wall anchors

• Two IR emitters

• Micro USB power supply

Requirements

• Composer Pro 2.10.0 or higher

Features

The ZigBee IO and Extender (Z2IO) is a single device that

combines the features of:

• Remote relays (up to two)

• Remote contact sensors (up to four)

• Remote thermistors (two)

• Internal contact (internal magnetic reed switch)

• ZigBee (IEEE 802.15.4) extender

• ZigBee-to-IR converters

Any of these inputs can be used to trigger and control automated

events—such as sending an e-mail or turning on a cabinet light

when its door is opened—throughout the Control4 system.

With this device, you can extend home automation control to the

most remote of locations and applications inside or outside the

home, reducing the need to run control wires over long distances

(or where you can’t run any wires at all).

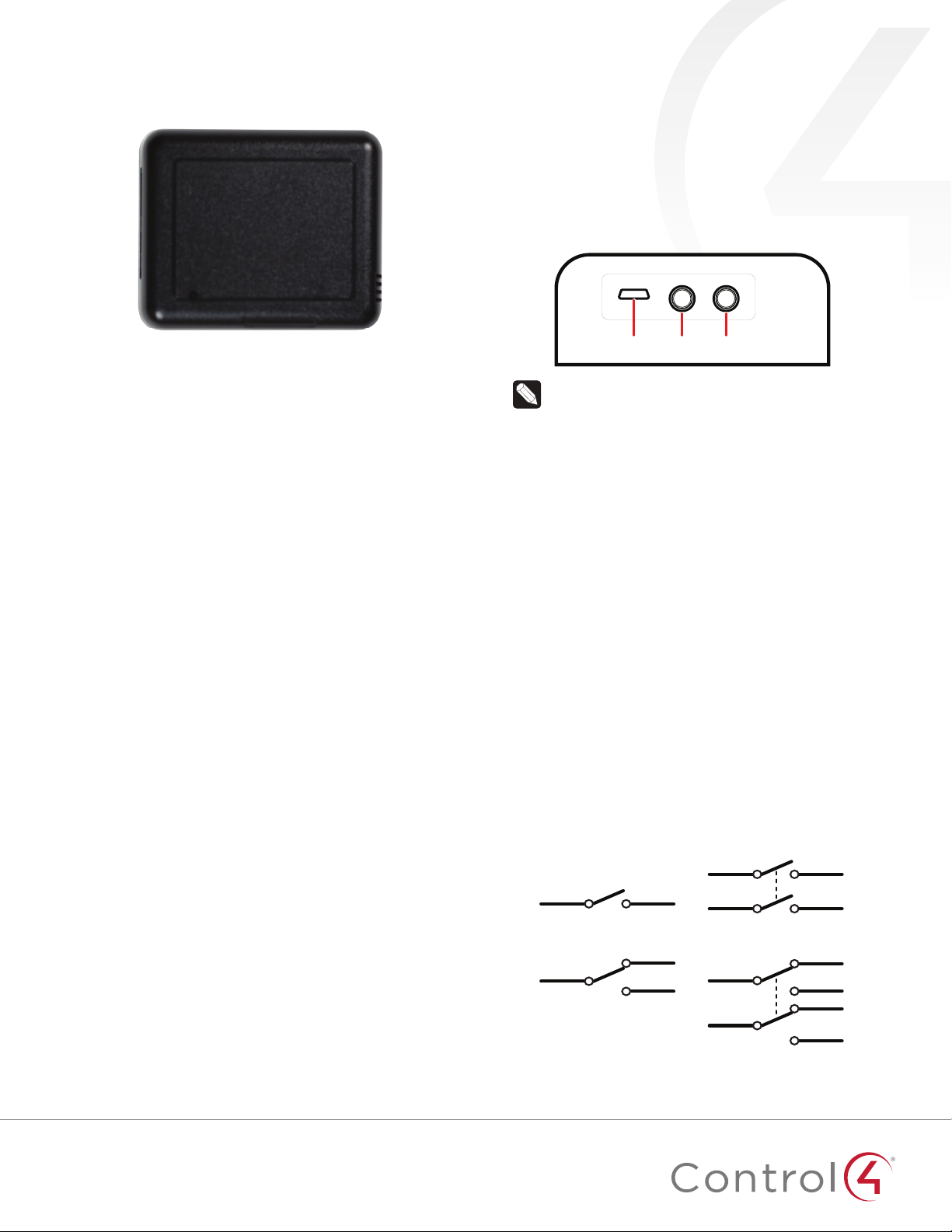

Micro USB IR 1 IR 2

Note: Y IR cables can be used, or IR cables can be

spliced together (in parallel, not in series), to increase

the number of controlled devices. Be aware that these

connected emitters cannot be controlled independently

but will all fire simultaneously from the shared IR

port. Test to verify that there is no crossover code

functionality between devices sharing the same IR port

to avoid unwanted side eects.

As a contact and relay

The device has an internal contact along one edge that can

be used to detect open or closed states when installed with

a mounted magnet. Up to four contacts (besides the internal

contact) or two additional relays, or a combination of the two,

can be used. Each option is outlined below in “Contact and Relay

Wiring Options,” and after it’s physically wired, the correct option

must be set on the Properties tab as outline further below in the

section “IO Options.”

As a relay

As a relay, this device provides wireless control of garage door

openers, window coverings, fireplaces, and pumps (along with

other relay control applications) inside or outside the home. It

integrates into Control4 systems as standard relays that can be

opened, closed, toggled, or pulsed.

The relay enables wireless control of any device controllable

by one or two low-voltage SPST relays or one simulated SPDT/

DPDT relay. These functions appear in a Control4 system as relay

outputs (relays) in Composer Pro.

As ZigBee to IR

The two 3.5 mm IR ports allow you to connect up to two standard

IR emitters to control any IR-controlled devices, such as TVs,

DVRs, and receivers.

When connecting IR emitters, make note of which port each

emitter is connected to (labeled “1” and “2”).

IR codes sent from the controller to the ZigBee IO and Extender

are cached at the device, resulting in faster IR control response

times.

11

Page 2

As a contact sensor

Depending on the selected IO configuration, up to four external

contacts are possible. As a contact sensor, this device allows

wireless monitoring of garage doors, gates, windows, mailboxes,

doorbells, and pool or spa covers (along with other contact

sensor monitoring applications you integrate or devise). These

functions appear in a Control4 system as contact sensor inputs,

which can trigger home automation events.

The internal contact is a magnetic reed switch. To use this

internal contact, the Z2IO should be mounted so that the

indention (along the same edge as the identify button) comes

in close proximity to a mounted magnet (not included) in a fully

closed state (door is closed). When the door opens, the magnetic

connection is lost, and that state change is pushed to the system.

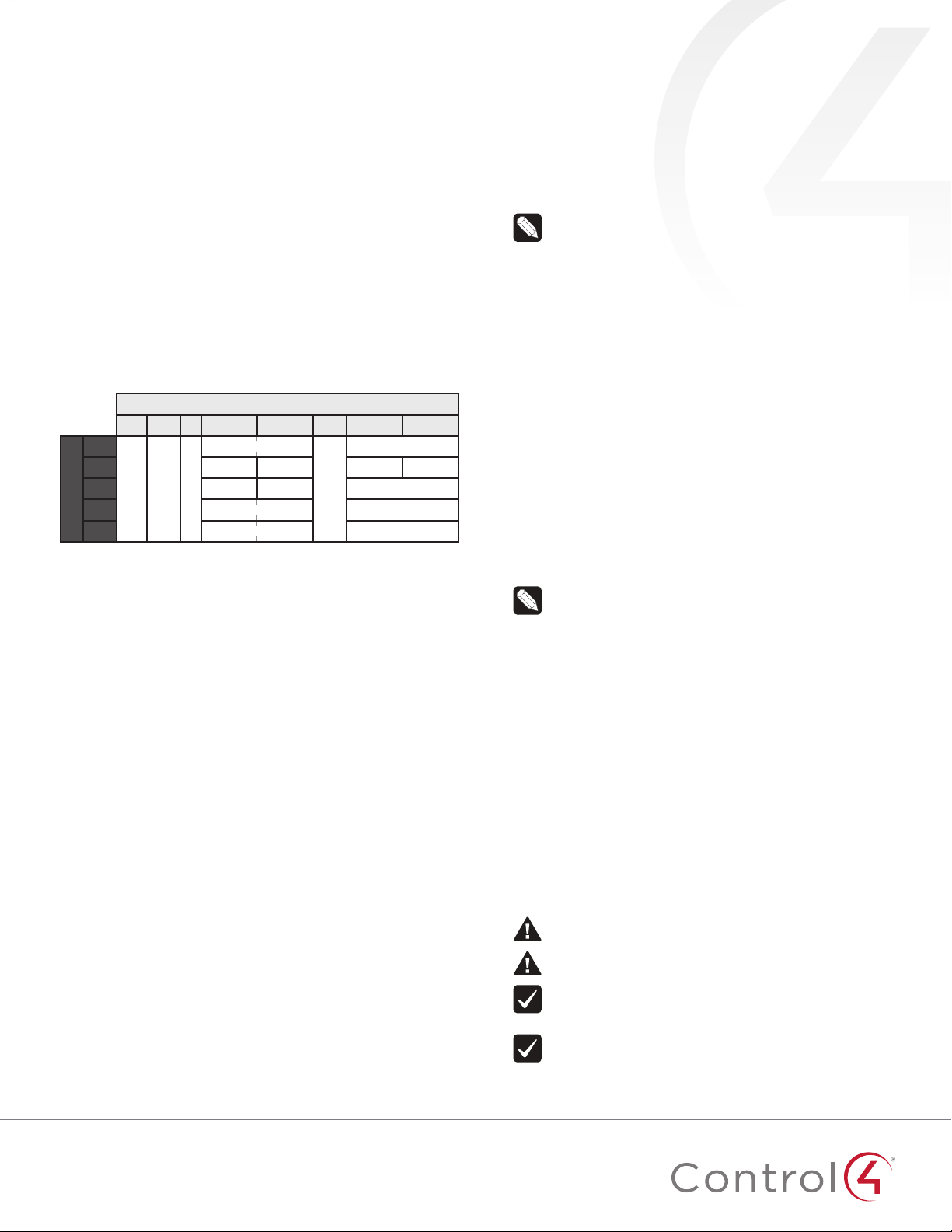

Contact and relay wiring options

There are five wiring options for contacts and relays. After they

are physically wired (as explained below), the correct option

must be manually selected on the Properties tab using the IO

Properties drop-down box.

Pins

PWR

Cm T

1

2

+ Cm T

3

Options

4

5

R# = Relay, C# = Contact, Cm = Common ground (-), T = Thermistor,

SPST = Single pole single throw, SPDT = Single pole double throw,

Option 1: Two Relays using R1, R2—Two independent, single

pole single throw (SPST) relays. Each relay controls a single

circuit.

• Relay 1 is wired to pins C1 and pin C2.

• Relay 2 is wired to pins C3 and pin C4

Option 2: Four Contacts using C1, C2, C3, C4—Four

independently sensed circuits.

• Contact 1 is wired to pin C1 and pin Cm (Common).

• Contact 2 is wired to pin C2 and pin Cm (Common).

• Contact 3 is wired to pin C3 and pin Cm (Common).

• Contact 4 is wired to pin C4 and pin Cm (Common)

Option 3: One Relay (SPST) and Two Contacts using R1 and

C1, C2.

• Relay 1 is wired to pin C1 and pin C2.

• Contact 1 is wired to pin C3 and pin Cm (Common).

• Contact 2 is wired to pin C4 and pin Cm (Common).

Option 4: One Relay using R1 and R2 (SPDT)—The two relays

operate together to simulate a single SPDT (single pole

double throw) relay. However, unlike a true SPDT relay, both

relays will open during a power failure.

• Relay 1 is wired to pin C1 and pin C2.

• Relay 2 is wired to pin C3 and pin C4.

Option 5: One Relay using R1 and R2 (DPST)—The two relays

operate together to simulate a single DPST (double pole

single throw configuration) relay. However, unlike a true

DPST relay, both relays will open during a power failure.

• Relay 1 is wired to pin C1 and pin C2.

• Relay 2 is wired to pin C3 and pin C4.

C4 C3 Cm C2 C1

R2

(SPST)

R2

(SPST)

C4 C3 C2 C1

C2 C1 R1

R2

(SPDT)

R2

(SPDT)

R2

(DPST)

R2

(DPST)

DPST = Double pole single throw

Cm

R1

R1

R1

(SPST)

(SPST)

(SPDT)

(DPST)

R1

R1

R1

R1

(SPST)

(SPST)

(SPDT)

(DPST)

As a ZigBee extender

This device acts as a ZigBee mesh extender and router. It is

designed to extend the ZigBee network into distant or hard-toreach areas. The Z2IO provides support for up to 32 nodes in

its ZigBee routing table. This is particularly useful in providing

ZigBee network extension to a large number of battery-operated,

non-routing ZigBee nodes. It can also be used to improve ZigBee

signal latency that can occur when ZigBee devices are installed

on the fringes of a ZigBee mesh network.

Note: Range and performance varies, depending

on variables such as location, building materials,

furnishings, and radio interference.

For optimal results, the device should be located within 50 feet

of another routing node and located in areas of the project where

the mesh may be weak or non-existent. This device should not be

placed next to a controller, inside a rack, or on a metal shelf. The

ZigBee extender functionality is always on.

As a thermistor and humidistat

The device contains an integrated thermistor and humidistat,

as well as a connection for an external thermistor, allowing it to

be used almost anywhere to report environmental conditions

or to inform the climate control system. The thermistor

senses temperatures from 32°F to 104°F (0°C to 40°C), and

the humidistat senses humidity from 5% to 90%. The device

checks the temperature and humidity every five seconds. If the

temperature has changed more than 0.5°F (0.28°C), the device

reports the new temperature. If the humidity has changed more

than 0.5%, the device reports the new humidity percentage.

Data from the integrated thermistor and humidistat is always

available, regardless of the selected IO configuration.

Notes:

• A value of -40° in the Remote Temperature field

could indicate either a negative temperature or that

no remote thermistor is connected.

• The integrated humidistat will return a zero value

after the device is rebooted until the actual humidity

value can be reported.

• To display the temperature and/or humidity in

Navigator, add the “Temperature Display Driver

(OS 2.10+)” to the project and connect the driver’s

temperature driver to the Z2IO.

• Given the variations in temperature and humidity

measurements and environments, it may be

necessary to independently test and verify the

local and remote temperature and humidity. The

properties Local Temperature Oset, Remote

Temperature Oset, and Local Humidity Oset can

be used for this purpose.

Important safety instructions

Caution! You should install this device in accordance

with all national and local electrical codes.

Caution! Improper use or installation of this device can

result in loss of and damage to property.

Important: This product is not intended for direct

connections to AC mains (120V/220V). Refer to the

specifications.

Important: You must operate this device in accordance

with the instructions and specifications in this

installation guide.

2

Page 3

Important: Using this product in any manner other than

outlined in this document voids your warranty. Also,

Control4 is not responsible or otherwise liable in any

way for any damage resulting from the misuse of this

product. See

Specifications

Model number

Control4 OS system

requirements

Control4 system

integration

Driver

Networks supported

ZigBee data rate

ZigBee frequency

range

Contact sensor input

Relay terminal ratings

External thermistor

Infrared

Internal contact

Integrated internal

thermistor

Integrated humidistat

Power consumption

External low-voltage

power supply

Available colors

Dimensions (L × W × H)

Weight

Environmental

Paintable enclosure

External thermistor

ctrl4.co/warranty

C4-Z2IO

for details.

System requirements

OS version 2.10.0 or greater

Each installed ZigBee IO and Extender adds sensor

and input connections to the Composer project.

The ZigBee IO and Extender (C4-Z2IO) is available

in the Composer Online Driver Database.

Communication

Control4 ZigBee Pro mesh networking protocol,

based on the IEEE 802.15.4 ZigBee standard

250 kbps

2.405 – 2.475 GHz

Connections

4 inputs, accepts AWG 16-28, common ground

connection.

0.5A @ 50V, 1A @ 24V or less

Max voltage: TBD

1 thermistor input, sold separately.

See “Accessories”

2 3.5 mm IR ports

Integrated features

Internal magnetic reed switch

Requires external magnet, sold separately

Internal thermistor can be used for local

temperature sensing: 32°F to 104°F (0°C to 40°C)

Can measure local humidity from 5% to 90%.

Power

100mA at 12V, fully active

Micro USB power supply (included)

AC/DC 5-24V (optional)

Other

Black (water-based paintable enclosure)

3.1” (78.7 mm) × 2.6” (65.7 mm) × 1.05” (26.6 mm)

2.5 oz. (70.9 grams)

Temperature:

Operational 32°F to 104°F (0°C to 40°C)

Storage -20°F to 158°F (-29°C to 70°C)

Humidity 5% to 95% non-condensing

This device is not waterproof and must be kept out

of direct contact with water. The product must not

be immersed.

The cover assembly plastics are paintable with any

water-based residential paints. Do not clog the

cover assembly vent holes with paint.

Accessories

ZCA-EXT10A, AC-DOTS1-W, AC-PMT51-W

Installing

1 Place the device in a location which ensures the following:

• Easy access to any externally-connected wires

• ZigBee mesh networking eciency

Note: Make sure the device has good ZigBee wireless

reception by (1) ensuring it is within range of another

ZigBee device and (2) avoiding other electrical

equipment that may cause interference with the ZigBee

signal (such as cordless telephones that operate on the

2.4 GHz frequency.)

• Avoiding unnecessary exposure to extreme environmental

conditions.

IMPORTANT! Do not place the device in direct sunlight.

2 If an external thermistor is used with the device, place

it away from direct sunlight, drafts, doorways, skylights,

windows, and exterior walls for best accuracy.

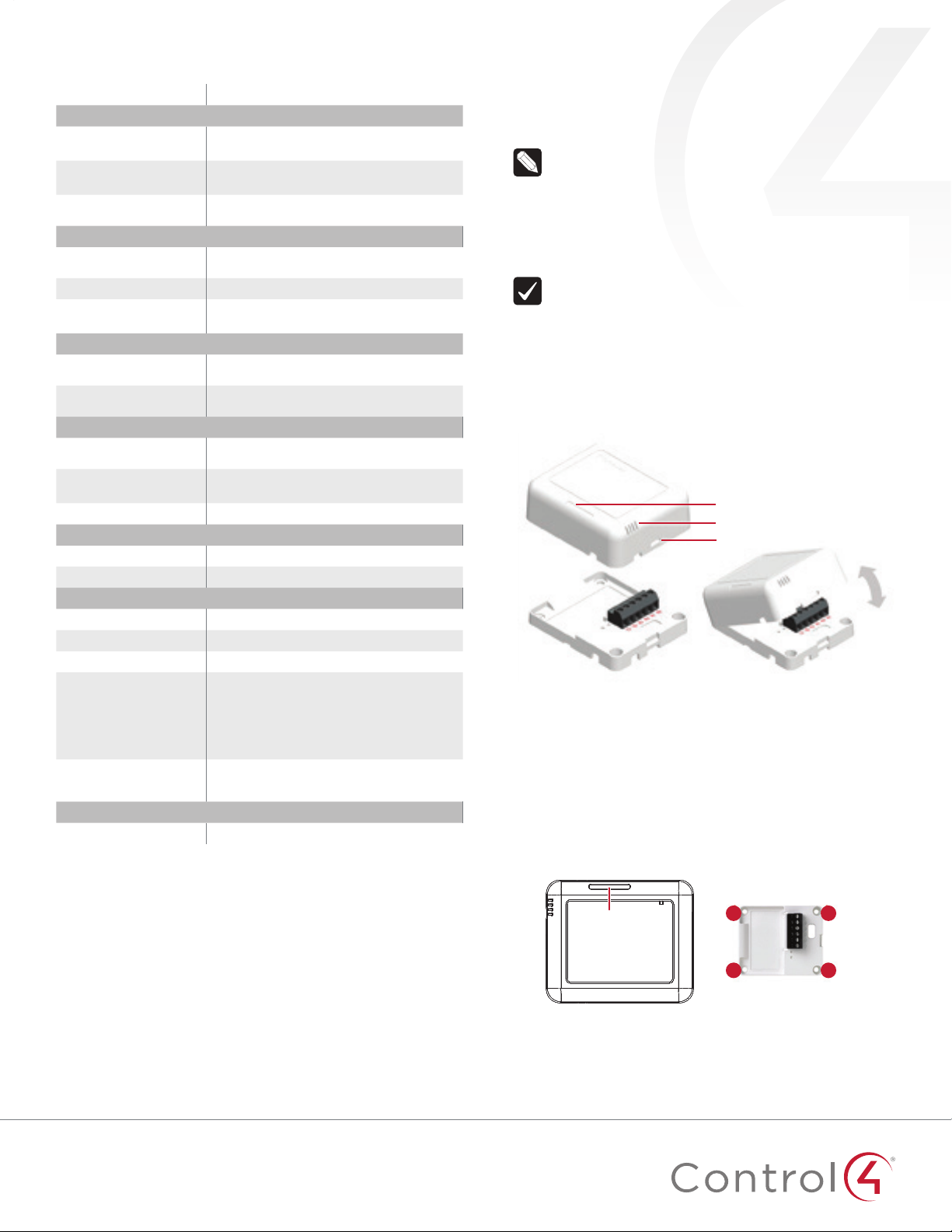

3 Detach the tray from the cover by inserting a flat screwdriver

into the opening slot in the side of the cover and pushing in

gently, while at the same time pulling the cover out and away

from the tray.

Cover

Reed switch location

Temperature chamber/LED display

Opening slot

Tra y

The cover holds the radio logic board

(the actual device) and pins, the IR

ports, the internal contact, and the

USB power connector. The cover

attaches to the tray. The tray holds the

wiring terminals and is mounted to a

wall or flat surface.

4 Position the tray against the wall or other flat surface.

5 If you are using the internal contact, position the device so

that the narrow indentation that marks the internal contact

(on the long edge of the cover) aligns with the external

magnet (not included).

Indentation

6 Mark the locations of the four screw holes on the wall.

7 If mounting the device to drywall, remove the tray from the

wall and drill four 3/16-inch (4.75mm) mounting holes at the

four screw hole locations (B) previously marked on the wall.

The cover “rocks” into contact with

the tray. To separate the two, insert a

screwdriver or other flat object into the

opening slot on the side of the cover,

gently push in and then “rock” it away

from the tray.

B

B

B

B

33

Page 4

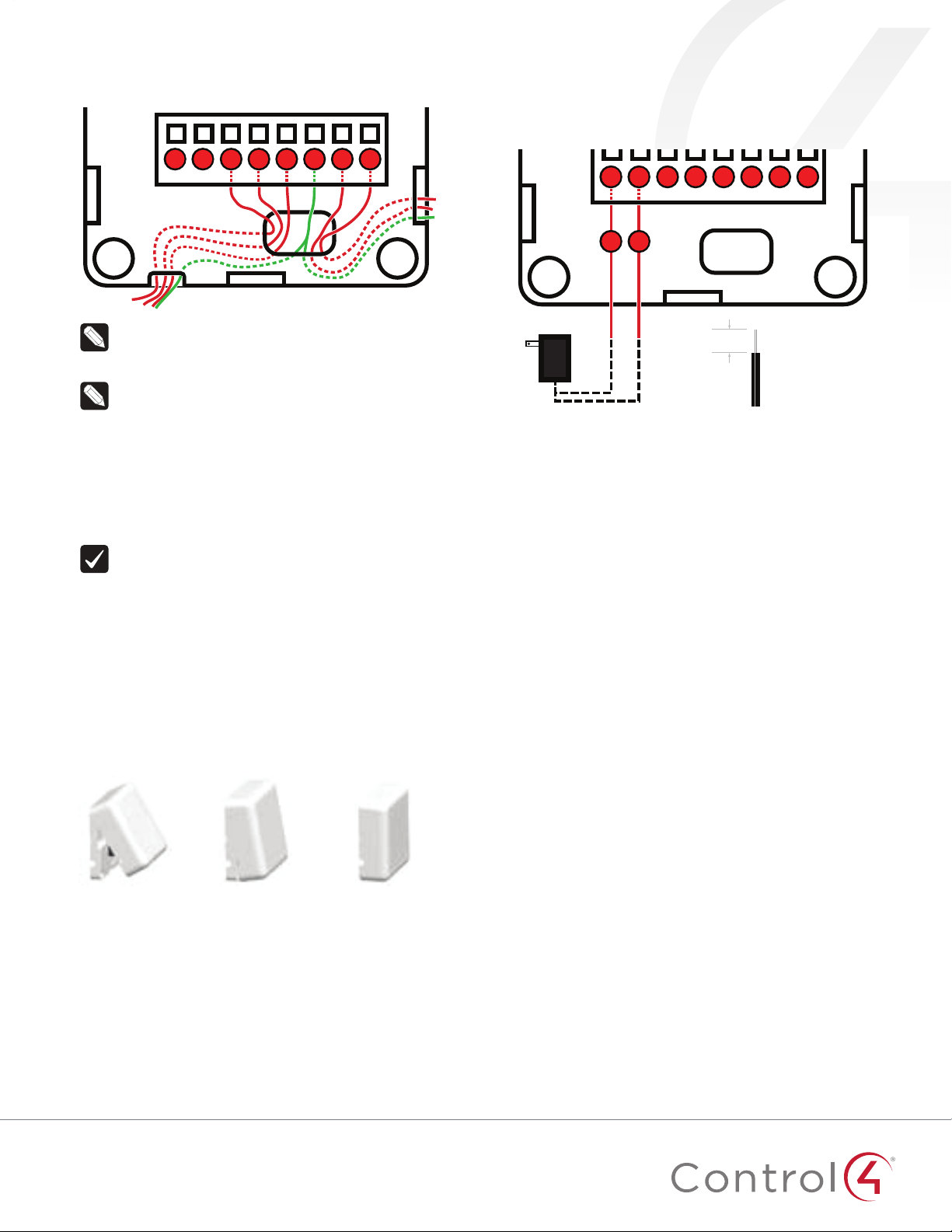

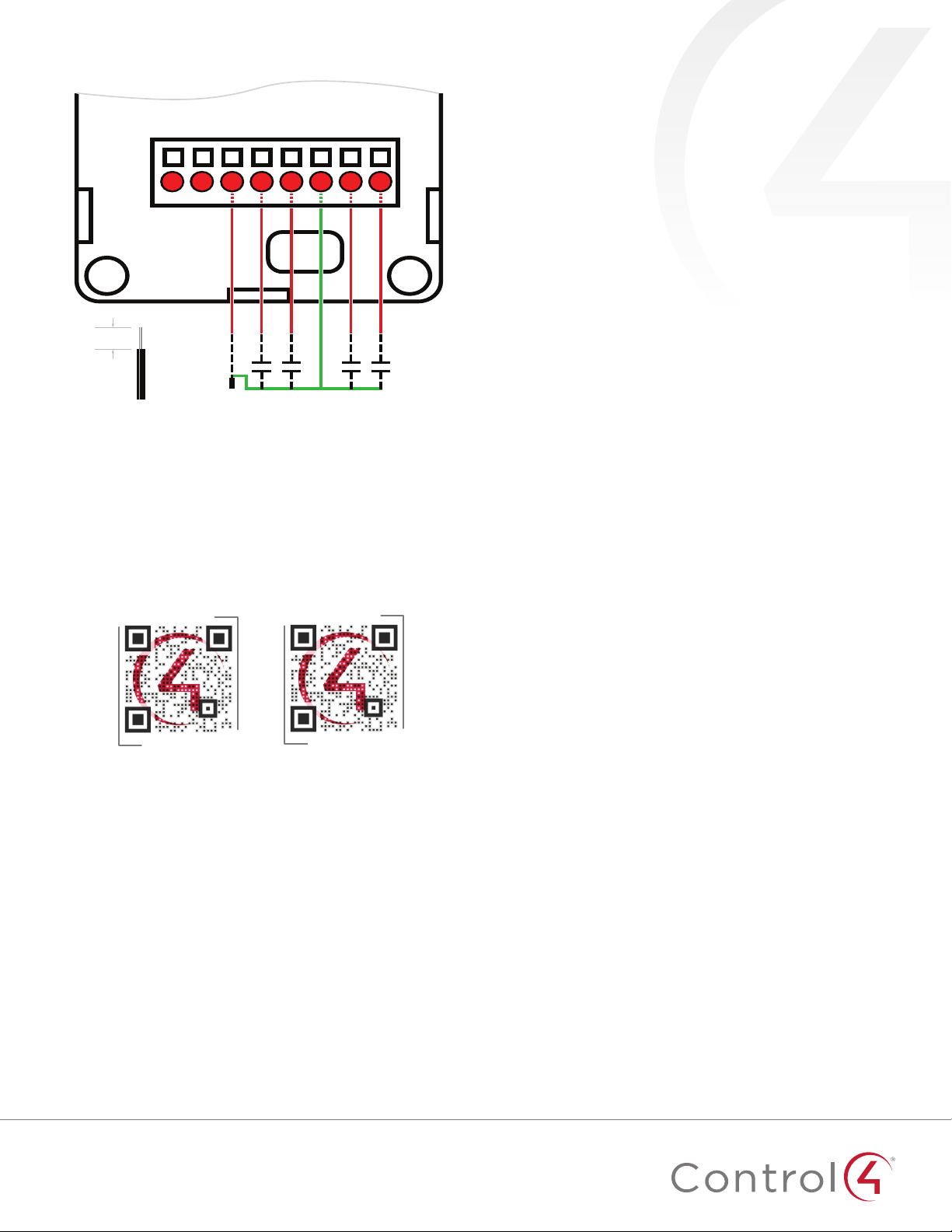

8 Thread any relay wires, contact wires, and external

thermistor wires from the wall through the openings in the

tray and to the terminal block.

Cm

T C1C2CmC3C4

PWR

Note: The two Cm (common/ground) pins are

connected and can be used interchangeably.

9 Insert and tighten the mounting screws.

Note: You may optionally choose to use robust two-

sided tape to mount the tray assembly to the wall or

other flat surface, as long as the tape won’t prevent the

back of the tray from sitting flush against the mounting

surface.

10 Connect the wires from the tray to the terminals in the cover,

matching the proper wires to the target terminal locations.

The pin/terminal definitions are defined within Composer

Pro. See “Configuring” on the next page. (Pins Cm and PWR

are used for optional external power connections.)

Important! When using multiple external contact

sensors, or when using an external contact sensor

along with an external thermistor, you MUST connect

each device to one of the Cm pins in addition to

the appropriate sensor or thermistor pin to make a

proper wiring connection. See the “Sample wiring

configurations” section of this document for examples.

11 Attach the cover assembly to the tray:

a Align the side of the cover with the side of the tray,

engaging the plastic tabs with the corresponding holes.

b Rock the cover into place, snapping it to the tray.

c Press firmly on the bottom center edge of the cover to

snap and lock it to the tray assembly.

a. Align the cover edge’s

two latching tabs with

corresponding tab

receivers on the tray’s

edge.

b. Close the cover by

rocking it toward the

other end of the tray.

c. Press firmly on the

center edge of the

cover until it snaps and

locks into place with

the tray.

12 For ZigBee to IR, connect any IR emitters to the two IR

ports, then ax the emitter head to the IR window on the

device to control (such as a TV).

Connecting alternate DC power

Although a power adapter is included, you may elect to instead

connect an alternate 5-24V DC or AC power source to pins CmPWR. Connect DC positive polarity to pin PWR, and negative to

pin Cm.

Cm

T C1C2CmC3C4

PWR

+ –

3/8˝

(9.5 mm)

DC power

Configuring

Connections

Static connections

Some connections in the driver are static in that they are

always available regardless of any settings/options. These

include the two IR connections, IR Output 1 and IR Output 2,

and the internal contact.

Dynamic connections

Other connections in the driver are dynamic in that the

connections will appear based on certain options—in

particular, the IO Options property. If you change to another

IO option, any connections created in the original IO option

will be broken.

To configure your device:

1 Add the device to your Composer Pro project. When

prompted to identify the device, press the ID button on the

face of the cover four times. The green LED blinks twice to

confirm the ID has been sent to the Control4 system.

- OR -

In Composer Express, add a device into the project, scan for

ZigBee devices, then press the ID button on the face of the

cover four times.

2 In the driver’s Properties tab, view or configure the settings

explained below under “Properties,” then click Set to the

right of the setting after each change.

3 Configure each relay’s power up state. This is the state you

want the relay to adopt after a device reboot. For example,

after a power outage (resulting in a device reboot), you

may want the garage door to default to closed, the window

coverings to be restored to their last known state, and the

fireplace to be turned o.

4

Page 5

Tip: Two SPST relays can optionally be linked to simulate

a single SPDT relay. However, unlike a true SPDT relay,

both relays will open during a power failure.

4 Add generic contact drivers (such as Door Contact Sensor,

Gate, and Motion Sensor) and relay drivers (such as Blinds,

Door Lock, and Pump) in System Design view, then connect

the generic driver to the appropriate connection on the C4Z2IO device in Connections view.

5 For programming, use these events:

• Online: Triggers when the device comes online.

• Oine: Triggers when the device goes oine.

• Reboot: Triggers when the device reboots.

Properties

General properties

• Log Level: Standard for most drivers, this property

allows you to filter which message types display in the

Lua Output window. Options 0 - 5 correspond to Fatal

through Trace levels, increasing in level of verbosity.

Options are 0=Fatal, 1=Error, 2=Warning, 3=Info, 4=Debug,

and 5=Trace. Default is 1 - Error.

• Log Mode: Activates logging of diagnostic information.

The log level is set in the above property. Options include

O, Print (to the window), Log (to the Director Log), and

Print and Log (both). Default is O.

• Driver Version: (Read only) Shows the version number of

the driver currently in use.

• Device Status: (Read only) Shows the current status of

the product, whether online or oine. However, in some

cases, the device may not report its status immediately,

such as when the device is rebooting.

• Firmware Version: (Read only) Shows the version

number of the firmware currently in use on the device.

The firmware will be updated automatically over the air

when the Control4 OS is updated and when that update

includes a new firmware version for this device.

• Bootloader Version: (Read only) Shows the version

number of the firmware currently in use on the device.

The bootloader can only be updated by Control4, so this

property is for support/diagnostic information only.

• LED Mode: Determines the behavior of the LED light on

the top/front of the product. Options include O, ZigBee

(which shows the ZigBee status; see “Identification and

Button Presses” below), and IR (which shows activity

when IR signals are sent to the IR ports). Default is O.

When the property is set to O, button presses should still

temporarily prompt the LED to show the status.

Humidity prperties

• Local Humidity: (Read only) Shows the relative humidity

measured where the device is located. The value is shown

as a percentage.

• Local Humidity Oset: The humidity sensor provides

accuracy of +/- 4% relative humidity. Adjusting the

Local Humidity Oset can result in increased inaccuracy

of relative humidity reporting without using humidity

calibration equipment for validation.

Temperature and humidity properties

• Temperature Scale: Sets which scale is used to

calculate the temperature used in the Local and Remote

Temperature properties described below, and aects only

the Properties tab’s settings. Options include Fahrenheit

and Celsius. Default is Fahrenheit.

• Local Temperature: (Read only) Shows the most recent

reported temperature recorded by the internal thermistor.

The scale of the temperature is determined by the

Temperature Scale property.

• Local Temperature Oset—Modifies the reported local

temperature to account for environmental variances. The

temperature can be changed downward or upward by a

maximum of 20 degrees. The default is 0 (no correction).

• Remote Temperature: (Read only) Shows the most recent

reported temperature recorded by the remote thermistor.

The scale of the temperature is determined by the

Temperature Scale property.

• Remote Temperature Oset—Modifies the reported

remote temperature (the temperature recorded by

an external thermistor) to account for environmental

variances. (When multiple temperature sensors are

located in the same room, you may notice each sensor

shows a slightly dierent reading. This results from normal

manufacturing variances in temperature sensors and the

device’s position/location in the room.) The temperature

can be changed downward or upward by a maximum of

20 degrees. The default is 0 (no correction).

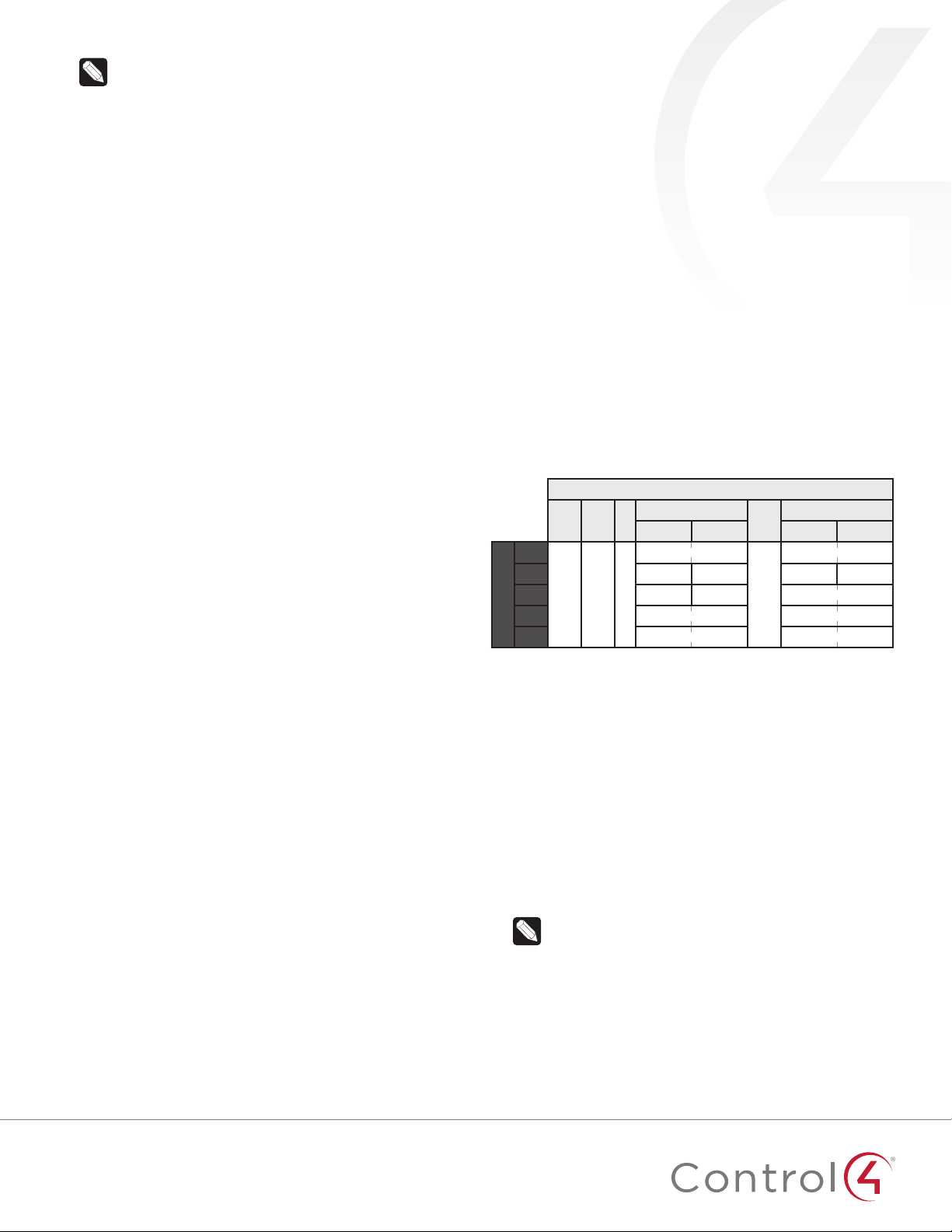

IO properties

• IO Options: Tells the device how its eight configuration

pins are assigned. The selected option is retained even

after a system reboot or update.

Pins

1

2

3

Options

4

5

R2

PWR

Cm T

+ Cm T

R# = Relay, C# = Contact, Cm = Common ground (-), T = Thermistor,

SPST = Single pole single throw, SPDT = Single pole double throw,

C4 C3 C2 C1

R2

(SPST)

R2

C4 C3 C2 C1

C2 C1 R1

R2

(SPDT)

R2

R2

(DPST)

R2

DPST = Double pole single throw

Cm

(SPST)

Cm

(SPDT)

(DPST)

R1

R1

R1

(SPST)

(SPST)

(SPDT)

(DPST)

R1

R1

(SPST)

R1

(SPST)

R1

(SPDT)

R1

(DPST)

• Option 1: R1, R2 (both SPST [single pole single throw]):

(Default) Both relays are single pole single throw,

meaning they are independent of each other; or, in

other words, each relay controls only one circuit.

• Option 2: C1, C2, C3, C4: Four contacts.

• Option 3: R1 (SPST), C1, C2: One relay (single pole

single throw) and two contacts.

• Option 4: R1 (SPDT [single pole double throw]): The

two relays operate together to simulate a single SPDT

(single pole double throw) relay. However, unlike a true

SPDT relay, both relays will open during a power failure.

• Option 5: R1 (DPST [double pole single throw]): The

two relays operate together to simulate a single DPST

(double pole single throw configuration) relay.

Notes:

• The ZigBee extender, IR emitter control, internal

contact, internal thermistor, and internal humidistat

remain active regardless of the selected IO

configuration.

• The selected IO option will change the available

connections, so existing connections will be

disconnected or deleted.

• The selected IO option determines the available fields

in Contact properties and Relay properties.

Contact properties

55

Page 6

• Contact Internal Status: (Read only) Shows the status of

the static connection for the internal contact.

• Contact 1-4 Status: (Read only) Represents the status of

the wired contacts if IO Option 1, 3, 4, or 5 is selected.

Relay properties

• Relay 1 Power Up State and Relay 2 Power Up State:

(Read only) Represents the status of the relays if IO

Option 1, 3, 4, or 5 is selected. The options are Restore

Last State, Set To OPEN, and Set To CLOSED. The default

is Restore Last State.

• Relay 1 Status and Relay 2 Status: (Read only) Represents

the status of the relays if IO Option 1, 3, 4, or 5 is selected.

Actions tab

Buttons located on the Actions tab allow you to view

version and diagnostic information and force relay actions.

(Relay actions will always be shown, regardless of the IO

configuration.)

• Version Information: This action button will display the

versions of the driver’s Base Template and Template, as

well as the Boot Loader to the Lua Output window of the

Lua tab. The Log Mode property does not have to be set

to Print to display this information to the window.

• Diagnostic Information: This action button will display the

following information to the Lua Output window of the

Lua tab (the Log Mode property does not have to be set

to Print to display this information to the window): device

ZigBee MAC address, ZigBee mesh PAN id, Template

Version, Base Template Version, Boot Loader Version,

ZigBee Node ID.

• Relay 1 Close and Relay 2 Close: These action buttons will

trigger the corresponding relay to close.

• Relay 1 Open and Relay 2 Open: These action buttons will

trigger the corresponding relay to open.

Troubleshooting

If the device is not working:

• Reboot the device by disconnecting power, then reconnecting power.

• Check for proper wiring. See the “Wiring Configuration”

diagrams.

• Review the log in the driver’s Lua tab.

• Restore factory defaults (13 button presses).

Note: Un-identifying a device o the ZigBee mesh will cause it to

do a factory reset. A factory reset reverts all relays to the open

state, and the settings for Power Up State will revert to Restore

Last State. The settings are preserved, however, after a power

cycle or reboot.

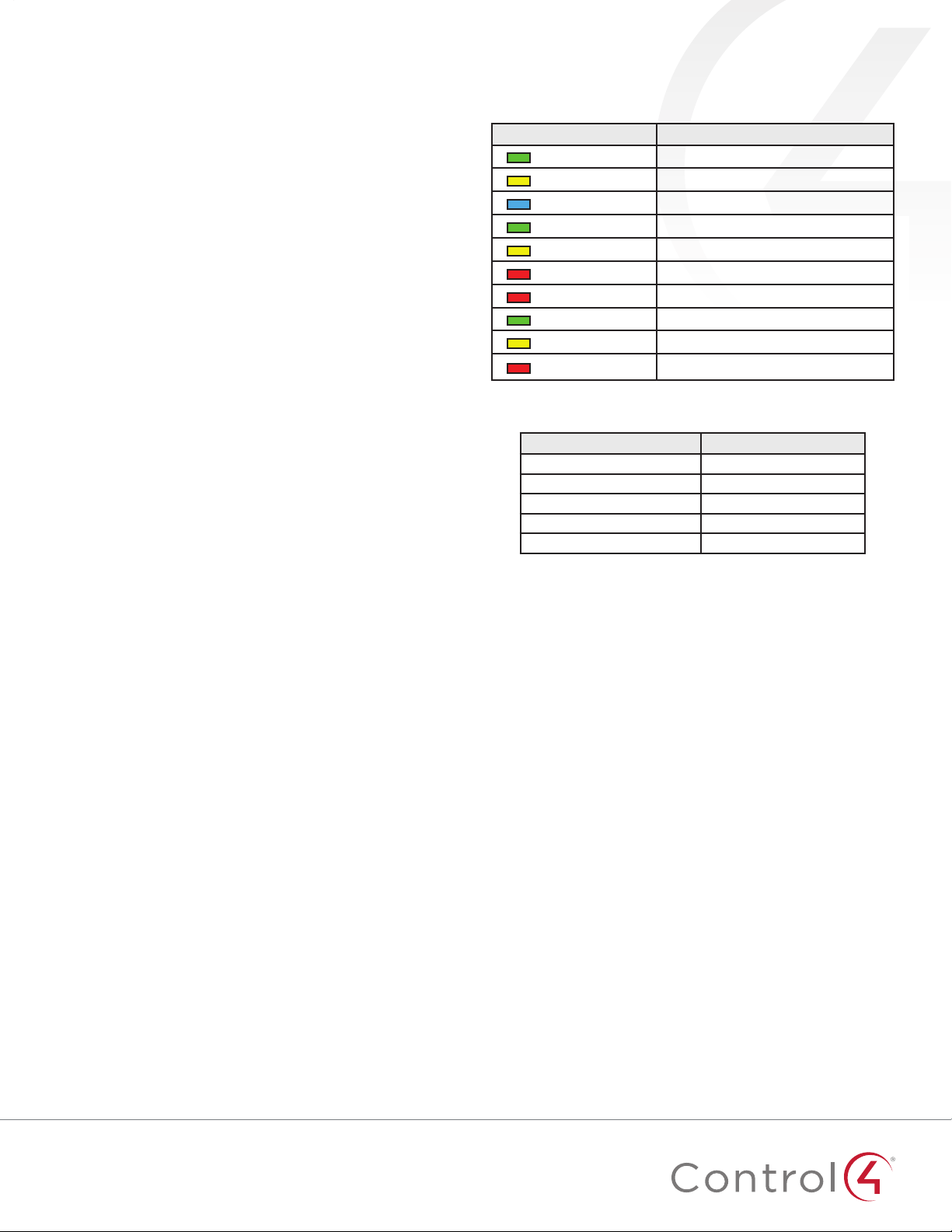

LED diagnostics

The indicated statuses appear during device identification and

when the ID button is pressed once.

LED Description

[Green] On

[Yellow] Slow flashing

[Blue] On

[Green] Fast flashing

[Yellow] Fast flashing

[Red] Fast flashing

[Red] Medium flashing

[Green] Slow flashing

[Yellow] Slow flashing

[Red] Slow flashing

Oine/Waiting for Director

Scanning

Join success

Join success signal strength=good

Join success signal strength=adequate

Join success signal strength=risk/low

Join failed (then returns to oine)

Signal strength=good (from Network Tools)

Signal strength=adequate (from Network Tools)

Signal strength=risk/low (from Network Tools)

Button sequences

Functions # of button presses

Identify 4

Reboot/Reset 15

Reset application defaults 9

Leave mesh, restore factory defaults 13

Signal strength flash LEDs 1

Restoring to previous firmware version

1 Power o the device (disconnect power).

2 While holding down the ID button, reconnect power, and

continue to press the ID button until the LED changes from

red to white (about five seconds).

3 Release the button. The device will reboot to its previous

firmware version in about one minute.

6

Page 7

ZigBee Contact Sensor

Installation Guide

Package contents

• C4-Z2C ZigBee Contact Sensor

• Four wall mounting screws

• Four plastic dry wall anchors

• AA batteries (2)

Requirements

• Composer Pro 2.10.0 or higher

Features

The ZigBee Contact Sensor (Z2C) is a single device that

combines the features of:

• Remote contact sensors (up to four)

• Remote thermistors (one)

• Internal contact (internal magnetic reed switch)

• Internal thermistor and humidistat

Any of these inputs can be used to trigger and control automated

events—such as sending an e-mail or turning on a cabinet light

when its door is opened—throughout the Control4 system.

You can position this wireless device anywhere you need contact

connections or climate reporting.

As a contact sensor

The device contains five contacts: one internal contact and

connections for four wired contacts.

The internal contact is a magnetic reed switch. To use this internal

contact, the Z2C should be mounted so that the indention (along

the same edge as the identify button) comes in close proximity

to a mounted magnet (not included) in a fully closed state (door

is closed). When the door opens, the magnetic connection is lost,

and that state change is pushed to the system.

Wiring guide:

Contact 1 -> Pin C1

Contact 2 -> Pin C2

Contact 3 -> Pin C3

Contact 4 -> Pin C4

(All can use either of the Cm pins as Common)

As a thermistor and humidistat

The device contains an integrated thermistor and humidistat,

as well as a connection for an external thermistor, allowing it to

be used almost anywhere to report environmental conditions

or to inform the climate control system. The thermistor

senses temperatures from 32°F to 104°F (0°C to 40°C), and

the humidistat senses humidity from 5% to 90%. The device

checks the temperature and humidity every five minutes. If the

temperature has changed more than 0.9°F (0.5°C), the device

reports the new temperature and humidity values.

Notes:

• A value of -40° in the Remote Temperature field

could indicate either a negative temperature or that

no remote thermistor is connected.

• The integrated humidistat will return a zero value

after the device is rebooted until the actual humidity

value can be reported.

• See “Sample wiring configurations” below for an

example of an external thermistor connection.

• To display the temperature and/or humidity in

Navigator, add the “Temperature Display Driver

(OS 2.10+)” to the project and connect the driver’s

temperature driver to the Z2C.

• Given the variations in temperature and humidity

measurements and environments, it may be

necessary to independently test and verify the

local and remote temperature and humidity. The

properties Local Temperature Oset, Remote

Temperature Oset, and Local Humidity Oset can

be used for this purpose.

Important safety instructions

Caution! You should install this device in accordance

with all national and local electrical codes.

Caution! Improper use or installation of this device can

result in loss of and damage to property.

Important: This product is not intended for direct

connections to AC mains (120V/220V). Refer to the

specifications.

Important: You must operate this device in accordance

with the instructions and specifications in this

installation guide.

Important: Using this product in any manner other than

outlined in this document voids your warranty. Also,

Control4 is not responsible or otherwise liable in any

way for any damage resulting from the misuse of this

product. See

ctrl4.co/warranty

for details.

11

Page 8

Specifications

Model number

Control4 OS system

requirements

Control4 system

integration

Driver

Networks supported

ZigBee data rate

ZigBee frequency

range

Contact sensor input

External thermistor

Internal contact

Integrated internal

thermistor

Integrated humidistat

Power consumption

Power

Available colors

Dimensions (L × W × H)

Weight

Environmental

Paintable enclosure

External thermistor

C4-Z2C

System requirements

OS version 2.10.0 or greater

Each installed ZigBee Contact Sensor requires

input connections to the Composer project.

The ZigBee Contact Sensor (C4-Z2C) is available in

the Composer Online Driver Database.

Communication

Control4 ZigBee Pro mesh networking protocol,

based on the IEEE 802.15.4 ZigBee standard

250 kbps

2.405 – 2.475 GHz

Connections

4 inputs, accepts AWG 16-28, common ground

connection.

1 thermistor input, sold separately.

See “Accessories”

Integrated features

Internal magnetic reed switch

Requires external magnet, sold separately

Internal thermistor can be used for local

temperature sensing: 32°F to 104°F (0°C to 40°C)

Can measure local humidity from 5% to 90%.

Power

100mA at 3V, fully active

AA batteries (2), included

Other

Black (water-based paintable enclosure)

3.1” (78.7 mm) × 2.6” (65.7 mm) × 1.05” (26.6 mm)

2.5 oz. (70.9 g) without batteries

Temperature:

Operational 32°F to 104°F (0°C to 40°C)

Storage -20°F to 158°F (-29°C to 70°C)

Humidity 5% to 95% non-condensing

This device is not waterproof and must be kept out

of direct contact with water. The product must not

be immersed.

The cover assembly plastics are paintable with any

water-based residential paints. Do not clog the

cover assembly vent holes with paint.

Accessories

ZCA-EXT10A, AC-DOTS1-W, AC-PMT51-W

Installing

1 Place the device in a location which ensures the following:

• Easy access to any externally-connected wires

• ZigBee mesh networking eciency

Note: Make sure the device has good ZigBee wireless

reception by (1) ensuring it is within range of another

ZigBee device and (2) avoiding other electrical

equipment that may cause interference with the ZigBee

signal (such as cordless telephones that operate on the

2.4 GHz frequency.)

• Avoiding unnecessary exposure to extreme environmental

conditions.

IMPORTANT! Do not place the device in direct sunlight.

2 If an external thermistor is used with the device, place

it away from direct sunlight, drafts, doorways, skylights,

windows, and exterior walls for best accuracy.

3 Detach the tray from the cover by inserting a flat screwdriver

into the opening slot in the side of the cover and pushing

in gently, while at the same time pulling the cover out and

away from the tray.

Cover

Internal contact location

Temperature chamber/LED display

Opening slot

Tra y

The cover holds the radio logic board

(the actual device) and pins and the

internal contact. The cover attaches

to the tray. The tray holds the wiring

terminals and is mounted to a wall or

flat surface.

4 Position the tray against the wall or other flat surface.

5 If you are using the internal contact, position the device so

that the narrow indentation that marks the internal contact

(on the long edge of the cover) aligns with the external

magnet (not included).

The cover “rocks” into contact with

the tray. To separate the two, insert a

screwdriver or other flat object into the

opening slot on the side of the cover,

gently push in and then “rock” it away

from the tray.

Indentation

B

B

B

B

6 Mark the locations of the four screw holes on the wall.

7 If mounting the device to drywall, remove the tray from the

wall and drill four 3/16-inch (4.75mm) mounting holes at the

four screw hole locations (B) previously marked on the wall.

2

Page 9

8 Thread any contact or thermistor wires from the wall through

the openings in the tray and to the terminal block.

T C1C2CmC3C4VO Cm

Note: The two Cm (common/ground) pins are

connected and can be used interchangeably.

9 Insert and tighten the mounting screws.

Note: You may optionally choose to use robust two-

sided tape to mount the tray assembly to the wall or

other flat surface, as long as the tape won’t prevent the

back of the tray from sitting flush against the mounting

surface.

10 Connect the wires from the tray to the terminals in the cover,

matching the proper wires to the target terminal locations.

Important! When using multiple external contact

sensors, or when using an external contact sensor along

with an external thermistor, you must connect each

device to one of the Common (Cm) pins in addition

to the appropriate sensor or thermistor pin to make

a proper wiring connection. See the “Sample wiring

configurations” section of this document for examples.

11 Attach the cover assembly to the tray:

a Align the side of the cover with the side of the tray,

engaging the plastic tabs with the corresponding holes.

b Rock the cover into place, snapping it to the tray.

c Press firmly on the bottom center edge of the cover to

snap and lock it to the tray assembly.

a. Align the cover edge’s

two latching tabs with

corresponding tab

receivers on the tray’s

edge.

b. Close the cover by

rocking it toward the

other end of the tray.

c. Press firmly on the

center edge of the

cover until it snaps and

locks into place with

the tray.

Configuring

To configure your device:

1 Add the device to your Composer Pro project. When

prompted to identify the device, press the ID button on the

face of the cover four times. The green LED blinks twice to

confirm the ID has been sent to the Control4 system.

- OR -

In Composer Express, add a device into the project, scan for

ZigBee devices, then press the ID button on the face of the

cover four times.

2 In the driver’s Properties tab, view or configure the settings

explained below under “Properties,” then click Set to the

right of the setting after each change.

3 Add generic contact drivers (such as Door Contact Sensor,

Gate, and Motion Sensor) in System Design view, then

connect the generic driver to the appropriate connection on

the C4-Z2C device in Connections view.

4 For programming, use these events:

• Missed Checkin: Triggers when the device misses a

controller check in for the number of times specified in

the driver’s “Missed Checkin Limit” setting.

• Online: Triggers when the device comes online.

• Oine: Triggers when the device goes oine.

• Reboot: Triggers when the device reboots.

Properties

General properties

• Log Level: Standard for most drivers, this property

allows you to filter which message types display in the

Lua Output window. Options 0 - 5 correspond to Fatal

through Trace levels, increasing in level of verbosity.

Options are 0=Fatal, 1=Error, 2=Warning, 3=Info, 4=Debug,

and 5=Trace. Default is 1 - Error.

• Log Mode: Activates logging of diagnostic information.

The log level is set in the above property. Options include

O, Print (to the window), Log (to the Director Log), and

Print and Log (both). Default is O.

• Driver Version: (Read only) Shows the version number of

the driver currently in use.

• Device Status: (Read only) Shows the current status of

the product, whether online or oine. However, in some

cases, the device may not report its status immediately,

such as when the device is rebooting.

• Firmware Version: (Read only) Shows the version

number of the firmware currently in use on the device.

The firmware will be updated automatically over the air

when the Control4 OS is updated and when that update

includes a new firmware version for this device.

• Bootloader Version: (Read only) Shows the version

number of the firmware currently in use on the device.

The bootloader can only be updated by Control4, so this

property is for support/diagnostic information only.

Battery properties

• Battery Level: Reports the charge level of the battery.

When the batteries on a Z2C are low, a low battery alert

can be configured using the Z2C’s battery level. When the

batteries are very low, the LED behavior and temperature

and humidity reporting become unreliable.

Humidity properties

• Local Humidity: (Read only) Shows the relative humidity

measured where the device is located. The value is shown

as a percentage.

• Local Humidity Oset: The humidity sensor provides

accuracy of +/- 4% relative humidity. Adjusting the

Local Humidity Oset can result in increased inaccuracy

of relative humidity reporting without using humidity

calibration equipment for validation.

33

Page 10

Temperature properties

• Temperature Scale: Sets which scale is used to

calculate the temperature used in the Local and Remote

Temperature properties described below, and aects only

the Properties tab’s settings. Options include Fahrenheit

and Celsius. Default is Fahrenheit.

• Local Temperature: (Read only) Shows the most recent

reported temperature recorded by the internal thermistor.

The scale of the temperature is determined by the

Temperature Scale property.

• Local Temperature Oset—Modifies the reported local

temperature to account for environmental variances. The

temperature can be changed downward or upward by a

maximum of 20 degrees. The default is 0 (no correction).

• Remote Temperature: (Read only) Shows the most recent

reported temperature recorded by the remote thermistor.

The scale of the temperature is determined by the

Temperature Scale property.

• Remote Temperature Oset—Modifies the reported

remote temperature (the temperature recorded by

an external thermistor) to account for environmental

variances. (When multiple temperature sensors are

located in the same room, you may notice each sensor

shows a slightly dierent reading. This results from normal

manufacturing variances in temperature sensors and the

device’s position/location in the room.) The temperature

can be changed downward or upward by a maximum of

20 degrees. The default is 0 (no correction).

Contacts properties

• Contact Internal Status: (Read only) Shows the status of

the static connection for the internal contact.

• Contact 1-4 Status: (Read only) Represents the status of

the wired contacts.

Checkin properties

• Checkin Interval: Defines how often the device checks

with the controller to see if the controller is requesting

information from the device, such as version information,

or if the controller is trying to update any settings on

the device, such as the check in interval. A check in can

also be manually triggered by pressing the button on the

Z2C. The check-in interval can be configured to check in

with the controller between 10 minutes and 4 hours. The

default is 10 minutes. Increasing the check-in interval will

increase the battery life of the device.

• Last Checkin Time: (Read only) Shows the most recent

time the device checked in with the controller.

• Missed Checkin Limit: Sets the number of times the

checkin is missed before triggering the “Missed Checkin”

programming event.

Actions tab

Buttons located on the Actions tab allow you to view version

and diagnostic information.

• Version Information: This action button will display the

versions of the driver’s Base Template and Template, as

well as the Boot Loader to the Lua Output window of the

Lua tab. The Log Mode property does not have to be set

to Print to display this information to the window.

• Diagnostic Information: This action button will display the

following information to the Lua Output window of the

Lua tab (the Log Mode property does not have to be set

to Print to display this information to the window): device

ZigBee MAC address, ZigBee mesh PAN id, Template

Version, Base Template Version, Boot Loader Version,

ZigBee Node ID.

Troubleshooting

If the device is not working:

• Reboot the device by disconnecting power, then reconnecting power.

• Check for proper wiring. See the “Wiring Configuration”

diagrams.

• Review the log in the driver’s Lua tab.

• Restore factory defaults (13 button presses).

Note: Un-identifying a device o the ZigBee mesh will cause it

to do a factory reset. The settings are preserved, however, after a

power cycle or reboot.

LED diagnostics

The indicated statuses appear during device identification and

when the ID button is pressed once.

LED Description

[Green] On

[Yellow] Slow flashing

[Blue] On

[Green] Fast flashing

[Yellow] Fast flashing

[Red] Fast flashing

[Red] Medium flashing

[Green] Slow flashing

[Yellow] Slow flashing

[Red] Slow flashing

Button sequences

Functions # of button presses

Identify 4

Reboot/Reset 15

Reset application defaults 9

Leave mesh, restore factory defaults 13

Signal strength flash LEDs 1

Restoring to previous firmware version

1 Power o the device (disconnect power).

2 While holding down the ID button, reconnect power, and

continue to press the ID button until the LED changes from

red to white (about five seconds).

3 Release the button. The device will reboot to its previous

firmware version in about one minute.

Oine/Waiting for Director

Scanning

Join success

Join success signal strength=good

Join success signal strength=adequate

Join success signal strength=risk/low

Join failed (then returns to oine)

Signal strength=good (from Network Tools)

Signal strength=adequate (from Network Tools)

Signal strength=risk/low (from Network Tools)

4

Page 11

Sample wiring configuration

16-28 AWG

from

equipment

C1C2C3C4

3/8˝

(9.5 mm)

Thermistor

Common

T C1C2CmC3C4VO Cm

Additional resources

The following resources are available for additional support:

• Control4 Knowledgebase and forums

• Control4 Technical Support

• Control4 website:

• Composer documentation available at

For the latest version of this document, open this URL or scan the

QR code on a device that can view PDFs.

MOST RECENT VERSION

www.control4.com

ctrl4.co/docs

DATA SHEET

.

ctrl4.co/z2c-ig

ctrl4.co/z2c-ds

Regulatory/Safety information

To review Regulatory information for your particular Control4

products, see the information located on the Control4 website at

ctrl4.co/reg

.

Patent information

Applicable patents are available at

ctrl4.co/patents

.

Warranty

Visit

ctrl4.co/warranty

Copyright ©2017, Control4 Corporation. All rights reserved. Control4, the Control4 logo, the 4-ball logo, 4Store, 4Sight, Control4 My Home, and Mockupancy are

registered trademarks or trademarks of Control4 Corporation or its subsidiaries in the United States and/or other countries. All other names and brands may be claimed

as the property of their respec-tive owners. All specifications subject to change without notice. .

55

for details.

A

DOC-00184-A

2017-07-18 MS

Page 12

Sample wiring configurations

16-28 AWG

from

equipment

C1C2C3C4

3/8˝

(9.5 mm)

Thermistor

Common

T C1C2CmC3C4

PWR

Cm

Option 1: R1, R2 (both SPST)

Cm

T C1C2CmC3C4

PWR

Additional resources

The following resources are available for additional support:

• Control4 Knowledgebase and forums

• Control4 Technical Support

• Control4 website:

• Composer documentation available at

For the latest version of this document, open this URL or scan

the QR code on a device that can view PDFs.

MOST RECENT VERSION

www.control4.com

ctrl4.co/docs

DATA SHEET

.

16-28 AWG

3/8˝

(9.5 mm)

from equipment

Relay 1 (SPST)

Source2Load2

Source1Load1

Relay 2 (SPST)

Option 2: C1, C2, C3, C4 (including an optional external thermistor)

ctrl4.co/z2io-ig

ctrl4.co/z2io-ds

Regulatory/Safety information

To review Regulatory information for your particular Control4

products, see the information located on the Control4 website at

ctrl4.co/reg

.

Patent information

Applicable patents are available at

ctrl4.co/patents

.

Warranty

Visit

ctrl4.co/warranty

for details.

Copyright ©2017, Control4 Corporation. All rights reserved. Control4, the Control4 logo, the 4-ball logo, 4Store, 4Sight, Control4 My Home, and Mockupancy are

registered trademarks or trademarks of Control4 Corporation or its subsidiaries in the United States and/or other countries. All other names and brands may be claimed

as the property of their respec-tive owners. All specifications subject to change without notice. .

7

A

DOC-00184-A

2017-07-18 MS

Page 13

Regulatory Compliance & Safety Information for Control4 Model C4-Z2IO & C4-Z2C

Electrical Safety Advisory

Sécurité électrique consultatif

Important Safety Instructions

Consignes de sécurité importantes

Read the safety instructions before using this product.

Lisez les consignes de sécurité avant d'utiliser ce produit.

1. Read these instructions.

1. Lisez ces instructions.

2. Keep these instructions.

2. Conservez ces instructions.

3. Heed all warnings.

3. Respectez tous les avertissements.

4. Follow all instructions.

4. Suivez toutes les instructions.

5. Do not use this apparatus near water.

5. Ne pas utiliser cet appareil près de l'eau.

6. Clean only with dry cloth.

6. Nettoyez-le uniquement avec un chiffon sec.

7. Do not block any ventilation openings. Install in accordance with the manufacturer’s

instructions.

7. Ne pas bloquer les ouvertures de ventilation. Installer conformément aux instructions du

fabricant.

8. Do not install near any heat sources such as radiators, heat registers, stoves, or other

apparatus (including amplifiers) that produce heat.

8. Ne pas installer près de sources de chaleur telles que des radiateurs, registres de

chaleur, poêles, ou autres appareils (incluant les amplificateurs) qui produisent de la

chaleur.

9. Do not defeat the safety purpose of the polarized or grounding-type plug. A polarized

plug has two blades with one wider than the other. A grounding type plug has two blades

and a third grounding prong. The wide blade or the third prong is provided for your safety.

If the provided plug does not fit into your outlet, consult an electrician for replacement of

the obsolete outlet.

9. Ne pas contourner le dispositif de sécurité de la fiche polarisée ou de mise à la terre. Une

fiche polarisée possède deux lames dont une plus larg e que l'autre. Une fiche de terre a

deux lames et une troisième broche de terre. La lame large ou la troisième broche est

Page 14

fournie pour votre sécurité. Si la fiche fournie ne s'adapte pas à votre prise, consultez un

électricien pour le remplacement de la prise obsolète.

10. Protect the power cord from being walked on or pinched particularly at plugs,

convenience receptacles, and the point where they exit from the apparatus.

10. Protégez le cordon d'alimentation ne soit piétiné ou pincé, en particulier au niveau des

fiches, des prises et au point où il sort de l'appareil.

11. Only use attachments/accessories specified by the manufacturer.

11. Utilisez uniquement des fixations / accessoires spécifiés par le fabricant.

12. Use only with the cart, stand, tripod, bracket, or table specified by the manufacturer, or

sold with the apparatus. When a cart is used, use caution when moving the

cart/apparatus combination to avoid injury from tip-over.

12. Utilisez uniquement avec le chariot, le socle, le trépied, le support ou la table spécifiés

par le fabricant ou vendu avec l'appareil. Lorsque vous utilisez un chariot, soyez prude nt

lorsque vous déplacez l'ensemble chariot / appareil pour éviter des blessures dues au

renversement.

13. Unplug this apparatus during lightning storms or when unused for long periods of time.

13. Débranchez cet appareil pendant les orages ou lorsqu'il n'est pas utilisé pendant d e

longues périodes de temps.

14. Refer all servicing to qualified service personnel. Servicing is required when the

apparatus has been damaged in any way, such as power-supply cord or plug is

damaged, liquid has been spilled or objects have fallen into the apparatus, the apparatus

has been exposed to rain or moisture, does not operate normally, or has been dropped.

14. Confiez toutes les réparations à un personnel qualifié. Une réparation est nécessaire

lorsque l'appareil a été endommagé de quelque façon que ce soit le cordon

d'alimentation ou la fiche est endommagé, du liquide a été renversé ou si des objets sont

tombés dans l'appareil, l'appareil a été exposé à la pluie ou à l'humidité, ne fonctionne

pas normalement, ou s'il est tombé.

15. This equipment uses AC power which can be subjected to electrical surges, typically

lightning transients which are very destructive to customer terminal equipment connected

to AC power sources. The warranty for this equipment does not cover damage caused

by electrical surge or lightning transients. To reduce the risk of this equipment becoming

damaged it is suggested that the customer consider installing a surge arrestor.

15. Cet équipement utilise la puissance AC qui peuvent être soumis à des surtensions

électriques, la foudre généralement transitoires qui sont très destructives envers les

équipements terminaux connectés à des sources d'alimentation CA. La garantie de cet

appareil ne couvre pas les dommages causés par les surtensions électriques ou

transitoires de foudre. Pour réduire le risque de cet équipement devient endommagé, il

est suggéré que le client envisager l'installation d'un limit eur de surtension.

16. To completely disconnect unit power from the AC mains, remove the power cord from the

appliance coupler and/or turn off the circuit breaker. To reconnect power, turn on the

Page 15

Caution: To reduce the risk of electric shock, do not remove cover (or back). No

personnel qualifié.

The exclamation point within the triangle is a warning sign alerting you of

signale des instructions importantes accompagnant le produit.

Voir le marquage sur les bas / dos du produit

apparatus to rain or moisture

AVERTISSEMENT! Pour réduire le risque de choc électrique,

circuit breaker f ollo wing all saf et y instruct ions and gu id eli nes . The circuit breaker shall

remain readily accessible.

16. Pour débrancher complètement l'alimentation secteur du réseau secteur, retirez le cordon

d'alimentation du coupleur de l'appareil et / ou éteignez le disjoncteur. Pour reconnecter

l'alimentation, allumez le disjoncteur en suivant toutes les consignes et consignes de

sécurité. Le disjoncteur doit être facilement accessible.

17. This product relies on the buildings installation for short-circuit (overcurrent) protection.

Ensure that the protective device is rated not greater than: 20A.

17. Ce produit repose sur l'installation des bâtiments pour les courts-circuits (surintensité) de

protection. Assurez-vous que le dispositif de protection est assignée ne dépassant pas:

20A.

18. Never push objects of any kind into this product through cabinet slots as they may touch

dangerous voltage points or short out parts that could result in fire or electric shock.

18. N'introduisez jamais d'objets d'aucune sorte dans ce produit à travers les fentes du

boîtier car ils pourraient toucher des points de tension dangereux ou court-circuiter des

pièces qui pourraient entraîner un incendie ou un choc électrique.

19. This product can interfere with electrical equipment such as tape recorders, TV sets,

radios, computers and microwave ovens if placed in close proximity.

19. Ce produit peut interférer avec des appareils électriques tels que les magnétophones,

téléviseurs, radios, ordinateurs et fours à micro-ondes si placés à proximité.

The lightning flash and arrow head within the triangle is a warning sign alerting

you of dangerous voltage inside the prod uc t

L'éclair et la flèche dans le triangle est un signe d'alerte pour vous avertir d'une

tension dangereuse à l'intérieur du produit

user serviceable parts inside. Refer servicing to qualified service personnel.

Attention: Pour réduire le risque de choc électrique, ne pas retirer le couvercle

(ou l'arrière). Aucune pièce réparable par l'utilisateur. Confiez l'entretien à un

important instructions accompanying the product.

Le point d'exclamation dans un triangle est un signe d'avertissement vous

See marking on bottom / back of product

Warning!: To reduce the risk of electrical shock, do not expose this

n'exposez pas cet appareil à la pluie ou à l'humidité.

Save these instructions

Conservez ces instructions

Page 16

Compliance of this equipment is confirmed by the following logo that is placed on the product ID

label that is placed on the bottom of the equipment:

La conformité de cet équipement est confirmée par le logo suivant qui est placé sur l'étiquette

d'identification du produit qui est placé au bas de l'équipement:

USA & Canada Compliance

FCC Part 15, Subpart B Unintentional Emissions Interference Statement

This equipment has been tested and found to comply with the limits for a Class B digital device,

pursuant to Part 15 of the FCC rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a residential installation. This

equipment generates uses and can radiate radio frequency energy and, if not installed and used

in accordance with the instructions, may cause harmful interference to radio communications.

However, there is no guarantee that interference will not occur in a particular installation. If this

equipment does cause harmful interference to radio or television reception, which can be

determined by turning the equipment off and on, the user is encouraged to try to correct the

interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver

is connected.

• Consult the dealer or an experienced radio/TV technician for help.

FCC Partie 15, sous-section B Unintentional Déclaration sur les interférences des

émissions

Cet équipement a été testé et jugé conforme aux limites établies pour un dispositif numérique de

classe B, conformément à la Partie 15 des règlements de la FCC. Ces limites sont conçues pour

fournir une protection raisonnable contre les interférences nuisibles lorsque l'équipement est

utilisé dans une installation résidentielle. Cet équipement génère, utilise et peut émettre de

l'énergie rayonnent fréquence et, s'il n'est pas installé et utilisé conformément aux instructions, il

peut causer des interférences nuisibles aux communications radio. Cependant, il n'existe aucune

garantie que des interférences ne se produiront pas dans une installation particulière. Si cet

équipement provoque des interférences nuisibles à la réception radio ou télévision, ce qui peut

être déterminé en mettant l'équipement hors et sous tension, l'utilisateur est encouragé à essayer

de corriger l'interférence par une ou plusieurs des mesures suivantes:

• Réorienter ou déplacer l'antenne de réception.

• Augmenter la distance entre l'équipement et le récepteur.

• Connecter l'équipement à une prise sur un circuit différent de celui sur lequel le récepteur

est branché.

• Consulter le revendeur ou un technicien radio / télévision qualifié pour obtenir de l'aide.

Page 17

This device complies with part 15 of the FCC rules and Industry Canada’s licence-exempt RSSs.

Operation is subject to the following two conditions: (1) This device may not cause harmful

interference, and (2) this device must accept any interference received, including interference that

may cause undesired operation.

Le présent appareil es t conforme aux CNR d’Industrie Canada applicables aux appareils radio

exempts de licence. L'exploitation est aut orisée aux deux c onditions suivantes : (1) l'appareil ne

doit pas produire de brouillage, et (2) l'utilisateur de l'appareil doit accepter tout brouillage

radioélectrique subi, même si le brouillage est susceptible d'en compromettre le fonctionnement.

IMPORTANT! Any changes or modifications not expressly approved by the party responsible for

compliance could void the user’s authority to operate this equipment.

IMPORTANT! Tous les changements ou modifications pas expressément approuvés par la partie

responsable de la conformité ont pu vider l’autorité de l’utilisateur pour actionner cet équipement.

FCC Part 15, Subpart C / RSS-247 Intentional Emissions I nterference Statement

Compliance of this equipment is confirmed by the following certification numbers that are placed

on the equipment:

Notice: The term “FCC ID:” and “IC:” before the certification number signifies that FCC and

Industry Canada technical s pec if icatio ns were m et.

FCC ID: R33C4Z2IO

IC: 7848A-C4Z2C

This equipment must be installed by qualified professionals or contractors in accordance with

FCC Part 15.203 & IC RSS-247, Antenna Requirements. Do not use any antenna other than the

one provided with the unit.

FCC Partie 15, sous-partie C / RSS-247 Déclaration volontaire des émissions interférences

Conformité de cet appareil est confirmé par les chiffres de certification suivants qui sont placés

sur l'équipement:

Avis: Le terme «FCC ID:" et "IC:" devant le numéro de certification signifie que les spécifications

techniques de la FCC et d'Industrie Canada ont été respectées.

FCC ID: R33C4Z2IO

IC: 7848A-C4Z2IO

Cet équipement doit être installé par des professionnels qualifiés ou entrepreneurs conformément

aux normes FCC partie 15.203 & IC RSS-247, Exigences d'antenne. Ne pas utiliser une antenne

autre que celui fourni avec l'appareil.

RF Radiation Exposure Statement

This equipment complies with the FCC/IC radiation exposure limits set fourth for portable

transmitting devices operation in an uncontrolled environment. End users must follow the specific

operating instructions to satisfy RF exposure compliance.

• The equipment should only be used or installed at locations where there is normally

greater than a 20cm separation between the antenna and all persons.

• This transmitter must not be co-located or oper ation in conj unct ion w ith any other

antenna or transmitter.

Page 18

• Any changes or modifications not expressly approved by the party responsible for

compliance could void the user’s authority to operate this equipment.

Déclaration d'exposition aux radiations RF

Cet équipement est conforme aux limites FCC / IC d'exposition aux rayonnements définies

quatrième opération appareils portables transmettre dans un environnement non contrôlé. Les

utilisateurs finaux doivent suivre les instructions de fonctionnement spécifiques pour satisfaire la

conformité aux expositions RF.

• L'équipement ne doit être utilisé ou installé à des endroits où il est normalement

supérieure à une séparation de 20 cm entre l'antenne et toute personne.

• Cet émetteur ne doit pas être co-localisés ou fonctionnement en conjonction avec une

autre antenne ou un autre émetteur.

• Tout changement ou modification non expressément approuvé par la partie responsable

de la conformité pourraient annuler l'autorit é de l'utilisateur à utiliser cet équipement.

Page 19

European Compliance (English)

Conformity of the equipment with the guidelines below is attested by the application of the CE

mark.

CE Declaration of Conformity

Manufacturer’s Name: CONTROL4 CORPORATION

Manufacturer’s Address: 11734 S. ELECTION ROAD SUITE 200

SALT LAKE CITY

UT 84020 USA

EU Representative Name: CONTROL4 EMEA LIMITED

EU Representative Address: UNIT3, GREEN PARK BUSINESS CENTRE

SULTON-ON-THE FOREST

YORK YO61 IET, UNITED KINGDOM

Product Name(s): ZigBee to IO & ZigBee to Contact

Brand: Contol4

Model(s): C4-Z2IO & C4-Z2C

Product Standard(s) to which Conformity of the Council Directive(s) is declared:

EMC - 2014/30/EU “Electromagnetic Compatibility (EMC) Directive”:

(Emissions) EN 55032:2012 (Immunity) EN 55024:2010 + A1:20 15, EN 61000-3-2:2014 & EN

61000-3-3:2013

Safety – 2006/95/EC “Low Voltage Directive (LVD)”:

EN 62368-1:2014

Radio - 2014/53/EU Radio Equipment Directive (RED):

EN 300 328 V1.9.1

ErP - 2009/125/EC Energy-related Product Directive.

RoHS - 2011/65/EU Restriction of the Use of certain Hazardous Substances in Electrical

and Electronic Equipment (EEE) & WEEE - 2002/96/EC Waste of Electrical and Electroni c

Equipment (EEE).

We, the undersigned, hereb y declare that the equipment s pecified above conform s to the above

directives and standards. Date of Issue: September 7, 2017

Legal Representative

Signature

Roger Midgley

Sr. Regulatory Compliance Engineer

Page 20

Conformité européenne (French)

Conformité de l'équipement avec les directives ci-dessous est attestée par l'apposition de la

marque CE.

Déclaration de conformité CE

Le nom du fabricant: CONTROL4 CORPORATION

Le fabricant Adresse: 11734 S. ÉLECTION Road Suite 200

SALT LAKE CITY

UT 84020 USA

Nom Représentant de l'UE: CONTROL4 EMEA LIMITED

UE représentant Adresse: Unit3, GREEN PARK CENTRE D'AFFAIRES

Sulton-ON-THE FOREST

YORK YO61 IET, ROYAUME-UNI

Nom (s) de produit: ZigBee to IO & ZigBee to Contact

Marque: Contol4

Modèle (s): C4-Z2IO & C4-Z2C

Produit standard (s) dont la conformité de la directive du Conseil (s) est déclarée:

EMC - 2014/30 / "compatibilité électromagnétique (CEM)" UE:

(Émissions) EN 55032:2012 (immunité) EN 55024:2010 + A1:20 15, EN 61000-3-2:2014 & EN

61000-3-3:2013

Sécurité - 2006/95 / CE "Directive Basse Tension (DBT)":

EN 62368-1:2014

Radio - 2014/53 / UE directive équipement radio (RED):

EN 300 328 V1.9.1

ErP - 2009/125 / CE liées à l'énergie directive sur les produits.

RoHS - 2011/65 / UE limitation de l'utilisation de certaines substances dan gereuses dans

les équipements électriques et électroniques (EEE) et DEEE - 2002/96 / CE Déchets

d'équipements électriques et électr o niques (EEE).

Nous, soussignés, déclaro ns que l'équipement indiqué ci-des sus est conforme aux directives et

normes ci-dessus. Date de publication 7 septembre 2017

Représentant légal

Signature

Roger Midgley

Ingénieur de conformité réglementaire Sr.

Page 21

European Compliance (German)

Die Konformität mit den folgenden Richtlinien wird durch die Anwendung des CE-Kennzeichen bestätigt.

CE-Konformitätserklärung

Name des Herstellers: Control4 CORPORATION Adresse des Herstellers: 11734 S. WAHL ROAD SUITE 200 SALT LAKE CITY UT 84020 USA

EU-Vertreter Name: Control4 EMEA LIM ITED EU-Vertreter Adresse: Unit3, GREEN Park Geschäftszentrum Sulton-ON-THE FOREST YORK YO61 IET, VEREINIGTES KÖNIGREICH

Produkt-Name (n): ZigBee to IO & ZigBee to Contact

Marke: Contol4

Modell (e): C4-Z2IO & C4-Z2C

Produkt-Norm (en), um die Konformität der Richtlinie (n) deklariert ist:

EMC - 2014/30 / EG "Elektromagnetische Verträglichkeit (EMV) Die Richtlinie":

(Emissionen) EN 55032:2012 (Immunität) EN 55024:2010 + A1:2015, EN 61000-3-2:2014 &

EN 61000-3-3:2013

Sicherheit - 2006/95 / EG "Niederspannungsrichtlinie (LVD)":

EN 62368-1:2014

Radio - 2014/53 / EU über Funkanlagen-Richtlinie (RED):

EN 300 328 V1.9.1

ErP - 2009/125 / EG Energiebez og ene Prod ukt richtlinie.

RoHS - 2011/65 / EU zur Beschränkung der Verwendung bestimmter gefährlicher Stoffe in

Elektro- und Elektronikgeräten (EEE) & WEEE - 2002/96 / EG Richtlinie über Elektro- und

Elektronikgeräten (EEE).

Wir, die Unterzeichneten, erklären hiermit, dass das oben angegebene Gerät zu den oben

genannten Richtlinien und Normen. Ausstellungsdatum: 7. September 2017

Gesetzlicher Vertreter

Stempel, Unterschrift

Roger Midgley

Sr. Regulatory Compliance-Ingenieur

Page 22

Conformità Europea (Italian)

Conformità del materiale con le linee guida qui sotto è attestata dall'applicazione del marchio CE.

Dichiarazione di conformità CE

Nome del produttore: Control4 CORPORATION Indirizzo del produttore: 11734 S. ELEZIONI STRADA SUITE 200 SALT LAKE CITY UT 84020 Stati Uniti d'America

UE Nome Rappresentante: Control4 EMEA LI M ITED UE Indirizzo Rappresentante: Unit3, GREEN PARK BUSINESS CENTRE Sulton-ON-THE FOREST YORK YO61 IET, REGNO UNITO

Nome del prodotto (s): ZigBee to IO & ZigBee to Contact

Marca: Contol4

Modello (s): C4-Z2IO & C4-Z2C

Prodotto standard (s) a cui conformità della direttiva del Consiglio (s) è dichiarato:

EMC - 2014/30 / UE "Compatibilità elettromagnetica (EMC)":

(Emissioni) EN 55032:2012 (immunità) EN 55024: 2010, EN 301 489-1 v1.9.2 (2011-09), EN

301 489-17 V2.2.1 (2012-09), EN 61000-3-2: 2006 + A1: 2009 + A2: 2009 e EN 61000-3-3: 2008

Sicurezza - 2006/95 / CE "Direttiva bassa tensione (LVD)":

EN 62368-1:2014

Radio - 2014/53 / Direttiva sulle apparecchiature radio dell'UE (RED):

EN 300 328 V1.9.1

ErP - 2009/125 / CE Energy legati direttiva sui prodotti.

RoHS - 2011/65 Limitazione / UE dell'uso di determinate sostanze pericolose nelle

apparecchiature elettriche ed elettroniche (AEE) e RAEE - 2002/96 / CE sui rifiuti di

apparecchiature elettriche ed elettroniche (AEE).

I sottoscritti, dichiariamo che l'apparecchiatura specificata in precedenza è conforme alle direttive e norme di cui sopra. Data di pubblicazione: 7 settembre 2017

Rappresentante legale

Firma

Roger Midgley

Suor Conformità alle normative Ingegnere

Page 23

Conformidad Europea (Spanish)

La conformidad de los equipos con las siguientes pautas es atestiguado por la aplicación de la marca CE.

Declaración de conformidad CE

Nombre del fabricante: Control4 CORPORACIÓN Dirección del fabricante: 11734 S. ELECCIÓN Road Suite 200 SALT LAKE CITY UT 84020 EE.UU.

UE Nombre Representante: Control4 EMEA LIMITED Dirección Representante de la UE: Tema 3., VERDE PARQUE EMPRESARIAL CENTRO Sulton-EN-EL BOSQUE YORK YO61 IET, REINO UNIDO

Nombre (s) del producto: ZigBee to IO & ZigBee to Contact

Marca: Contol4

Modelo (s): C4-Z2IO & C4-Z2C

Producto estándar (s) a la que la conformidad de la Directiva del Consejo (s) se declara:

EMC - 2014/30 / UE "Directiva de compatibilidad electromagnética (EMC)":

(Emisiones) EN 55032:2012 (inmunidad) EN 55024: 2010, EN 301 489-1 v1.9.2 (2011-09), EN

301 489-17 V2.2.1 (2012-09), EN 61000-3-2: 2006 + A1: 2009 + A2: 2009 e EN 61000-3-3: 2008

Seguridad - 2006/95 / CE "Directiva de Baja Tensión (LVD)":

EN 62368-1:2014

Radio - 2014/53 / Directiva de Equipos de Radio de la UE (RED):

EN 300 328 V1.9.1

ErP - 2009/125 relacionados con energía / CE Directiva del producto.

RoHS - 2011/65 restricción del uso de ciertas sustancias peligrosas en equipos

electrónicos (AEE) y WEEE eléctricos y / UE - 2002/96 / CE de Residuos de Aparatos

Eléctricos (AEE) y electrónicos.

Nosotros, los abajo firmantes, declaramos por la presente que el equipo anteriormente mencionado se ajusta a las directrices y estándares anteriores. Fecha de emisión: 7 de septiembre de 2017

Representante legal

Firma

Roger Midgley

Ingeniero Sr. Cumplimiento de la normativa

Page 24

Conformidade Europeia (Portuguese)

Conformidade do equipamento com as diretrizes abaixo é atestada pela aplicação da marca CE.

Declaração de Conformidade CE

Nome do fabricante: Control4 CORPORATION Do fabricante Endereço: 11734 S. ELEIÇÃO ROAD SUITE 200 SALT LAKE CITY UT 84020 EUA

Representante da UE Nome: Control4 EMEA LIM ITED Representante da UE Endereço: UNIT3, GREEN PARK CENTRO DE NEGÓCIO Sulton-ON-THE FOREST YO61 IET YORK, REINO UNIDO

Nome (s) produto: ZigBee to IO & ZigBee to Contact

Marca: Contol4

Modelo (s): C4-Z2IO & C4-Z2C

Padrão do produto (s) a que Conformidade da Directi va do Conselho (s) é declarado:

EMC - 2014/30 / UE "Compatibilidade Electromagnética (EMC)":

(Emissões) EN 55032:2012 (Imunidade) EN 55024: 2010, EN 301 489-1 v1.9.2 (2011-09), EN

301 489-17 V2.2.1 (2012-09), EN 61000-3-2 : 2006 + A1: 2009 + A2: 2009 e EN 61000-3-3: 2008

Segurança - 2006/95 / CE "Directiva de Baixa Tensão (LVD)":

EN 62368-1:2014

Rádio - 2014/53 / UE Directiva equipamento de rádio (RED):

EN 300 328 v1.9.1

ERP - 2009/125 relacionados Energy-/ CE Directiva do produto.

RoHS - 2011/65 / UE Restrição do Uso de Certas Substâncias Perigosas em Equipamentos

Eléctricos e Electrónicos (EEE) e WEEE - 2002/96 / EC de Resíduos de Equipamentos

Eléctricos e Electrónicos (EEE).

Nós, abaixo-assinado, declaro que o equipamento especificado acima está em conformidade com as diretrizes e normas acima referidas. Data de Emissão: 7 de setembro de 2017

Representante legal

Assinatura

Roger Midgley

Sr. Engenheiro Conformidade Regulatória

Page 25

Recycling

Control4 understands that a commitment to the environment is essential for a health life and

sustainable growth for future generations. We are committed to supporting the environmental

standards, laws, and directi ves that have been put in place by various communities and countries

that deal with concerns for the environment. This commitment is represented by combining

technological innovation with sound environmental business decisions.

WEEE Compliance

Control4 is committed to meeting all requirements of the Waste Electrical and Electronic

Equipment (WEEE) directive (2012/19/EC). The WEEE directive requires the manufacturers of

electrical and electronic equipment who sell in EU countries: (1) label their equipment to notify

customers that it needs to be recycled, and (2) provide a way for their products to be

appropriately disposed of or recycled at the end of their product lifespan. For collection or

recycling of Control4 products, please contact your local Control4 representative or dealer.

About this Document

Copyright © 2017 Control4 Corporation. All rights reserved. Control4 and the Control4 logo are