Page 1

M–T raverse

User Manual

0001-0122

Revision F

i

Page 2

Technical Assistance

If you have comments or questions concerning the operation of the M–Traverse, a member of

our Technical Support Staff will be happy to assist you. Ask for Technical Support:

(763) 424-7800 or (800) 342-4411

Copyright © 1996 Contrex

ii

Contrex

®

8900 Zachary Lane North

Maple Grove, Minnesota 55369

Page 3

DANGER

Improper installation

or improper operation

of this motion control unit

can cause severe injury, death or

damage your system.

Integrate this motion control unit

into your system

with caution.

Comply with the National

Electrical Code

and all applicable local

and national codes.

Page 4

Table of Contents

Introduction 1-1

Introducing the M–Traverse........................................................................... 1-3

Examples of M–Traverse Applications .......................................................... 1-4

Installation / Setup 2-1

Configuration.................................................................................................. 2-3

Mounting ........................................................................................................ 2-7

Wiring ............................................................................................................. 2-9

Inputs.................................................................................................. 2-10

Outputs............................................................................................... 2-19

Serial Communications ...................................................................... 2-24

Calibration.................................................................................................... 2-27

Motor Drive Set Up............................................................................. 2-29

Encoder Polarity Check ..................................................................... 2-29

M–Traverse Calibration...................................................................... 2-30

Operation3-1

Keypad Operation.......................................................................................... 3-3

Control Parameters........................................................................................ 3-7

Follower Mode...................................................................................... 3-8

Direct Mode........................................................................................ 3-29

Jog...................................................................................................... 3-30

Tuning ................................................................................................. 3-32

Output Control.................................................................................... 3-34

M–Traverse Operation................................................................................. 3-43

Follower Mode.................................................................................... 3-44

Home Set ........................................................................................... 3-45

Home Seek......................................................................................... 3-45

Home Return...................................................................................... 3-50

Direct Mode........................................................................................ 3-51

Jog...................................................................................................... 3-52

i

Page 5

Monitor Variables ......................................................................................... 3-53

Input Monitoring ................................................................................. 3-54

Output Monitoring............................................................................... 3-56

Performance Monitoring..................................................................... 3-58

Status Monitoring ............................................................................... 3-60

Serial Communications................................................................................ 3-63

Using Serial Communications............................................................ 3-64

Communications Software Design..................................................... 3-66

Troubleshooting 4-1

Diagnostics .................................................................................................... 4-3

Troubleshooting ........................................................................................... 4-13

EPROM Chip Replacement ......................................................................... 4-19

References 5-1

Glossary......................................................................................................... 5-3

Appendix A: M–Traverse Specifications ..................................................... 5-11

Appendix B: Formulas ................................................................................ 5-13

Appendix C: Parameter Summary - Numeric Quick Reference ................. 5-14

Appendix D: Control Parameter Reference................................................ 5-36

Appendix E: Monitor Variable Reference.................................................... 5-38

Appendix F: Fax Cover Sheet .................................................................... 5-39

Appendix G: Wiring Diagram Examples ..................................................... 5-40

Appendix H: Revision Log .......................................................................... 5-44

Service policy............................................................................................... 5-45

Warranty....................................................................................................... 5-46

Index ............................................................................................................ 5-47

ii

Page 6

List of Illustrations

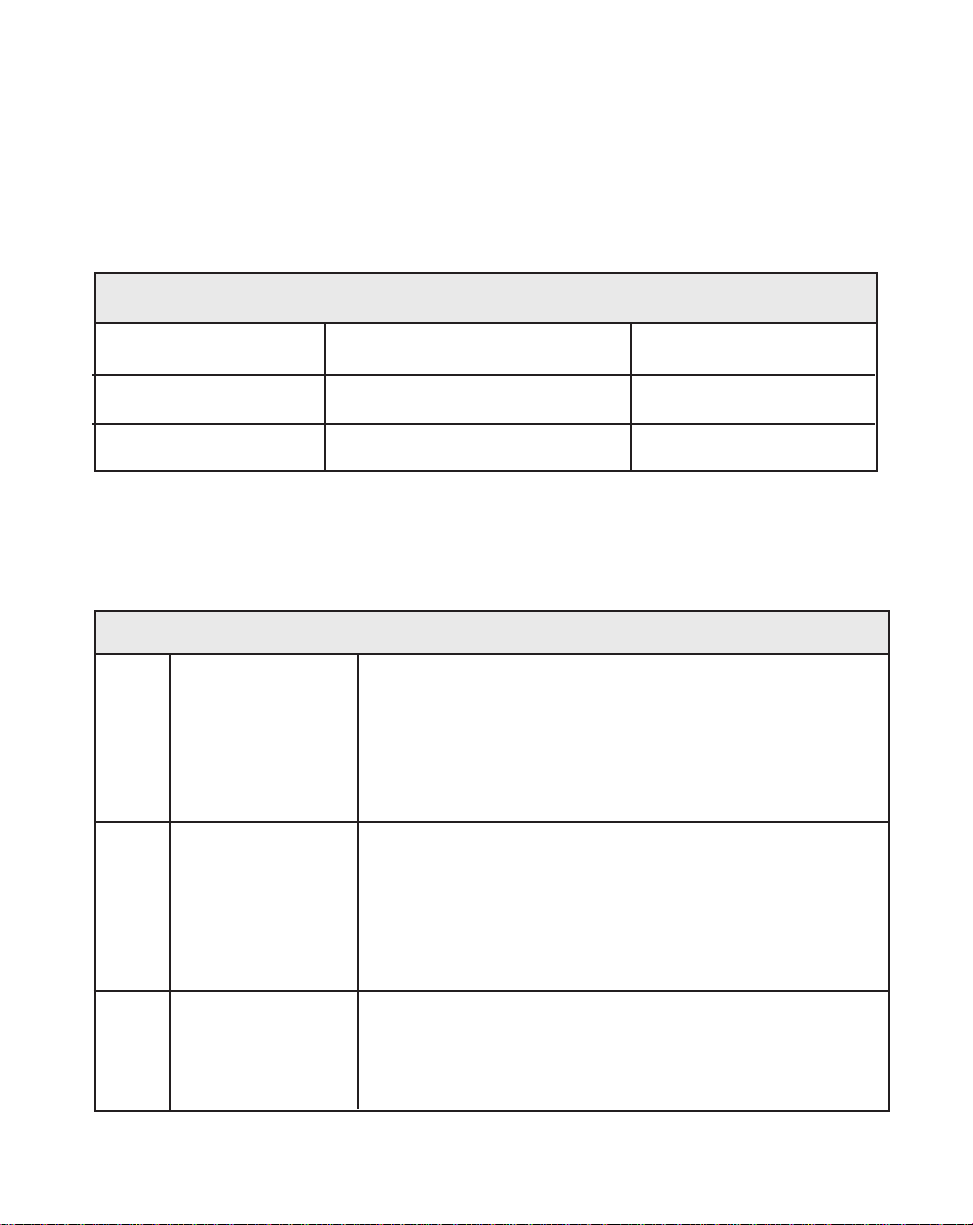

Figure 1-1 M–Traverse Level Wind Application ........................................ 1-4

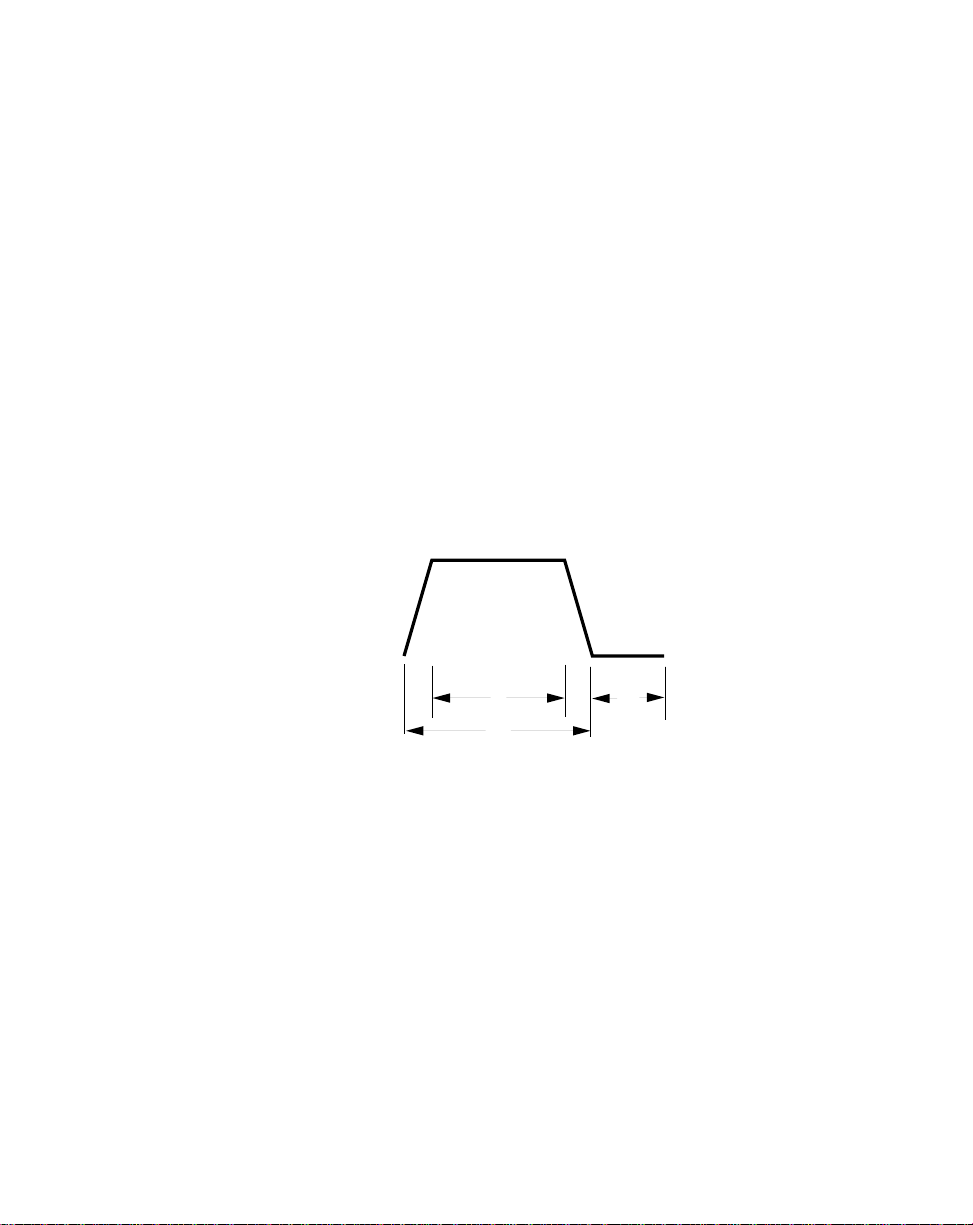

Figure 1-2 M–Traverse Web Scanning Application.................................... 1-5

Figure 2-1 Rear View of M–Traverse ........................................................ 2-3

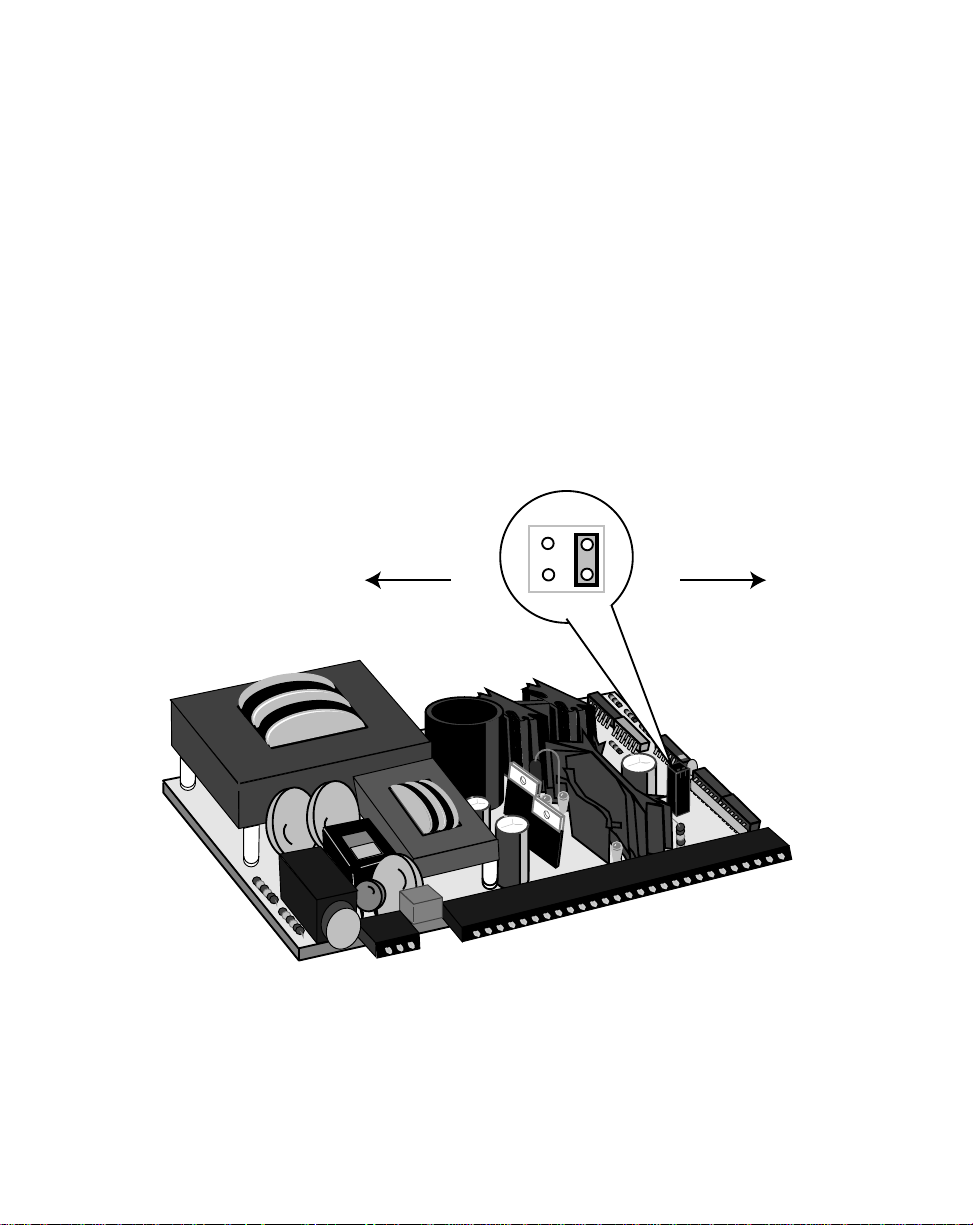

Figure 2-2 Power Board / Isolator Jumper ................................................ 2-4

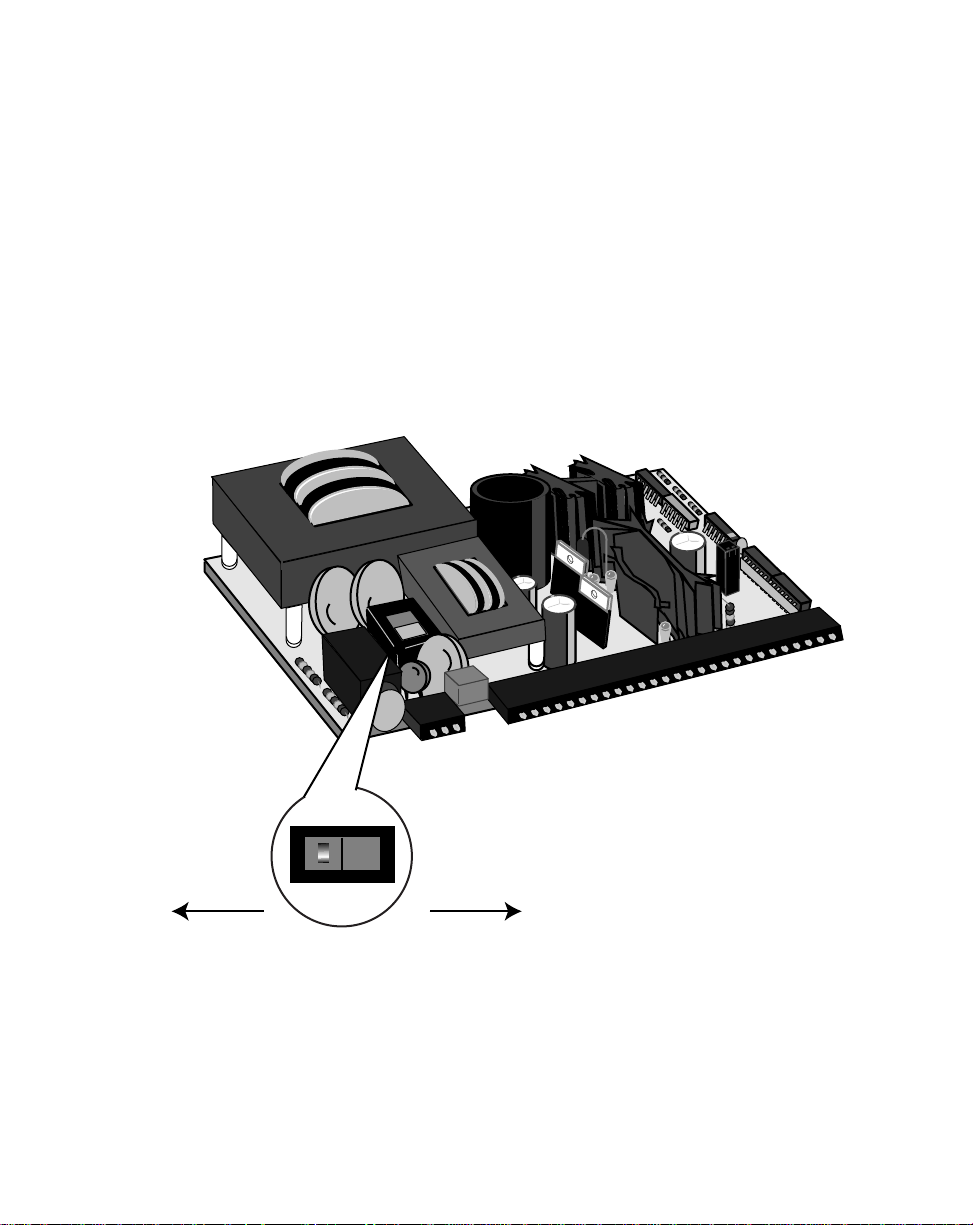

Figure 2-3 Power Board / SW1 Switch ...................................................... 2-5

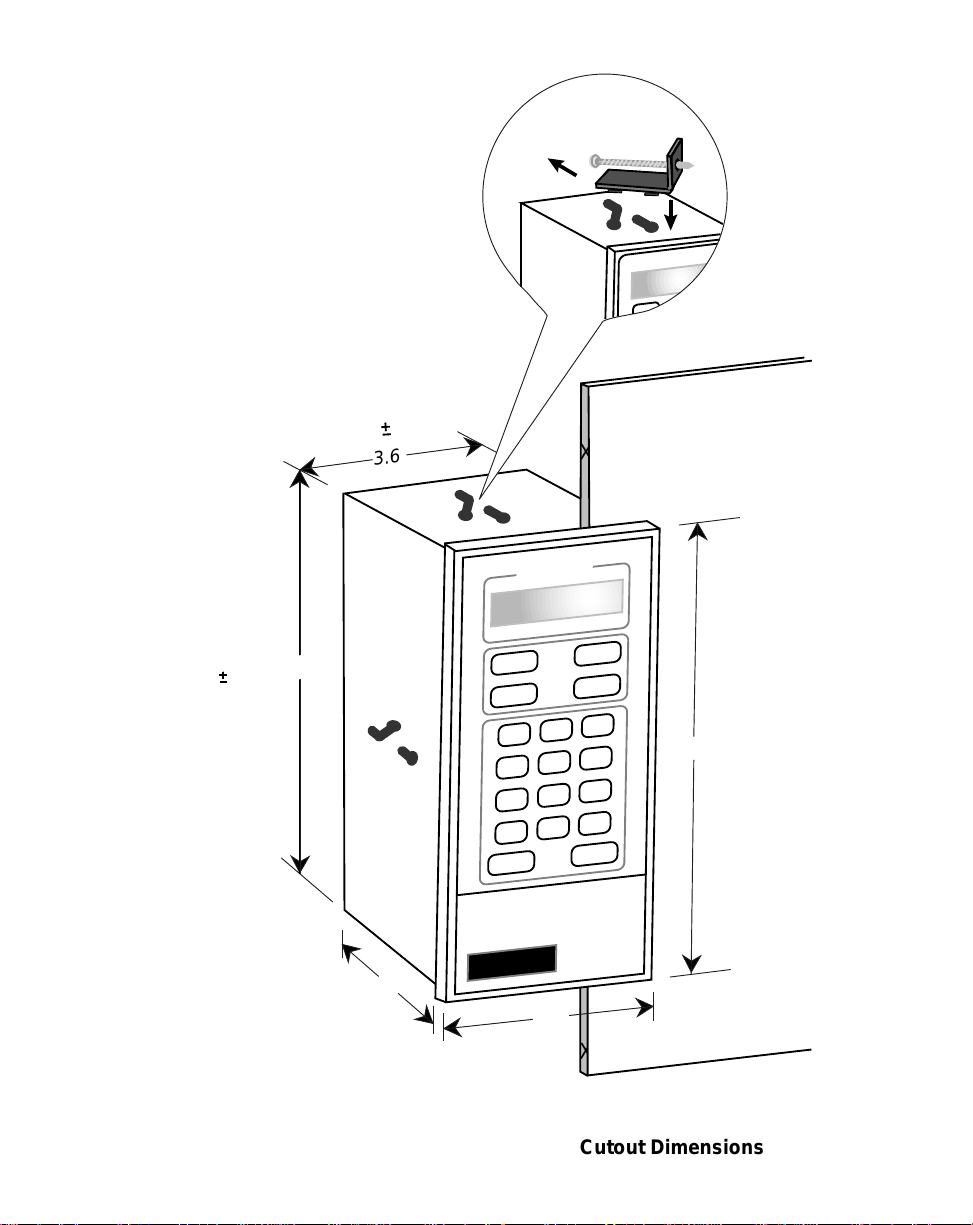

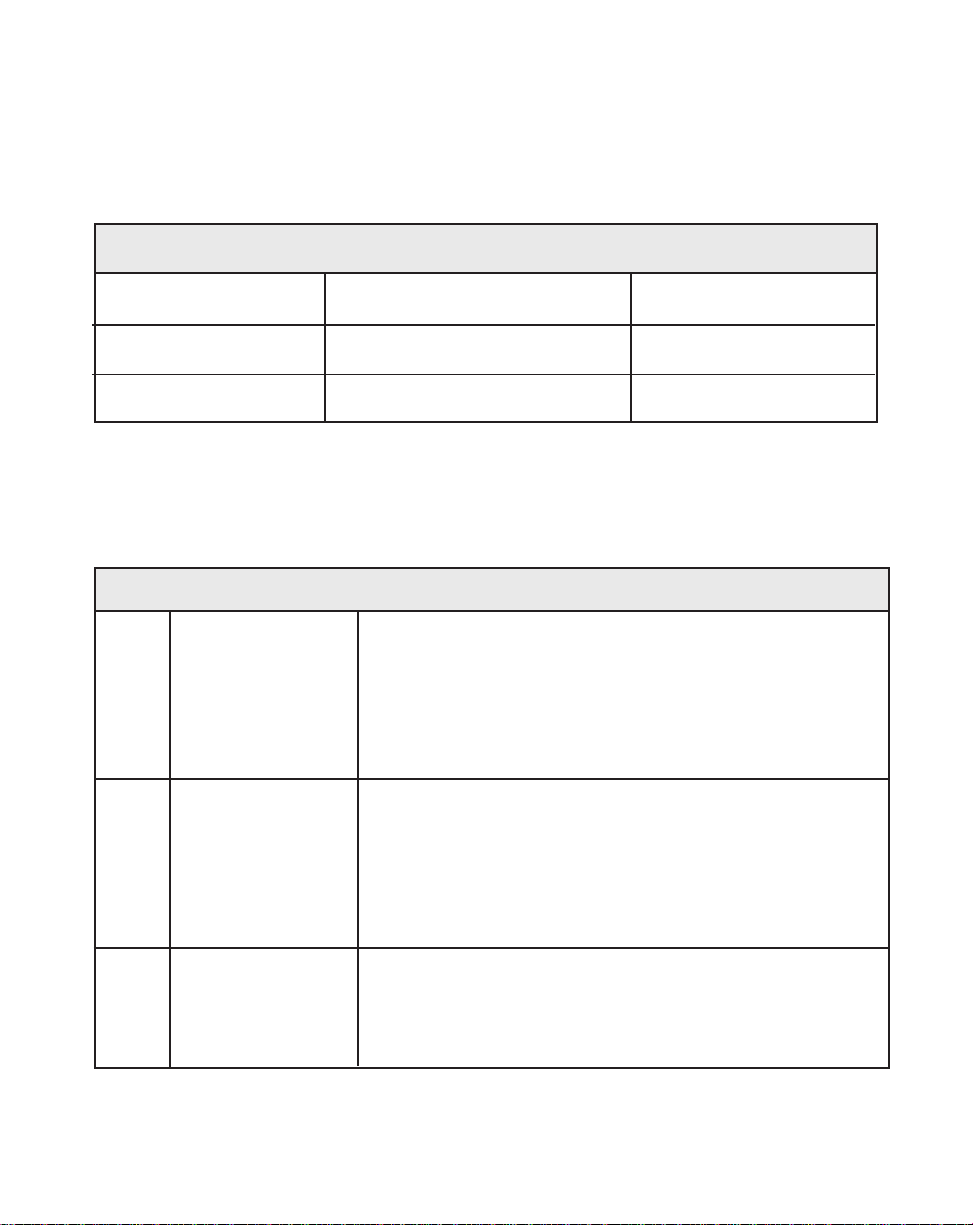

Figure 2-4 M–Traverse Mounting and Cutout Dimensions ....................... 2-6

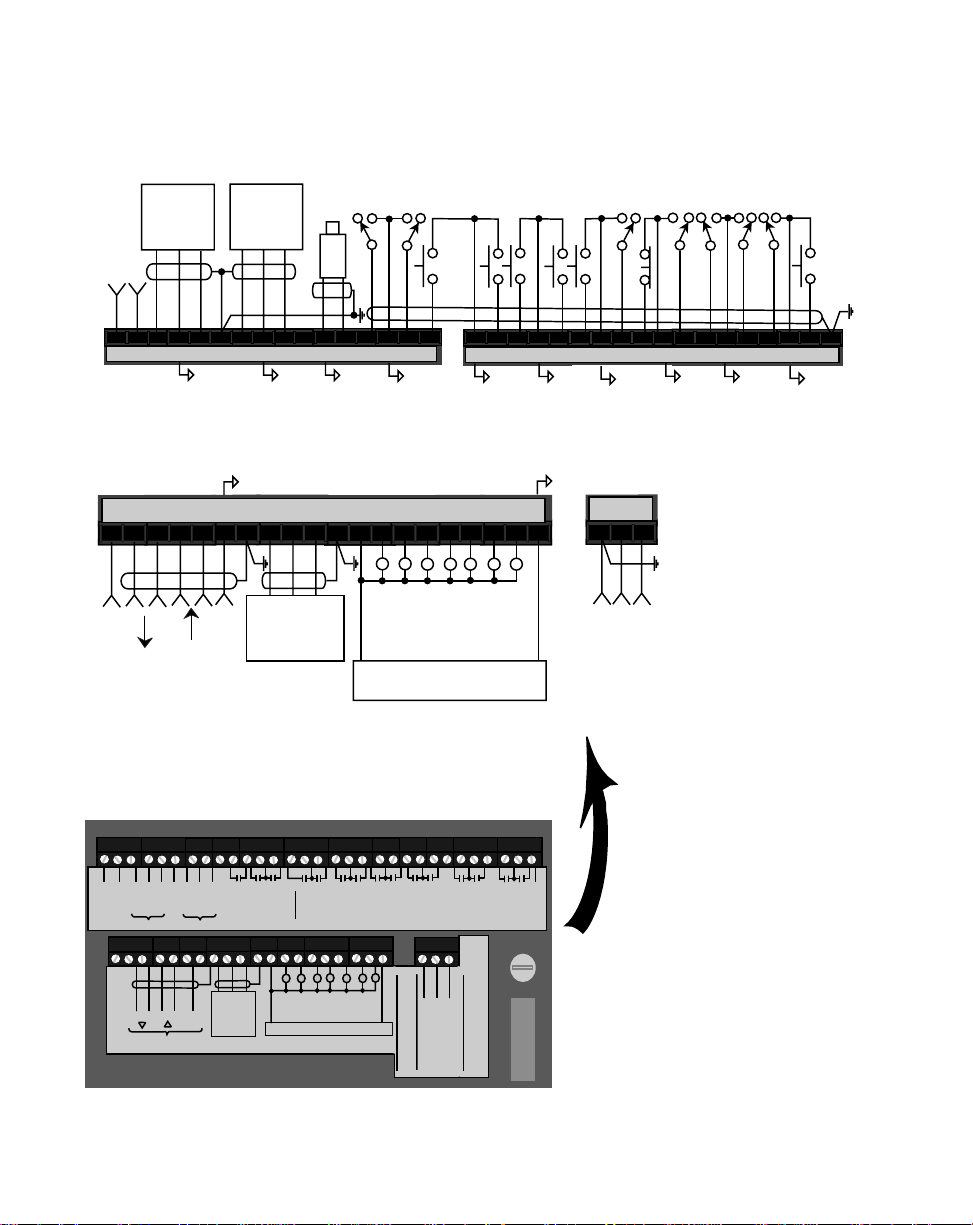

Figure 2-5 M–Traverse General Wiring Schematic ................................... 2-8

Figure 2-6 Input Power............................................................................. 2-10

Figure 2-7 Lead frequency ...................................................................... 2-10

Figure 2-8 Feedback frequency .............................................................. 2-11

Figure 2-9 Home Sync ............................................................................. 2-11

Figure 2-10 Setpoint Select A .................................................................... 2-12

Figure 2-11 Setpoint Select B .................................................................... 2-12

Figure 2-12 Home Set ................................................................................ 2-13

Figure 2-13 Home Seek ............................................................................. 2-13

Figure 2-14 Home Return........................................................................... 2-14

Figure 2-15 Batch Reset ............................................................................ 2-14

Figure 2-16 Run ......................................................................................... 2-15

Figure 2-17 Wait......................................................................................... 2-15

Figure 2-18 F-Stop ..................................................................................... 2-16

Figure 2-19 Keypad Lockout ..................................................................... 2-16

Figure 2-20 Forward Limit .......................................................................... 2-17

Figure 2-21 Reverse Limit ......................................................................... 2-17

Figure 2-22 Jog Forward/Reverse ............................................................. 2-18

Figure 2-23 Jog ......................................................................................... 2-18

Figure 2-24 Speed Command Out ............................................................2-19

Figure 2-25 Discrete Outputs ..................................................................... 2-23

Figure 2-26 M-Traverse Multidrop Installation .......................................... 2-24

Figure 2-27 M-Traverse Serial Communications Connections .................. 2-25

Figure 2-28 Location of M-Traverse Scale and Zero Pot........................... 2-28

Figure 3-1 M–Traverse Front Panel .......................................................... 3-5

Figure 3-2 M–Traverse Internal Structure ............................................... 3-58

Figure 4-1 Motor Does Not Stop Flowchart ............................................ 4-14

iii

Page 7

Figure 4-2 Motor Does Not Run Flowchart ............................................. 4-15

Figure 4-3 Motor Runs at Wrong Speed Flowchart ................................ 4-16

Figure 4-4 Motor Runs Unstable Flowchart ............................................ 4-17

Figure 4-5 EPROM Location ................................................................... 4-18

Figure G-1 M–Traverse Wiring Connections without Relays .................. 5-40

Figure G-2 Relay Run/Stop Wiring Connections .................................... 5-41

Figure G-3 Run/Stop for Regen with Armature Contactor ...................... 5-42

Figure G-4 Run/Stop for Non-Regen with Armature Contactor .............. 5-43

iv

Page 8

List of Tables

Table 3-1 Basic Keypad Entry ................................................................. 3-4

Table 3-2 Default Control Mode Control Parameters .............................. 3-9

Table 3-3 Entering Control Mode Control Parameters ............................ 3-9

Table 3-4 Default Follower Scaling Control Parameters ....................... 3-11

Table 3-5 Entering Follower Scaling Control Parameters ..................... 3-12

Table 3-6 Default Setpoint Control Parameters ..................................... 3-13

Table 3-7 Entering Setpoint Control Parameters ................................... 3-14

Table 3-8 Default Traverse Length Control Parameters ........................ 3-15

Table 3-9 Entering Traverse Length Control Parameters ...................... 3-15

Table 3-10 Default Accel/Decel Length Control Parameters ................... 3-17

Table 3-11 Entering Accel/Decel Length Control Parameters ................. 3-17

Table 3-12 Default Dwell Control Parameters ......................................... 3-18

Table 3-13 Entering Dwell Control Parameters ...................................... 3-18

Table 3-14 Default Control Parameters for Changes .............................. 3-23

Table 3-15 Entering Control Parameters for Changes ............................ 3-23

Table 3-16 Default Resume Enable Control Parameter .......................... 3-25

Table 3-17 Entering Resume Enable Control Parameter ........................ 3-25

Table 3-18 Default Polarity Control Parameters ...................................... 3-27

Table 3-19 Entering Polarity Control Parameters .................................... 3-27

Table 3-20 Default Direct Mode Control Parameters ............................... 3-28

Table 3-21 Entering Polarity Control Parameters ................................... 3-28

Table 3-22 Default Direct Mode Control Parameters ............................... 3-29

Table 3-23 Entering Direct Mode Control Parameters ............................. 3-29

Table 3-24 Default Jog Control Parameters ............................................ 3-30

Table 3-25 Entering Jog Control Parameters .......................................... 3-30

Table 3-26 Default Tuning Control Parameters ....................................... 3-32

Table 3-27 Entering Tuning Control Parameters ..................................... 3-33

Table 3-28 Default Batch Control Parameters .........................................3-35

Table 3-29 Entering Batch Control Parameters ....................................... 3-35

Table 3-30 Default Alarm Control Parameter ........................................... 3-36

Table 3-31 Entering Alarm Control Parameter ......................................... 3-36

Table 3-32 Default At-Home Control Parameter ...................................... 3-37

Table 3-33 Entering At-Home Control Parameter .................................... 3-37

v

Page 9

Table 3-34 Default Control Parameters for Output A ............................... 3-39

Table 3-35 Entering Control Parameters for Output A ............................. 3-39

Table 3-36 Default Control Parameters for Output B ............................... 3-41

Table 3-37 Entering Control Parameters for Output B ............................ 3-41

Table 3-38 Parameter Send - Host Transmission..................................... 3-67

Table 3-39 Parameter Send - M–Traverse Response ............................. 3-69

Table 3-40 Control Command Send - Host Transmission ....................... 3-71

Table 3-41 Control Command Send - M–Traverse Response ................. 3-73

Table 3-42 Data Inquiry - Host Transmission ........................................... 3-75

Table 3-43 Data Inquiry - M–Traverse Response .................................... 3-77

Table 3-44 ASCII to Binary ...................................................................... 3-79

Table 3-45 Binary Monitor Parameters .................................................... 3-80

vi

Page 10

Introduction

Introducing the M–Traverse

Examples of M–Traverse Applications

1-1

Page 11

1-2

Page 12

INTRODUCING THE M–TRAVERSE

The M–Traverse is a highly accurate, digital, position controller. The M–Traverse's

technically advanced, internally embedded, control software is specifically designed for

the precise control of reciprocating lead/follower motion applications. These

applications are characterized by symmetric forward and reverse follower profiles. The

M–Traverse is often used for level winding, web scanning and fabric lapping, however it

can be used in any operation that requires symmetrical follower profiling against a lead.

The M-Traverse allows you to enter information that is unique to your system's

operation through user friendly Control Parameters. The M–Traverse uses this

information to calculate and determine a variety of controls and functions and frees you

from complex computations. When your system is engaged (Run), the traversing

mechanism (Follower) accelerates from the “Home” position to the preset laypitch

(Setpoint). Operating at the laypitch, the traverse mechanism can precisely align a

product on a reel or web then decelerate the traversing mechanism to the end of the

Traverse Length before beginning the end Dwell. At the “Dwell,” the M-Traverse

assures that the product is properly aligned before returning in the opposite direction.

The M–Traverse is remarkably precise - within one encoder line.

The M–Traverse accepts up to four preset pairs of “Setpoint” and “Traverse Length”

parameters. These parameters can be engaged with a quick flip of a switch during a

product change over. The M-Traverse features additional advanced control that

includes; profile definition that uses engineering unit parameters, dynamic profile

redefinition during a run, automatic profile generation, batch counting, unipolar/bipolar

drive compatibility and dynamic system monitoring. There are seven discrete outputs

for external control integration, which includes two user specified profile position

outputs.

Although the M–Traverse has many advanced control capabilities, it is easy to use. The

integrated keypad and display make access to the control and monitor parameters both

direct and simple. A “Keypad Lockout” function allows you to restrict access to the

control parameters after you have completed the setup process.

The M–Traverse features dedicated short-cut keys for quick access to the “Setpoint,”

“Batch Count,” “Tach,” and “Status” parameters. In addition to the integrated user

keypad and display, the M–Traverse has a RS-422 serial communications port through

which you can gain computer access to all of the control and monitor parameters.

Integrating the M–Traverse's applied intelligence with your system puts precise control

and perfect synchronization at your fingertips, quickly, easily and cost effectively.

1-3

Page 13

EXAMPLES OF M–TRAVERSE

APPLICATIONS

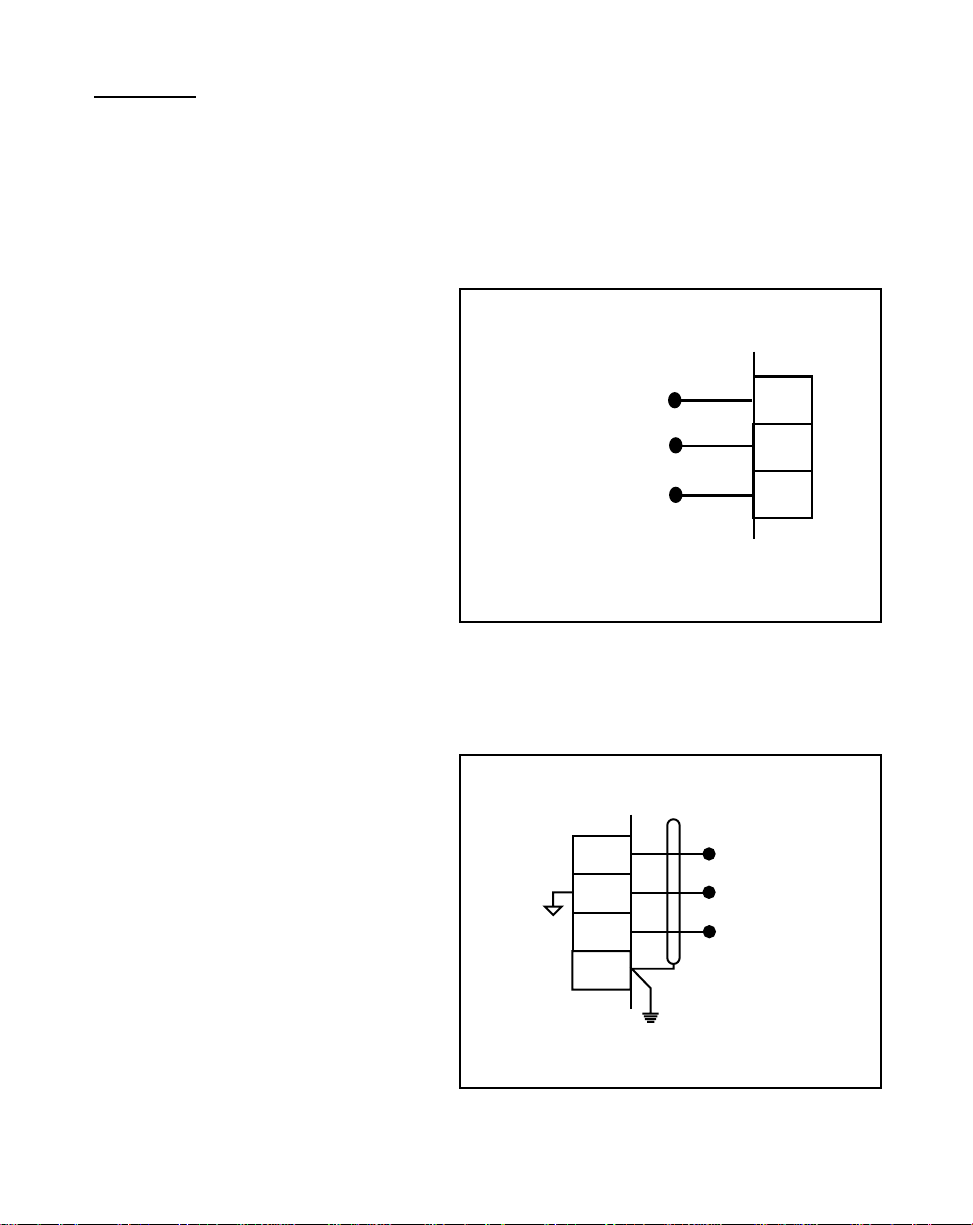

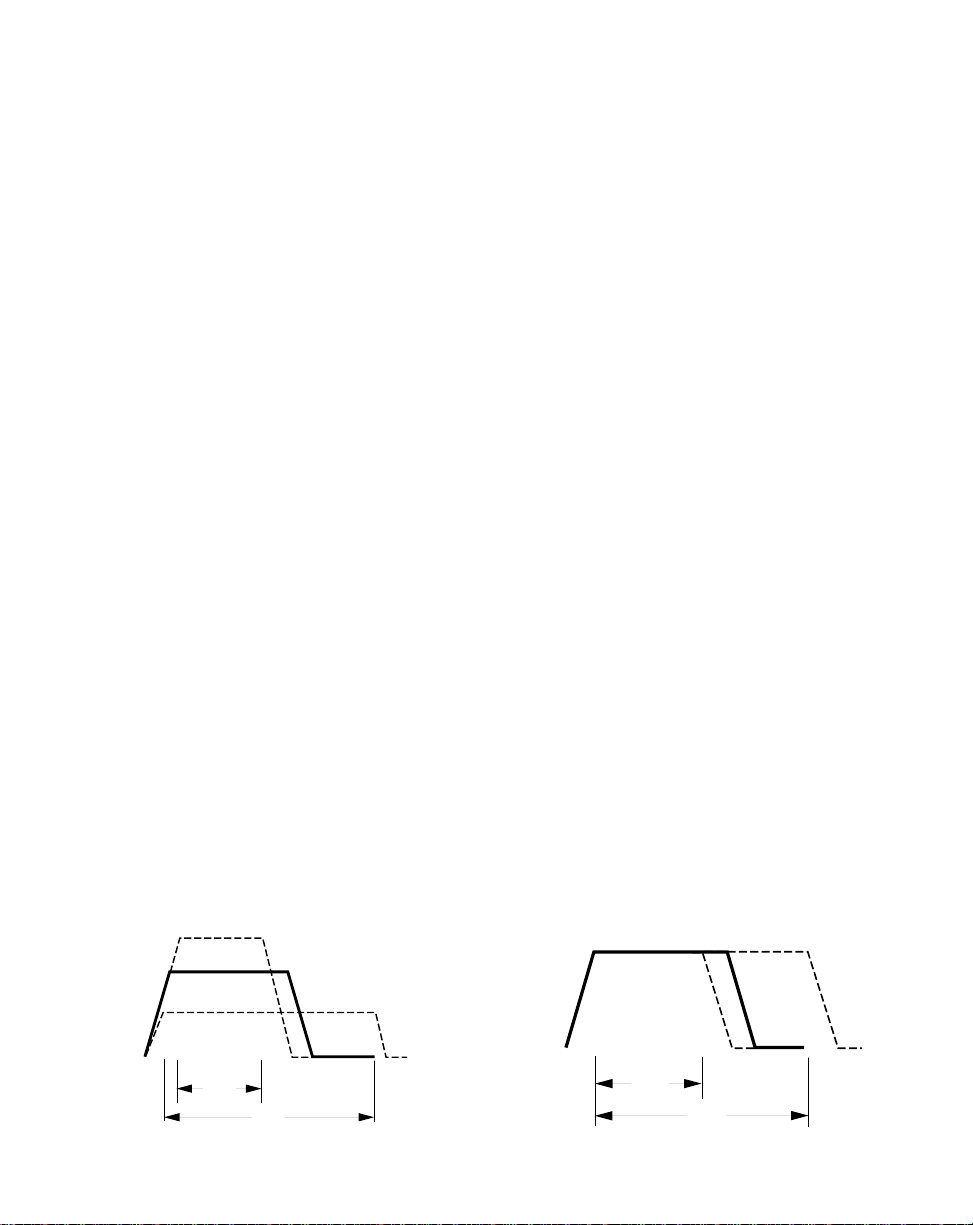

The Level Wind is one of the M–Traverse's principle applications. The Level Wind

application uses the Lay Adjusted option in the Follower mode of operation. In a Level

Wind application, the M–Traverse locates the start or “Home” position and accelerates

the traversing mechanism (Follower) to the preset laypitch (Setpoint). The traversing

mechanism feeds a web product such as a wire, fiber optic cable or tape, onto the

rotating reel (Lead) at this laypitch then decelerates the traversing mechanism to the

end of the Traverse Length. At the “Dwell,” the M-Traverse assures that the web

material is properly aligned on the reel before returning in the opposite direction.

Figure 1-1 illustrates a typical Level Wind application.

HOME SYNC

FOLLOWER

DIRECTION

OF WIND

FEEDBACK FREQUENCY

LEAD

Cut

Position

Length

Batch

Status

Count

9

7

8

45

6

23

1

0

Alt

Enter

Clear

M-TRAVERSE

M–Traverse

CONTREX

LEAD FREQUENCY

1-4

Figure 1-1 M–Traverse Level Wind Application

Page 14

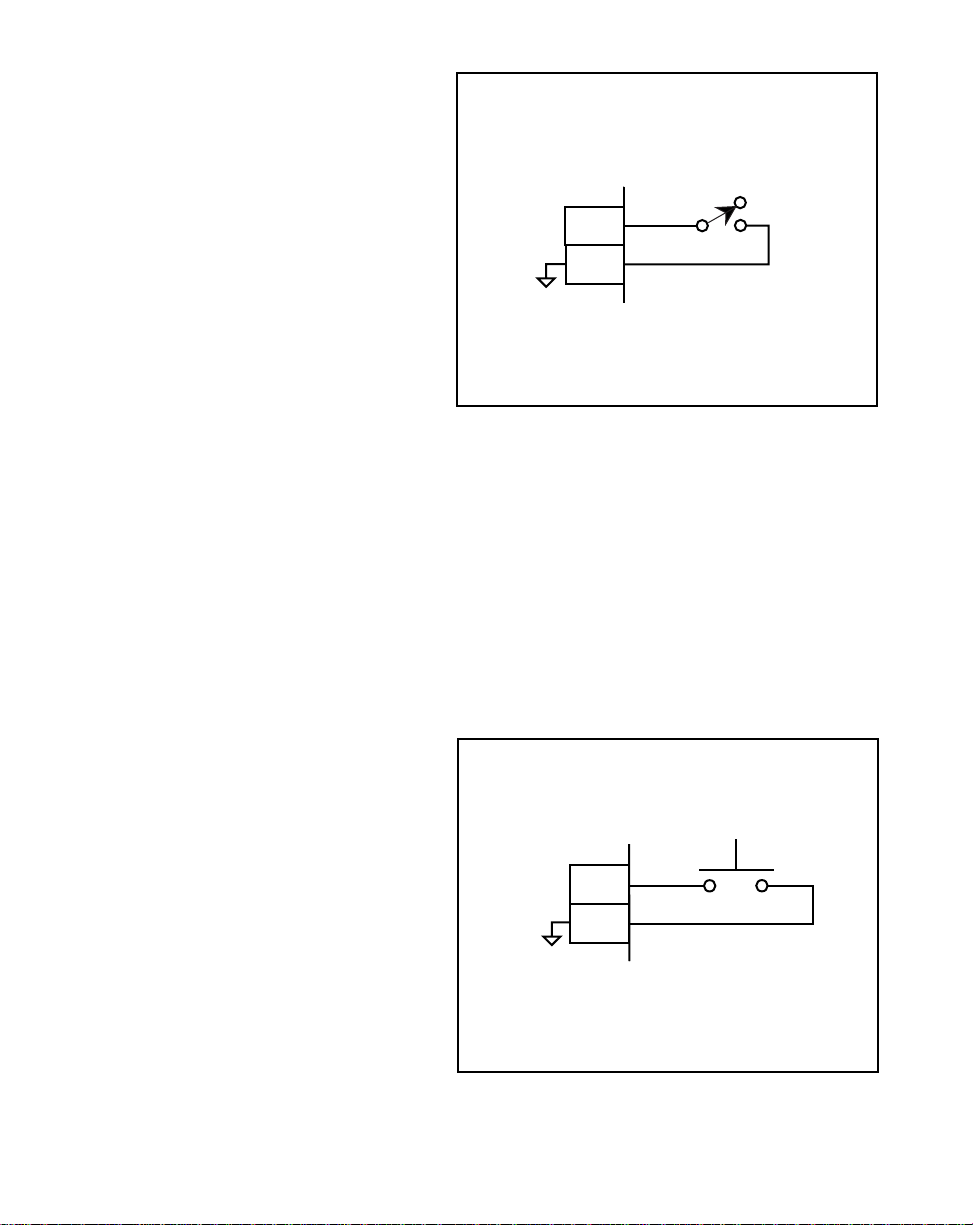

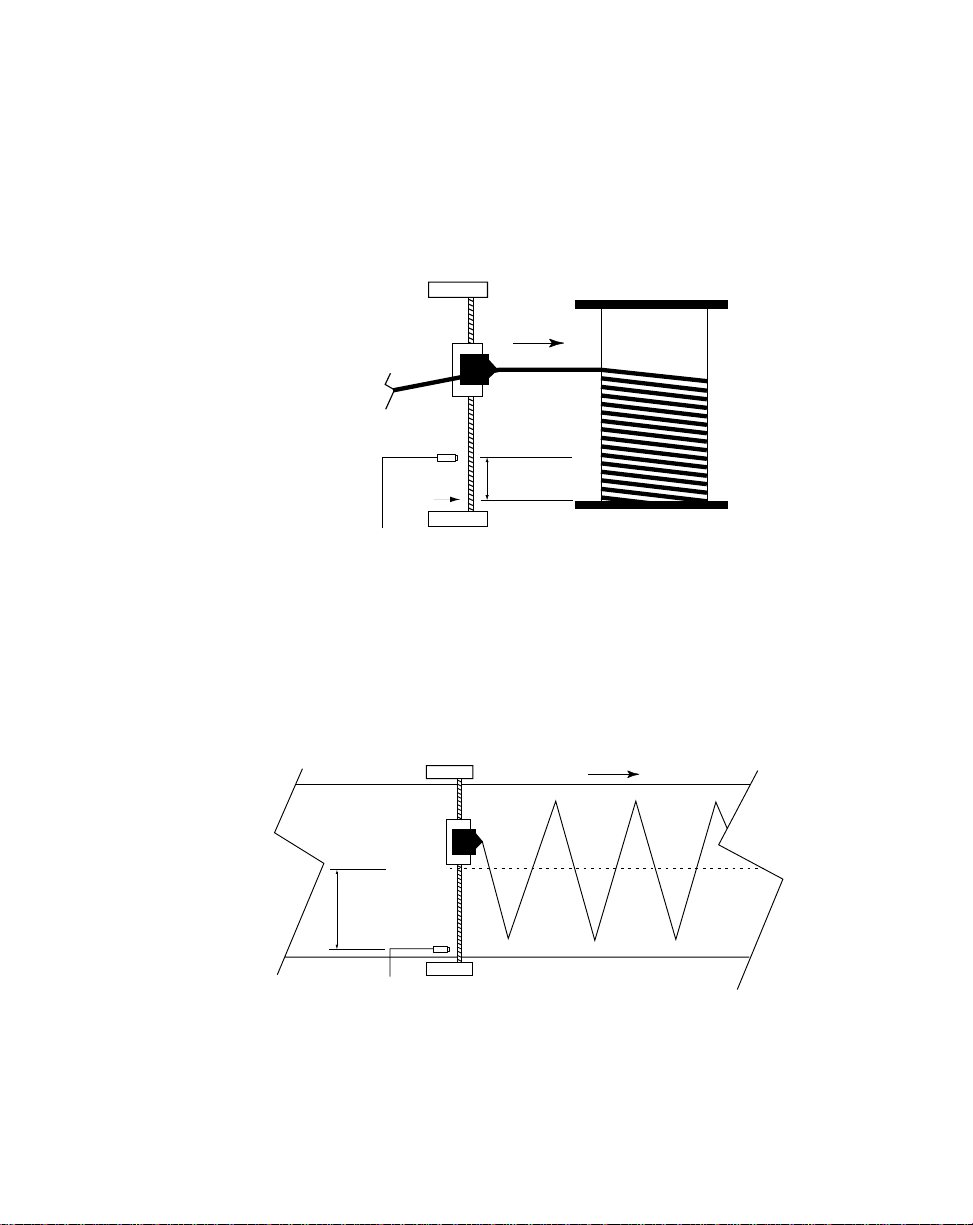

Web Scanning is another common M–Traverse application. The Web Scanning

application frequently uses the Standard option in the Follower mode of operation,

however, there are applications for which Web Scanning may use the Lay Adjusted

option in the Follower mode of operation. The M–Traverse locates the start or “Home”

position and accelerates the traversing mechanism (Follower) to the preset laypitch

(Setpoint). The traversing mechanism applies a secondary product, such as glue or

reinforcing fiber, onto the moving web. Then the M–Traverse decelerates the traversing

mechanism to zero speed at the end of the “Traverse Length”. At the “Dwell” (which is

usually set at zero) the traversing mechanism reverses its direction and returns with a

symmetric reverse profile. Using zero or very low “Accel / Decel” and “Dwell”

parameters creates a zigzag pattern. Figure 1-2 illustrates a typical Web Scanning

application.

LEAD

HOME SYNC

FOLLOWER

LINE FLOW

FEEDBACK FREQUENCY

Cut

Position

Length

Batch

Status

Count

9

7

8

45

6

23

1

0

Alt

Enter

Clear

M-TRAVERSE

M–Traverse

CONTREX

LEAD FREQUENCY

Figure 1-2 M–Traverse W eb Scanning Application

1-5

Page 15

—NOTES—

1-6

Page 16

Installation / Setup

Configuration

Mounting

Wiring

Inputs

Outputs

Serial Communications

Calibration

Motor Drive Setup

M-Traverse Calibration

2 - 1

Page 17

2 - 2

Page 18

CONFIGURATION

This section will show you how to re-configure the M-Traverse for electrical

compatibility. Complete these procedures prior to installation. These procedures do

not require power to complete.

The two areas that are involved in re-configuring the M-Traverse are the Isolator

Voltage jumper and the Power Voltage switch. Do not re-configure the M-Traverse's

Frequency Input. Use the default Quadrature position.

To re-configure the Isolator Voltage jumper and the Power Voltage switch, remove the

back plate, then carefully remove the Power Board. Figure 2-1 illustrates the location

of the boards.

Power Board CPU Board

Figure 2-1 Rear View of M-Traverse

2 - 3

Page 19

The Isolator Voltage jumper (J3) is located on the Power Board (see Figure 2-2). It

configures the isolated analog output for either voltage that is ranged by an internal +15

volt reference or for voltage that is auto-ranged by the voltage level of the motor drive.

The auto-range voltage position is the default configuration for the Isolator Voltage

jumper.

NOTE: In most cases, the default configuration will be appropriate for your application

and it will not be necessary to re-configure.

If the motor drive does not have an external voltage reference, re-configure the Isolator

Voltage by moving the jumper from the default auto-range voltage position (1) to the

internal +15 volt reference position (2).

Internal Reference

Position

115

J3

2 1

Auto Range

Position (default)

2 - 4

Figure 2-2 Power Board / Isolator Jumper

Page 20

The Power Voltage switch (SW1) is located on the Power Board (see Figure 2-3). The

default configuration for the Power Voltage switch is 115 VAC.

NOTE: In most cases, the default configuration will be appropriate for your application

and it will not be necessary to re-configure.

To re-configure for 230V, move the switch from the 115V position (left) to the 230V

position (right).

115

115V

(default)

115V

230V

Figure 2-3 Power Board / SW1 Switch

2 - 5

Page 21

Set

Contrex

CUTOUT

(

7.25" .03"

CUTOUT

(

3.65" .03"

3.6"

7.2"

)

5.7"

(

DOOR PANEL

Contrex

7.5"

M-TRAVERSE

2 - 6

3.9"

Figure 2-4 M–Traverse Mounting and Cutout Dimensions

Page 22

MOUNTING

This section contains instructions for mounting the M–Traverse in the door panel of a

NEMA Industrial Electrical enclosure. The M–Traverse is packaged in a compact 1/2

DIN Vertical Instrument Enclosure that mounts easily in the door of your Industrial

Electrical Enclosure.

To mount the M–Traverse:

1) The NEMA Industrial Electrical Enclosure that will house the M–

Traverse must conform to the following environmental conditions:

Temperature: 0 - 55 degrees C

(Internal NEMA enclosure temperature)

Humidity: 0 - 90% RH non-condensing

2) The dimensions for the door panel cutout are 3.65"+ .03" X 7.25 +.03"

(see figure 2-4). Allow two inches of clearance on all sides of the

cutout for mounting clamp attachments, wire routing and heat

convection.

3) Insert the M–Traverse through the door panel cutout until the gasket

and bezel are flush with the door panel (see figure 2-4).

4) The mounting clamps can be inserted in the holes that are located

either on the top and bottom or on the sides of the M–Traverse.

Tighten the mounting screws until the M–Traverse is mounted securely

in the NEMA Electrical Enclosure. Do not overtighten.

2 - 7

Page 23

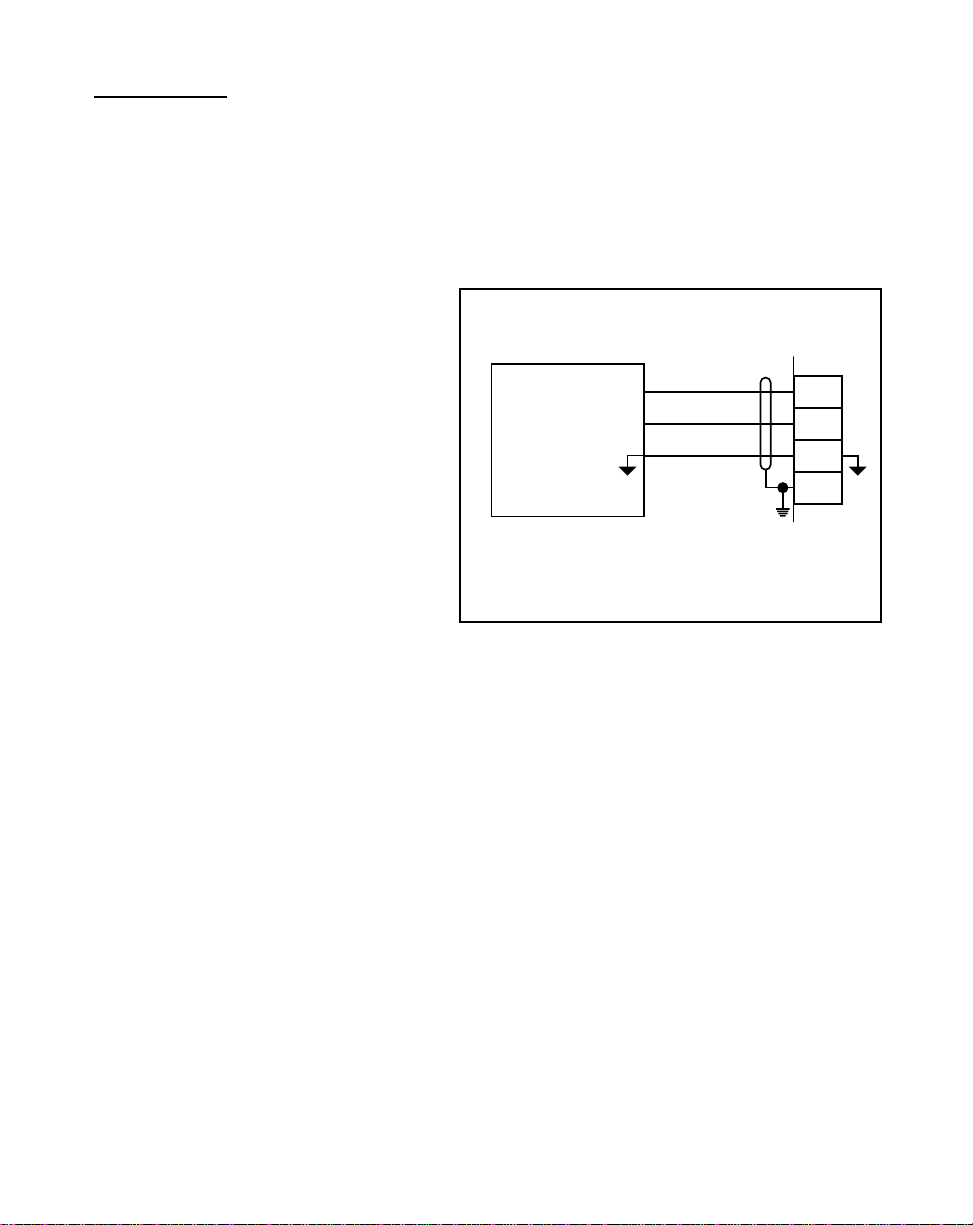

* Power for encoder and prox switches may be supplied by J3, pins 1 or 2.

Total +5 VDC current should not exceed 250 mA

Total +12 VDC current should not exceed 200 mA

J1

+12 V OUT

50 MA MAX

+

TXD–+

RXD

–

COM

+V

SIG

SIO

COM

DRIVE

ENABLE

BATCH

DONE

ALARM

PROFILE

DIRATHOME

OUTPUTAOUTPUT

B

+EXTDCSUPPLY–

RRR

R

D

R

I

V

E

SERIAL COMMUNICATIONS

RS 485

L

E

A

D

F

E

EDB

ACK

J3

CHA

COM

CHB

SHIELD

CHA

COM

CHB

COM

HOME SYNC

STPT SEL A

(C)

COM

STPT SEL B

(C)

HOME SET

J3 (C)J4 COM

HOME

SEEK(C)

HOME

RETURN(C)

COM

BATCH

RESET(C)

RUN(C)

COM

WAIT (O)

F–STOP(O)

COM

KEYPAD

LOCKOUT(C)

FORWARD

LIMIT(C)

COM

REVERSE

LIMIT(C)

FWD(O)

JOG

REV(C)

COM

JOG(C)

SHIELD

J4

+5 V OUT

500 MA MAX

+12 V OUT

150 MA MAX

INPUT VOLTAGE – 115/230 VAC

INPUT CURRENT – 0.25 AMP

INPUT FREQUENCY – 50/60 HZ

J2

USE COPPER WIRE ONLY.

SELECT WIRE SIZE ACCORDING TO AMPACITY

FOR 60/75 C WIRE

TIGHTEN TERMINALS TO 5 IN/LB

120 V

F

US

E

F

US

E

R

R

R

123456789

1011121314151617181920

123

123

+ 12VDC AUX OUT

R

R

RRR

R

DRIVE

+ VDC

SIGNAL

ISO COMMON

DRIVE ENABLE

BATCH DONE

ALARM

PROFILE DIR

AT-HOME

OUTPUT A

OUTPUT B

R

EXT

DC

SUPL

+

–

TXD +

TXD –

RXD +

RXD –

COMMON

RS422

SERIAL

COMM

CHASSIS GND

NEUTRAL / L2

L1

AC

POWER

J1

J2

50 V Max

123456789

101112131415161718

123456789

10111213141516

+ 5VDC AUX OUT

+12VDC AUX OUT

J3

CHA

COM

CHB

SHLD

CHA

COM

CHB

LEAD *QUAD

ENCODER

FEEDBACK

*

QUAD

ENCODER

HOME

*

SYNC

SETPOINT

SELECT A

SETPOINT

SELECT B

HOME SET

HOME SEEK

HOME RETURN

BATCH RESET

RUN

WAIT

F–STOP

KEYPAD LOCKOUT

FORWARD LIMIT

REVERSE LIMIT

JOG FORWARD

/REVERSE

JOG

SHIELD

J4

CHASSIS GND

NEUT/L2

L1

2 - 8

Figure 2-5 M-Traverse General Wiring Schematic

Page 24

WIRING

This section contains the input, output and serial communications wiring information for

the M–Traverse. Please read this section prior to wiring the M–Traverse to ensure that

you make the appropriate wiring decisions.

NOTE: The installation of this motor control must conform to area and local electrical

codes. See

National Fire Protection Association, or

Use local codes as applicable.

Use a minimum wire gauge of 18 AWG.

Use shielded cable to minimize equipment malfunctions from electrical noise

and terminate the shields at the receiving end only.

Keep the AC power wiring (J2) physically separated from all other wiring on

the M–Traverse. Failure to do so could result in additional electrical noise and

cause the M–Traverse to malfunction.

Inductive coils on relay, contactors, solenoids that are on the same AC power

line or housed in the same enclosure should be suppressed with an RC

network across the coil. For the best results, use resistance (r) values of 50

ohms and capacitance (c) values of 0.1 microfarads.

The National Electrical Code

The Canadian Electrical Code

(NEC,) Article 430 published by the

(CEC).

Install an AC line filter or isolation transformer to reduce excessive EMI noise,

such as line notches or spikes, on the AC power line.

DANGER

Hazardous voltages.

Can cause severe injury, death or

damage to the equipment.

The M–Traverse should only be

installed by a qualified

electrician.

2 - 9

Page 25

INPUTS

NOTE: The installation of this motor control must conform to area and local electrical

codes. See

National Fire Protection Association, or

Use local codes as applicable.

Input Power (J2 pins 1, 2, 3)

The M–Traverse operates on either a

115 VAC or 230 VAC (-10% + 15%,

0.25 Amps., 50/60 Hz). Use the

separate 3 pin connector (J2) for the

power connection.

The National Electrical Code

The Canadian Electrical Code

(NEC,) Article 430 published by the

(CEC).

Chassis Gnd

Neutral / L2

1

2

Lead Frequency (J3 pins

3,4,5,6)

The Lead Frequency is a pulse train

input that the M-Traverse uses to

determine the Lead motor's speed

and position. The Lead Frequency

signal must be quadrature. For

signal level specifications, refer to

References: Appendix A

M–Traverse Specifications.

,

L1

Figure 2-6 Input Power

3

4

5

6

J3

CHA

COM

CHB

Shield

3

J2

Lead

Quad

Encoder

2 - 10

Figure 2-7 Lead Frequency

Page 26

Feedback Frequency

(J3 pins 6,7,8,9)

The Feedback Frequency is a pulse

train input that the M-Traverse uses to

determine the Follower motor's speed

and position. The Feedback

Frequency signal must be quadrature.

For signal level specifications, refer to

References: Appendix A, M–T raverse

Specifications.

If the Feedback Frequency is lost,

the M-Traverse will command a !00% Speed Out

and the motor will run at 100% of the calibrated range.

This can cause severe injury, death or

it can damage your equipment.

Home Sync (J3 pins 6,11,12)

Figure 2-8 Feedback Frequency

WARNING

6

7

8

9

J3

Shield

CHA

COM

CHB

Feedback

Quad

Encoder

The Home Sync input identifies the

location of “Home” for the Home Seek

operation. This input is operated by

either a proximity switch or an optical

sensor switch (NPN output).

6

11

12

J3

Shield

Common

Home Sync

Figure 2-9 Home Sync

2 - 11

Page 27

Setpoint Select A

(J3 pins 13,14)

The Setpoint Select A and B inputs

are used in conjunction with each

other to select one of four

M–Traverse setpoints and traverse

lengths. The chart below displays

these four setpoints.

Setpoint Select B

(J3 pins 14,15)

Setpoint Select A

13

14

J3

Figure 2-10 Setpoint Select A

The Setpoint Select A and B inputs

are used in conjunction with each

other to select one of four

M–Traverse setpoints and traverse

lengths. The chart below displays

these four setpoints.

Setpoint Select B

Setpoint Select B

Open

Open

Setpoint Select B

Closed

2 - 12

Figure 2-11 Setpoint Select B

Setpoint Select A

Open

Setpoint 1

Traverse Length 1

Setpoint 3

Traverse Length 3

14

15

J3

Setpoint Select B

Setpoint Select A

Closed

Setpoint 2

Traverse Length 2

Setpoint 4

Traverse Length 4

Page 28

Home Set (J3 pins 14,16)

Home Set is a momentary input that

is edge triggered. When Home Set is

closed, it sets the current position as

the new “Home” position.

Home Set

14

16

J3

Figure 2-12 Home Set

Home Seek (J4 pins 1,2)

Home Seek is a momentary input that

is edge triggered. When Home Seek

is closed, the Follower makes a

sustained move at Jog speed, until it

reaches the “Home” sensor. As a

momentary input, Home Seek is

internally latched and does not need

to be maintained by an operator

device.

Home Seek

1

2

J4

Figure 2-13 Home Seek

2 - 13

Page 29

Home Return (J4 pins 3,4)

Home Return is a momentary input

that is edge triggered. When Home

Return is closed, the follower returns

to the established “Home” position.

As a momentary input, Home Return

is internally latched and does not

need to be maintained by an operator

device.

Home Return

3

4

J4

Figure 2-14 Home Return

Batch Reset (J4 pins 4,5)

In a closed position, the Batch Reset

input resets the batch count to zero.

2 - 14

Batch Reset

4

5

J4

Figure 2-15 Batch Reset

Page 30

Run (J4 pins 6,7)

When the Run input is momentarily

closed, the M–Traverse enters Run.

As a momentary input, Run is

internally latched and does not need

to be maintained by an operator

device.

NOTE: Close the F–Stop input prior

to entering Run.

RUN

6

7

J4

Figure 2-16 Run

Wait (J4 pins 7,8)

When the M–Traverse is in Run, it

checks the Wait input before it

proceeds with the next profile move

in either the forward or reverse

direction. If the Wait input is closed,

it will pause at the end of the profile

until the wait input opens.

Wait

8

7

J4

Figure 2-17 Wait

2 - 15

Page 31

F-Stop (J4 pins 9,10)

F-Stop is a momentary input. When

it is opened, the Follower stops

immediately (zero RPM) and ignores

the specified deceleration rate. As a

momentary input, F-STOP is

internally latched and does not need

to be maintained by an operator

device.

F-STOP

9

10

J4

Figure 2-18 F-Stop

Keypad Lockout (J4 pins 10,11)

When the Keypad Lockout is closed,

it selectively disables the front

keypad so that setpoint and other

control parameters can not be

changed. All of the monitoring

functions remain enabled.

2 - 16

10

11

J4

Keypad

Lockout

Figure 2-19 Keypad Lockout

Page 32

Forward Limit (J4 pins 12,13)

When Forward Limit is closed (edgetriggered), it prevents the follower

from moving forward. When the

M–Traverse detects a Forward Limit,

it will go to F–Stop from Forward Jog,

Home Seek or Run, if CP-37 is set to

“1”. If CP-37 is set to “2”, then the

M-Traverse will begin a reverse

profile when it detects a Forward

Limit. To deactivate Forward limit,

use any reverse command (e.g.,

Reverse Jog).

12

13

J4

Forward

Limit

Figure 2-20 Forward Limit

Reverse Limit (J4 pins 13,14)

When Reverse Limit is closed (edgetriggered), it prevents the follower

from moving in reverse. When the

M–Traverse detects a Reverse Limit,

it will go to F–Stop from either Run,

Reverse Jog or Home Seek (any

reverse move). To deactivate

Reverse limit, use any forward

command (e.g., Forward Jog).

13

14

J4

Reverse

Limit

Figure 2-21 Reverse Limit

2 - 17

Page 33

Jog Forward/Reverse (J4 pins

15,16)

The Jog Forward/Reverse input

controls the direction of the Speed

Command Output while it is in Jog.

Jog is in the forward direction when

the input is open. Jog is in the

reverse direction when the input is

closed.

Jog (J4 pins 16, 17)

Jog Forward / Reverse

15

16

J4

Figure 2-22 Jog Forward/Reverse

Jog is a maintained input. When the

Jog input is closed, the M–Traverse

sends a Speed Command Out signal

to the drive at the selected jog speed.

As a maintained input, Jog is only

active when the operator device is

closed.

NOTE: Close the F–Stop input and

open the Run input, prior to

entering Jog.

2 - 18

Jog

17

16

J4

Figure 2-23 Jog

Page 34

OUTPUTS

NOTE: The installation of this motor control must conform to area and local electrical

codes. See

National Fire Protection Association, or

Use local codes as applicable.

Speed Command Out

(J1 pins 8, 9,10,11)

The National Electrical Code

The Canadian Electrical Code

(NEC,) Article 430 published by the

(CEC).

Speed Command Out is an isolated

analog output signal that is sent to

the motor drive to control the speed

of the motor. Wire the Speed

Command Out (J1 pin 9) into the

± V (15V Max)

SIGNAL INPUT

DRIVE COMMON

*

Voltage Reference

Speed Command Out

Isolated Common

Shield

8

9

10

11

Speed Signal Input of the drive. If

the motor drive has a potentiometer

MOTOR DRIVE

J1

speed control, remove the

potentiometer connections, then wire

the Speed Command Output to the

potentiometer wiper input and wire

the Voltage Reference and Isolated

Figure 2-24 Speed Command Out

Common to the other two

potentiometer input connections. The

M–Traverse's isolated common

should always be connected to the

drive common.

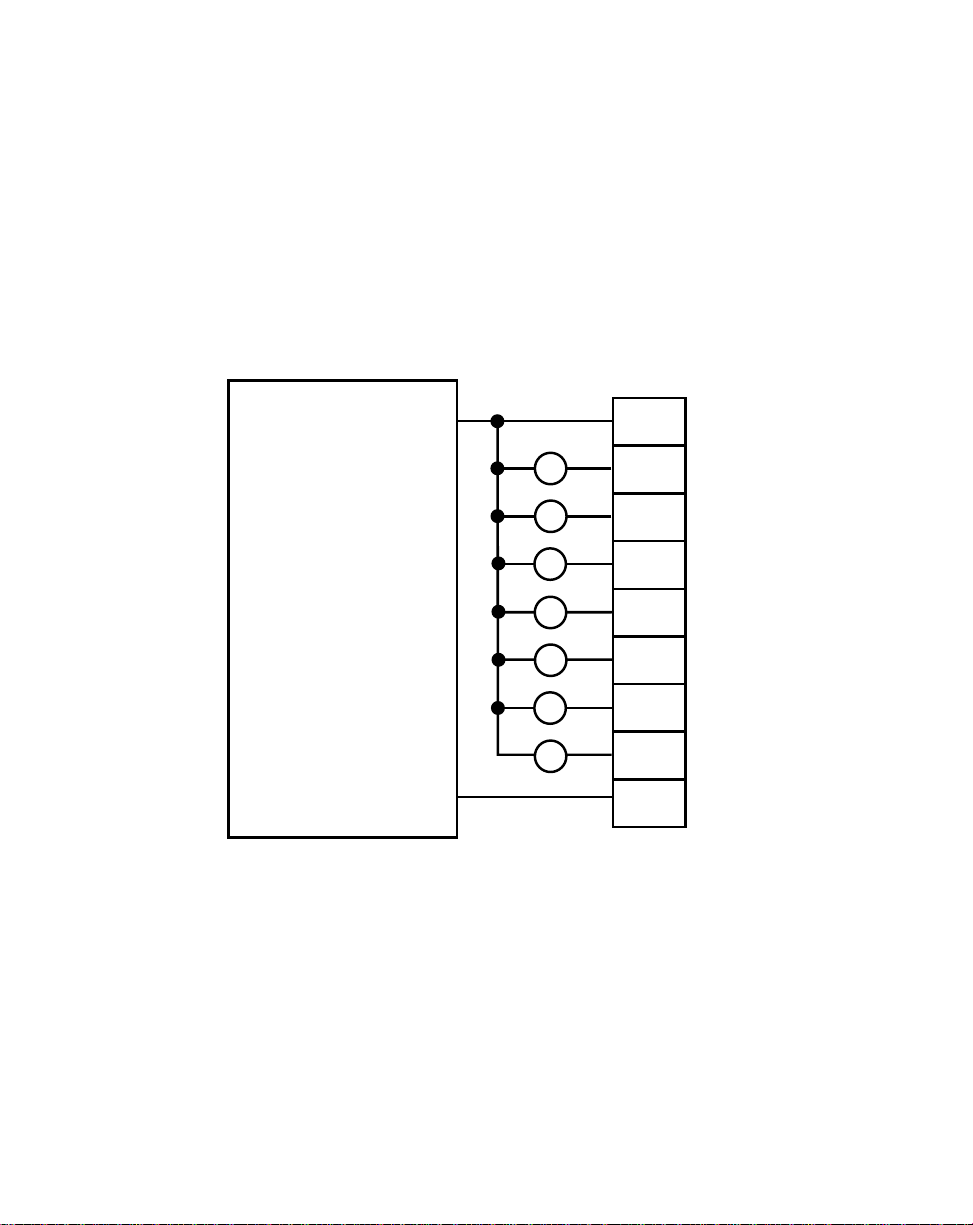

Drive Enable (J1 pin 13)

The Drive Enable output is activated (driven low) when the M–Traverse is signaling a

speed command to the motor drive. The Drive Enable output is driven high (relay

deactivated) after Power Up and during F–Stop. Refer to Figure 2-25.

NOTE: This is an open-collector relay driver. For specification details, see

ences: Appendix A, M–Traverse Specifications

. Use an external DC power

supply to power the relays. Free-wheeling diodes are incorporated internally

in the M–Traverse and do not need to be added externally.

Refer-

2 - 19

Page 35

Batch Done (J1 pin 14)

The Batch Done output is relay activated (driven low ) when the Batch count is

completed. Refer to Figure 2-25.

NOTE: This is an open-collector relay driver. For specification details, see

ences: Appendix A

supply to power the relays. Free-wheeling diodes are incorporated internally

in the M–Traverse and do not need to be added externally.

,

M–Traverse Specifications

. Use an external DC power

Refer-

Alarm (J1 pin 15)

The Alarm output is relay activated (driven low) if the system's speed is above the

speed alarm setting that has been entered in the High Speed Alarm (CP-23) parameter.

Refer to Figure 2-25.

NOTE: This is an open-collector relay driver. For specification details, see

ences: Appendix A

supply to power the relays. Free-wheeling diodes are incorporated internally

in the M–Traverse and do not need to be added externally.

,

M–Traverse Specifications

. Use an external DC power

Refer-

Profile Direction (J1 pin 16)

The Profile Direction output indicates the commanded direction of the profile.

This output is relay deactivated (driven high) when the profile is commanded to move

forward. This output is relay activated (driven low) when the profile is commanded to

move in reverse. Refer to Figure 2-25.

NOTE: This is an open-collector relay driver. For specification details, see

ences: Appendix A, M–Traverse Specifications

supply to power the relays. Free-wheeling diodes are incorporated internally

in the M–Traverse and do not need to be added externally.

2 - 20

. Use an external DC power

Refer-

Page 36

At-Home (J1 pin 17)

In order for this output to function, “Home” must have already been determined (using

Home Set or Home Seek). Once ”Home” has been determined, this output is relay

activated (driven low) when the traverse Follower Position is within the At-Home Band

specified in CP-30. Refer to Figure 2-25.

NOTE: This is an open-collector relay driver. For specification details, see

ences: Appendix A

supply to power the relays. Free-wheeling diodes are incorporated internally

in the M–Traverse and do not need to be added externally.

,

M–Traverse Specifications

. Use an external DC power

Refer-

Output A (J1 pin 18)

Output A can be set to activate at different segments of the forward and reverse

profiles. The parameter values set in CP-90, CP-91 and CP-92 determine the profile

segment and direction of activation, as well as the polarity (high or low). Refer to

Figure 2-25.

NOTE: This is an open-collector relay driver. For specification details, see

ences: Appendix A

supply to power the relays. Free-wheeling diodes are incorporated internally

in the M–Traverse and do not need to be added externally.

,

M–Traverse Specifications

. Use an external DC power

Refer-

Output B (J1 pin 19)

Output B can be set to activate at different segments of the forward and reverse

profiles. The parameter values set in CP-93, CP-94 and CP-95 determine the profile

segment and direction of activation, as well as the polarity (high or low). Refer to

Figure 2-25.

NOTE: This is an open-collector relay driver. For specification details, see

ences: Appendix A, M–Traverse Specifications

supply to power the relays. Free-wheeling diodes are incorporated internally

in the M–Traverse and do not need to be added externally.

. Use an external DC power

Refer-

2 - 21

Page 37

Auxiliary DC Power (J3 pins 1, 2)

The 5 volt output (J3 pin 1) is a DC regulated output that can be used to power

encoders or other auxiliary equipment that is used in conjunction with the M–Traverse.

The 12 volt output (J3 pin 2) is a DC regulated output that can be used to power the

proximity sensors or other auxiliary equipment that is used in conjunction with the M–

Traverse. Refer to Figure 2-25.

WARNING

Do not exceed

the maximum current output of

250 mA for +5 VDC and

200 mA for +12 VDC.

2 - 22

Exceeding the maximum

current output

can damage the M–Traverse.

Page 38

+

12

Diode Protect

EXTERNAL

DC

POWER

SUPPLY

(50V Max)

R

R

R

R

R

R

R

–

13

14

15

16

17

18

19

20

Drive Enable

Batch Done

Alarm

Profile Dir

At-Home

Output A

Output B

Common

J1

Figure 2-25 Discrete Outputs

2 - 23

Page 39

SERIAL COMMUNICATIONS

NOTE: The installation of this motor control must conform to area and local electrical

codes. See

National Fire Protection Association, or

Use local codes as applicable.

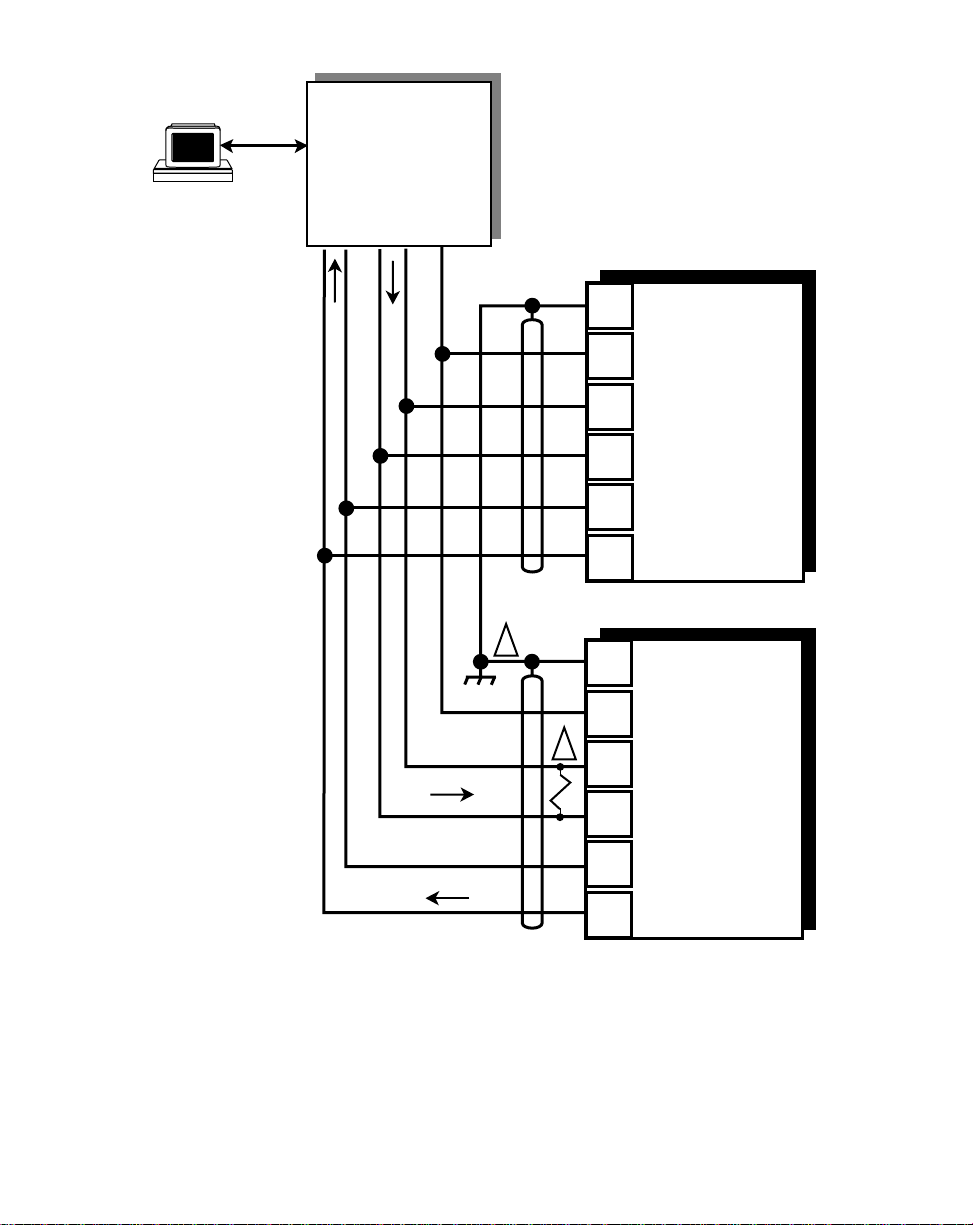

The Serial Communications interface on the M–Traverse complies with EIA Standard

RS–422 for balanced line transmissions. This interface allows the host computer to

perform remote computer parameter entry, status or performance monitoring, and

remote control of the M–Traverse. See

information on using Serial Communications.

Figures 2-26 and 2-27 illustrate a multidrop installation of the Serial Communications

link and Serial Communications connections.

The National Electrical Code

The Canadian Electrical Code

Operations: Serial Communications

(NEC,) Article 430 published by the

(CEC).

for

2 - 24

M-TRAVERSE

M-TRAVERSE

RS-232 to RS-422

Converter

M-TRAVERSE

Figure 2-26 M-Traverse Multidrop Installation

M-TRAVERSE

M-TRAVERSE

M-TRAVERSE

Page 40

RS232 to RS422

Converter

RXD TXD COM

+ — + —

J1

7

6

5

4

3

2

M-Traverse #1

SHIELD

COMMON

- RXD

+ RXD

- TXD

+ TXD

J1

1

1. Terminate shield only at one end of the cable.

2. If you need to terminate the communication line, then

terminate it at the unit which is the furthest away from

the converter. A 100 ohm, 1/2 Watt resistor will usually

terminate successfully. Refer to EIA Standard

RS–422, for more information.

Figure 2-27 M–Traverse Serial Communications Connections

7

6

2

5

4

3

2

M-Traverse #2

SHIELD

COMMON

- RXD

+ RXD

- TXD

+ TXD

2 - 25

Page 41

2 - 26

Page 42

CALIBRATION

Calibration matches the analog output of the M–Traverse with the analog input of the

motor drive. Calibration is accomplished in two steps. The first step is to set up the

motor drive. The second step is to calibrate the M–Traverse to the motor drive so that

the speed is adjusted to the maximum operating speed. The M–Traverse must be

properly installed prior to calibration. Refer to

Installation/Setup; Wiring

.

DANGER

Hazardous voltages.

Can cause severe

injury, death or

damage

to the equipment.

Installation/Setup; Mounting

and

Make adjustments with caution.

2 - 27

Page 43

Turn the screws fully clockwise for the maximum setting.

Turn the screws fully counterclockwise for the minimum setting.

Zero Pot

Scale Pot

R1

R2

2 - 28

Power Board

Figure 2-28 Location of M–Traverse Scale and Zero Pot

Page 44

MOTOR DRIVE SET UP

1) Put the M–Traverse in “F–Stop” by opening the F–Stop input (J4 pins 9

and 10). Refer to

2) Set the drive's Acceleration and Deceleration potentiometers to their

fastest rates (minimum ramp time). The goal is to make the drive as

responsive as possible, which allows the M–Traverse to control the

speed changes.

3) If the drive has a Zero Speed Potentiometer, adjust it to eliminate any

motor creep. If the drive does not have a zero speed pot, then adjust

the zero speed pot on the M–Traverse to eliminate any motor creep.

Figure 2-28 shows the location of the M–Traverse zero speed pot.

4) If the drive has an IR Compensation Potentiometer, set it at minimum.

5) Each motor drive has settings that are unique to its particular model.

Adjust any remaining drive settings according to the manufacture's

recommendations.

Installation/Setup: Wiring, F–Stop.

ENCODER POLARITY CHECK

1) Observe MV-41 while you rotate the lead encoder in the direction that is

“forward” during normal operation. Switch the lead encoder lines on J3

pins 3 and 5 if MV-41 is negative.

2) Observe MV-42 while you rotate the Follower encoder in the direction

that is “forward” during normal operation. Switch the follower encoder

lines on J3 pins 7 and 9 if MV-42 is negative.

2 - 29

Page 45

M–TRAVERSE CALIBRATION

1) Make sure that the M–Traverse is still in “F–Stop”. If it is not, put the

M–Traverse in “F–Stop” by opening the F–Stop Logic input (J4 pins 9

and 10). Refer to

2) Enter the resolution (PPRs) of the feedback sensor in the PPR Follower

(CP-18) parameter by entering the following on the keypad:

Press “Code Select”

Enter “18”

Press “Enter”

Enter the Pulses Per Revolution (PPR) of the feedback sensor

Press “Enter”

The Tach is now scaled for feedback RPMs.

3) If the M–Traverse is using the drive voltage for reference (J1 pin 8),

then set the drive's max speed potentiometer to its minimum setting. If

the M–Traverse is using its internal voltage for reference (no

connection to J1 pin 8) then set the drive's max speed potentiometer to

its maximum setting and set the M–Traverse's scale pot to its minimum

setting (fully counterclockwise). Figure 2-28 shows the location of the

M–Traverse scale pot.

Installation/Setup: Wiring, F–Stop

.

2 - 30

4) The M-Traverse is defaulted for use with bi-directional drives that use

bipolar (positive and negative) voltage commands to indicate the

direction. If you are using a single quadrant (direction) drive, then

change CP-29 to unipolar operation, as follows:

Press “Code Select”

Enter “29”

Press “Enter”

Enter “1”

Press “Enter”

5) Enable the M–Traverse's direct control mode by entering the following

on the keypad:

Press “Code Select”

Enter “14”

Press “Enter”

Enter “2”

Press “Enter”

Page 46

6) Put the M–Traverse into RUN by shorting the F–STOP input (J4 pins 9

and 10) and the RUN input (J4 pins 6 and 7). Although the motor is

now in RUN, it will have zero speed until you adjust the Direct Analog

Command (CP-62).

7) Gradually set the M–Traverse's Direct Analog Command to 90% (3686)

by entering the following on the keypad:

Press “Setpoint”

Enter “400”

Press “Enter”

Enter “800”

Press “Enter”

Continue to gradually increase these increments by 400 until you reach

“3686”. Since there are no acceleration/deceleration ramps in Direct

mode, a sudden increase to “3686” could cause damage in some

systems. If the Follower is not moving in a forward direction, then

rewire the drive/motor leads for forward operation.

Note: A value of –3686 will change the direction of the motor.

8) Turn either the motor drive's max speed or the M–Traverse's scale

potentiometer clockwise until the drive motor's RPMs are at the

maximum operating speed at which you want the system to operate.

Check the speed (RPMs) by pressing the Tach” key. “Tach” should

display the RPM speed that you enter in CP-19.

9) Put the Direct Analog Command back to 0% by entering the following

on the keypad:

Press “Setpoint”

Enter “0”

Press “Enter”

10) Disable the M–Traverse's direct mode by entering the following on the

keypad:

Press “Code Select”

Enter “14”

Press “Enter”

Enter “1”

Press “Enter”

11) Put the M–Traverse in “F–Stop” by opening the F–Stop input (J4 pins 9

and 10). Refer to

Installation/Setup: Wiring, F–Stop

.

2 - 31

Page 47

—NOTES—

2 - 32

Page 48

Operation

Keypad Operation

Control Parameters (CP)

Follower Mode

Direct Mode

Jog

Tuning

Output Control

M-Traverse Operation

Follower Mode

Home Set

Home Seek

Home Return

Direct Mode

Jog

Monitor Variables (MV)

Input Monitoring

Output Monitoring

Performance Monitoring

Status Monitoring

Serial Communications

Using Serial Communications

Communications Software Design

3 - 1

Page 49

3 - 2

Page 50

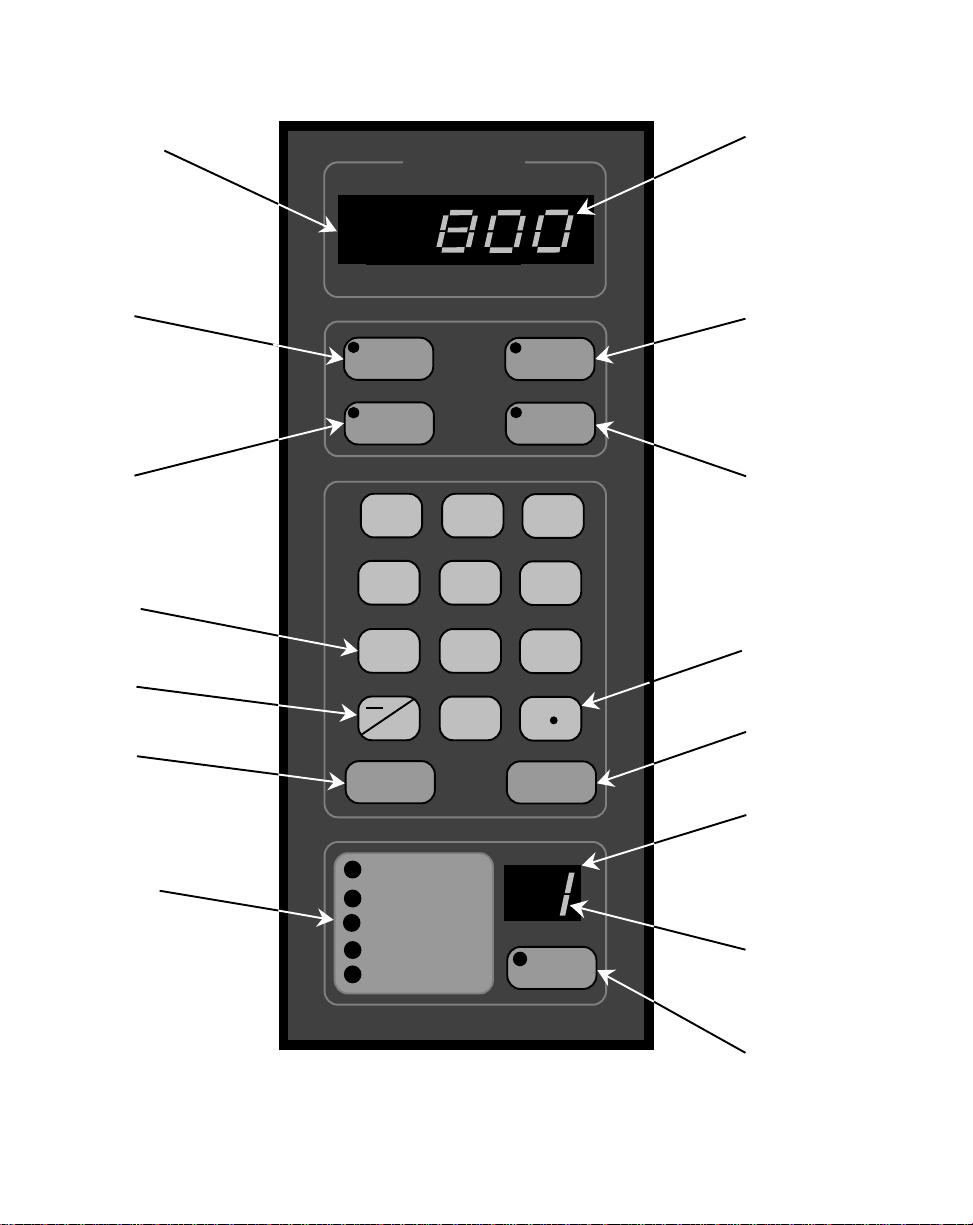

KEYPAD OPERATION

The front panel of the M–Traverse is an easy to use keypad that gives you direct

access to the Parameters (Control Parameters and Monitor Variables) by entering the

Parameter Code. You can also use the keypad to change the value of a Control

Parameter. The keypad has keys for Code Select, Enter and Clear. It also has

numeric keys and four dedicated keys: Setpoint, Tach, Status and Batch Count. The

LED display is the above the keys. Refer to figure 3-1 for the location of the keys and

LED display on the keypad. Table 3-1 demonstrates basic keypad entry.

The keypad functions as follows:

Code Select Use the “Code Select” key prior to entering a Parameter Code

for either a Control Parameter (CP) or Monitor Variable (MV).

Numeric Use the numeric keys to enter a Parameter Code for either a

Control Parameter (CP) or a Monitor Variable (MV) or to enter

a value for a Control Parameter. Use the “Clear” key to delete

your entry. Use the “Enter” key after each entry, to enter it in

the M-Traverse.

—/Alt Use the “—/Alt” key to enter a negative value. In MVs 43, 44,

80, 81 and 84, the “—/Alt” key toggles between four lower and

four higher digits because some numbers exceed the six digit

display panel limit.

. Use the decimal key for values with a decimal point.

Clear The “Clear” key will delete the entry, if you have not used the

“Enter” key.

Tach The “Tach” key is a dedicated or shortcut key. You can access

the tach Parameters directly, rather than manually entering the

Parameter Code (MV-40).

Setpoint The “Setpoint” Key is a dedicated or shortcut key. You can

directly access the active setpoint in the Follower mode (either

CP-01, CP-03, CP-05 or CP-07) or the active setpoint in the

Direct mode (CP-62).

3 - 3

Page 51

Batch Count Key The “Batch Count” Key is a dedicated or shortcut key. You can

directly access the Batch Count parameter (MV-89).

Status Key The “Status” Key is a dedicated or shortcut key. You can

directly access the Alarm Status parameter (MV-51).

Lower LED Display The two-digit Parameter Code is displayed on the Lower LED

Display.

Upper LED Display The Parameter Code's value is displayed on the Upper LED

display. This value can be up to six digits.

Discrete LED Display There are five discrete LED display lights. When a specific

light is “on”, it indicates the following condition:

Run..................The M-Traverse is in Follower mode and is executing

a profile.

Wait .................The Wait input (J4 pin 8 ) is active.

Drive Enable....The Drive Enable output (J1 pin 13) is active.

At-Home ..........The Follower position is within the At-Home band of

the Home position.

Alarm ............... There is an active alarm condition.

To Enter a Parameter Code:

To Enter a Parameter Value:

(For Control Parameters only - Monitor

Variables can not be changed

manually)

To Use the Tach Key:

To Use the Status Key:

To Use the Setpoint Key:

To Use the Batch Count Key:

3 - 4

Table 3-1 Basic Keypad Entry

Press “Code Select”.

Enter a Parameter Code (For a Control Parameter or Monitor Variable).

Press “Enter” (within 15 seconds).

The Parameter Code and its current value are displayed on the LED displays.

Follow the steps to enter a Parameter Code.

Enter a new value (Use the numeric keys) .

Press “Enter” (within 15 seconds).

Press “Tach”.

The scaled Tach - Velocity is displayed (MV -40).

Press “Status”.

The code for the alarm status is displayed (MV-51).

Press “Setpoint”.

The value of the active setpoint is displayed, in engineering units. (CP-01,

CP-03, CP-05, CP-07 or CP-62).

Press “Batch Count” .

The number of complete batch counts is displayed (MV-89).

Page 52

Upper

LED

Display

Setpoint

Key

Set

Point

ONTREX

C

Parameter Value

(up to 6 digits)

Tach

Key

Tach

Batch

Count

Key

Numeric

Keys

—/Alt

Key

Clear

Key

Discrete

LED Indicator

Display

Batch

Count

7

8

45

1

Alt

23

0

Clear

Run

Wait

Drive Enbl

At-Home

Alarm

Status

9

6

Enter

Code

Select

Status

Key

Decimal

Key

Enter

Key

Lower

LED

Display

Parameter

Code

(2 digits)

Figure 3-1 The M–Traverse Front Panel

Code

Select

Key

3 - 5

Page 53

3 - 6

Page 54

CONTROL PARAMETERS

Parameters are divided into two classifications; Control Parameters (CP) and Monitor

Variable (MV). The numbered code that represents the parameter is the Parameter

Code. The operational data is the parameter's value.

Control Parameter 14 = 1

Parameters =

Monitor Variable 40 = 200

Parameter Code Parameter Value

This section is about Control Parameters. Monitor Variables are explained in

Operation: Monitor Parameters.

The M–Traverse comes factory pre-loaded with a complete set of default Control

Parameters values. The majority of these default settings are suitable for most

applications and do not require modification.

Control Parameters allow you to enter data that is unique to your system (e.g., encoder

resolution, Lead to Follower ratios) and modify the M–Traverse for your specific needs

(e.g., maximum RPM, setpoints, acceleration/deceleration ramp rates) by entering a

parameter value. Control Parameters can be "locked out" so that they become

inaccessible from the Keypad. For details, refer to

References: Appendix C, CP-79.

The M–Traverse is designed to execute either the Direct mode of operation or the

Follower mode of operation. The values that you enter in the relevant Control

Parameters determine which of the modes of operation your M–Traverse is set up for.

The mode of operation that you use is determined by your systems operational

requirements.

The following sections demonstrate how to enter Control Parameters for the Direct

mode or the Follower mode of operation. In addition, Control Parameters for Jog,

Tuning and Output Control are addressed.

3 - 7

Page 55

FOLLOWER MODE

The M-Traverse is a multi-motor operation that is specifically designed for the precise

control of reciprocating lead/follower motion control applications. Its primary mode of

operation is the Follower mode. This section discusses the set up procedures for the

Follower mode of operation. Refer to

Applications

Operation

Caution: To avoid damage to your system, the M-Traverse must be calibrated and the

In order to set up the M-Traverse for the Follower mode of operation, Control

Parameters must be entered for the following procedures:

for an example of the Follower Mode. Refer to

for instructions on the operation of the Follower mode.

motor drive set up before you enter the Follower mode. Refer to

Setup: Calibration

.

Introduction: Examples of M-Traverse

Operation: M–Traverse

Installation/

Control Mode Parameter

Follower Scaling Parameters

Preset Parameters

Follower Profile Parameters

Other Follower Parameters

3 - 8

Page 56

Control Mode Parameter

The Control Mode (CP-14) parameter allows you to choose between either the

Standard (1) or Lay Adjusted (3) option in the Follower mode of operation. Both options

will operate your system. The calculation of the Follower profile length is the only

difference between the Standard and the Lay Adjusted option. In the lay adjusted

option, one lay pitch is subtracted from the profile length to adjust for the initial lay on

the reel.

NOTE: You can also use Control Mode (CP-14) to choose the Direct mode of opera-

tion, which is used for calibration and trouble shooting. Refer to

Direct Mode

The factory default for the Control Mode Control Parameter is found in Table 3-2. To

modify the default parameter refer to Table 3-3. If you are uncertain how to enter a

Control Parameter, review the

for information on the Direct mode.

Operations: Keypad

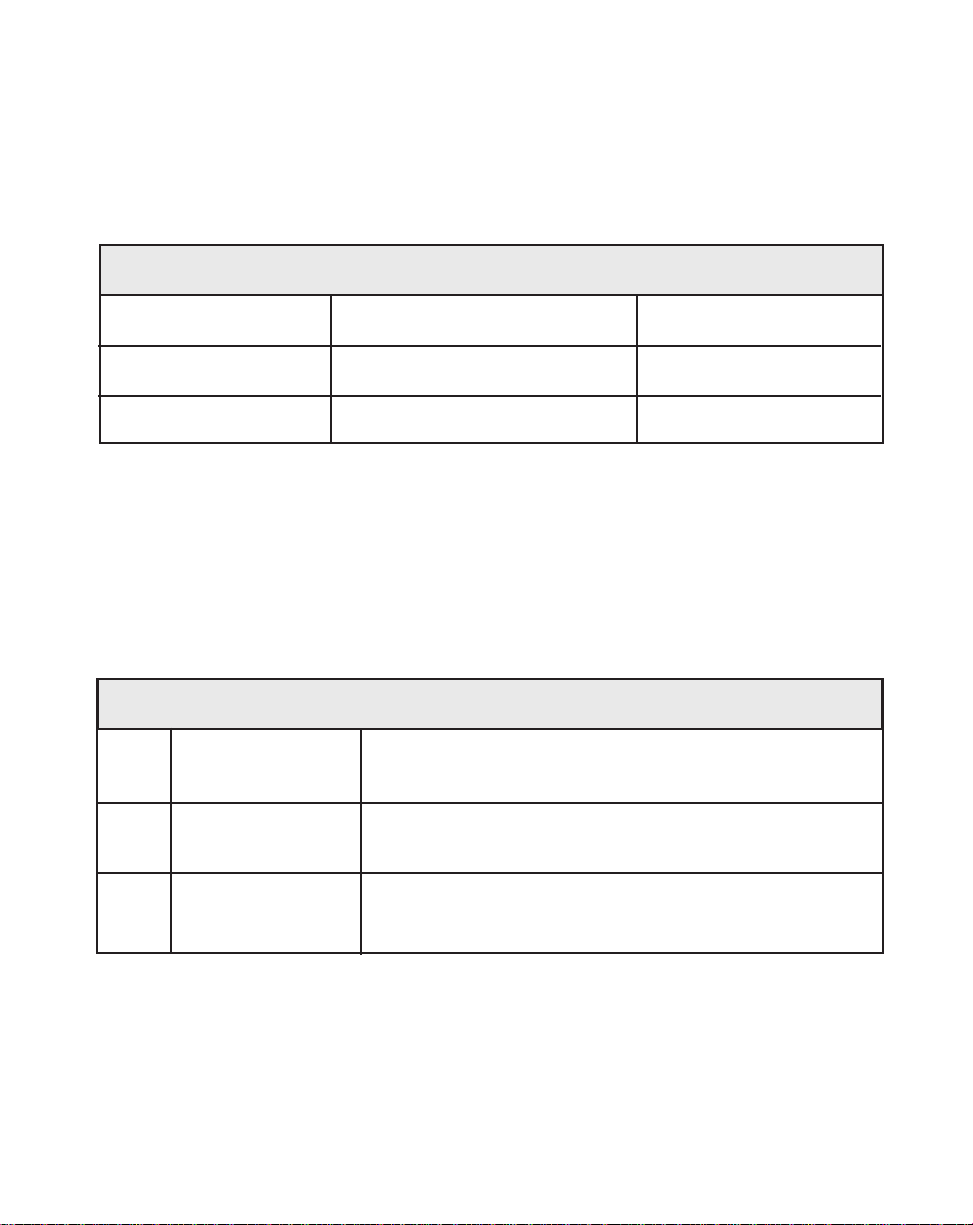

Table 3-2 Default Control Mode Control Parameter

section.

CP Parameter Name Parameter Value

CP-14 Control Mode 1 (Follower /Standard)

Operation:

Table 3-3 Entering Control Mode Control Parameters

CP Parameter Name Parameter Value

CP-14 Control Mode Enter “1” to enable the Follower Mode / Standard

Enter “3” to enable the Follower Mode / Lay Adjusted

3 - 9

Page 57

Follower Scaling Parameters

The M-Traverse allows you to use Engineering Units (e.g., feet, inches) to control and

monitor your system. Follower Scaling is a convenient method for converting encoder

lines to Engineering Units. Scaling Control Parameters give the M-Traverse the

following information:

Engineering Units (CP-15)

In a level wind application, CP-15 is your Engineering Unit (E.U.)

measurement of a laypitch. In a web scanning application, CP-15 is

your E.U. measurement for a traverse length. If your application uses

the M-Traverse's setpoint flexibility to change over the operation, and

you have more than one measurement, then pick one arbitrarily.

However, be sure to reference that same measurement consistently

throughout the scaling set up. In setting up the scaling, you are simply

allowing the M-Traverse to establish a conversion of encoder lines to

the E.U. that you prefer to use. Place the decimal in the location of

your desired resolution (to the tens, hundreds or thousands place). All

of the other Control Parameters or Monitor Parameters that display in

E.U.s will automatically display the correct decimal position.

Lead PPR Reel (CP-16)

In a level wind application, CP-16 is the number of Lead encoder lines

that the Lead Frequency input registers as a result of one revolution of

the reel. In a web scanning application, CP-16 is the number of Lead

encoder lines that the Lead Frequency input registers when the

Follower travels one traverse length. When you calculate this variable,

be sure to consider all gear reductions, belt reductions and other types

of reducers. Use the following procedure to check CP-16:

• Place the M-Traverse in F-Stop.

• Activate the Home Set input (clears the Lead position to zero).

• Place the M-Traverse in F-Stop.

• Display MV-43 (Lead Position).

• Move the Lead either one revolution of the reel (level wind) or one

traverse length (web scan).

• MV-43 should have the same value as CP-16.

Follower Lines per Engineering Units (CP-17)

In a level wind application, CP-17 is the number of Follower encoder

lines that the Feedback Frequency input registers as a result of the

Follower laypitch that was entered in CP-15. In a web scanning

application,

3 - 10

Page 58

CP-17 is the number of Follower encoder lines that the Feedback

Frequency input registers when the Follower travels one traverse

length. When you calculate this variable, be sure to consider all gear

reductions, belt reductions and other types of reducers. Use the

following procedure to check or find CP-17 :

• Place the M-Traverse in F-Stop.

• Activate the Home Set input (clears the Follower position to zero).

• Place the M-Traverse in F-Stop.

• Display MV-44 (Follower Position).

• Jog the Follower either one laypitch (CP-15) for level wind or one

traverse length( CP-15) for web scan.

• MV-44 should have the same value as CP-17.

PPR Follower (CP-18)

The PPR Follower (CP-18) parameter is the number of pulses per

revolution of the feedback encoder (encoder resolution in lines).

Maximum RPM Follower (CP-19)

The Maximum RPM Follower (CP-19) parameter is the RPM of the

feedback encoder shaft when the Follower is operating at maximum

speed. Although this entry does not need to be exact, highly inaccurate

entries will make it difficult to tune the M-Traverse for precision Follower

profiling. When you calculate this variable, be sure to consider all gear

reductions, belt reductions and other types of reducers.

The factory defaults for the Follower Scaling Control Parameters are found in Table 3-4.

To modify the default parameters refer to Table 3-5. If you are uncertain how to enter a

Control Parameter, review the

Operations: Keypad

section.

Table 3-4 Default Follower Scaling Control Parameters

CP Parameter Name Parameter Value

CP-15 Engineering Units 0.000

CP-16 Lead PPR Reel 1000

CP-17 Follower Lines/E.U. 1000

CP-18 PPR Follower (Feedback) 60

CP-19 Max RPM Follower 2000

3 - 11

Page 59

Table 3-5 Entering Follower Scaling Control Parameters

CP Parameter Name Parameter Value

CP-15 Engineering Units In a level wind application, enter your E.U.

measurement of one laypitch.

In a web scanning operation, enter your E.U.

measurement for one traverse length.

CP-16 Lead PPR Reel In a level wind application, enter the number of Lead

encoder lines that the Lead Frequency input registers as

a result of one revolution of the reel.

In a web scanning application, enter the number of Lead

encoder lines that the Lead Frequency input registers as

a result of one traverse length.

Include calculations for all gear reductions, belt

reductions and other types of reducers.

CP-17 Follower Lines/E.U. In a level wind application, enter the number of Follower

encoder lines that the Feedback Frequency input

registers as a result of one Follower laypitch (reference

CP-15).

In a web scanning application, enter the number of

Follower encoder lines that the Feedback Frequency

input registers when the Follower travels one traverse

length. Include calculations for all gear reductions, belt

reductions and other types of reducers.

CP-18 PPR Follower (fdbk) Enter the number of pulses per revolution of the

feedback encoder (encoder resolution in lines).

CP-19 Max RPM Follower Enter the RPM of the feedback encoder shaft when the

Follower is operating at maximum speed. Include

calculations for all gear reductions, belt reductions and

other types of reducers.

3 - 12

Page 60

Preset Parameters

Setpoints (CP-01, CP-03, CP-05, CP-07)

The Setpoint parameters are set up as pairs in conjunction with the

Traverse Length parameters. There are four pairs of Setpoint and

Traverse Length parameters. The Setpoint value is entered in Engineering Units (E.U.s) and automatically displays the decimal position

that was entered in the Engineering Units (CP-15). The Setpoint

parameter determines how far the Follower travels based on the Lead.

The Follower travels the setpoint distance while the Lead travels the

distance entered into CP-17. In the level wind application, the Setpoint

parameters are the laypitch (center-to-center distance between windings on the reel). In the web scanning application, the Setpoint parameters are the traverse length. These preset parameters can be switch

selected (via the Setpoint Select switches) which gives the operator the

option of changing over the product up to four times.

The factory defaults for the Default Setpoint Control Parameters are found in Table 3-6.

To modify the default parameters refer to Table 3-7. If you are uncertain how to enter a

Control Parameter, review the

Operations: Keypad

section.

Table 3-6 Default Setpoint Control Parameters

CP Parameter Name Parameter Value

CP-01 Setpoint 1 0.000

CP-03 Setpoint 2 0.000

CP-05 Setpoint 3 0.000

CP-07 Setpoint 4 0.000

3 - 13

Page 61

Table 3-7 Entering Setpoint Control Parameters

CP Parameter Name Parameter Value

CP-01 Setpoint 1 In a level wind application, enter your E.U.

measurement of one laypitch.

In a web scanning operation enter your E.U.

measurement for one traverse length.

CP-03 Setpoint 2 In a level wind application, enter your E.U.

measurement of one laypitch.

In a web scanning operation enter your E.U.

measurement for one traverse length.

CP-05 Setpoint 3 In a level wind application, enter your E.U.

measurement of one laypitch.

In a web scanning operation enter your E.U.

measurement for one traverse length.

CP-07 Setpoint 4 In a level wind application, enter your E.U.

measurement of one laypitch.

In a web scanning operation enter your E.U.

measurement for one traverse length.

Traverse Length (CP-02, CP-04, CP-06, CP-08)

The Traverse Length parameters are set up as pairs in conjunction with

the Setpoint parameters. There are four pairs of Setpoint and Traverse

Length parameters. The Traverse Length value is entered in Engineering Units (E.U.s) and the decimal position that was entered in the

Engineering Units (CP-15) parameter is automatically displayed. The

traverse length is the distance that the Follower mechanism will travel.

In level wind applications, the traverse length is generally the length of

the reel. In web scanning applications, the traverse length is generally

the width of the web. The traverse length measurement, corresponds

to the setpoint measurement. For example, in a level wind application,

you may have a reel that measures one foot, that is wrapped with two

inch hose. You would enter "2" (inches) in Setpoint 1 (CP-01) and "12"

(inches) in Traverse Length 1 (CP-02).

The factory defaults for the Traverse Length Control Parameters are found in Table 3-8.

To modify the default parameters refer to Table 3-9. If you are uncertain how to enter a

Control Parameter, review the

3 - 14

Operations: Keypad

section.

Page 62

Table 3-8 Default Traverse Length Control Parameters

CP Parameter Name Parameter Value

CP-02 Traverse Length 1 0.000

CP-04 Traverse Length 2 0.000

CP-06 Traverse Length 3 0.000

CP-08 Traverse Length 4 0.000

Table 3-9 Entering Traverse length Control Parameters

CP Parameter Name Parameter Value

CP-02 Traverse Length 1 In a level wind application, enter your reel length in

E.U.s (reference Setpoint 1).

In a web scanning operation, enter the width of your

web, in E.U.s (reference Setpoint 1).

CP-04 Traverse Length 2 In a level wind application, enter your reel length in

E.U.s (reference Setpoint 2).

In a web scanning operation, enter the width of your

web, in E.U.s (reference Setpoint 2).

CP-06 Traverse Length 3 In a level wind application, enter your reel length in

E.U.s (reference Setpoint 3).

In a web scanning operation, enter the width of your

web, in E.U.s (reference Setpoint 3).

CP-08 Traverse Length 4 In a level wind application, enter your reel length in

E.U.s (reference Setpoint 4).

In a web scanning operation, enter the width of your

web, in E.U.s (reference Setpoint 4).

3 - 15

Page 63

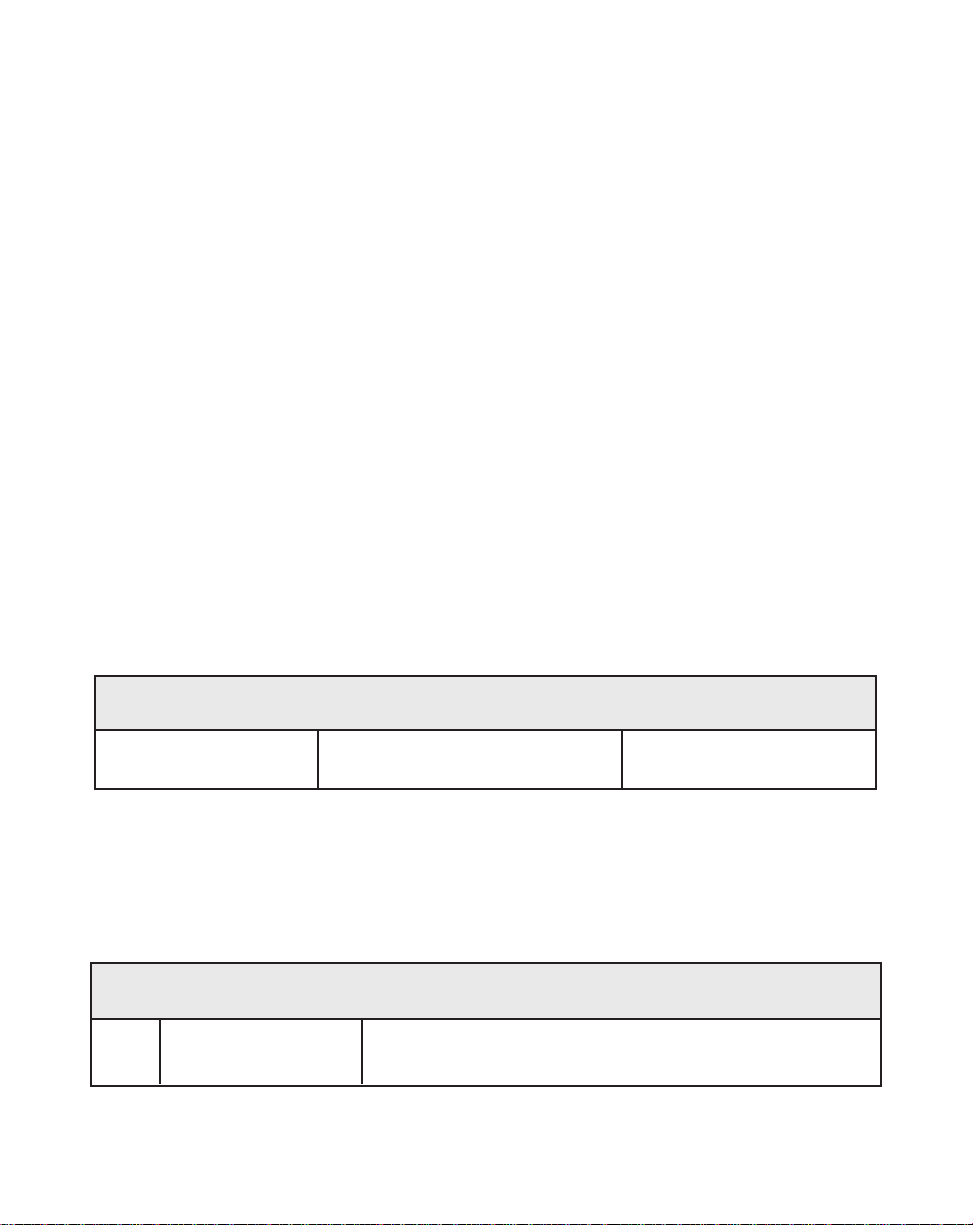

The following chart demonstrates how Setpoint and Traverse Length

pairs are selected by the various positions of the Setpoint Select A and

Setpoint Select B discrete inputs.

Setpoint Select B

Setpoint Select B

Open

Open

Setpoint Select B

Closed

(Closed = shorted to common)

Setpoint Select A

Open

Setpoint 1(CP-01)

Traverse Length 1(CP-02)

Setpoint 3 (CP-05)

Traverse Length 3 (CP-06)

Setpoint Select A

Closed

Setpoint 2 (CP-03)

Traverse Length 2 (CP-04)

Setpoint 4 (CP-07)

Traverse Length 4 (CP-08)

3 - 16

Page 64

Follower Profile Parameters

In addition to being part of a setpoint pair, the traverse length acts in conjunction with

the Accel/Decel Length (CP-09) parameter and the Dwell (CP-10) parameter to define

the Follower Profile. The Follower Profile creates a smooth transition to dwell before

reversing directions. This takes place at the reel's end in level wind applications or at

the edge of the web in web scanning applications.

Accel/Decel Length (CP-09)

The Accel/Decel Length (CP-09) parameter allows the Follower mechanism to ramp to either the constant pitch plateau or end dwell, either

gradually or rapidly. This parameter is the number of encoder lines for

the desired Accel/Decel Length. The lower the number, the more

rapidly the Follower mechanism ramps to the constant pitch plateau or

end dwell. The higher the number, the more gradually the Follower

mechanism ramps to the control pitch plateau or end dwell. As a

guideline, keep in mind that you do not want the accel/decel rate to

exceed the load that the motor drive or mechanics can accommodate.

The Accel/Decel Length parameter does not need to be an exact

number, the system will perform adequately with a close estimate.

The factory default for the Accel/Decel Length Control Parameter is found in Table 3-10.

To modify the default parameter refer to Table 3-11. If you are uncertain how to enter a

Control Parameter, review the

Operations: Keypad

section.

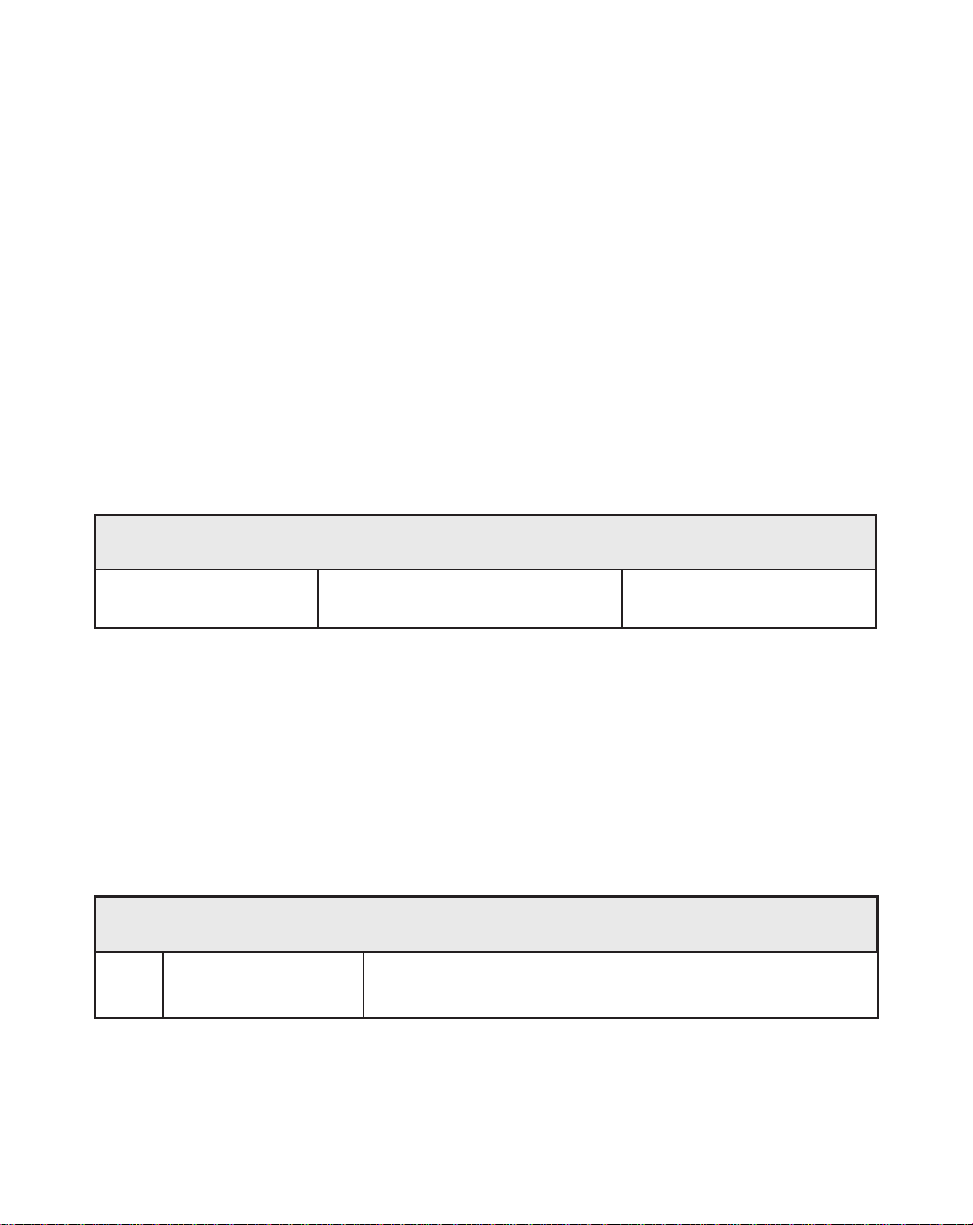

Table 3-10 Default Accel/Decel Length Control Parameter

CP Parameter Name Parameter Value

CP-09 Accel/Decel Length 0

Table 3-11 Entering Accel/Decel Length Control Parameter

CP Parameter Name Parameter Value

CP-09 Accel/Decel Length Enter the number of encoder lines for the desired

Accel/Decel Length.

3 - 17

Page 65

Dwell (CP-10)

The Dwell (CP-10) parameter allows the Follower mechanism to pause

at the end of the Follower profile before ramping back in the opposite

direction. In level wind applications, this parameter is a portion of the

encoder lines in one rotation of the reel (Lead). In web scanning

applications, this parameter is a portion of the encoder lines in one

traverse length. The Dwell parameter does not need to be an exact

number, the system will perform adequately with a close estimate .

The factory default for the Dwell Control Parameter is found in Table 3-12. To modify

the default parameter refer to Table 3-13. If you are uncertain how to enter a Control

Parameter, review the

Operations: Keypad

section.

Table 3-12 Default Dwell Control Parameter

CP Parameter Name Parameter Value

CP-10 Dwell 0

3 - 18

Table 3-13 Entering Dwell Control Parameter

CP Parameter Name Parameter Value

CP-10 Dwell In a level wind applications, enter a portion of the

encoder lines in one rotation of the reel

In a web scanning applications, enter a portion of the

encoder lines in one traverse length.

Page 66

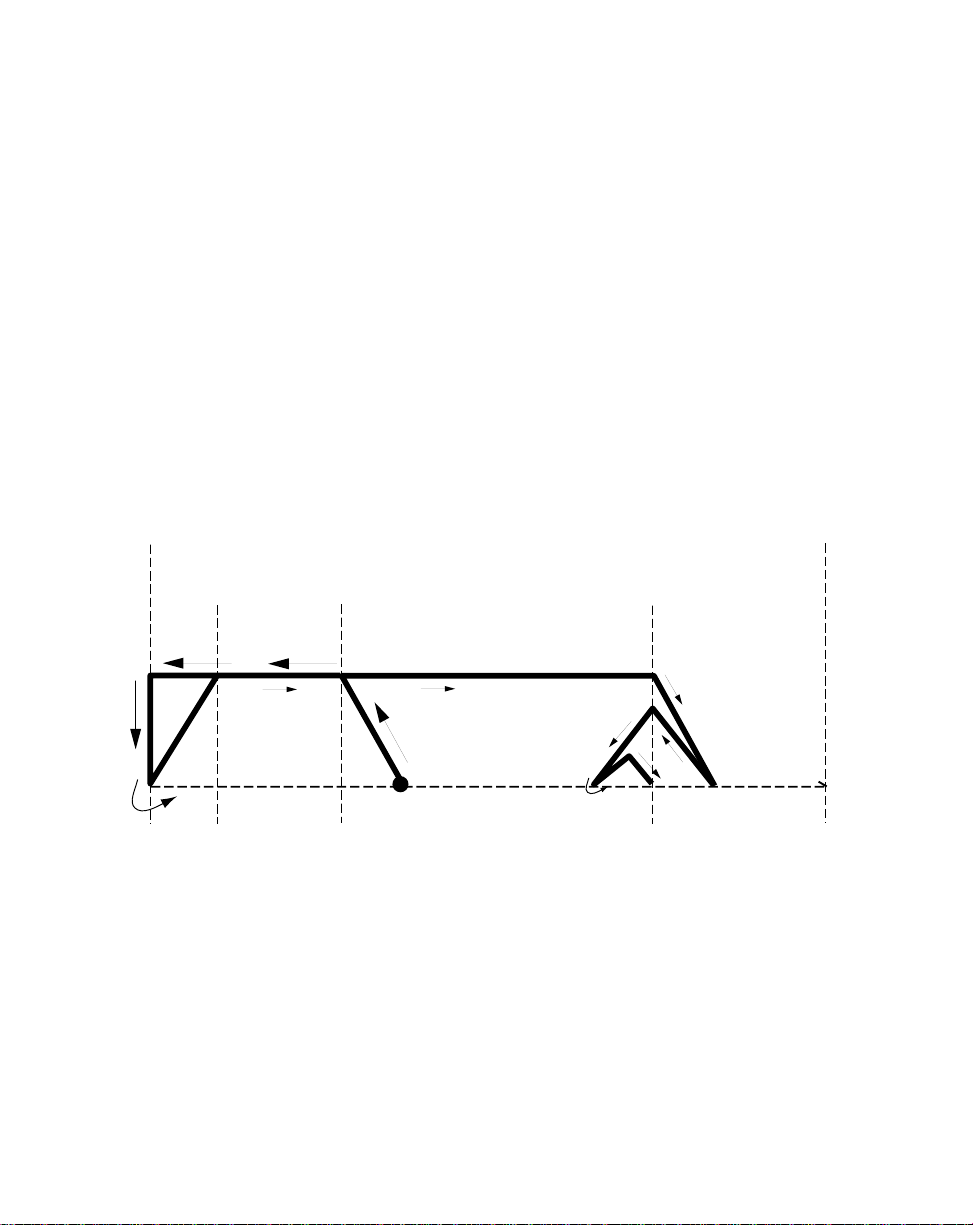

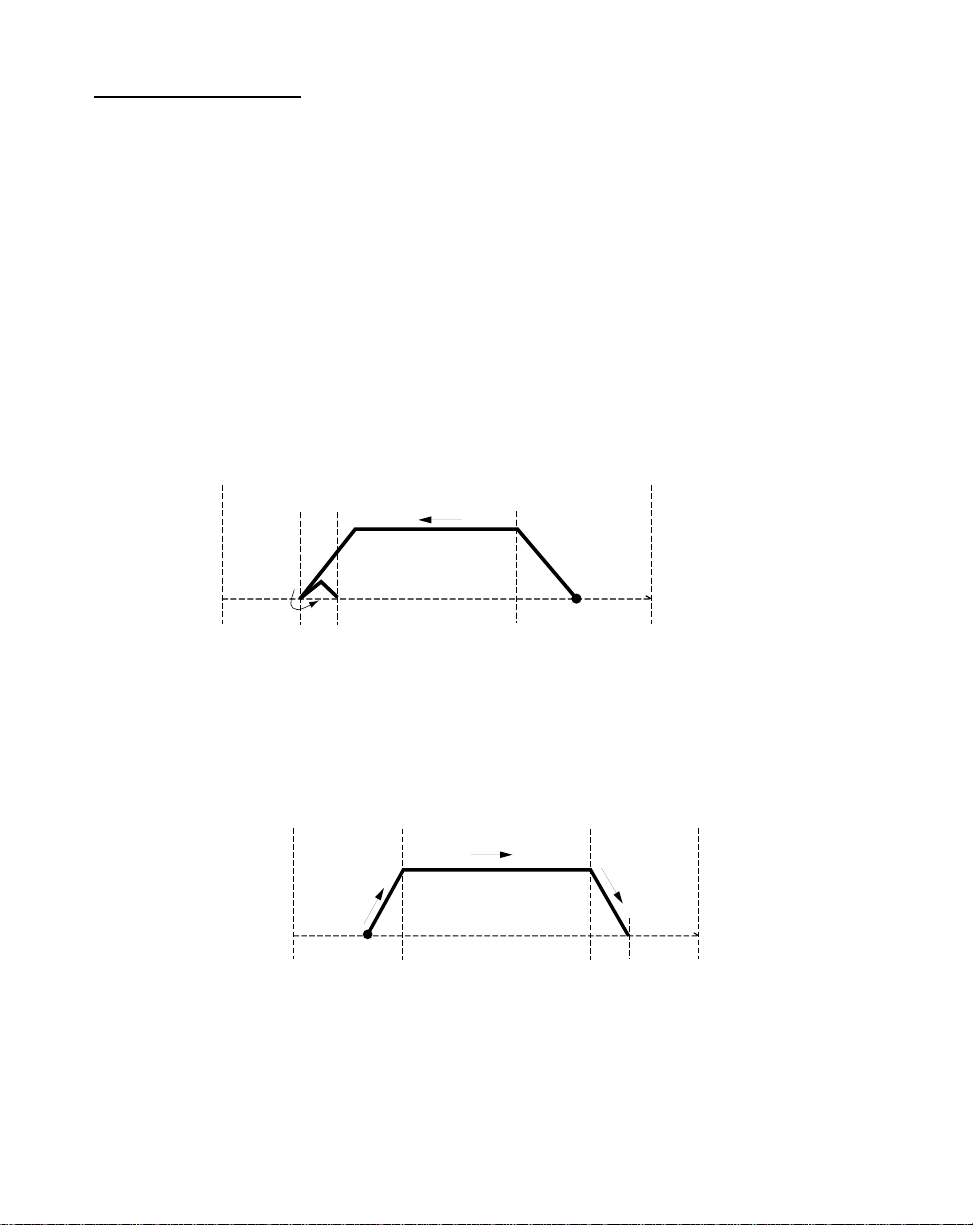

Other Follower Parameters

The orientation (edge or center) of “Home,” changes in the “Home” position and

changes made on the fly, are determined by the following parameters:

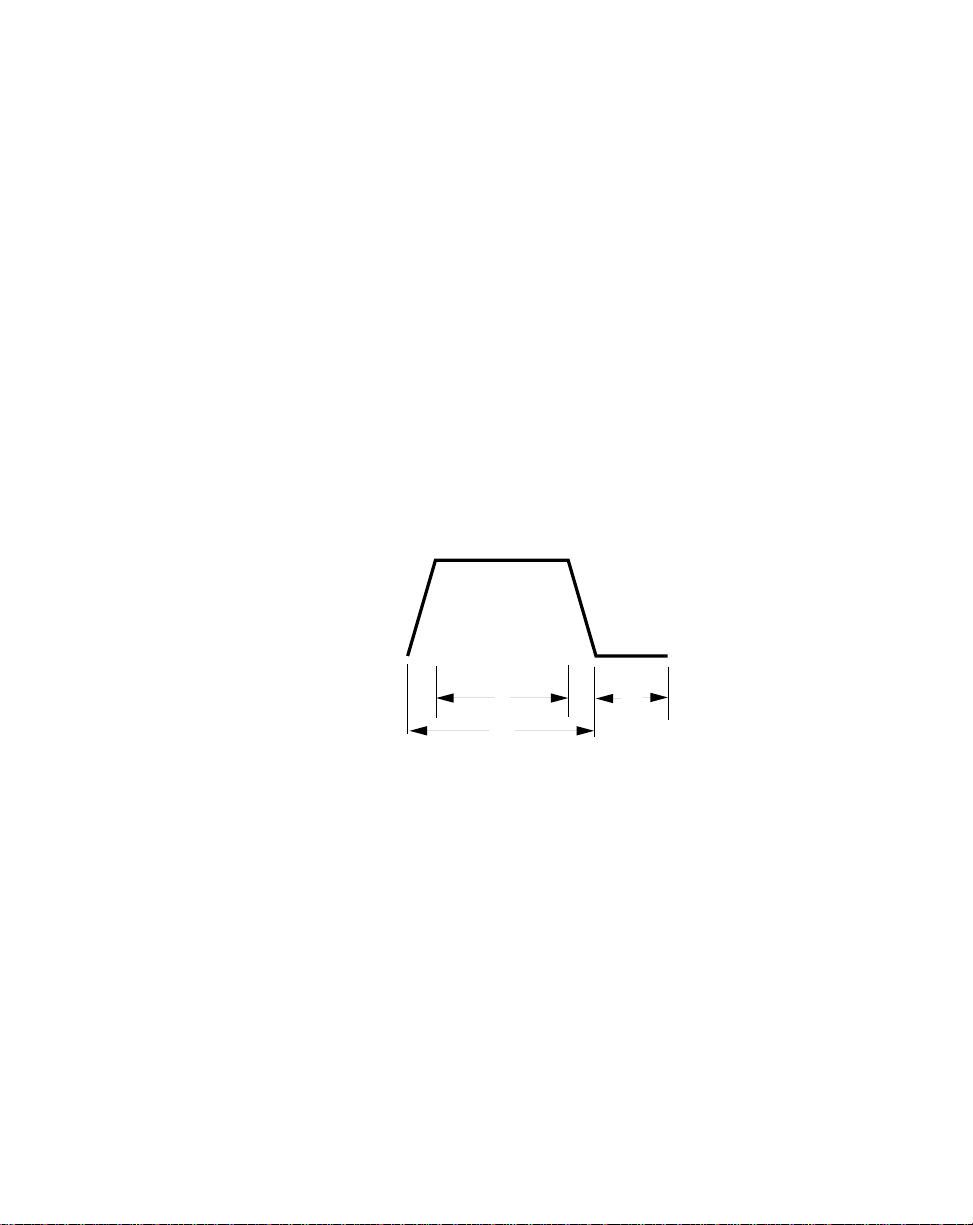

Edge/Center Based Profile (CP-24)

The traverse length is measured from “Home”. The Edge/Center Based

Profile (CP-24) parameter allows you to set “Home” relative to either the

edge or the center of your reel or web. The Follower mechanism

moves a traverse length from that position and then returns.

To set “Home” as an edge based profile, enter “1” in CP-24. All

traverse length changes occur from the edge, in the forward direction

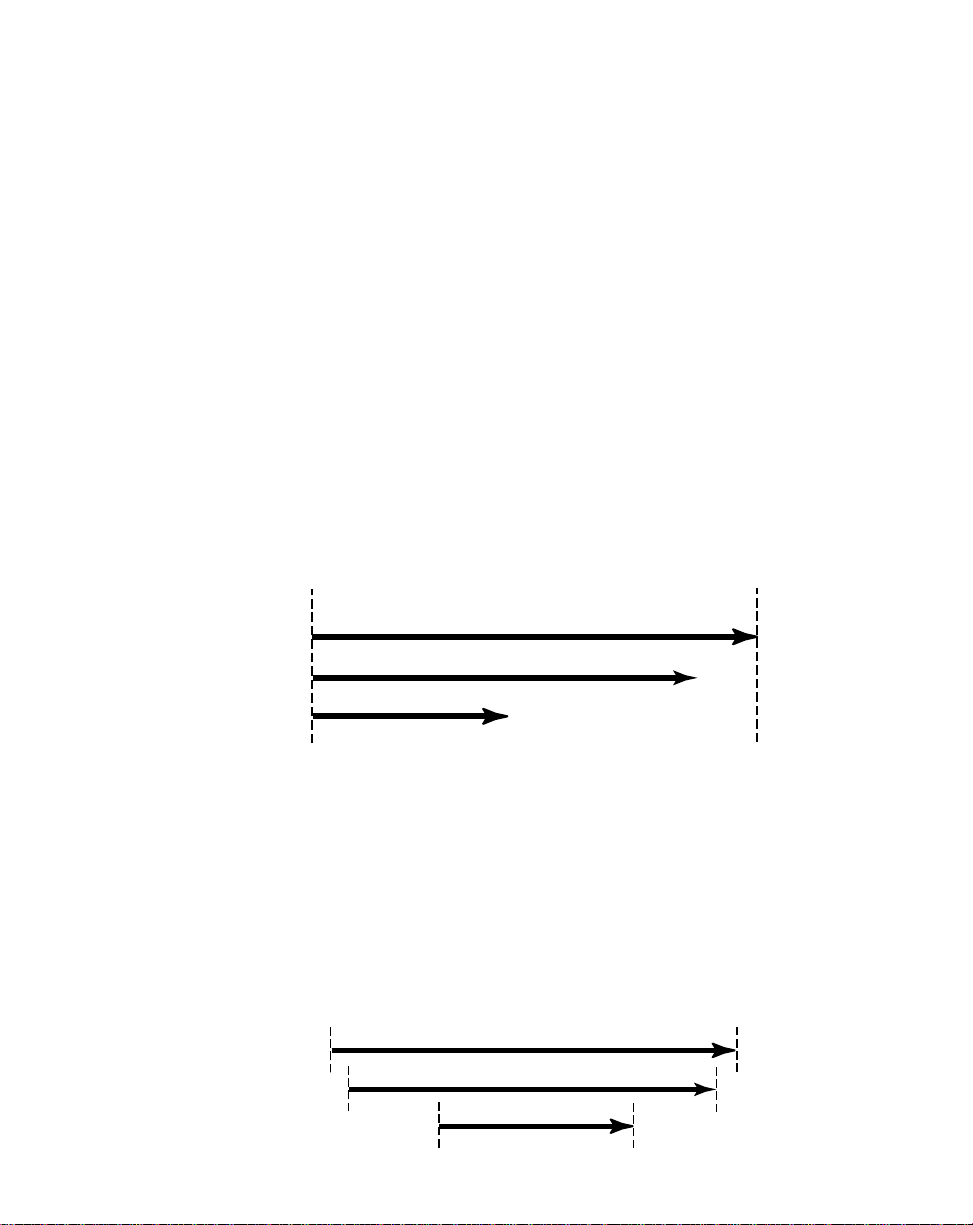

and the “Home” position does not change. The diagram below illustrates this profile. Traverse length changes can be made on the fly and

the timing on these changes is a crucial factor. For the timing on edge

based traverse length changes, refer to the Change Activation (CP-25)

parameter.

Edge Based

“Home”

12" Traverse Length

10" Traverse Length

5" Traverse Length

To set “Home” as a center based profile, enter “2” in CP-24. All

traverse length changes occur from the center and the “Home” position

changes to compensate for traverse length changes. The diagram

below illustrates this profile. Traverse length changes will occur automatically when the Follower mechanism is in the center of the web.

Center Based

C

L

“Home”

“Home”

“Home”

12" Traverse Length

10" Traverse Length

5" Traverse Length

3 - 19

Page 67

Change Activation (CP-25)

The Change Activation (CP-25) parameter works in conjunction with the

Edge/Center Based Profile (CP-24) parameter. When CP-24 is set to

“1” (edge based), then CP-25 determines when changes will occur. If

CP-24 is set to “2” (center based), then CP-25 has no effect.

Change Activation (CP-25) can be set to “1”, “2” or “3”. Settings “2” and

“3” have a number of variables:

If CP-25 is set to “1” then all of the changes will occur when the Follower is at “Home”.