CONTOURA MAJOR MJ75-360 Operator's Manual

Operators Manual

MAJOR

CONTOURA

ROLLERMOWER

MJ75-360

B

Head Ofce

Major Equipment Intl. Ltd.

Ballyhaunis,

Co. Mayo,

Ireland.

Tel.: +353 (0) 9496 30572

Fax: +353 (0) 9496 30788

Email: info@major-equipment.com

UK Ofce

Major Equipment Ltd.

Major Industrial Estate,

Middleton Rd.,

Heysham,

Lancs.

LA3 3JJ

Tel.: +44 (0) 1524 850 501

Fax: +44 (0) 1524 850 502

Email: ukinfo@major-equipment.com

NETHERLANDS & GERMANY OFFICE

Major Equipment Intl. Ltd.

Postbus 29,

NL-7700 AA ,

Dedemsvaart,

Nederland.

Tel: +31 (0) 6389 19585

Email: euinfo@major-equipment.com

Web: www.major-equipment.com

Find us on FACEBOOK

MAJOR MACHINERY

View our channel

MAJOREQUIPMENT

Disclaimer

While every effort has been made in the production of this manual to ensure that the information

contained herein is full and correct, Major assumes no responsibility for errors or omissions.

Major reserves the right to modify the machinery and the technical data contained within the

manual without prior notice.

Further to this, Major assumes no liability for any damages which may result from the use of the

information contained within this manual.

Contents

Introduction

Thank you 1

Using Your Operator’s Manual 1

Safety Aspects 1

Intended use 1

Product Identication

Machine Serial Numbers 1

Register Your Product and Warranty Online 1

Product Specications 2

Safety

Machine Safety Labels 2

Hazards associated with operating Grass Cutting Machinery 3

Operating Safely 4

Workstation 4

Regulations for use of the transmission 4

PTO Shaft Safety 5

Driving Safely on Public Roads 5

Operating the Machine

Key to Main Parts 6

Inspections before Use 7

Starting Regulations 8

Attaching machine to the Tractor 8

Transport Position 8

Operating the Machine/Mowing 9

Roller adjustment 10

Maintenance

PTO Shaft Maintenance 11

Blade Rotation 11

Maintenance position of the rear deck 12

Greasing Schedule 12

Rollers 13

Gearbox Oil 13

Troubleshooting 13

MJ75 Spare Parts

MJ75 Shafts and Rams 15

MJ75 Rear Deck 15

MJ75 List of gearboxes 16

MJ75 Roller 16

MJ75 Wing Deck 16

MJ75 Height adjuster 17

MJ75 Blades 18

EEC certicate of conformity for machines

(conforming to Directive 98/37/EEC)

Company: Major Equipment Ltd.

Address: Coolnaha,

Ballyhaunis,

Co. Mayo,

Ireland.

Tel. +353949630572

Fax +353949630788

declares in sole responsibility that the product:

MJ75 ROLLERMOWER (CONTOURA)

When properly installed, maintained and used only for it’s intended purpose, complies with

all the essential Health & Safety requirements of:

• THE SUPPLY OF MACHINERY (SAFETY) REGULATIONS 2008.

• S.I. No. 299 of 2007, Safety, Health and Welfare at Work (General Application)

Regulations 2007 (Ireland).

• Health & Safety at Work, etc. Act 1974 (c.37) (UK).

• EN ISO 14121-1: 2007 ‘Safety of machinery. Principles for risk assessment’.

• EN 745 - Agricultural Machinery - Rotary Mowers and Flail Mowers - Safety.

• EN ISO 13857 - Safety of machinery: Safety distances to prevent hazard zones

being reached by upper and lower limbs.

I certify on behalf of Major Equipment Int. Ltd., that this machine when properly installed

and operated correctly, complies with all the essential Health & Safety requirements of

all legislation referred to above.

Signature : ______________ Date 06/04/2017

Managing Director

www.major-equipment.com

1

000517

Introduction

Thank you

We appreciate having you as a customer and wish you many years of safe and satised use of your machine.

Using Your Operator’s Manual

This manual is an important part of your machine and should remain with the machine when you buy it. Reading your

operator’s manual will help you and others avoid personal injury or damage to the machine. Information given in this

manual will provide the operator with the safest and most effective use of the machine.

Sections in your operator’s manual are placed in a specic order to help you understand all the safety messages so you

can operate this machine safely. You can also use this manual to answer any specic operating or servicing questions.

Safety Aspects

Your manual contains special messages to bring attention to potential safety concerns, machine damage as well as

helpful operating and servicing information. Please read all the information carefully to avoid injury and machine damage.

Intended use

This machine is a grass cutting machine and designed for cutting grass. Moreover, it must only be used with a suitable

tractor (see “Product Specications” section of this booklet) and driven by an adequate drive-line of the tractor PTO. All

other use is strictly prohibited.

Product Identication

Machine Serial Numbers

If you need to contact MAJOR or your MAJOR dealer for information on servicing or spare parts, always provide the

product model and serial numbers. Model and Serial number can be found on the Serial Plate located on the machine.

We suggest that you record your machine details below:

Model No: ______________________________

Serial No: ______________________________

Date of Purchase: ______________________________

Dealer Name: ______________________________

Dealer Telephone: ______________________________

Register Your Product and Warranty Online

To register your product through the Internet, simply go to the Support section on www.major-equipment.com. Completing

the information, either online or with the product warranty card, will ensure the customer that their product receives all

post sales service and important product information.

This machine is warranted for 12 months with. No warranty is given where the machine is being used as a hire machine.

Warranty is against faulty workmanship or parts.

Warranty covers parts only. All parts must be returned to the manufacturer. No warranty can be considered unless parts

are returned. All replacement parts will be supplied on a chargeable basis until warranty has been accepted.

www.major-equipment.com

2

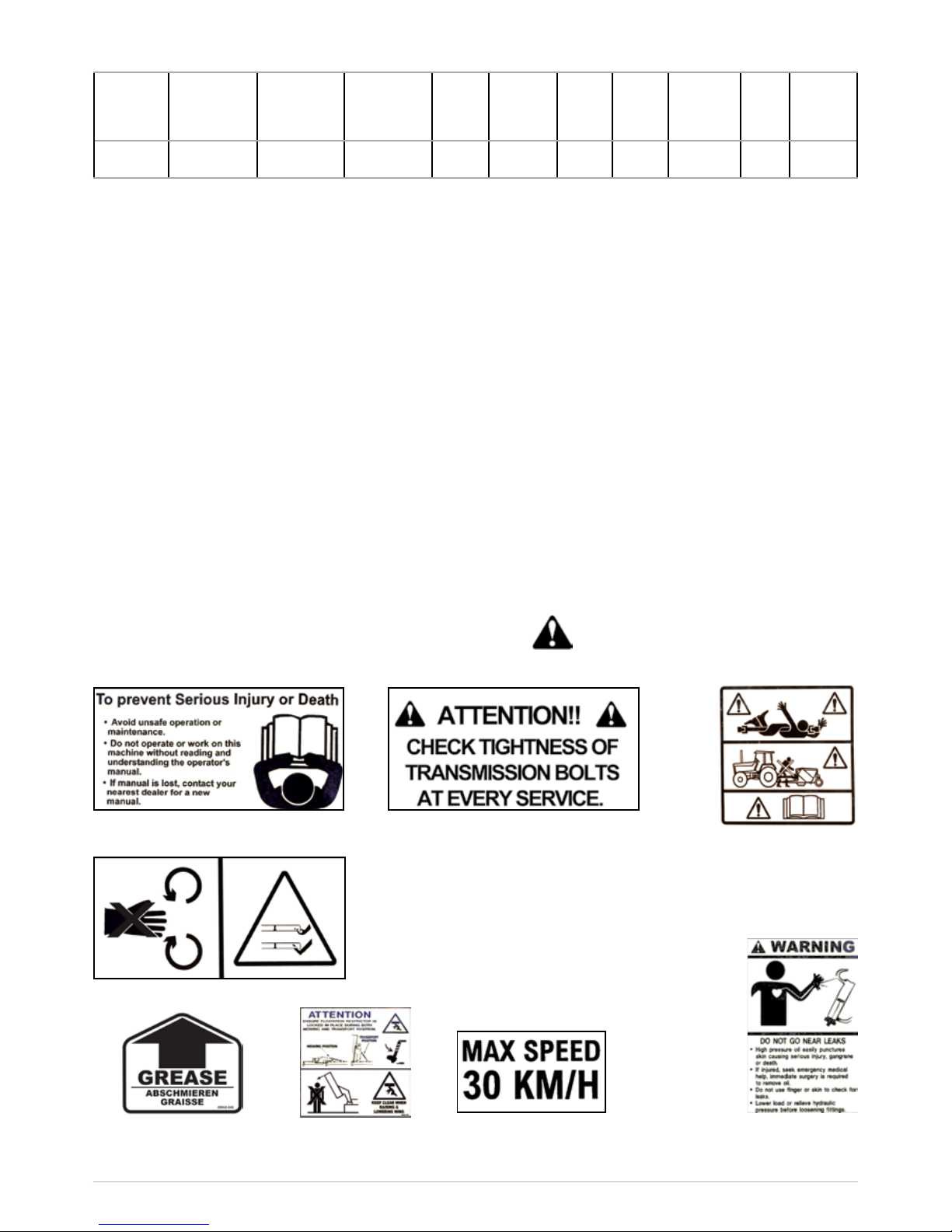

Product Specications

Model Overall

Width

Working

Width

Transport

Width

Power

(HP)

PTO rpm Cutting

Height

(mm)

Rotors/

Blades

Weight

(kg)

Blade

tip

speed

(m/s)

Mowing

Rates

(Acres/hr

at 7mph)

MJ75-360 3.67mm

(12’)

3.60m (11’

9”)

2.14m (7’) 45-75 540 15-85 6/

12+12

1395 86 5.3

To avoid injury, read the manual Check the tightness of the transmission

Rotating blade hazard

PTO entanglement

hazard - keep clear

of PTO drives.

Safety

Machine Safety Labels

The machine safety labels shown in this section are placed in important areas on your machine to draw attention to

potential safety hazards.

On your machine safety labels, the words DANGER, WARNING, and CAUTION are used with this safety alert symbol.

DANGER identies the most serious hazards.

The operator’s manual also explains any potential safety hazards whenever necessary in special safety messages that

are identied with the word, CAUTION, and the safety-alert symbol .

Grease points

High oil pressure

hazard

Moving parts

Maximum speed

www.major-equipment.com

3

Hazards associated with operating Grass Cutting Machinery

Shear Hazard

Shear hazards are created when the edges of two objects move toward or next to each other closely enough to cut

relatively soft material. This can include the parts of the machine under hydraulic control when operating from transport

to mowing position. Note, the wing units are designed to oat independently of the centre deck & are free to move within

operating limits.

Crush Hazard

Bystanders can be injured when machine is lowered into mowing position. Winged machines have crush points around

the hinge areas & between the wing & main body. Always use transport locking bars when not in use (winged models

only).

Rotating Blade Hazard

All persons are at risk if they place their hands or feet under the machine when it is raised from the ground when the

blades are in motion.

Pinch Hazard

Pinch points are created when two objects move together, with at least one of them moving in a circle. This hazard is

common in power transmission devices such as Belt Drives, Gear Drives & Rollers. Ensure all guarding is present.

Wrap Hazard

Any exposed, rotating machine component is a potential wrap point. Injuries usually occur when loose clothing or long

hair catch on and wrap around rotating parts such as PTO shafts or Drive shafts on the machine. Ensure all guarding

is present.

Free-wheeling parts Hazard

The heavier a revolving part is, the longer it will continue to rotate after power is shut off. This characteristic is called

‘free-wheeling.’ Blades, and various other components, drive shafts etc., will continue to move after power is shut off often for several minutes. Injuries occur when:

• Operators shut off equipment, and attempt to clean or adjust a machine before components have completely stopped

moving.

• Shear bolt protection device in PTO shaft shears & the mowing parts are still spinning but the primary PTO shaft is

stationary. Operator awareness is the key to safety around freewheeling parts. Never raise the machine while the

blades are still rotating.

Thrown objects Hazard

Machines throw material as a natural part of doing their job. Foreign objects, such as stones, sticks and other debris,

may be taken into this equipment and expelled at tremendous speed. These objects are contained by the sides of the

machine and by the rear/front rollers / guards / chain guards / rubber skirts depending on model of your machine.

Ensure bystanders are clear from the machine & cannot be hit with debris expelled from the machine. Bystanders or

animals in the path of thrown objects could be seriously injured. Never operate machine with decks raised from the

ground as this makes the front/rear protection redundant.

Hydraulic Hazard (if applicable)

Hydraulic systems store considerable energy. Careless servicing, adjustment, or replacement of parts can result in

serious injury. High pressure blasts of hydraulic oil can injure eyes or other body parts. The following precautions are

crucial:

• Make certain the hydraulic pump is turned off.

• Lower attached equipment to the ground.

• Conrm that load pressure is off the system.

A pinhole leak in an hydraulic hose is a serious hazard. A leak may not be visible, and the only sign may be a few drops

of uid. Never inspect hydraulic hoses with your hands, because a ne jet of hydraulic uid can pierce the skin.

Slips, Trips and Falls Hazard

Slips and falls often result from:

1. Slippery footing on the ground

2. Cluttered steps and work platforms.

The potential for slips and falls can be greatly reduced by using good judgement and practicing good housekeeping on

and around equipment.

Loading...

Loading...