Page 1

Group or Division Here

Industrial Fluid Solutions

PC440i Crimper

with CrimpIQ™ Controller

Operator Manual

www.contitech.us

www.contitech.us

Page 2

2 PC440i Crimper – Operator Manual

Table of Contents

PC440i Safety Precautions ...................................................................................................................................................................................................................................................................................................................... 4

PC440i Initial Crimper Setup .................................................................................................................................................................................................................................................................................................................5

High-Level CrimpIQ™ Controller Capabilities...................................................................................................................................................................................................................................................................6

CrimpIQ™ supports the following features.............................................................................................................................................................................................................................................................6

PC440i Series ............................................................................................................................................................................................................................................................................................................................................................ 7

PC440i Features ....................................................................................................................................................................................................................................................................................................................................................8

Initial Crimper Setup .........................................................................................................................................................................................................................................................................................................................................9

Overview ......................................................................................................................................................................................................................................................................................................................................................... 9

Crimper Operations .......................................................................................................................................................................................................................................................................................................................................10

Logging In .................................................................................................................................................................................................................................................................................................................................................10

Default User Accounts ................................................................................................................................................................................................................................................................................................................10

Navigating the CrimpIQ™ Controller .......................................................................................................................................................................................................................................................................................11

Basic Application Guide ............................................................................................................................................................................................................................................................................................................11

Top Menu ...................................................................................................................................................................................................................................................................................................................................................11

Left Slide-Out Menu Functions .........................................................................................................................................................................................................................................................................................12

Left Slide-Out Menu Information ....................................................................................................................................................................................................................................................................................12

Using the Main Menu ...................................................................................................................................................................................................................................................................................................................................13

CrimpIQ™ controller Main Menu Screen Options ...................................................................................................................................................................................................................................... 13

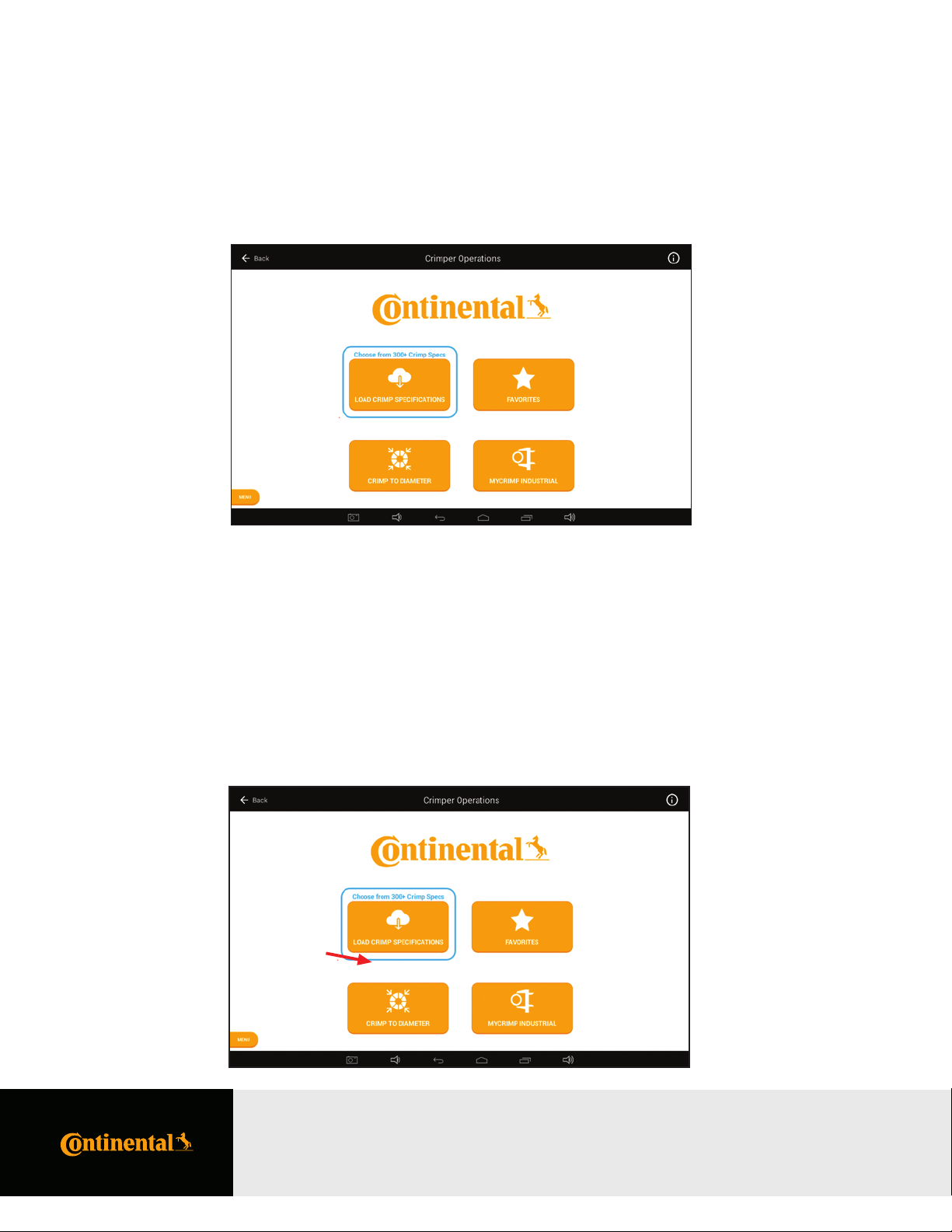

Crimper Operations .......................................................................................................................................................................................................................................................................................................................................14

Main Crimper Operations Screen .................................................................................................................................................................................................................................................................................14

Load Crimp Speciications .....................................................................................................................................................................................................................................................................................................14

MyCrimp® – Search Screen ...................................................................................................................................................................................................................................................................................................15

Key Functions of MyCrimp® ................................................................................................................................................................................................................................................................................................ 15

MyCrimp® – Results Screen ..................................................................................................................................................................................................................................................................................................16

MyCrimp® – Crimp This Speciication ...................................................................................................................................................................................................................................................................... 17

Managing Crimp Speciications ...................................................................................................................................................................................................................................................................................... 17

Crimp Speciications with Special Handling Requirements ...........................................................................................................................................................................................................18

Favoriting Crimp Speciications .................................................................................................................................................................................................................................................................................................... 19

Editing a Favorite ..............................................................................................................................................................................................................................................................................................................................20

Favorite Special Handling .......................................................................................................................................................................................................................................................................................................20

Crimp to Diameter ...........................................................................................................................................................................................................................................................................................................................................21

MyCrimp® Industrial ...................................................................................................................................................................................................................................................................................................................................... 22

Entering Industrial Measurements ..............................................................................................................................................................................................................................................................................22

Beginning a Crimp ........................................................................................................................................................................................................................................................................................................................................... 24

Loading Dies ...........................................................................................................................................................................................................................................................................................................................................24

Selecting a Die ...................................................................................................................................................................................................................................................................................................................................... 25

Change Die Mode ............................................................................................................................................................................................................................................................................................................................26

Crimp Operations .............................................................................................................................................................................................................................................................................................................................................27

Performing the First Crimp ................................................................................................................................................................................................................................................................................................... 27

Measuring a Crimp ......................................................................................................................................................................................................................................................................................................................... 28

Crimp Operations Screen .......................................................................................................................................................................................................................................................................................................29

Crimp Operations Screen Sections .............................................................................................................................................................................................................................................................................29

Operational Information .......................................................................................................................................................................................................................................................................................................... 30

Crimp Detail Panel ...........................................................................................................................................................................................................................................................................................................................30

Crimp Mode ............................................................................................................................................................................................................................................................................................................................................32

Crimp Information ...........................................................................................................................................................................................................................................................................................................................33

Crimp Management Function Buttons ..................................................................................................................................................................................................................................................................34

Table of Contents

PC440i Crimper with CrimpIQ™ Controller

Page 3

Settings and Support ...................................................................................................................................................................................................................................................................................................................................35

Machine Coniguration ..............................................................................................................................................................................................................................................................................................................36

Machine Coniguration Options ......................................................................................................................................................................................................................................................................................36

Managing Preset Dies .................................................................................................................................................................................................................................................................................................................37

Managing Users .................................................................................................................................................................................................................................................................................................................................38

Self Calibration Mode ...................................................................................................................................................................................................................................................................................................................38

Default User Accounts ............................................................................................................................................................................................................................................................................................................... 38

Maintenance Mode ........................................................................................................................................................................................................................................................................................................................ 39

Setting Up an Internet Connection .............................................................................................................................................................................................................................................................................39

Using an Ethernet Connection .........................................................................................................................................................................................................................................................................................39

Using a Wi-Fi Connection ........................................................................................................................................................................................................................................................................................................40

Connecting to a Captive Portal ........................................................................................................................................................................................................................................................................................40

Verifying Connection Status ................................................................................................................................................................................................................................................................................................40

Testing Proper Connectivity ................................................................................................................................................................................................................................................................................................41

Additional Connection Options .......................................................................................................................................................................................................................................................................................41

Internet Access Requirements ......................................................................................................................................................................................................................................................................................... 41

Backup to CrimpCloud® ............................................................................................................................................................................................................................................................................................................42

General Coniguration .................................................................................................................................................................................................................................................................................................................42

Support .......................................................................................................................................................................................................................................................................................................................................................................... 45

Create a Ticket ...................................................................................................................................................................................................................................................................................................................................... 46

What Happens Next? ...................................................................................................................................................................................................................................................................................................................46

Conti Fluid Solutions ..................................................................................................................................................................................................................................................................................................................... 47

Training Manuals ...............................................................................................................................................................................................................................................................................................................................47

Machine Information ....................................................................................................................................................................................................................................................................................................................47

Other Topics ............................................................................................................................................................................................................................................................................................................................................................ 48

Integrated Caliper Measurements ...............................................................................................................................................................................................................................................................................48

Coniguring CrimpIQ™ Calipers (Bluetooth) .....................................................................................................................................................................................................................................................48

Coniguring CrimpIQ™ Calipers (USB) .....................................................................................................................................................................................................................................................................48

Setting Up USB Calipers ........................................................................................................................................................................................................................................................................................................... 48

Using CrimpIQ™ Calipers .........................................................................................................................................................................................................................................................................................................49

PC440i Lubrication Procedure ......................................................................................................................................................................................................................................................................................................50

PC440i Die Installation and Management ......................................................................................................................................................................................................................................................................51

Adapter Die Installation ..............................................................................................................................................................................................................................................................................................................51

Hydraulic Die Installation ......................................................................................................................................................................................................................................................................................................... 52

PC440i PLC Reset Procedure ............................................................................................................................................................................................................................................................................................................53

Resetting the PLC to Its Original Settings ........................................................................................................................................................................................................................................................... 53

PC440i Troubleshooting ......................................................................................................................................................................................................................................................................................................................... 54

PC440i Component Parts Breakdown ..................................................................................................................................................................................................................................................................................55

PC440i Warranty ...............................................................................................................................................................................................................................................................................................................................................61

CustomCrimp® “No Nonsense” Warranty ............................................................................................................................................................................................................................................................61

3PC440i Crimper – Operator Manual

Table of Contents

PC440i Crimper with CrimpIQ™ Controller

Page 4

4 PC440i Crimper – Operator Manual

SAFETY PRECAUTIONS

• Read instructions and identify all component parts before using the crimper.

i

• PC440i crimper can produce 265 tons of crimping force.

• Keep both hands away from pinch points.

• Consult the Continental Crimp Speciications Manual for correct crimper setting

and crimp measurements.

• Always wear eye protection.

PC440i Safety Precautions

PC440i Crimper with CrimpIQ™ Controller

Page 5

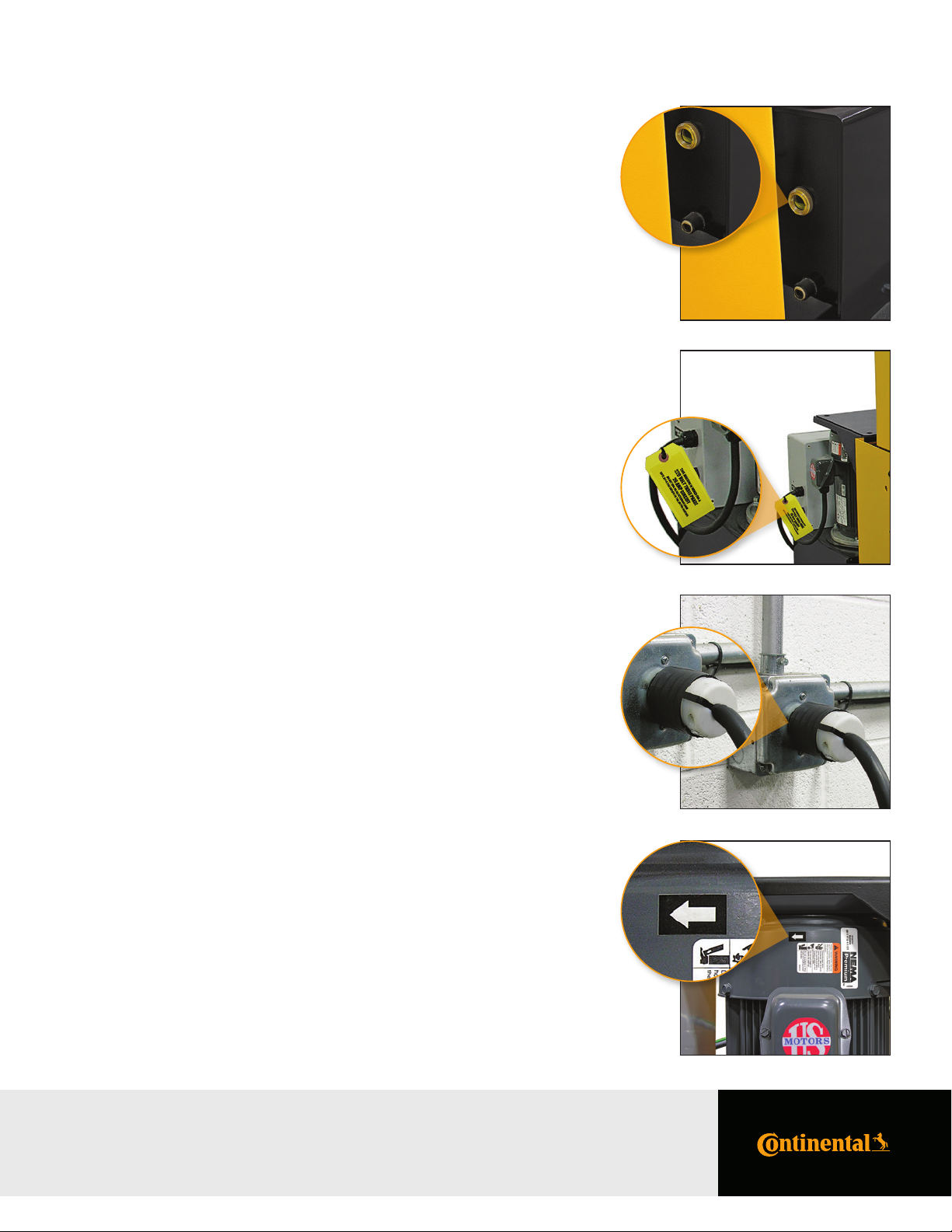

PC440i Initial Crimper Setup

Hydraulic Oil Check: Check the hydraulic oil level in the sight

glass window on the front of the reservoir.

Notes:

• The reservoir requires 8 gallons of ISO grade 46 hydraulic

oil for complete ill.

• If necessary, oil can be drained from either of the two ports

at the bottom of the reservoir.

Voltage Tag Check: Check electrical circuit to be certain that

it matches the crimper’s requirements

shown on the voltage tag attached to the

crimper cord.

5PC440i Crimper – Operator Manual

Notes:

• Plug the PC440i crimper directly into the appropriate electrical circuit/wall outlet.

• Electrical Requirements:

7.5HP/230V/3Phase (20 Amp)

7.5HP/440V480V/3Phase (20 Amp)

5HP/230V/1Phase (30 Amp)

Caution: Do not run the crimper on an extension cord as low voltage

can damage the motor and/or electrical components.

Rotation of the Motor Check to be certain that the motor rotates

Check: in the direction of the arrow shown on the

motor housing.

Caution: Damage to the pump can result if the motor does not rotate

in the correct direction.

PC440i Initial Crimper Setup

PC440i Crimper with CrimpIQ™ Controller

Page 6

6 PC440i Crimper – Operator Manual

High-Level CrimpIQ™ Controller Capabilities

This version of the CrimpIQ™ controller is designed to take full advantage of the tablet interface and the connection to

CrimpCloud®. CrimpCloud® is a web portal that provides users access to crimping and quality results captured in the

CrimpIQ™ controller.

CrimpIQ™ Supports the Following Features

Ease of Use:

• Quick access to simple hydraulic and industrial crimping modes.

• Optional semi and full automatic crimping modes.

• New touchscreen interface with clear, easy to read icon driven operations.

• Integrated measurement tools: Choice of USB wired or Bluetooth caliper provide direct measure

input for crimp, diameters and industrial hose measurements.

• Integrated help and tutorial guides for easy feature reference.

• Ability to easily favorite crimp speciications, complete with notes, for easy reference and accurate repeat crimping.

• Ability to track and report on crimp measurements and crimp pressures.

Integrated Crimping Tools:

• Full integration with MyCrimp®, for easy importing and handling of full crimp speciications.

• Integrated Industrial Crimp Calculator computes appropriate crimp diameter based on hose and itting measurements.

• Support for foot pedal and electronic backstop.

Customizable:

• User account speciic settings, such as choice of millimeters or inches as irst choice for data entry.

• Create individual user logins (4-digit pins) to track usage and restrict machine coniguration.

Connected:

• Wi-Fi or Ethernet connections, for easy reference to manufacturer web content straight from the crimper,

automatic coniguration backup and operations tracking.

• Ability to wirelessly update crimper software, providing up-to-date crimp speciications and new

functionalities to crimper software.

• CrimpCloud® reporting to provide various reports on assemblies, crimps and machine maintenance.

Integrated Support and Maintenance:

• Simple on-crimper support ticket creation, with enhanced technical diagnostics for quicker and more responsive

help when needed most.

• Built-in tutorials and training, including feature tutorials on every screen.

• Dynamic machine maintenance tracking and reporting, showing historical tracking of maintenance.

• Preventive maintenance alerts avoid machine downtime and costly repairs.

• Detailed on-machine availability of machine capacities.

Expansion Options:

• Bluetooth 4.0 supports Bluetooth calipers and other approved accessories.

• 8GB on-device storage, for support of crimp speciications or other future applications.

High-Level CrimpIQ™ Controller Capabilities

PC440i Crimper with CrimpIQ™ Controller

Page 7

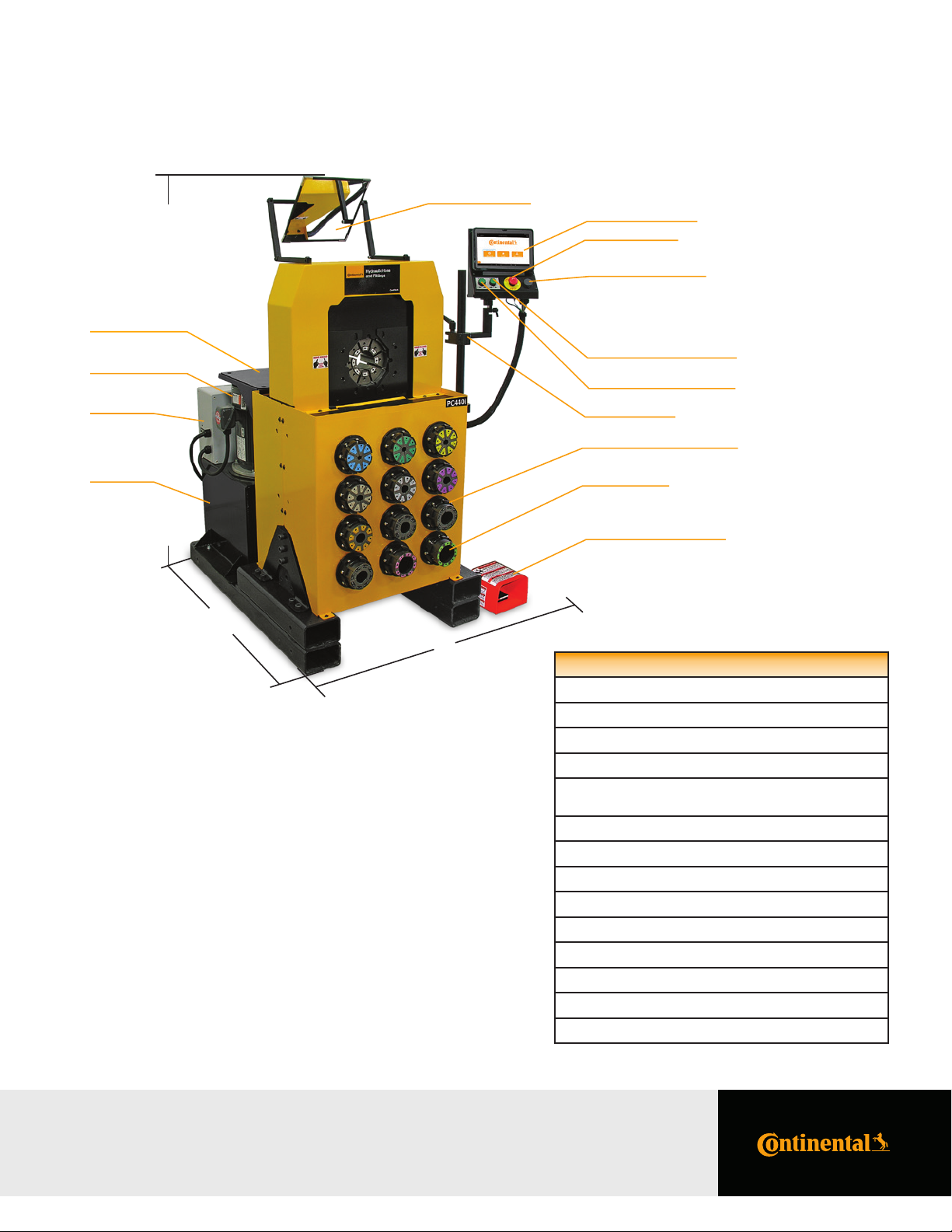

PC440i Series

67"

Back Shelf

7.5 HP Motor High

Capacity Pump

Electrical

Enclosure

7PC440i Crimper – Operator Manual

Adjustable Mirror

CrimpIQ™ Controller

Emergency Stop

Audio and USB Ports

Crimper Head Open Button

Crimper Head Close Button

Adjustable Arm

Built-in Die Storage Pockets

Reservoir

46-½"

Small Footprint for

Minimum Use of Space

99P Die Series

Foot Pedal for Use in Semi

and Full Automatic Mode

52"

PC440i Speciications

Crimping force: 265 Ton

Hose capacity: Max 2SP: 2", 4SP: 2", 6SP: 1-½", Industrial: 4"

Size: L: 46-½" x W: 52" x H: 67"

Weight: 1,840 lbs.

Power: 7.5HP/230V/3Phase (Standard) 7.5HP/440V480V/3Phase (Optional) 5HP/230V/1Phase (Optional)

Hydraulic die series: 99P

Adapter die series: 160MM to 99MM

Industrial die series: 160S

Adjustability: Inch/Metric

Opening w/o dies: 248mm/9.75"

Master die inside diameter: 160mm/6.3"

Master die travel: 102mm/4"

Reservoir capacity: 8 U.S. Gallons

Oil type: ISO 46 Hydraulic Oil

PC440i Series

PC440i Crimper with CrimpIQ™ Controller

Page 8

8 PC440i Crimper – Operator Manual

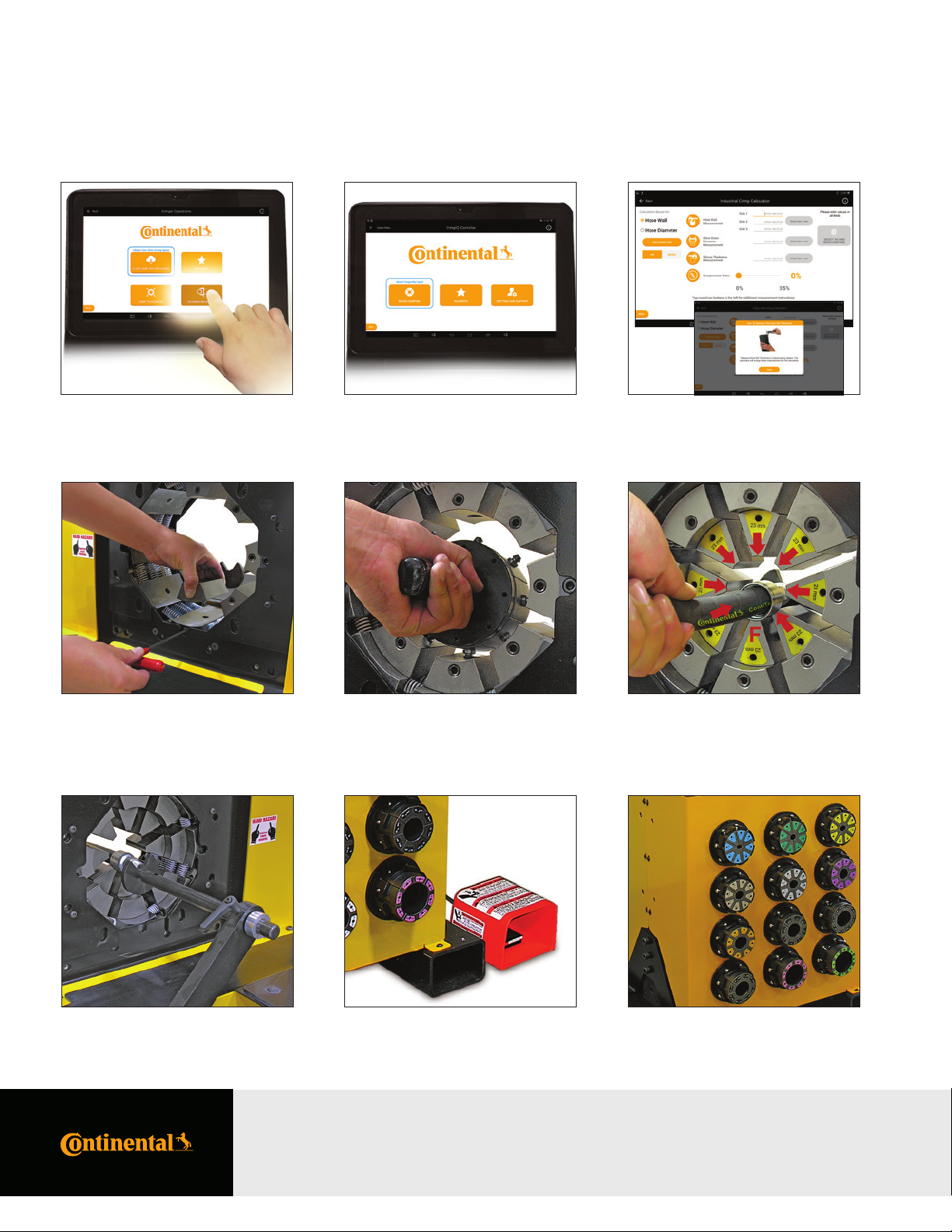

PC440i Features

Continental CrimpIQ™ controller, the

future of crimping at your ingertips.

Quickly Interchangeable

Adapter Dies.

10-inch color capacitive touchscreen

and user- friendly navigation.

Quick change tool makes die

changes a quick and simple process.

Intuitive screens lead the operator

through the setup and crimping process.

Fixed 6 o’clock die position allows

the operator to place the itting on

bottom die and crimp.

Manual backstop makes hydraulic hose

production crimping fast and accurate.

PC440i Features

PC440i Crimper with CrimpIQ™ Controller

Foot pedal for use in semi and full

automatic mode.

Built-in die storage pockets keeps

frequently used die sets readily available.

Page 9

Initial Crimper Setup

Overview

Before the crimper can be used for the irst time, a brief setup process must be completed. This process sets some initial

parameters, identiies this machine to the CrimpCloud® system and allows the user to conirm the Terms and Conditions

for use of this machine.

This process only needs to be completed once when the machine is installed. After that, the machine will power up and

be ready for use.

9PC440i Crimper – Operator Manual

Initial Crimper Setup

PC440i Crimper with CrimpIQ™ Controller

Page 10

10 PC440i Crimper – Operator Manual

Crimper Operations

Logging In

To begin using the crimper, you must irst login.

The crimper supports multiple users to allow tracking of activities as well as restrict access to some coniguration type functions.

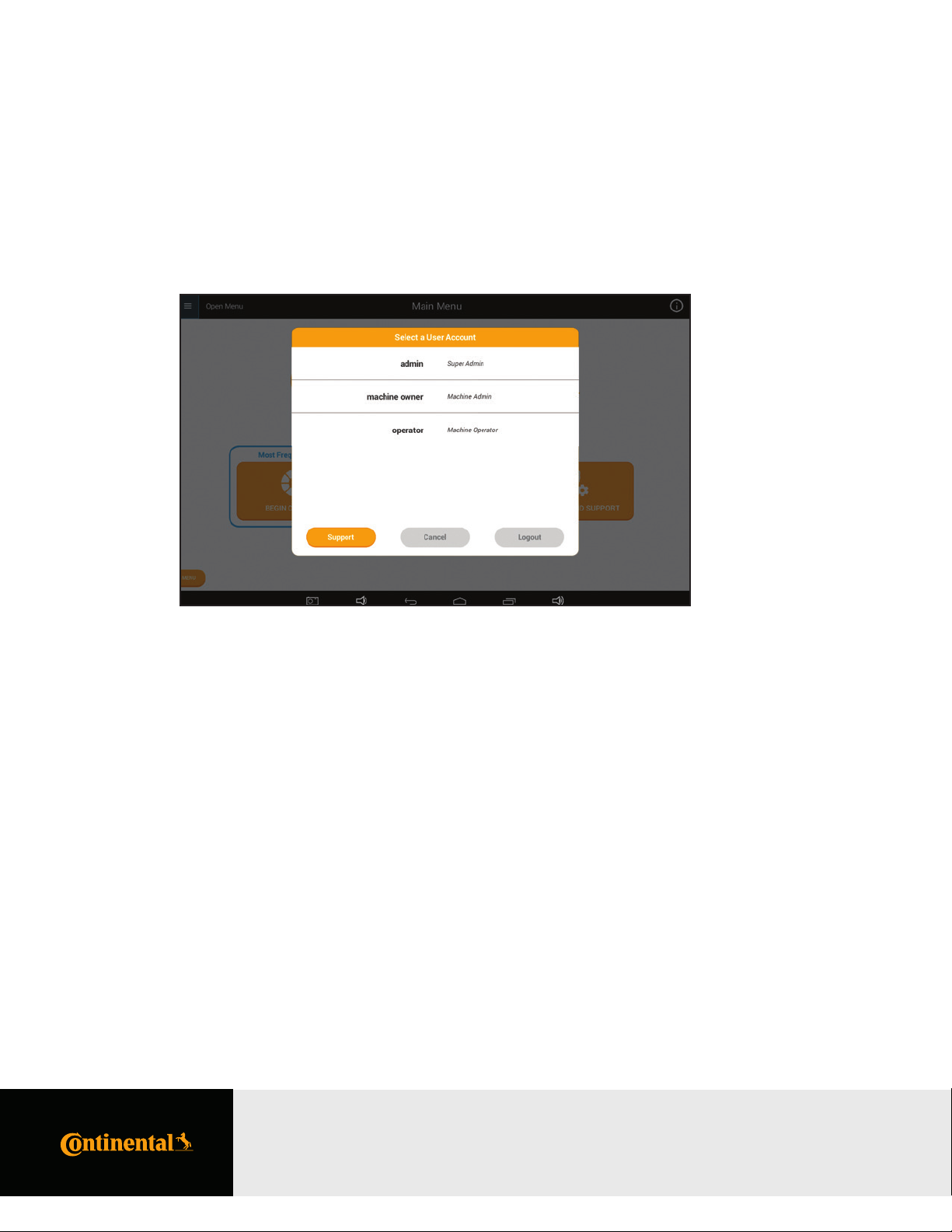

Default User Accounts

The system comes with 3 users already created: admin, machine owner and user. Additional accounts can be added if

required using the machine coniguration menu.

Pin codes listed below are defaults, and they can be changed by machine owners in the user menu:

If you have conigured additional users, their names will appear in this list as well. Once you have logged in, you can begin

using the crimper.

Admin: A private account for certiied technicians and engineering maintenance.

Machine This account is an admin level account intended for the local administration.

Owner: It has full access to all settings and functions. Default pin code is 9876.

User: This account has the permissions and capabilities to perform crimping operations but

has limited access to settings and diagnostics/setup functions. Default pin code is 1234.

Note: The system will automatically log users out of the system after the machine is idle for 1 hour.

This feature can be disabled or conigured in the Machine Coniguration screen.

Crimper Operations

PC440i Crimper with CrimpIQ™ Controller

Page 11

11PC440i Crimper – Operator Manual

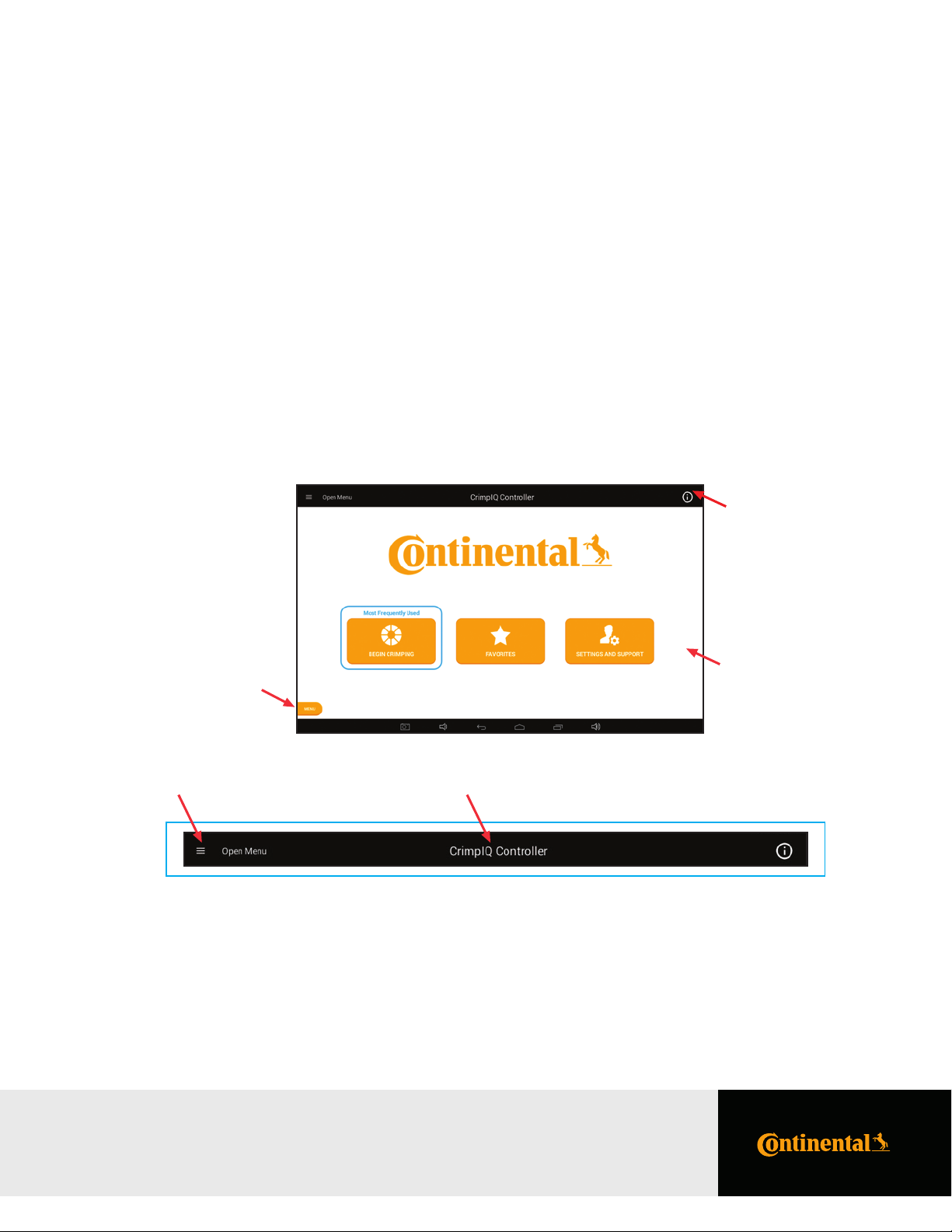

Navigating the CrimpIQ™ Controller

This section provides an introduction to the controller screens and functions that are common throughout the application.

Basic Application Guide

This section outlines basic functions within the app that are common throughout the application. The basic outline and

functionality is common throughout the application.

The screen is divided into the following sections:

Top Menu: This area of the screen provides high-level application and controller information

and access to help and settings.

Main Screen: Main screen with information and functions related to this screen

(directly linked to the screen title).

Left Menu: Provides access to information and functions that need to be available from everywhere

within the application. Access this with the menu button or by “swiping” left to right

from the left side of the screen.

Top

Menu

Left Menu

Access

Main

Screen

Top Menu

The top menu includes a screen title, access to menus and information.

Back/Menu Screen Title Information/Help

Back/Menu: This allows you to return one screen back (when you reach the main menu,

it brings out the left slide-out menu).

Information/Help: This option brings up help information relevant to the speciic location within the app.

Other: There are a few other status indicators that may be helpful.

• Right section displays Wi-Fi strength, Bluetooth status and machine time.

Navigating the CrimpIQ™ Controller

PC440i Crimper with CrimpIQ™ Controller

Page 12

12 PC440i Crimper – Operator Manual

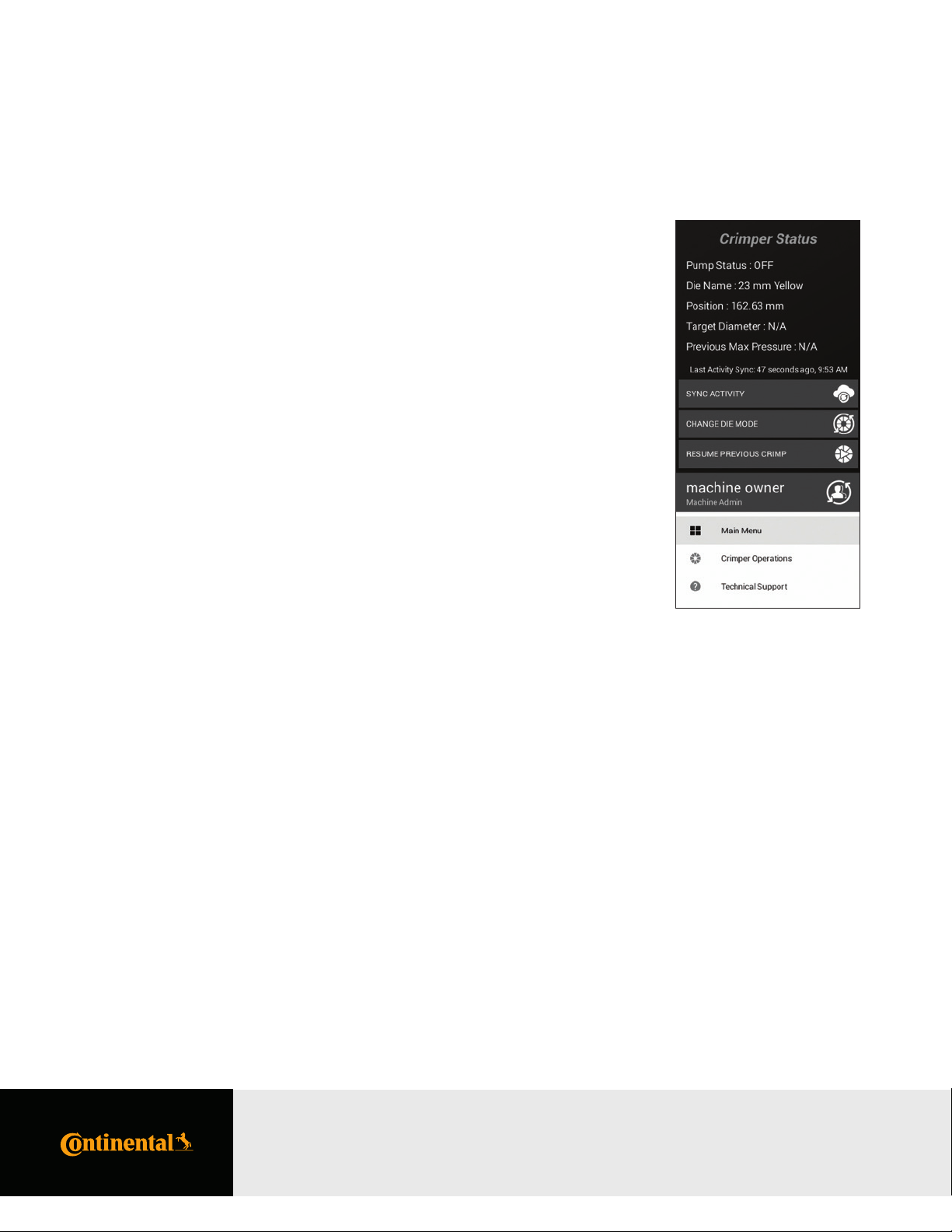

Left Slide-Out Menu

The left slide-out menu is available from anywhere within the Crimp controller app. It can be accessed by pressing the Menu button

(always on the lower left side) or by swiping left from the left side of the screen.

Once opened, pressing anywhere on the right side of the screen (right of the left slide-out menu) will close the menu.

The left menu contains information and functions that could be used at any time within the application.

Left Slide-Out Menu Information

The left slide-out menu provides a quick status of the system. This information includes:

Die Name: Name of the die (if any) that is currently loaded in the machine.

Position: Position of the crimp head, relative to the die currently loaded.

Target Diameter: The crimp diameter target currently loaded into the machine.

This is the diameter the crimper will close to given the size of

the dies loaded into the machine.

Previous Max Max pressure on the last successful crimp.

Pressure:

Last Activity Sync:

The last time that the machine has synced with CrimpCloud®.

Left Slide-Out Menu Functions

The left slide-out menu provides functions that can be executed from anywhere at any time:

Sync Activity: Sync Activity sends the latest crimper activity up to CrimpCloud®. Last Activity Sync data and time

described above detail the last successful data sync.

Change Die Mode: This mode allows the user to position the head to change dies. The machine tracks which dies are

loaded and will update information according to which dies are loaded.

"User Name" Change user function. This button displays the currently logged in user and provides a function to

login as a dierent user.

Main Menu: Return to the main menu of the application.

Crimper Return to the crimper operations menu.

Operations:

Technical Support: Bring up the technical support function.

Navigating the CrimpIQ™ Controller

PC440i Crimper with CrimpIQ™ Controller

Page 13

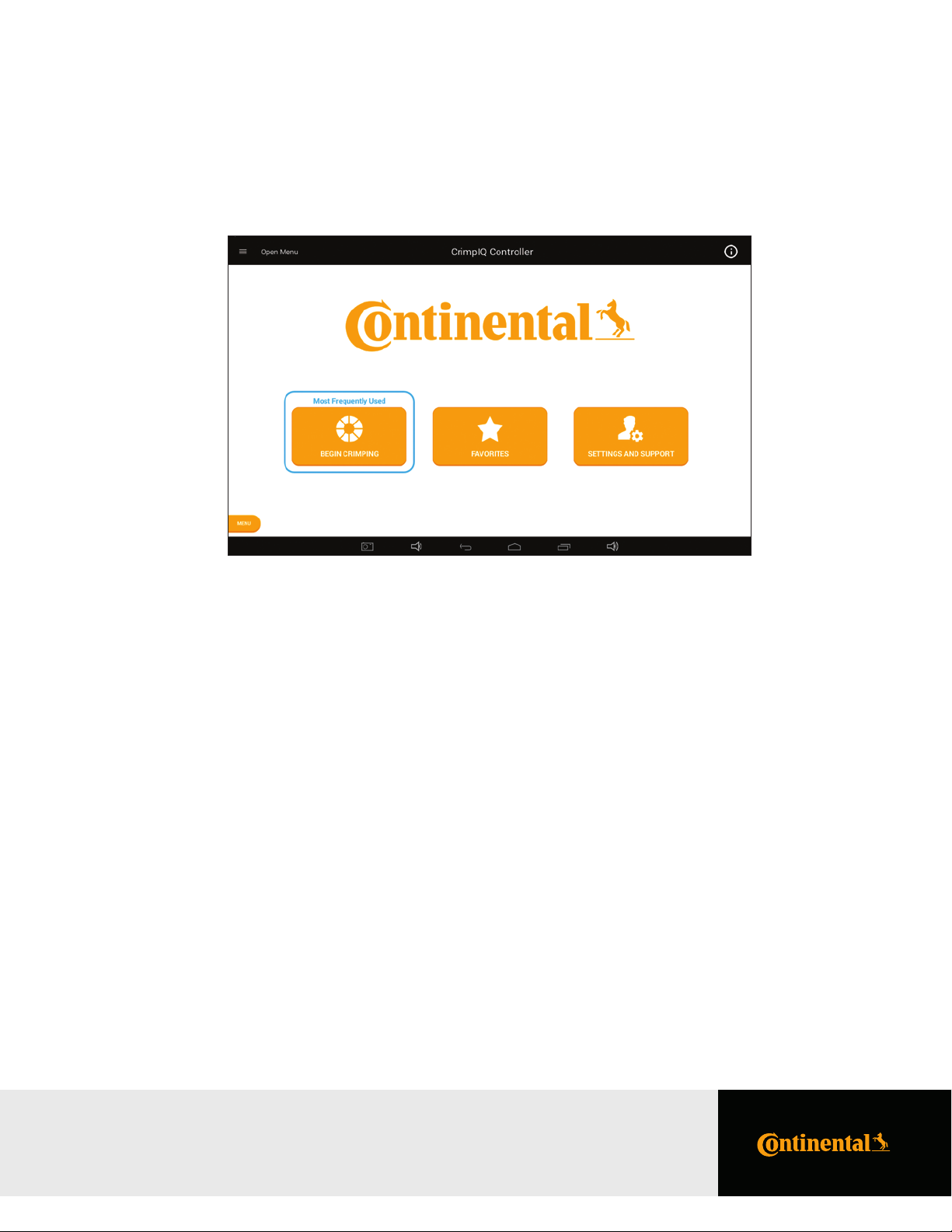

Using the Main Menu

This screen provides the main functions of the crimper.

13PC440i Crimper – Operator Manual

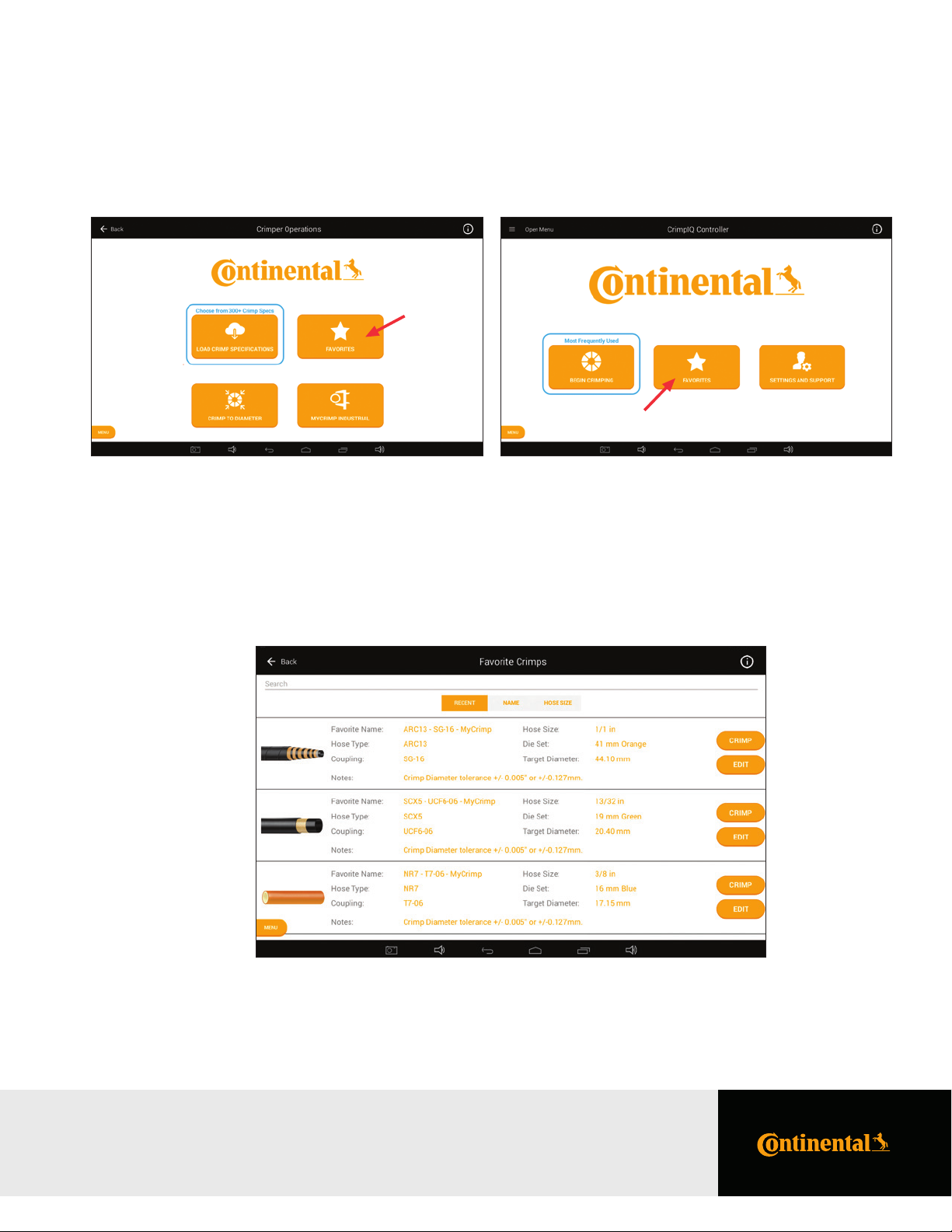

CrimpIQ™ Controller Main Menu Screen Options

Begin Crimping:

This button brings up the functions to perform hydraulic and industrial hose crimping.

Favorites: The Favorites button provides users with direct access to favorited crimp speciications.

Setting and This button brings up all of the support, information, training manuals and coniguration options

Support: available for this machine.

Using the Main Menu

PC440i Crimper with CrimpIQ™ Controller

Page 14

14 PC440i Crimper – Operator Manual

Crimper Operations

Main Crimper Operations Screen

The crimper operations screen is the starting point for setting up a crimping operation.

Favorites: This function contains all of the crimp speciications that have been previously favorited.

Crimp to Diameter: This function allows the user to directly enter a crimp diameter. Once entered, the system

will recommend a die and allow the user to proceed to Crimp Operations.

MyCrimp® Industrial: This brings up an Industrial Crimp Calculator. This calculator can determine the crimper

setup based on the hose diameter or hose wall thickness.

Load Crimp Speciications

This function allows the user to retrieve and load a crimp speciication from MyCrimp®.

Crimper Operations

PC440i Crimper with CrimpIQ™ Controller

Page 15

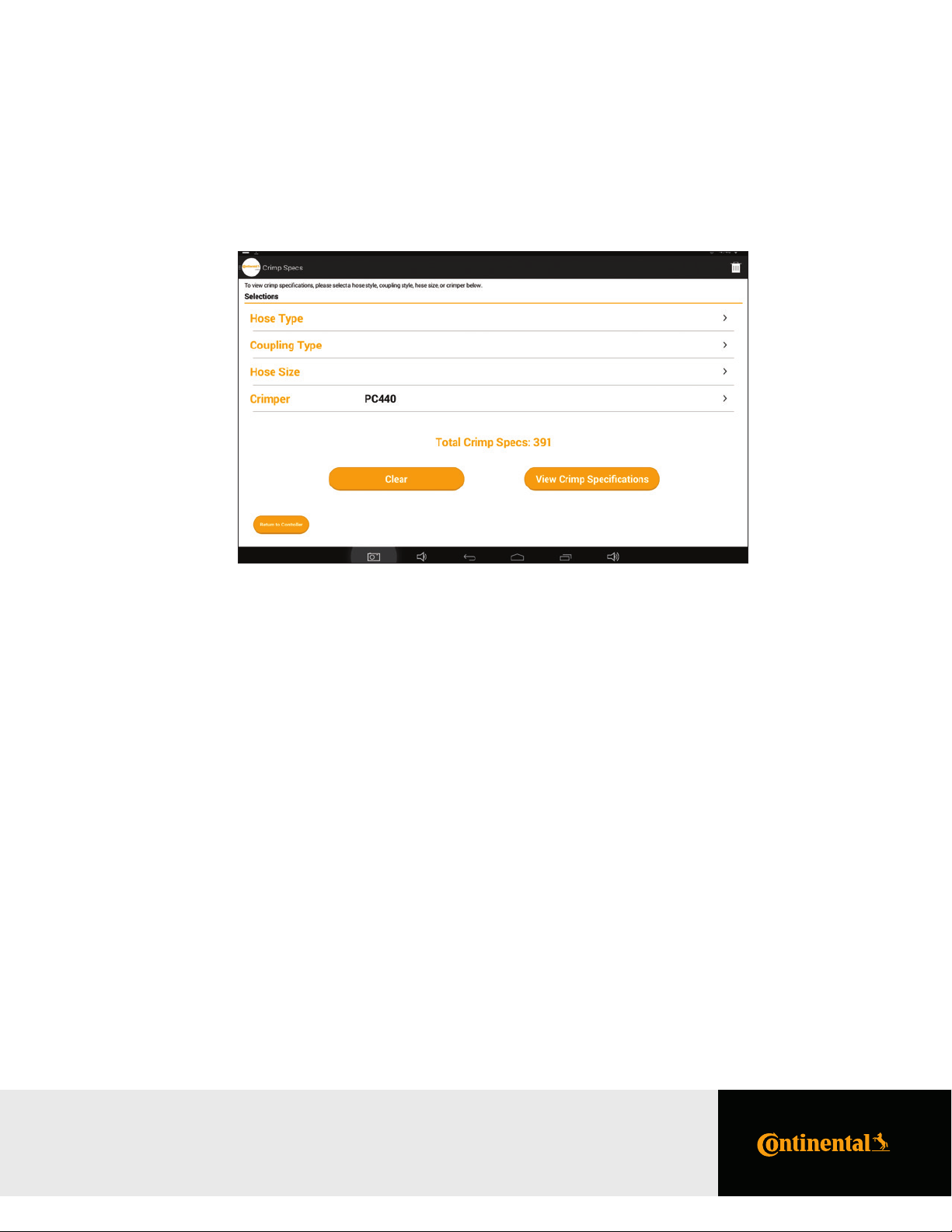

MyCrimp® – Search Screen

Use the Hose Type, Coupling Type and Hose Size to ind the crimp speciications you need.

15PC440i Crimper – Operator Manual

Key Functions of MyCrimp®

Hose Type:

Drill down into a list of hose types.

Coupling Type: Drill down into a list of coupling types.

Hose Size: Drill down into the list of hose sizes.

Crimper: This is preset to the current crimper type and cannot be changed.

Favorite: Allows the user to favorite selections and view them at the top of the list.

Clear: The clear button and trash can icon clear previous selections and let the user

begin a new search.

Total Crimp Specs: Lists the total number of crimp speciications found that match the search criteria.

View Crimp Allows the user to view a list of matching crimp speciications.

Speciications:

Return to controller: Allows the user to abort the MyCrimp® search and return to the controller.

Crimper Operations

PC440i Crimper with CrimpIQ™ Controller

Page 16

16 PC440i Crimper – Operator Manual

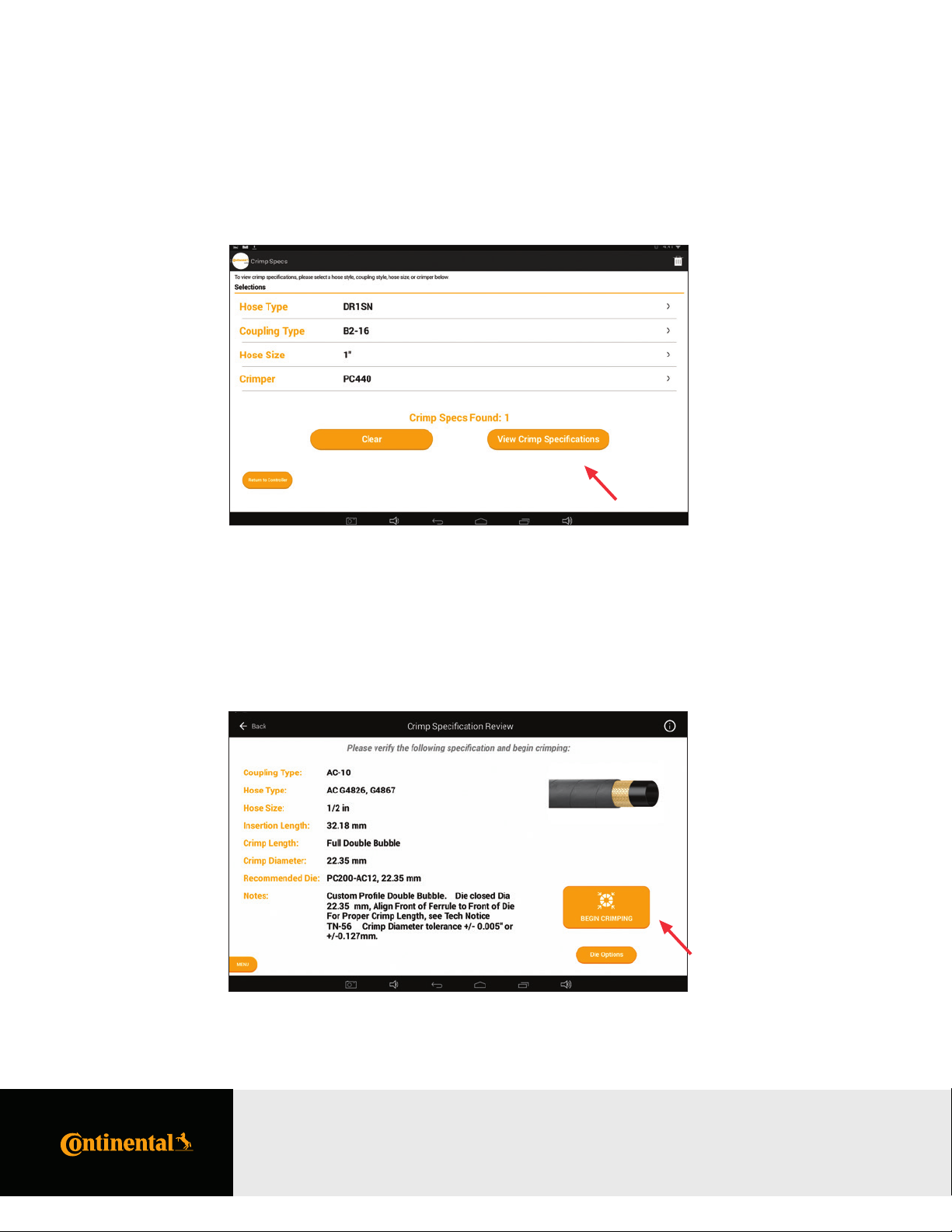

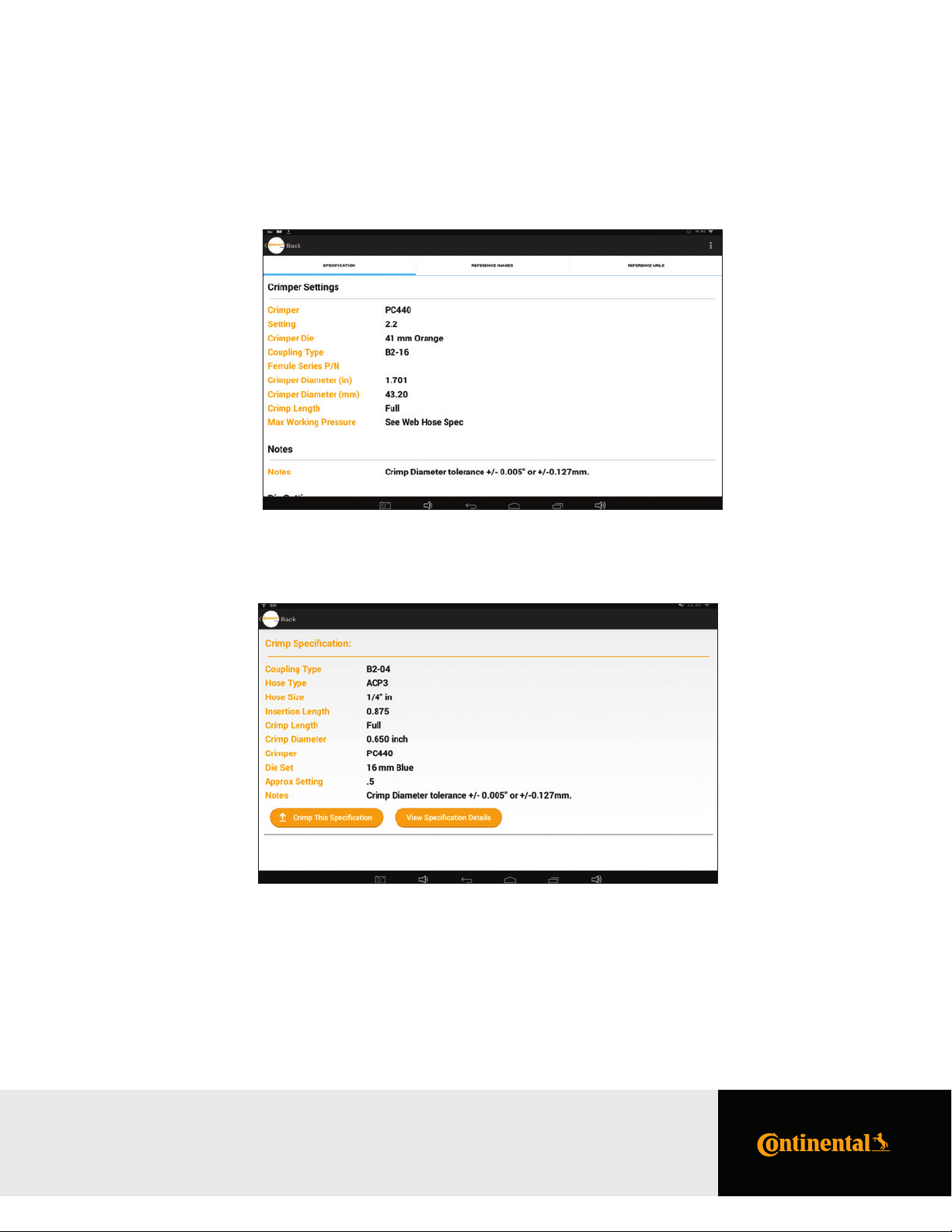

Once you ind the desired crimp speciication, View Crimp Speciications will allow users to review the matching

crimp speciications.

MyCrimp® – Results Screen

This view provides a review of the hose and itting selected. Select “Begin Crimping” to begin crimping.

Crimper Operations

PC440i Crimper with CrimpIQ™ Controller

Page 17

From the detailed view, users can view the full details of the crimp speciications.

Users can return to the previous screen with the Back button in the upper left corner or by using the "More Options" menu

in the upper right to “Export Speciication.” An Export Speciication button is also found below the speciication details.

17PC440i Crimper – Operator Manual

MyCrimp® – Crimp This Speciication

Selecting “Crimp This Speciication” will allow the user to conirm the crimp speciication details.

Managing Crimp Speciications

Begin Crimping: Select this option to have the controller conigure the crimper and allow the operation to load/

conirm the correct die is loaded.

Die Options: In special situations, the user may wish to use an alternative die. To accomplish this, select the

Die Options button to bring up a list of all dies conigured for this machine.

Crimper Operations

PC440i Crimper with CrimpIQ™ Controller

Page 18

18 PC440i Crimper – Operator Manual

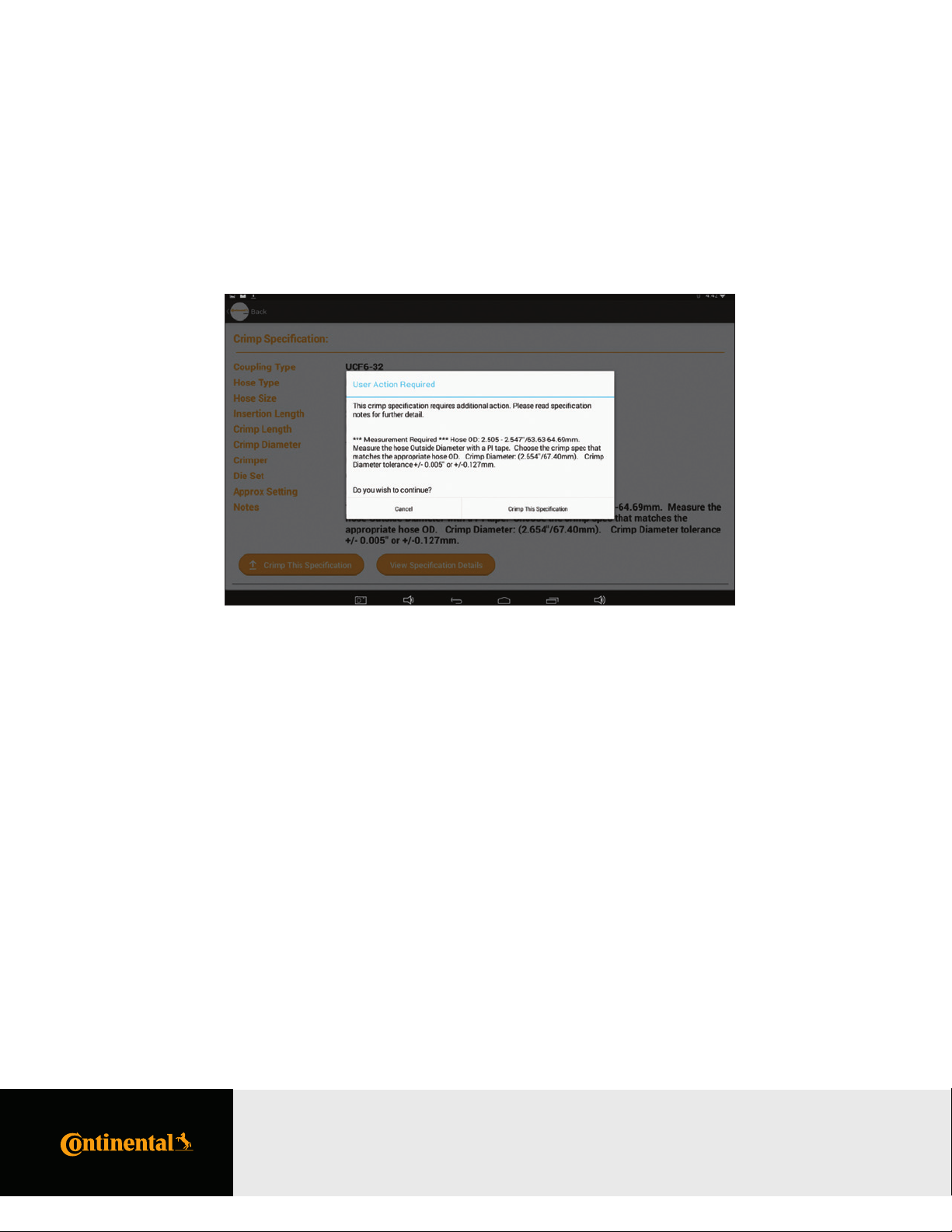

Crimp Speciications with Special Handling Requirements

There are cases where the user has to perform additional steps in order to select the correct crimp speciication for the

hose and itting combination. In these cases, MyCrimp® will prompt the user with additional information. Users can

then take the appropriate actions.

Crimper Operations

PC440i Crimper with CrimpIQ™ Controller

Page 19

Favoriting Crimp Speciications

The user can save frequently crimped speciications for easy access and repeated crimping.

19PC440i Crimper – Operator Manual

This brings up a list of all the favorites saved on this machine. This scrollable list can be sorted by date added (Recent),

Favorite name (Name) or hose size.

Favoriting Crimp Speciications

PC440i Crimper with CrimpIQ™ Controller

Page 20

20 PC440i Crimper – O perator Manual

Editing a Favorite

Users have the option to edit the Favorite name and notes. You also have the option to delete favorites

that are no longer needed.

Favorite Special Handling

There are a subset of crimp speciications that require special handling. For these favorites, users must make an additional

check to verify that the correct crimp speciication has been selected. The system will automatically bring up a

“User Action Required” dialog and ask the user for an additional conirmation (or cancel).

Note: For these speciications, the edit function does not allow the note to be changed.

Favoriting Crimp Speciications

PC440i Crimper with CrimpIQ™ Controller

Page 21

Crimp to Diameter

If you already have the crimp speciication information, you can enter this directly and begin crimping. Simply choose the

Crimp to Diameter option from the Crimper Operations page.

Enter the appropriate crimp diameter target (in inches or mm). As you enter a target diameter, the crimp automatically

calculates the equivalent measurement in the other unit of measure.

The system will recommend a die and you can proceed to crimping.

21PC440i Crimper – O perator Manual

Note: If the keyboard is not visible, tap the Diameter data entry area and the keyboard will appear.

Crimp to Diameter

PC440i Crimper with CrimpIQ™ Controller

Page 22

22 PC440i Crimper – Operator Manual

MyCrimp® Industrial Crimp Calculator

The Industrial Crimp Calculator allows users to enter information about the industrial hose, stem and sleeve,

along with a compression ratio. The calculator will then calculate the appropriate crimp diameter.

The calculator provides additional details on each required value. Press on the measurement icon and a more

detailed description pops up.

Entering Industrial Measurements

Hose Wall: Allows users to perform the calculation based on 3 measurements (averaged)

of the hose wall thickness.

Hose Diameter: A single hose diameter measurement.

Stem Outer Diameter: The diameter of the stem.

MyCrimp® Industrial Crimp Calculator

PC440i Crimper with CrimpIQ™ Controller

Page 23

23PC440i Crimper – Operator Manual

Sleeve Thickness: The thickness of the sleeve.

Compression Ratio: Compression ratios are available from hose and itting manufacturers.

Ratios must be between 10% and 35%.

As data is entered, the calculator will determine the inal crimp diameter (users cannot proceed to crimping until all ields

have information entered).

Once the data is entered and the calculation complete, you can proceed to crimping.

MyCrimp® Industrial

PC440i Crimper with CrimpIQ™ Controller

Page 24

24 PC440i Crimper – Operator Manual

Beginning a Crimp

Loading Dies

Regardless of how the crimp speciication/crimper was set up, the irst step in crimping is to load the correct die into the crimper.

As part of the crimper coniguration, the dies available to this crimper have been conigured (see Managing Preset Dies

on page 37). This pre-determined list of dies allows the crimper to determine which die to recommend for each crimp.

Crimp speciications and favorited crimp specs all include a recommended die. If that die is conigured for this crimper, the

user is prompted to install the recommended die.

Notes:

• Continental dies use color coding to help the user select the correct die set.

• The crimper will always prompt the user to “Install/Conirm” that the die is loaded. Therefore, even if the recommended

die is already loaded, the user will always be prompted to conirm that the correct die is installed in the crimper.

• While on the Change Die screen, the pump is on and the Open/Close button is enabled. The user can move the crimp

head as required to install the dies.

• In rare situations, the user may need to override the recommended die. This can be done by pressing the Die Options button.

This will bring up the list of available dies (described below).

• Caution: In Change Die mode, the crimper head will close to the die diameter.

Beginning a Crimp

PC440i Crimper with CrimpIQ™ Controller

Page 25

Selecting a Die

If a non-recommended die or no die is set, the controller will prompt the user with a list of conigured dies. The CrimpIQ™

controller will recommend a die that can crimp the required crimp diameter.

Once a die is selected, the machine will prompt the user to conirm/install the die in Change Die mode (described above).

25PC440i Crimper – Operator Manual

Notes:

• Dies that are grayed out are excluded because they are not capable of reaching the crimp diameter.

• This list is scrollable. You can slide the list up and down but, in general, the list will be centered on the dies that can be used

for this crimp.

• This list is limited to the dies conigured when the initial machine setup was completed

(either in the factory or during the initial machine setup).

• If you have a die appropriate for this crimp but it is not in the list of dies, you can manually

enter this die by choosing the Enter Manual Die option on the bottom right.

• If the selected die cannot crimp to the required crimp diameter, the crimper will display a warning.

Beginning a Crimp

PC440i Crimper with CrimpIQ™ Controller

Page 26

26 PC440i Crimper – Operator Manual

Change Die Mode

When you select the die, the pump will start and the Open/Close buttons will work to allow you to load the die in the crimper.

Once the die has been loaded, press the OK to continue.

Note: If the desired die is already loaded, simply press OK to continue.

Beginning a Crimp

PC440i Crimper with CrimpIQ™ Controller

Page 27

Crimp Operations

Performing the First Crimp

The irst crimp always needs to be measured to ensure the crimp is within tolerance of the crimp diameter.

Note: Once the calibration crimp has been completed and an initial crimp diameter entered (manually entered

or entered via USB CrimpIQ™ calipers), the crimper will automatically adjust to accurately crimp subsequent crimps.

27PC440i Crimper – Operator Manual

Crimp Operations

PC440i Crimper with CrimpIQ™ Controller

Page 28

28 PC440i Crimper – Operator Manual

Measuring a Crimp

The crimper will always prompt the user to measure the irst crimp. The crimper uses this measurement to adjust the

crimper to correctly crimp the next crimps.

When prompted, enter the measured crimp diameter. Measurements can be entered in inches or mm (the cursor will be

placed in either ield based on the preferred units of measure setup in the machine coniguration).

Notes:

• If the crimp diameter measurement matches the current crimp target, the user can press the Crimped to Target button to

automatically enter the measurement with a single button press.

• If a value is incorrectly entered, simply press the clear button.

• Once the measurement has been entered, the Save button is enabled and saves the measured crimp diameter for quality

assurance reporting.

• A keyboard will pop up on the bottom of the screen to allow users to enter crimp diameter data.

• If calipers are connected to the crimper, measurements can automatically be transferred into the measurement ield.

• The preferred units of measure are set up per user and can be conigured in the machine settings.

Crimp Operations

PC440i Crimper with CrimpIQ™ Controller

Page 29

Crimp Operations Screen

This screen provides the main controls for operating the crimper. While on this screen, the pump is running and the

Open/Close buttons are enabled (limited by Crimp Mode).

Crimp Operations Screen Sections

The operations screen is divided into 5 sections: Operations Information, Crimp Detail Panel, Crimp Mode, Crimp Settings

and Crimp Management.

29PC440i Crimper – Operator Manual

Operations Information

Crimp Mode Crimp Settings Crimp Management

Crimp Detail Panel

Crimp Operations

PC440i Crimper with CrimpIQ™ Controller

Page 30

30 PC440i Crimper – Operator Manual

Operational Information

Die Name: The name of the die that is currently installed in the machine.

Target Diameter: The diameter the machine is set to crimp to.

Current Position: Current die opening in inches and millimeters.

Crimp Detail Panel

This area of the screen provides the user with additional information about the crimping processes. The data in this area

rotates through a series of screens with dierent information. Users can cycle through each view with the icon in the

lower right section of this screen area.

Last 10 Diameters: A list of the last 10 crimp diameters

measured/entered into the CrimpIQ™ controller.

Note: The most recent is noted with a “*”

Last 10 Pressures: The last 10 maximum crimping

pressures measured in PSI.

Note: The most recent is noted with a “*”

Combined View: This view combines the measurement and the max pressure view into one.

Note: Users may not be required to measure every crimp.

Cycle Through Views

Crimp Operations

PC440i Crimper with CrimpIQ™ Controller

Page 31

Crimp Spec: Hose, itting and hose size information when loading a MyCrimp® speciication.

Hose Image: If a hose image is available, this image will be displayed.

31PC440i Crimper – Operator Manual

Spec Notes: This view shows the crimp speciications notes.

Industrial Crimp: This view summarizes the values entered into the Industrial Crimp Calculator.

Crimp Operations

PC440i Crimper with CrimpIQ™ Controller

Page 32

32 PC440i Crimper – Operator Manual

Crimp Mode

The crimper can operate in any of 3 dierent modes:

Manual Mode: Use this mode to manually Open/Close the head. Holding the Close button will close the head to

the target position and no further.

Semi-Automatic This mode allows the user to manually close the head to the target position. Once the crimper

Mode: reaches the target position, the crimper will automatically open back to the retraction point.

Full Automatic This mode allows the crimper to complete a complete cycle (close then open) with just a single

Mode: push of the close button. Once the hose and itting are correctly positioned, press the close button

once and the crimper will close to the target position and then automatically open back to the

retraction point.

Note: In either of the automatic modes, the foot pedal can also be used in place of the Close button.

Crimp Operations

PC440i Crimper with CrimpIQ™ Controller

Page 33

Crimp Information

33PC440i Crimper – Operator Manual

The Crimp Settings section contains status information and also a number of conigurable settings that the user

can change to adjust the crimp run.

Note: Each of these information areas can be conigured by pressing the icon to the left of the information.

Favorite: If this crimp speciication has been saved as a favorite, the name of the favorite will

be displayed here. To save a new favorite, simply press the favorite icon on the left.

PSI Monitoring/ The CrimpIQ™ controller has the option to monitor the crimping pressure and alert the user if the

Max PSI: PSI is out of range. Press the PSI icon to conigure the target PSI and tolerance.

Crimp Count: The CrimpIQ™ controller keeps track of the crimps completed. By default, this count goes up but

you can also set it to count down. This is conigured using the count icon on the left.

Users also have the option to “bump” the count up or down if needed.

Quality Mode: Quality mode automatically stops the crimping process after a speciied number of crimps and

prompts the user to measure the crimp diameter.

Crimp Operations

PC440i Crimper with CrimpIQ™ Controller

Page 34

34 PC440i Crimper – Operator Manual

Crimp Management Function Buttons

This section provides buttons to conigure and operate the crimper.

Measure/Adjust Crimp: This button allows the user to measure and record the crimp diameter. When activated, the

user can enter a crimp diameter measurement.

Change Die Mode: This mode allows the user to change die.

Suspend Crimp: Suspend Crimp is intended to put the crimper in a safe mode when the user needs to step

away from the machine for a short time. While suspended, the pump is turned o and the

Open/Close buttons are disabled.

Done: This button should be used when the user has inished all crimps with these settings.

Crimp Operations

PC440i Crimper with CrimpIQ™ Controller

Page 35

Settings and Support

In addition to the basic crimping operations, the CrimpIQ™ controller oers a number of other capabilities.

These include:

Machine Coniguration: Crimp setup/coniguration page with all of the conigurable options of this device.

See Machine Coniguration below.

Support: Support page allows users to request support directly from the machine.

See the Support below.

Manufacturer Website: Access to all of the information on the Continental corporate website.

See the Manufacturer Website below.

Training Manuals: Direct access to setup, guides and training manuals for the machine and controller.

See Training Manuals below.

Machine Information: Informational pages that provide users with basic machine stats and

operational information.

35PC440i Crimper – Operator Manual

Settings and Support

PC440i Crimper with CrimpIQ™ Controller

Page 36

36 PC440i Crimper – Operator Manual

Machine Coniguration

The CrimpIQ™ controller has a number of coniguration options that allow the machine operation to be customized to

meet the needs of each installation.

Main coniguration functions are grouped into menu options at the top of the page. The rest of the coniguration screen

provides access to all the remaining coniguration settings.

Notes:

• The options available vary by user type. Operators have very limited options and Machine Owners

have access to all options.

• After making coniguration changes, the CrimpIQ™ controller will attempt to back these changes up to CrimpCloud®.

This backup requires an Internet connection to complete.

Machine Coniguration Options

Manage Preset Dies: Setup the dies that are available for crimping on this machine.

See Manage Preset Dies above.

Manage Users: Edit and setup machine users. See Manage Users above.

Self-Calibration: Check the crimper calibration. See Self-Calibration Mode above.

Maintenance Mode: List of maintenance tasks, schedules and due dates for machine maintenance.

See Maintenance Mode above.

Setup Internet: Conigure and verify a tablet Internet connection. See Setup Internet above.

Backup to CrimpCloud®: Backup CrimpIQ™ controller coniguration to CrimpCloud®.

See Backup to CrimpCloud® above.

General Coniguration: Other Coniguration settings. See General Coniguration above.

Settings and Support

PC440i Crimper with CrimpIQ™ Controller

Page 37

Managing Preset Dies

This screen provides a list of all of available dies for this crimper. Administrators can set each die to Not Purchased/Purchased to

allow the CrimpIQ™ controller to ilter the list of dies the user sees to only dies that are available with this machine.

Each die has a name, type, size in inches and size in mm. If there is also a color code associated with the die that is displayed.

Administrators also have the option to create additional dies. Select the “Create New Preset Die” button and setup additional dies.

37PC440i Crimper – Operator Manual

Settings and Support

PC440i Crimper with CrimpIQ™ Controller

Page 38

38 PC440i Crimper – Operator Manual

Managing Users

The crimper comes conigured with three user accounts but Administrators have the option to setup additional users.

Additional users can be useful to track what each user/admin is doing on the machine. Information on the default users is

available in the Key User Information.

This setup screen allow Administrators to create new users and edit existing users.

Edit User: User name, 4 digit passcode and user type can be changed with this menu.

This is where an Administrator would reset the pin for a user who has forgotten their pin.

Create New User: Enter the user name, 4 digit passcode and user type to create a new user.

The CrimpIQ™ controller has been conigured with multiple user types. Each type has dierent capabilities within the crimper.

The goal is to provide users with all the privileges they require to do their tasks but no more.

Machine Admin: This is the highest privilege user type that can be conigured. This user type can change all machine

settings, access all support information and perform all crimp operations.

Machine Tech: This type has privileges to maintain the machine but cannot perform crimping tasks.

Supervisor: This type has privileges to monitor machine operations but cannot perform maintenance tasks.

Machine User: This type has privileges to use the machine, perform all crimping related tasks and has limited ability

to change machine coniguration.

Self-Calibration Mode

Self-calibration is a built-in test that veriies the accuracy of the crimper is within tolerance of its initial factory setup. If the test

fails (out of tolerance), a warning message is displayed showing the dierence from its initial set point.

To run the test, follow the instructions on the screen. At a high level, the test lows as follows:

• Load dies into the crimper (any standard hydraulic dies work). Make sure the crimp head is at least 1/3 open.

• Begin the self-calibration mode. This will prompt the user the press the Close button. The test then runs

automatically and returns a success/failure result.

Default User Accounts

To learn more about Default User Accounts, refer to page 10.

Settings and Support

PC440i Crimper with CrimpIQ™ Controller

Page 39

Maintenance Mode

This machine keeps track of a number of dierent periodic maintenance tasks. Tasks are based on machine model.

Maintenance tasks are either triggered by the number of crimps or the number of days since the last maintenance.

Tasks include: Check Hydraulic Oil, Grease the Crimper, Perform Self Calibration and Data Synchronization. Most of these are

self-explanatory with the exception of Data Synchronization (update crimp speciication, check for application updates and

sync data with the CrimpCloud®).

39PC440i Crimper – Operator Manual

Notes:

• When a maintenance event is triggered (by crimp count or date), the user gets a popup indicating that the maintenance

needs to be performed. To limit interference with operations, tasks can be delayed until a later date (Snoozed).

• Maintenance tasks are either triggered by the number of crimps or the number of days since the last maintenance, based

on the requirements of the task.

• Users can come to this Maintenance Mode screen and perform maintenance tasks or wait for the popup alert.

• Recording a maintenance task provides the user with an opportunity to add notes. The logged in user and date/time are

recorded along with the maintenance task.

• A complete history of maintenance performed is also available via the History button on the Maintenance Mode screen.

Setting Up an Internet Connection

This process allows users to conigure/verify Internet connections. An Internet connection is not required for day-to-day

operation but is beneicial. This section describes how to conigure dierent types of Internet connections and verify these

connections are working.

Using an Ethernet Connection

Plug the Ethernet cable into the base of the controller. The tablet will take a few moments to conigure the connection.

Once successful, the connectivity status will turn green.

Settings and Support

PC440i Crimper with CrimpIQ™ Controller

Page 40

40 PC440i Crimper – Operator Manual

Using a Wi-Fi Connection

Initiating the Wi-Fi setup process brings the user to the standard Android Wi-Fi setup screens. Choose the appropriate

Wi-Fi Network, enter in any required credentials and connect.

When the connection has been established, use the return arrow to return to the CrimpIQ™ controller application.

Connecting to a Captive Portal

Some customer locations have restrictions on which machines can connect to the company’s internal network. If this is the case,

see the additional connection options section below.

Verifying Connection Status

When the Internet connection has been successfully established, the connection status will change to a green check mark.

Please verify the connection before moving on to the next step.

Settings and Support

PC440i Crimper with CrimpIQ™ Controller

Page 41

Testing Proper Connectivity

You can use the “Verify Connection” button to verify that the crimper can reach the Internet. Users should see the

ContiFluidSolutions home page. If you don’t see this page, please contact your network administrator to enable access

from the CrimpIQ™ controller to the Internet.

Once the CrimpIQ™ controller is connected to the Internet, use the back button to go back to the setup process and then

continue to the next step by pressing the arrow in the bottom right of the screen.

41PC440 i Crimper – Operator Manual

Additional Connection Options

In some cases, network administrators may restrict which machines can access the company network.

There are 2 alternative connection options to complete the Crimp setup process:

1. Temporarily connect to a guest network:

The controller supports connecting to guest networks to complete the installation. The CrimpIQ™ controller needs an

Internet connection but does not require access to any internal company resources. A guest network can be used to

complete the setup and update processes for the controller. Simply enter the guest network credentials and the setup

can continue.

a. Enter the guest Wi-Fi credentials (via the Android Wi-Fi setup screens) and verify the connection is active (as described

above). The setup process only takes a few minutes after which the Wi-Fi connection is not needed.

b. Some facilities Wi-Fi connection use a web page to request user Wi-Fi login credentials. The controller supports this.

After selecting the appropriate network, return to the CrimpIQ™ controller setup screen. Use the verify connection

option to bring up the ContiFluidSolutions home page. The local network will then prompt for the required credentials.

2. Connect with a hot spot from a mobile device:

In some cases, network administration policies will not allow the CrimpIQ™ controller to access any network.

In that case, users must setup a Wi-Fi hotspot and use this connection to complete the setup process.

Internet Access Requirements

The CrimpIQ™ controller was designed to work with or without a dedicated Internet connection. If a dedicated connection

is not available, all of the essential crimping functions will work. The Internet associated features (ContiFluidSolutions home

page, support tickets, reporting) will not work because they require an active Internet connection to operation. Periodically, users

will be prompted to connect to the Internet to allow the CrimpIQ™ controller to sync information with CrimpCloud®. This sync

ensures the crimper has the latest software, crimp speciications and updates. It also ensures the machine coniguration

and operational history is backed up to CrimpCloud®. Operational information is used to generate reports and other

features available to users from CrimpCloud®.

Settings and Support

PC440i Crimper with CrimpIQ™ Controller

Page 42

42 PC440i Crimper – Operator Manual

Backup to CrimpCloud®

CrimpCloud® has the ability to provide reports on crimper operation and maintenance. In addition, it stores the coniguration

of the CrimpIQ™ controller (users, dies, favorites). Saving this coniguration allows Continental to replace the controller tablet,

pre-loaded, with all the backed up coniguration. Simply press “Backup to CrimpCloud” and the backup is performed.

General Coniguration

The following is a collection of other settings available to Administrators to conigure the CrimpIQ™ crimper

to meet their speciic needs.

User Settings - Preferred Units: Each user can have own settings for default units. Default units determine which

data entry ield the cursor is placed in.

Update Machine Registration: The Machine registration information provides the Continental support team with

location and contact information used to support the crimper.

Settings and Support

PC440i Crimper with CrimpIQ™ Controller

Page 43

Check Internet This feature is used to verify the Internet connection. A green check mark indicates a

successful network connection via Ethernet or Wi-Fi. A red exclamation point (!) indicates

there is no network connection. There are circumstances where the Wi-Fi signal is present

but the tablet still cannot access the Internet. To conirm the connection to the Internet, the

“Verify Connection” brings up the ContiFluidSolutions home page in a web browser. If the

site comes up, the CrimpIQ™ controller has a connection to the Internet.

Change Local Time Zone: Output ield to let Administrators know which time zone the tablet is set to. This information

is important for logging and reporting. This can be changed by selecting the correct time

zone from the drop down list.

Dual Pump: Larger crimpers has a dual pump coniguration to improve the speed of operation.

Slow Start Oset (mm): This setting indicates how far above the target crimp the pump/crimper switches from fast

to full power crimping mode.

Note: The default value generally does not need to be changed.

User Timeout Length: Length of time idle (in minutes) before the machine automatically locks and

requires a pin to login.

Note: This feature has an option to turn o (disables user timeout).

43PC440i Crimper – Operator Manual

Die Selection Tolerance: This setting helps the crimper recommend the best die for each crimp. This tolerance value

ensures that the crimper does not recommend a die that is too close to the target crimp

diameter that cannot crimp to the required diameter.

Note: The default value generally does not need to be changed.

Pressure Compensation On/O for Pressure Compensation. Pressure compensation uses the crimp pressure as

Mode: feedback to improve the accuracy of the irst crimp.

Note: Turning this feature on or o impacts the behavior of the irst crimp in crimp operations. It turns the

calibration crimp screen on or o, respectively.

Screen Brightness: Adjust the screen brightness for best viewing.

Enable Crimp Target On/O for a popup letting the user know that the crimper has successfully

Reached Popup: reached the target.

Enable Crimp Target On/O for a sound letting the user know that the crimper has successfully

Reached Beep: reached the target.

Settings and Support

PC440i Crimper with CrimpIQ™ Controller

Page 44

44 PC440i Crimper – Operator Manual

Require Measurement On/O setting for measurement popup on the initial crimp. Continental recommends

After 1st Crimp: that users ALWAYS measure the initial hydraulic crimp to ensure that the crimp

target is being reached (within tolerance). Turning this setting on always causes the

crimper to trigger the measurement popup on the initial crimp.

Connect Bluetooth Calipers: Coniguration and support to setup Bluetooth connected calipers.

Check for Update to CrimpIQ™ Trigger the CrimpIQ™ controller to connect to CrimpCloud® and check for

Controller: application updates. If found, the controller will download and install the latest

version of the application.

Note: Internet connection is required.

Check for Update to MyCrimp®: Trigger the CrimpIQ™ controller to connect to CrimpCloud® and check for

MyCrimp® application updates. If found, the controller will download and install the

latest version of the MyCrimp® application.

Note: Internet connection is required.

Force CrimpCloud® Operation Trigger the CrimpIQ™ controller to upload all operational data to CrimpCloud®.

Sync:

Note: In general, Administrators should not need to manually sync data. The controller will automatically sync data to

CrimpCloud® when appropriate.

Product Information – Email Provides a way for the Administrator to view the Terms of Service and if

Terms of Service: required, email them to the main contact for this machine.

View Source Attribution: Provides information on open source software incorporated into

the CrimpIQ™ controller.

Settings and Support

PC440i Crimper with CrimpIQ™ Controller

Page 45

Support

The application provides the user with a Technical Support system. This system allows the user to create a support ticket from

within the app. The support ticket and machine status information are automatically uploaded to the Continental support sta.

Note: The system must be connected to the Internet for this function to work.

45PC440i Crimper – Operator Manual

The user should create a ticket to get support:

Create a Ticket: This option allows the user to enter text to describe their issue. They can attach an image (using the

camera button on the bottom menu bar to capture the screen where the error is encountered).

Once submitted, this information is sent to CMS technical support sta for review and resolution.

Note: The machine must have Internet access to use this function.

Support

PC440i Crimper with CrimpIQ™ Controller

Page 46

46 PC440i Crimper – Operator Manual

Create a Ticket

To create a ticket, follow these steps:

1) Enter your email address: It is very important that this is entered correctly to ensure the support team can

quickly respond directly to the person having the issue.

2) Describe your problem: Enter a detailed description of the issue you are encountering so that the support

team can quickly provide support.

3) Attach an image: The CrimpIQ™ controller allows users to capture an image of

any screen (using the camera button in the bottom row of icons).

Images can be attached by pressing the paperclip icon in the

upper right corner of the screen.

4) Add images and text: You can attach multiple images to the ticket and add text to explain your issue.

5) Complete the process: To complete the process and send the support ticket, press the arrow icon in the upper

right section of the screen.

What Happens Next?

Once you submit the ticket, the information you entered (along with machine status and diagnostics) are sent to the

Tech Support team. The team will review your ticket along with the diagnostic information and respond back to the

email address provided.

The system will also send you a copy with a link to allow users to follow up on status or with additional information.

Support

PC440i Crimper with CrimpIQ™ Controller

Page 47

Conti Fluid Solutions