Continental Refrigerator IOF-240-B Maintenance Manual

IOF-240-B

CONTINENTAL® AIRCRAFT ENGINE

MAINTENANCE

MANUAL

TECHNICAL PORTIONS OF THIS MANUAL ARE FAA APPROVED

Publication M-22 Change 2

© 2007 TELEDYNE CONTINENTAL MOTORS INCORPORATED DEC 2007

TM

Teledyne Continental Motors, Inc.

Supersedure Notice

This manual is a revision of TCM IOF-240-B Maintenance Manual, M-22, dated July 2003. Instructions previously

referred to in the F-4 FADEC System Manual, dated July 2003, have been incorporated in this manual. This m an ual

supersedes both the M-22 and F-4 Manuals. Previo us versions are obsolete upon release of this manual.

Effective Changes for this Manual

0 ................................29 Nov 2006

1 ................................30 Aug 2007

2 ................................1 Dec 2007

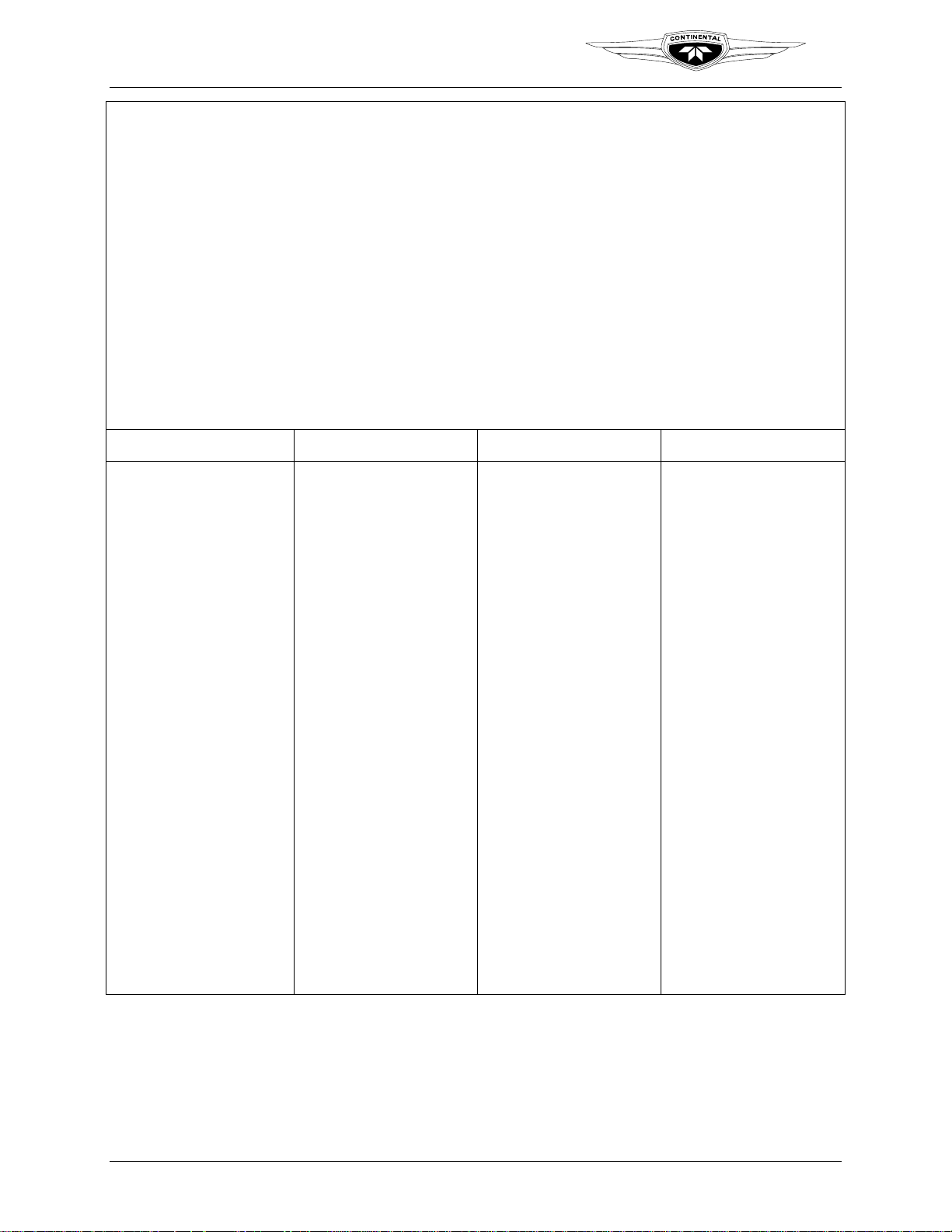

List of Effective Pages

Document Title: IOF-240 Series Engine Maintenance Ma nual

Publication Number: M-22 Original Publication Date: 29 Nov 2006

Page ...................Change Page ...................Change Page................... Change Page................... Change

Cover – ii....................2 4-1 thru 4-2.................0 B-1 thru B-12..............1

iii-viii...........................0 5-1 thru 5-2.................0 C-1 thru C-20.............0

1-1 thru 1-3 ................0 6-1 thru 6-14...............1 C-21...........................1

1-4..............................1 7-1 thru 7-64...............1 C-22 ...........................0

1-5 thru 1-6 ................0 8-1 thru 8-44...............1

1-7 thru 1-9 ................1 9-1 thru 9-17...............0

1-10 ............................0 9-18 thru 9-22.............1

2-1 thru 2-21 ..............1 10-1 thru 10-6.............1

2-22 ............................2 10-7 thru 10-8.............0

2-23 thru 2-26 ............1 10-9 thru 10-15...........1

3-1 thru 3-11 ..............1 10-16 thru 10-43.........0

3-12 thru 3-16 ............0 10-44 thru 10-55.........1

3-17............................1 10-56 thru 10-57......... 0

3-18 thru 3-21 ............0 10-58 thru 10-59.........1

3-22 thru 3-23 ............1 10-60 thru 10-66.........0

3-24 thru 3-25 ............0 10-67 thru 10-69.........1

3-26............................1 10-70 thru 10-77......... 0

3-27 thru 3-29 ............0 10-78 thru 10-84.........1

3-30 ............................1 A-1 thru A-8................0

Published and printed in the U.S.A. by Teledyne Continental Motors.

Available exclusively from the publisher: P.O. Box 90, Mobile, AL 36601

Copyright © 2007 by Teledyne Continental Motors. All rights reserv ed. This materia l may not be re printed , repub lishe d, broadc as t, or oth erwise

altered without the publisher’s writte n permission. This manua l is provided without ex press, statutory, or implied warranties. The publisher will

not be held liable for any damages c aused by or alleged to b e caused by use, mis use, abuse, or misin terpretation of the cont ents. Content is

subject to change without notice. Other products and companies mentioned herein may be trademarks of the respective owners.

ii IOF-240 Series Engine Maintenance Manual

Change 2 1 December 2007

TM

Teledyne Continental Motors, Inc.

Service Document and Technical References

Service Documents and technical information cited in this edition of TCM’s Maintenance

Manual (M-22) are listed in the chart below. Information relevant to this engine series from these

Service Documents has been incorporated in this manual. The full content of all TCM and

supplier service documents is available on TCMLINK. Refer to the section “Publication Access”

in Chapter 1 of this manual for TCMLINK details.

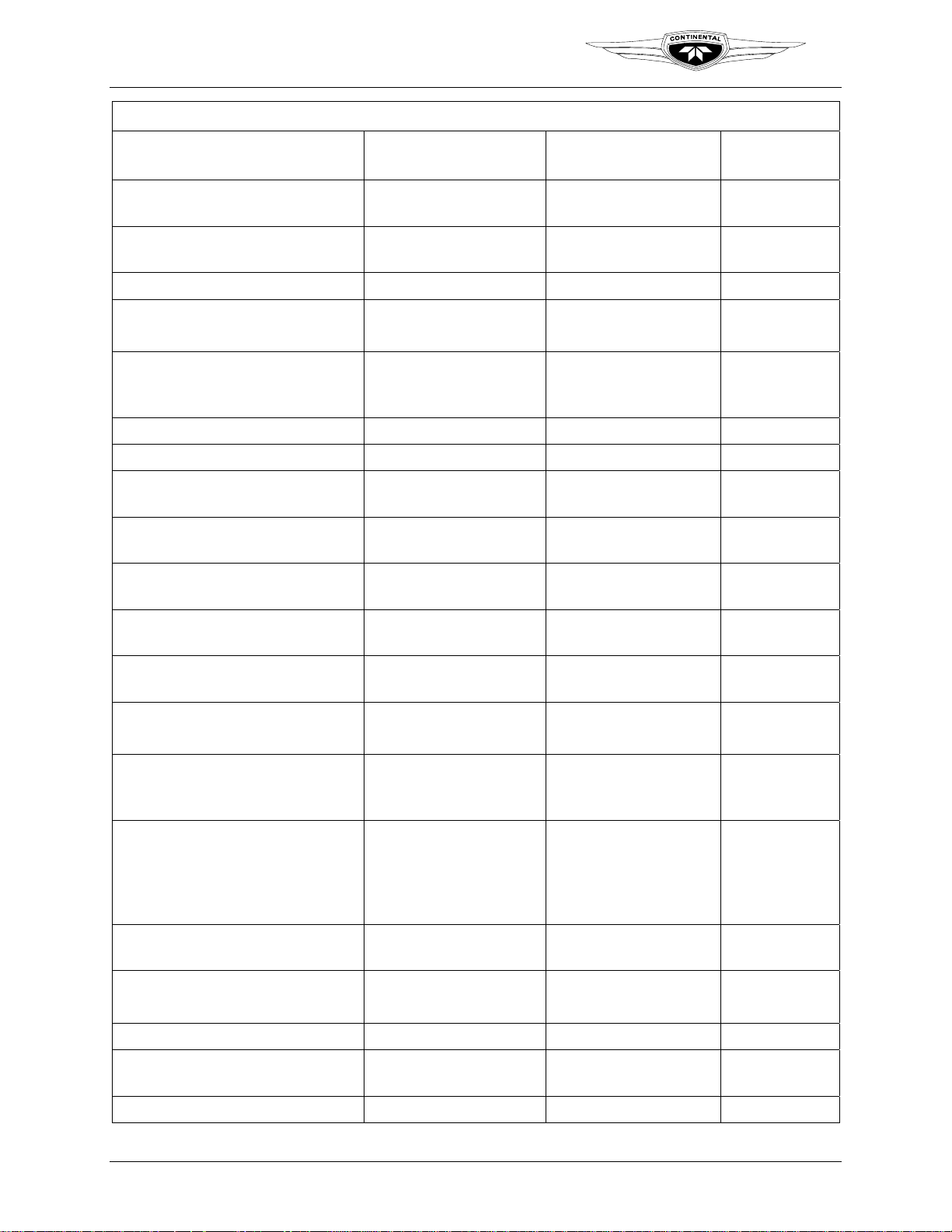

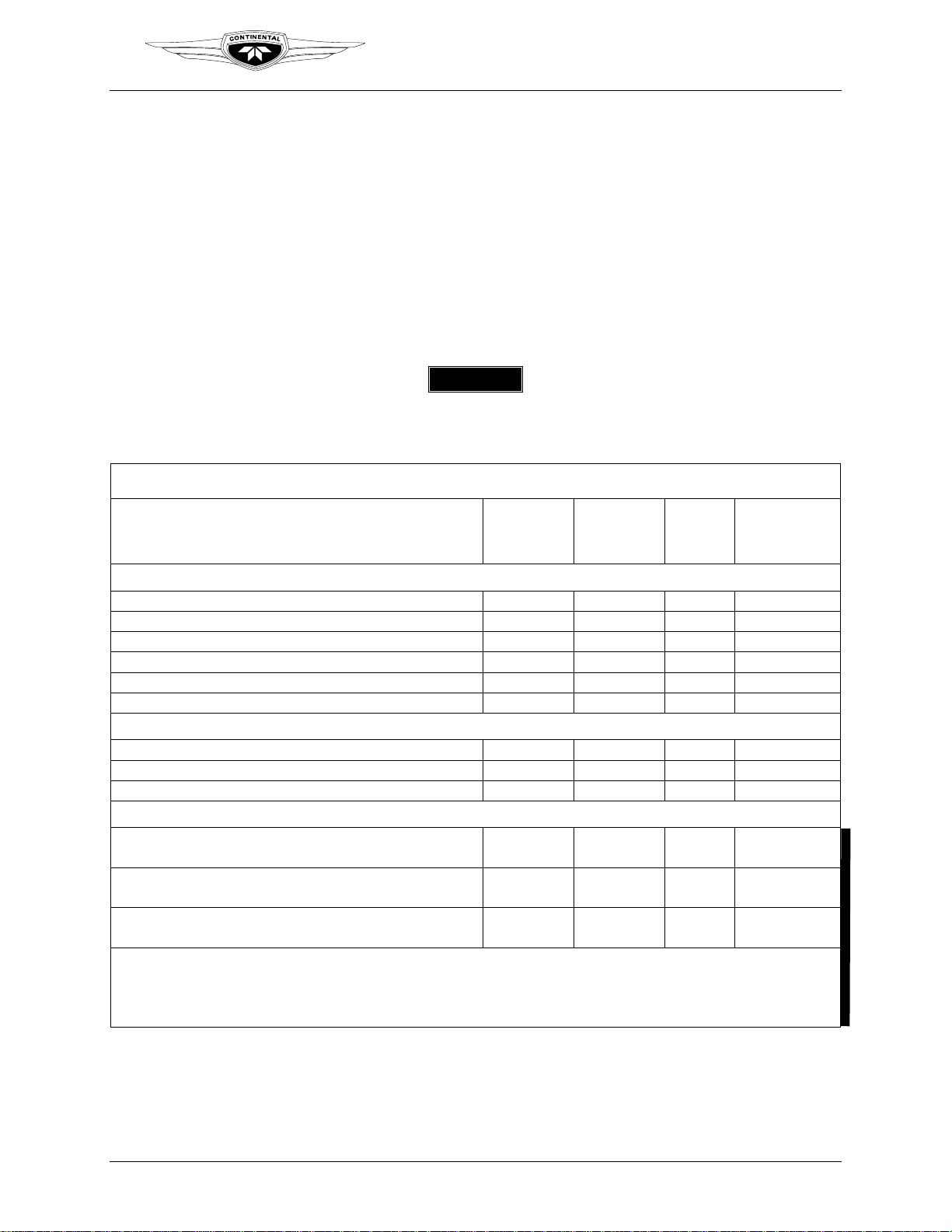

Service Documents Incorporated in this Manual

Service Document Subject Section Affected

Chapter

MHS-24, Ashless Dispersant

Lubricating Oil

MHS-24, Appendix

MHS-27,“Engine Break-in and

Preservation Oil

M76-4, Installation of Propeller shaft

Oil specifications

Break-in and preservation

oil specifications

Oil seal replacement N/A N/A

Specifications and

Operating Limits

Chapter 2

Chapter 7

Chapter 9

Break-in Oil Chapter 2

Chapter 9

or nose oil seals

M87-15, Alternator Ground Strap Alternator Replacement N/A N/A

M88-9, Lightning Strikes

Unscheduled

Inspections Chapter 7

Maintenance

M88-10, Contaminated Fuels

Unscheduled

Inspections Chapter 7

Maintenance

M89-9, Excessive Crankcase

Pressure

M90-13, Exhaust Valve Stem

Unscheduled

Inspections Chapter 7

Maintenance

Inspection and Overhaul N/A N/A

Corrosion/Erosion

M91-9, Cam and Lifter Lubrication

Overhaul N/A N/A

during Rebuild

SIL93-11A, New Service Document

Format

Service Documents

Service Document

Categories

Chapter 1

SIL93-14, CFC Compliance N/A N/A N/A

SIL93-15, General Practices for

Standard Practices Standard Practices Appendix C

Installation of Lock Wire, Tab

Washers, and Cotter Pins

SIL94-5, Mobil AV-1 Oil Authorized Lubricants Authorized Lubricants

Engine Oil Servicing

CSB95-4, Intake Valve Guide Seal

N/A N/A N/A

Chapter 2

Chapter 9

Inspection

SB95-2, Inspection and Maintenance

Inspection Scheduled Inspections Chapter 7

of Engine Control Cables and

Linkage

SB95-3B, Alternator/Generator Drive

Inspection Inspection Chapter 7

Couplings

SB95-7, Manifold Valve Cover

Inspection Inspection Chapter 7

Inspection

IOF-240 Series Engine Maintenance Manual iii

29 November 2006

Teledyne Continental Motors, Inc.

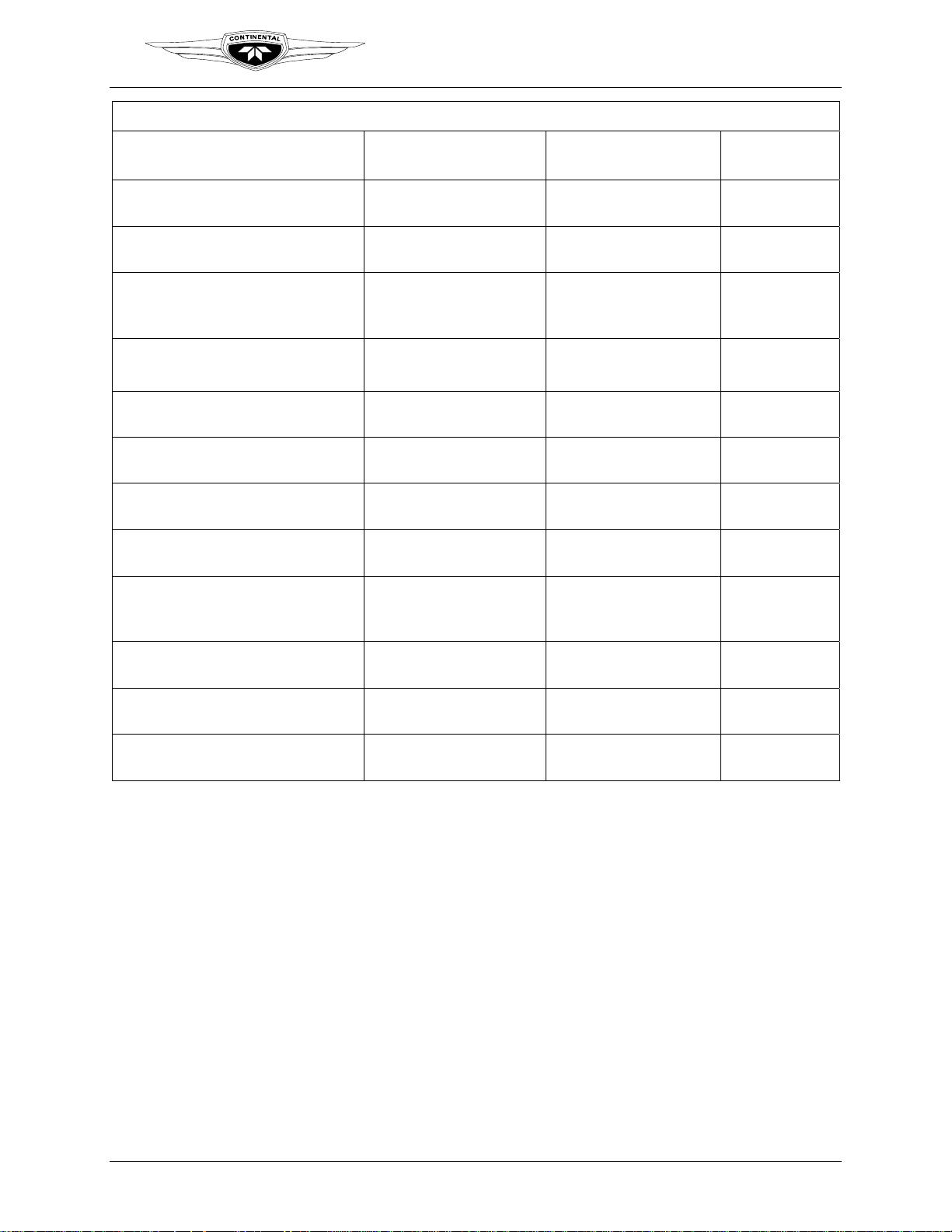

Service Documents Incorporated in this Manual

Service Document Subject Section Affected

Chapter

TM

SIL95-5, Hose and Tubing Installation

Hose and tubing

Standard Practices Appendix C

installation

CSB96-1, Starter Gear and Clutch

N/A N/A N/A

Assembly, P/N 653575

SB96-7C, Torque Limits Specific torque values Torque Values Appendix B

SB96-11A, Propeller Strikes and

Hydraulic Lock

SB96-12, Continued Airworthiness for

TCM Cylinders

Inspections Propeller Strikes

Chapter 7

Hydraulic Lock

Inspections

Visual Inspection,

Chapter 7

Compression Check,

Leak Check,

SIL97-1, “Airworthiness Limitations Airworthiness Limitations Airworthiness Limitations Chapter 3

SID97-2B, TCM Cylinder Warranties N/A N/A N/A

SID97-4C, Cylinder Bore and Piston

Fit Specifications

M97-6, Mandatory Replacement

Service Limits

Inspection and Repair Various Throughout

Cylinder Removal and

Replacement

Chapter 10

Parts

CSB97-10A, Piston Pin Plug Wear Service Limits

Cylinder Removal and

Chapter 10

Replacement

CSB98-1B, Intake and Exhaust Valve

Inspection

Service Limits

Cylinder Removal and

Replacement

Chapter 10

SIL98-6B, Fuel Injection System

N/A N/A N/A

Application Guide

SIL98-9A, Time Between Overhaul

Periods

SIL99-1, Engine Preservation for

Active and Stored Aircraft

Engine Specifications,

Scheduled Maintenance

Engine preservation and

returning an engine to

Overhaul Periods Chapter 2

Chapter 7

Placing an Engine in

Chapter 10

Service After Storage

service after storage

SIL99-2B, Current Listing of

Sealants, Lubricants and Adhesives

Materials

Engine Operation in

Extreme Cold

Chapter 2

Chapter 6

Authorized by TCM

Chapter 7

Chapter 10

SB99-8, Engine Fuel Injection

System Preservation

SB00-4A, Australian AVGAS

Contamination

Fuel Injection system

Engine Installation Chapter 5

storage

Inspection and Operation Inspection Requirements Chapter 2

Chapter 7

SB00-10, Fuel Pump Seal Fuel Pump Installation Fuel Pump Installation Chapter 10

SIL00-7A, Oil Gauge Rod Application

Inspection and Oil

Engine Oil Servicing Chapter 9

Servicing

SIL00-9A, Engine Data Plates N/A N/A N/A

iv IOF-240 Series Engine Maintenance Manual

29 November 2006

TM

Teledyne Continental Motors, Inc.

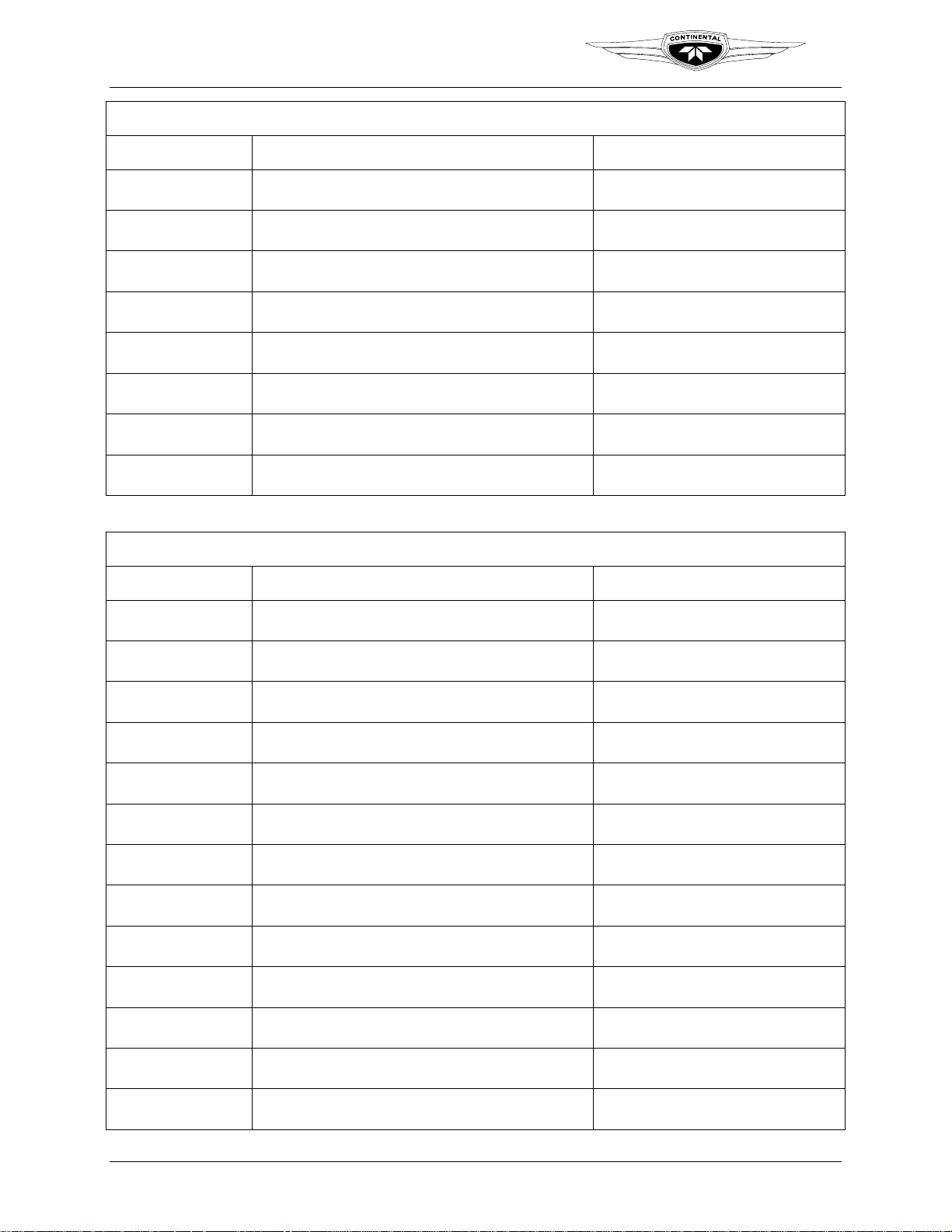

Service Documents Incorporated in this Manual

Service Document Subject Section Affected

Chapter

SIL00-11B, Release of new Cylinder

Induction Port Drain Connector

SIL02-6A, Production Release of

optional intake and exhaust valves

SIL03-1, Cold Weather Operation –

Engine Preheating

SIL03-2, Currently Active Approved

Spark Plug Application

SIL03-3, Differential Pressure Test

and Borescope Inspection

SB04-4A, Manifold Valve Spring

Replacement

SB04-11, Valve Guide Application,

Installation and Reaming

SIL04-2, Cylinder Barrel Ultrasonic

Inspection

SIL04-12, TCM Authorized Engine

Adjustments, Component

Replacement and Repositioning

Cylinder Assembly Cylinder Assembly Chapter 10

N/A N/A N/A

Preheating procedures

Spark plugs

Inspection Criteria Inspection Chapter 7

N/A N/A N/A

N/A N/A N/A

N/A N/A N/A

Engine Specification

Engine Operation in

Extreme Cold and

subsections

Engine Specifications

and Operating Limits

Engine Specifications

and Operating Limits

Chapter 7

Chapter 2

Chapter 9

Chapter 2

SB05-2, Overspeed Limitations

SIL05-3, Engine Specification

Numbers

SIL06-4, FADEC Health Status

Annunciator Indications

Unscheduled

Maintenance

Engine Specification Engine Designation Chapter 2

Engine Operating

Characteristics

Inspections Chapter 7

N/A N/A

Service Bulletins Released After Publication

TCM strives to provide clear, concise, and accurate information and instructions based on best

known engineering data at the time of publication. Ongoing process improvements at TCM may

change a specification or procedure after a manual is released. Service Documents, defined in

Chapter 1, expedite customer notification and serve as the prevailing instruction over conflicting

information until the new information is incorporated in the manual text. Such bulletins are part

of TCM’s Instructions for Continued Airworthiness. As bulletins are received, note the bulletin

number, title, and applicable section affected by the bulletin in the blank cells below and insert a

copy of the Service Bulletin behind the last page of this section.

The following bulletins, released after this manual, affect and supplement the procedures herein.

When performing procedures affected by the bulletins, review the bulletin content prior to

commencing the task to ensure completion using the most current information and methods.

TCM recommends placing a note at the beginning of the affected section in the manual as a

reminder to review the service document.

IOF-240 Series Engine Maintenance Manual v

29 November 2006

TM

Mandatory and Critical Service Bulletins Published After this Manual

Document Number Title Affected Section(s) in this Manual

Teledyne Continental Motors, Inc.

Other Service Documents Published After This Manual

Document Number Title Affected Section(s) in this Manual

vi IOF-240 Series Engine Maintenance Manual

29 November 2006

TM

Teledyne Continental Motors, Inc.

PREFACE

Teledyne Continental Motors (TCM) provides Instructions for Continued Airworthiness based

on the design, testing, and certification of engines and parts for which TCM is the holder of the

Type Certificate (TC) or Parts Manufacturing Approval (PMA) issued by the Federal Aviation

Administration (FAA). Instructions in TCM manuals, which include maintenance, repair limits,

overhaul, and installation, are applicable only to engines and parts supplied by TCM.

This manual, the Installation and Operation manual and the Overhaul Manual, applicable service

documents, and other related publications constitute the Instructions for Continued

Airworthiness (ICAs) prepared by TCM and approved by the FAA. Pursuant to Federal Aviation

Regulation (FAR) § 43.13, each person performing maintenance, alteration, or preventive

maintenance on the engine or accessories must use methods, techniques, and practices prescribed

in the ICAs.

Except for FAR part 43.3 authorized owner maintenance, TCM ICAs are written for

exclusive use by FAA (or equivalent authority) licensed mechanics or FAA (or equivalent

authority) certified repair center employees working under the supervision of an FAA

licensed mechanic. Information and instructions contained in this manual anticipate the

user possesses and applies the knowledge, training, and experience commensurate with the

requirements to meet the prerequisite FAA license and certification requirements. No other

use is authorized.

Installation of non-TCM parts on a TCM engine constitutes a deviation from TCM type-design

criteria. TCM has not participated in design, test, or certification of any non-TCM parts. TCM

does not provide product manufacturing specifications to aftermarket parts manufacturers and

accepts no liability for the suitability, durability, longevity, or safety of such parts installed on

TCM engines. Installation of non-TCM parts on a TCM engine must be performed using

Instructions for Continued Airworthiness prepared by the manufacturer and approved by the

FAA for the subject installation. TCM ICAs must not be used for such parts.

Service documents may contain general information or information specific to a group of

engines or be in effect for a limited time frame. Service Documents may also contain advance

changes to the ICAs. It is the responsibility of the organization/person maintaining or operating

the engine to verify that current and complete information, including Service Bulletins, FAA

Airworthiness Directives (ADs), and publications are used.

To facilitate the use of current data, TCM provides information via the Internet on TCMLINK.

The information available includes a listing of the latest manual versions, service bulletins, FAA

ADs, and other information applicable to the ICAs. This information is free of charge to owners

of TCM engines by registering as an Aviator Service Member.

The latest manuals are available through TCMLINK to Fixed Base Operators (FBOs) who are

TCM FBO Services subscribers. Information available through Aviator Services is also available

through FBO Services. Hardcopies and service subscriptions are available from TCM. Refer to

“Publication Access” listed in Chapter 1.

IOF-240 Series Engine Maintenance Manual vii

29 November 2006

TM

Teledyne Continental Motors, Inc.

CONTENTS

Chapter 1 - Introduction............................................................................................................... 1-1

Chapter 2 - Engine Description.................................................................................................... 2-1

Chapter 3 - Special Tools and Supplies ....................................................................................... 3-1

Chapter 4 - Airworthiness Limitations ........................................................................................4-1

Chapter 5 - Engine Removal and Installation.............................................................................. 5-1

Chapter 6 - Operational Performance Tests................................................................................. 6-1

Chapter 7 - Maintenance Inspections........................................................................................... 7-1

Chapter 8 - Troubleshooting ........................................................................................................8-1

Chapter 9 - Maintenance and Adjustments.................................................................................. 9-1

Chapter 10 - Non-Overhaul Repair and Replacement ............................................................... 10-1

Appendix A - Glossary ............................................................................................................... A-1

Appendix B - Torque Specifications........................................................................................... B-1

Appendix C - Standard Practices ................................................................................................ C-1

OVERHAUL MANUAL (OH-22)

Chapter 1 - Introduction............................................................................................................... 1-1

Chapter 2 - Engine Description.................................................................................................... 2-1

Chapter 3 - Special Tools and Supplies ....................................................................................... 3-1

Chapter 4 - Airworthiness Limitations ........................................................................................4-1

Chapter 5 - Engine Removal and Installation.............................................................................. 5-1

Chapter 6 - Engine Disassembly..................................................................................................6-1

Chapter 7 - Component Disassembly ..........................................................................................7-1

Chapter 8 - Engine Cleaning........................................................................................................ 8-1

Chapter 9 - Overhaul Inspection and Repair................................................................................ 9-1

Chapter 10 - Component Assembly........................................................................................... 10-1

Chapter 11 - Engine Assembly .................................................................................................. 11-1

Chapter 12 - Post-Overhaul Testing ..........................................................................................12-1

Appendix A - Glossary ............................................................................................................... A-1

Appendix B - Torque Specifications........................................................................................... B-1

Appendix C - Standard Practices ................................................................................................ C-1

viii IOF-240 Series Engine Maintenance Manual

29 November 2006

TM

Teledyne Continental Motors, Inc.

Introduction

Chapter 1. INTRODUCTION

CONTENTS

Chapter 1. Introduction.............................................................................................................1-1

1-1. Scope and Purpose of This Manual......................................................................................1-2

1-1.1. Advisories.................................................................................................................................................. 1-3

1-1.2. Using this Manual...................................................................................................................................... 1-3

1-1.3. Compliance................................................................................................................................................ 1-4

1-1.4. Order of Precedence..................................................................................................................................1-5

1-2. Publications ..........................................................................................................................1-6

1-2.1. Service Documents.................................................................................................................................... 1-6

1-2.2. Related Publications..................................................................................................................................1-7

1-2.3. Publication Access..................................................................................................................................... 1-8

1-2.4. Publication Changes..................................................................................................................................1-8

1-3. TCM Contact Information....................................................................................................1-9

LIST OF TABLES

Table 1-1. Related Publications...................................................................................................1-7

IOF-240 Series Engine Maintenance Manual 1-1

29 November 2006

Introduction

1-1. Scope and Purpose of This Manual

This manual provides instructions for installing and operating IOF-240 aircraft engines,

equipped with Full Authority Digital Engine Control (FADEC), manufactured by

Teledyne Continental Motors (TCM).

Instructions in this manual are specific to IOF-240 engines. For information specific to

other TCM engine series, accessories, or the airplane, refer to the appropriate manual.

Chapters are arranged in sequential order to install, test, and operate the engine.

This Maintenance Manual (M-22) is supplemented by the TCM Installation and

Operation Manual (OI-22) and Overhaul Manual (OH-22). Procedures in the OI-22

provide instructions for installing a new TCM engine in an airframe at a Fixed-Base

Operator location. The OI-22 supplements the Pilot’s Operating Handbook with enginespecific technical information and instructions.

This manual, along with the overhaul manual provides complete maintenance and

overhaul information for the engine series. This manual provides general maintenance

information including maintenance schedules, inspection and service requirements,

troubleshooting and repair procedures. The overhaul manual provides detailed engine

overhaul instructions to return the engine to like-new specifications.

The maintenance section begins with administrative instructions regarding access to

TCM publications and a list of other manuals that will enable the mechanic to perform

the procedures required to maintain the engine’s airworthiness. Chapter 2 contains a

detailed engine description including engine specifications and operating limits. Chapter

3 lists special tool and supply requirements as well as vendor contact information.

Chapter 4 contains FAA airworthiness limitations. Chapter 5 provides engine removal

and installation instructions. Chapter 6 contains instructions to verify the engines

serviceability after maintenance or overhaul. Chapter 7 provides maintenance and

inspection scheduling as well as unscheduled maintenance and the associated procedures

to accomplish those tasks. Chapter 8 contains troubleshooting procedures and suggested

corrective actions. Chapter 9 contains maintenance and adjustment procedures. Chapter

10 contains non-overhaul repair and replacement procedures, referred to as “heavy

repair.”

The overhaul manual is arranged in the sequential order of tasks required to complete the

overhaul process. Overhaul instructions include disassembly, cleaning and inspection

requirements to determine which parts are suitable for overhaul. Overhaul instructions

also include required replacement items and detailed part refurbishing procedures.

Finally, instructions are provided for detailed engine assembly and post overhaul testing.

Appendix A in this manual provides acronym definitions and a glossary of common

terms used in the manual. Appendix B lists fastener torque specifications; Appendix C

contains procedures and illustrations for standard practices.

TM

Teledyne Continental Motors, Inc.

1-2 IOF-240 Series Engine Maintenance Manual

29 November 2006

TM

Teledyne Continental Motors, Inc.

1-1.1. Advisories

This manual utilizes three types of advisories; defined as follows:

A warning emphasizes information which, if disregarded,

could result in severe injury to personnel or equipment failure.

CAUTION: Emphasizes certain information or instructions, which if

disregarded, may result in damage to the engine or accessories.

NOTE: Provides special interest information, which may facilitate

performance of a procedure or operation of equipment.

Warnings and cautions precede the steps to which they apply; notes are placed in the

manner which provides the greatest clarity. Warnings, cautions and notes do not impose

undue restrictions. Failure to heed advisories will likely result in the undesirable or

unsafe conditions the advisory was intended to prevent. Advisories are inserted to ensure

maximum safety, efficiency, and performance. Abuse, misuse, or neglect of equipment

can cause eventual engine malfunction or failure.

Introduction

WARNING

1-1.2. Using this Manual

This manual, the Installation and Operation Manual, applicable service documents, and

other related publications constitute the Instructions for Continued Airworthiness (ICAs)

prepared by TCM and approved by the FAA. TCM prepared this manual in a userfriendly format suited equally for electronic viewing and print. Figures in this manual are

for reference only, depicting the most prominent configuration in the engine series.

Consult the parts catalogs for an illustrated parts breakdown of your specific engine and

each subsystem.

Teledyne Continental Motors (TCM) provides Instructions for Continued Airworthiness

based on the design, testing, and certification of engines and parts for which TCM is the

holder of the Type Certificate (TC) or Parts Manufacturing Approval (PMA) issued by

the Federal Aviation Administration (FAA).

Instructions in TCM manuals are applicable only to engines

and parts supplied by TCM. TCM ICAs should not be used for

non-TCM parts.

Installation of non-TCM parts on a TCM engine constitutes a deviation from TCM typedesign criteria. TCM has not participated in design, test or certification of any non-TCM

parts. TCM does not provide product manufacturing specifications to aftermarket parts

manufacturers and accepts no liability for the suitability, durability, longevity, or safety

of such parts installed on TCM engines. Installation of non-TCM parts on a TCM engine

must be performed using Instructions for Continued Airworthiness prepared by the

manufacturer and approved by the FAA for the subject installation.

WARNING

IOF-240 Series Engine Maintenance Manual 1-3

29 November 2006

Introduction

Teledyne Continental Motors, Inc.

1-1.3. Compliance

The owner/operator and designated mechanic are responsible for ensuring the engine is

maintained in an airworthy condition, including compliance with applicable service

documents and FAA Airworthiness Directives. Engine service life is calculated based on

compliance with the aircraft and engine manufacturer’s required instructions, inspections

and maintenance schedule. Failure to comply may void the engine warranty.

Prior to authorizing engine installation or maintenance, the

owner must ensure the mechanic meets the requirements of

FAR 65 and must follow FAR parts 43, 91 and 145 as

applicable.

Except for FAR part 43.3 authorized owner maintenance, TCM ICAs are written for

exclusive use by FAA (or equivalent authority) licensed mechanics or FAA (or

equivalent authority) certified repair center employees working under the supervision of

an FAA licensed mechanic. Information and instructions contained in this manual

anticipate the user possesses and applies the knowledge, training and experience

commensurate with the requirements to meet the prerequisite FAA license and

certification requirements. No other use is authorized.

TM

WARNING

WARNING

Failure to comply with ICAs may result in injury or

subsequent engine failure. Pursuant to Federal Aviation

Regulation (FAR) § 43.13, each person performing

maintenance, alteration or preventive maintenance on an

engine or accessory must use methods, techniques and

practices set forth in the Instructions for Continued

Airworthiness or other methods, Techniques, and practices

acceptable to the Administrator.

This manual must be used in conjunction with FAA Advisory Circular 43.13-1B

“Acceptable Methods, Techniques and Practices” as well as Teledyne Continental Motors

Maintenance and Overhaul Manual, service documents, related publications and

accessory manufacturer’s instructions. Pursuant to Federal Aviation Regulation (FAR)

§43.13, each person performing maintenance, alteration or preventive maintenance on the

engine or accessories must use methods, techniques and practices prescribed in the ICAs

or other methods, techniques, and practices approved by the Administrator.

1-4 IOF-240 Series Engine Maintenance Manual

Change 1 31 August 2007

TM

Teledyne Continental Motors, Inc.

1-1.4. Order of Precedence

Teledyne Continental Motors (TCM) engine operating instructions are generated prior to

and independently of the aircraft operating instructions. TCM operating instructions are

developed using factory controlled parameters that are not necessarily the same as those

specifications required to satisfy a specific aircraft/engine installation.

The aircraft operator must use the airframe manufacturer’s

operating instructions found in the Airplane Flight Manual

/Pilot’s Operating Handbook/ (AFM/POH) while operating the

aircraft unless the AFM/POH directs otherwise.

Refer to the AFM/POH published by the airframe manufacturer for operating instructions

and specifications relative to your aircraft.

New or updated Instructions for Continued Airworthiness may

be contained in TCM Service Documents. Service Documents

applicable to the engine or accessories within the scope of this

manual must be consulted and complied with prior to

performing any installation, maintenance, or overhaul

function.

Introduction

WARNING

WARNING

New information contained in service documents may override the instructions contained

in this manual. Prior to commencing engine maintenance, consult TCMLINK to verify

the current status of the ICAs relating to the intended procedure.

IOF-240 Series Engine Maintenance Manual 1-5

29 November 2006

Introduction

1-2. Publications

1-2.1. Service Documents

Six categories of Service Documents may be issued by TCM ranging from mandatory

(Category 1) to informational (Category 6). Definitions of the categories are listed below:

NOTE: Upon FAA approval, all TCM service documents are

published and available on TCMLINK. Service Documents which

contain updates to the Instructions for Continued Airworthiness

must be inserted in the affected manual until such time the manual

is revised to include the Service Document instructions or the

Service Document is cancelled or superseded. Affected manuals

will be referenced in all Service Documents containing updates to

the manufacturer’s Instructions for Continued Airworthiness.

Procedure

Category 1: Mandatory Service Bulletin (MSB)

Used to identify and correct a known or suspected safety hazard which has been

incorporated in whole or in part into an Airworthiness Directive (AD) issued by the FAA

or have been issued at the direction of the FAA by the manufacturer requiring compliance

with an already-issued AD (or an equivalent issued by another country’s airworthiness

authority). May contain updates to TCM’s Instructions for Continued Airworthiness to

address a safety issue.

Category 2: Critical Service Bulletin (CSB)

This category identifies a condition that threatens continued safe operation of an aircraft,

persons or property on the ground unless some specific action (inspection, repair,

replacement, etc.) is taken by the owner or operator. Documents in this category are

candidates for incorporation into an FAA Airworthiness Directive. May contain updates

to TCM’s Instructions for Continued Airworthiness to address a safety issue.

Category 3: Service Bulletin (SB)

Information which the product manufacturer believes may improve the inherent safety of

an aircraft or aircraft component; this category includes the most recent updates to

Instructions for Continued Airworthiness.

Category 4: Service Information Directive (SID)

The manufacturer directs the owner/operator/mechanic in the use of a product to enhance

safety, maintenance or economy. May contain updates to TCM’s Instructions for

Continued Airworthiness in the form of maintenance procedures or specifications.

Category 5: Service Information Letter (SIL)

This category includes all information (not included in categories 1 through 4) that may

be useful to the owner/operator/technician. May contain updates to TCM’s Instructions

for Continued Airworthiness for optional component installations, which are not covered

in the Applicable Operator, Maintenance, or Overhaul Manuals.

TM

Teledyne Continental Motors, Inc.

1-6 IOF-240 Series Engine Maintenance Manual

29 November 2006

Teledyne Continental Motors, Inc.

TM

Category 6: Special Service Instruction (SSI)

This category is used to address an issue limited to specific model and/or serial number

engines. TCM will distribute SSI notification directly to the affected engine’s owners.

SSIs will not be included in the general service document set but will be made available

through TCM Customer Service to owners of the affected engines only. An SSI may

contain updates to the Instructions for Continued Airworthiness applicable to the listed

engines.

1-2.2. Related Publications

The chart below lists related publications, source, and accessibility relevant to installing,

maintaining, and overhauling the IOF-240 series engines.

Use only the latest revision of all publications. Using

superseded information jeopardize engine airworthiness.

Introduction

WARNING

Table 1-1. Related Publications

Supplied

With

Publication

TCM Publications

Installation and Operation Manual (OI-22) Yes Yes Yes N/A

Overhaul Manual (OH-22) No Yes Yes N/A

Parts Catalogues No Yes No N/A

Detailed Model Specifications No No Yes N/A

Service Documents No Yes Yes N/A

Material Handling Specifications (MHS) No No Yes N/A

Supplier Bulletins

FAA Airworthiness Directives No Yes No N/A

Accelagold No Reference No Yes

Emhart Fastening Teknologies No Reference No Yes

Accessory Documents

Aerosance Engine Data Interface, EDI-100/200 Manual

(AM14164)

Kelly Aerospace Power Systems Alternator Overhaul

Manual (OE-A2)

Kelly Aerospace Power Systems Lightweig ht Series

Alternator Overhaul Manual (ES1010-1/2)

*TCMLINK Information Services® provides 24-hour-a-day access via the Internet. If you are a TCMLINK

subscriber, you can access TCMLINK to confirm and review the latest revision of this manual. If you have not

subscribed to TCMLINK through TCM and are using hardcopies, contact TCM (see Section

Information

”) to confirm that you have the latest revision of the manual.

Engine

No Reference No Yes

No Reference No Yes

No Reference No Yes

Internet

via

TCMLINK*

Order

From

TCM

1-3, “TCM Contact

Available

From

Manufacturer

IOF-240 Series Engine Maintenance Manual 1-7

31 August 2007 Change 1

Introduction

Teledyne Continental Motors, Inc.

1-2.3. Publication Access

TCMLINK Alpha Services, Information Services, Aviator Services, and FBO Services

programs provide an array of benefits including access to electronic versions of TCM

technical publications (manuals, service documents, and parts catalogs) via the Internet.

Aviator Services and Alpha Services memberships are free to TCM engine owners. FBO

and Information Services are available with a paid subscription fee. Contact a TCM

distributor to discuss service subscription options and pricing or visit our website

(Section

1-3, “TCM Contact Information”).

Printed TCM publications may be ordered through Teledyne Continental Motors

authorized distributors or via the Internet at TCMLINK. Your TCM printed document

purchase includes three years of updates at no extra charge. Use ““

Information

” in Section 1-3, or our Internet website.

1-2.4. Publication Changes

The instructions in this manual represent the best and most complete information

available at the time of publication. Product or process improvements may trigger

changes to existing product design specifications or procedures contained in publications.

As new technical information becomes available, TCM will deliver the updated

information to the customer in the most expedient manner.

TM

TCM Contact

New information may be contained in Teledyne Continental

Motors service documents. Service documents applicable to

engines and accessories within the scope of this manual must

be complied with as defined in these documents. This manual,

together with TCM’s Installation and Operation Manual (OI-

22), Service Documents, and other related publications noted

constitute the Instructions for Continued Airworthiness (ICAs)

prepared by Teledyne Continental Motors and approved by

the Federal Aviation Administration (FAA).

Teledyne Continental Motors releases publication changes in the form of either change

pages or complete publication revisions, depending upon the extent of change. Service

Documents may supplement or replace technical information contained in one

publication or an entire series of publications. Such Service Documents represent a

change to the published ICA until the individual publications incorporate the latest

technical information.

1-2.4.1. Update/Change Distribution

Updates are available via TCMLINK upon notification of FAA document approval. TCM

notifies engine owners of technical publication changes free of charge. TCM notifies

current TCMLINK service subscribers by mail as publications are updated. Current

subscribers receive a complete publication library on CD delivered quarterly. Printed

publication subscribers receive printed changes and revisions as they are released.

WARNING

1-8 IOF-240 Series Engine Maintenance Manual

Change 1 31 August 2007

Teledyne Continental Motors, Inc.

TM

Introduction

1-2.4.2. Suggestions and Corrections

Teledyne Continental Motors solicits and encourages user comments regarding suggested

changes to this manual. Direct recommended changes or questions to the attention of

“Publications” at the TCM address listed in Section 1-3, “TCM Contact Information.”

Notify TCM Customer Service immediately, using our toll-free number, if you discover

incorrect information which adversely affects safety.

1-3. TCM Contact Information

Teledyne Continental Motors is available to answer technical questions and encourages

suggestions regarding products, parts, or service. If customers have an inquiry or require

technical assistance, they should contact their local TCM distributor or TCM field

representative. To contact TCM, refer to the contact information below:

Teledyne Continental Motors, Inc.

P. O. Box 90

Mobile, AL 36601

Toll Free Customer Service Phone Numbers: 888-826-5465

Internet Address: http://www.tcmlink.com

IOF-240 Series Engine Maintenance Manual 1-9

31 August 2007 Change 1

Introduction

TM

Teledyne Continental Motors, Inc.

This Page Intentionally Left Blank

1-10 IOF-240 Series Engine Maintenance Manual

29 November 2006

Teledyne Continental Motors, Inc.

TM

Engine Description

Chapter 2. ENGINE DESCRIPTION

CONTENTS

Chapter 2. Engine Description..................................................................................................2-1

2-1. General Engine Description..................................................................................................2-3

2-1.1. Engine Model Number Definition............................................................................................................. 2-4

2-1.2. Cylinder Number Designations ................................................................................................................. 2-4

2-2. Detailed Engine Description.................................................................................................2-5

2-2.1. Crankcase .................................................................................................................................................. 2-5

2-2.2. Engine Drive Train.................................................................................................................................... 2-6

2-2.3. Accessory Case.......................................................................................................................................... 2-8

2-2.4. Cylinders..................................................................................................................................................2-10

2-2.5. Lubrication System.................................................................................................................................. 2-12

2-2.6. Ignition System ........................................................................................................................................ 2-14

2-2.7. Fuel System............................................................................................................................................. 2-15

2-2.8. Starter Assembly......................................................................................................................................2-18

2-2.9. Alternator................................................................................................................................................. 2-19

2-2.10. Engine Cooling...................................................................................................................................... 2-19

2-2.11. Induction System................................................................................................................................... 2-20

2-3. Engine Specifications and Operating Limits......................................................................2-21

2-3.1. Accessory Drive Ratios........................................................................................................................... 2-23

2-3.2. Oil Specifications.................................................................................................................................... 2-23

2-3.3. Performance Data.................................................................................................................................... 2-24

LIST OF TABLES

Table 2-1. IOF-240-B Specifications and Operating Limits .....................................................2-21

Table 2-2. Accessory Drive Ratios, Rotation, Speed, Torque & Moments...............................2-23

Table 2-3. Engine Oil Type Requirements................................................................................2-23

IOF-240 Series Engine Maintenance Manual 2-1

31 August 2007 Change 1

Teledyne Continental Motors, Inc.

TM

Engine Description

LIST OF FIGURES

Figure 2-1. Engine Model Identifier............................................................................................2-4

Figure 2-2. Cylinder Number Designation ..................................................................................2-4

Figure 2-3. IOF-240 Crankcase ...................................................................................................2-5

Figure 2-4. Engine Drive Train....................................................................................................2-6

Figure 2-5. Crankshaft.................................................................................................................2-6

Figure 2-6. Camshaft ...................................................................................................................2-7

Figure 2-7. Camshaft Gear...........................................................................................................2-8

Figure 2-8. Accessory Case .........................................................................................................2-9

Figure 2-9. Cylinder Assembly..................................................................................................2-10

Figure 2-10. Lubrication Schematic ..........................................................................................2-12

Figure 2-11. Oil Pump ...............................................................................................................2-13

Figure 2-12. Oil Cooler Adapter................................................................................................2-14

Figure 2-13. Fuel Injection System............................................................................................2-15

Figure 2-14. Fuel Pump .............................................................................................................2-16

Figure 2-15. Fuel Injector Nozzle..............................................................................................2-17

Figure 2-16. Starting System .....................................................................................................2-18

Figure 2-17. Engine Cooling Airflow........................................................................................2-19

Figure 2-18. Typical Crossflow Induction Airflow...................................................................2-20

Figure 2-19. IOF-240-B Fuel Flow vs. Brake Horsepower.......................................................2-25

Figure 2-20. IOF-240-B Sea Level Performance.......................................................................2-26

2-2 IOF-240 Series Engine Maintenance Manual

Change 1 31 August 2007

Teledyne Continental Motors, Inc.

TM

Engine Description

2-1. General Engine Description

The IOF-240 engines are four-cylinder, four-stroke reciprocating aircraft engines

designed for fixed pitch, ground adjustable, or electric constant speed propellers. There is

no provision for a hydraulic propeller governor.

These horizontally-opposed, air-cooled, naturally-aspirated engines have a wet oil sump,

high pressure Lubrication System, an overhead plenum intake manifold, a side-mounted

accessory drive pad and provisions for a downdraft exhaust system.

The engines are equipped with a Full Authority Digital Engine Control (FADEC) System

for continuously monitoring and controlling ignition timing, fuel injection timing, and

fuel mixture. The microprocessor-based FADEC System monitors engine operating

conditions and then automatically sets the fuel mixture and ignition timing accordingly

for any given power setting. Consequently, FADEC engines do not require magnetos and

eliminate the need for manual fuel/air mixture control. There is no fuel mixture control

lever in a FADEC engine.

A FADEC-controlled engine differs from a non-FADEC engine in that a cylinder can be

leaned or enriched individually without affecting the other cylinders. The FADEC

System controls the fuel supplied to each cylinder using solenoid-actuated sequential port

fuel injectors. An engine-driven, positive displacement vane fuel pump supplies fuel as

required to the injectors. The fuel pump is directly driven at the same speed as the

crankshaft. Therefore, fuel flow and fuel pressure vary directly with engine speed. Fuel

exits the pump, passes through a 32-micron fuel filter situated between the engine-driven

fuel pump and the fuel distribution block, where it filters particulates larger than 10microns. From this point, fuel travels to each fuel injector.

Since the fuel system requires fuel with minimum vapor to operate normally, an electric

boost pump is required for starting the engine and during low RPM operation. Ignition

spark is timed to the engine’s crank position. The timing is variable from cranking speed

up to 2,000 RPM depending on engine load conditions. The spark energy varies with

respect to engine load.

The FADEC System is electrically powered by the aircraft’s primary electrical bus and a

secondary power source (SPS); it is not self-excited. The SPS may be an alternator or

battery. It is used to supply power to the FADEC System independently from the

aircraft’s primary bus. If the SPS is a battery, it will be constantly charged by the

aircraft’s primary power bus. The charging current supplied to the SPS battery is

monitored by the Health Status Annunciator (HSA) and the charging circuit is protected

by a circuit breaker.

Electrical power to the FADEC System is controlled from the cockpit by two switches

used to interrupt the primary power and secondary power. The pilot starts, enables, and

stops the FADEC System using a conventional aircraft-style Ignition Switch.

IOF-240 Series Engine Maintenance Manual 2-3

31 August 2007 Change 1

Engine Description

Teledyne Continental Motors, Inc.

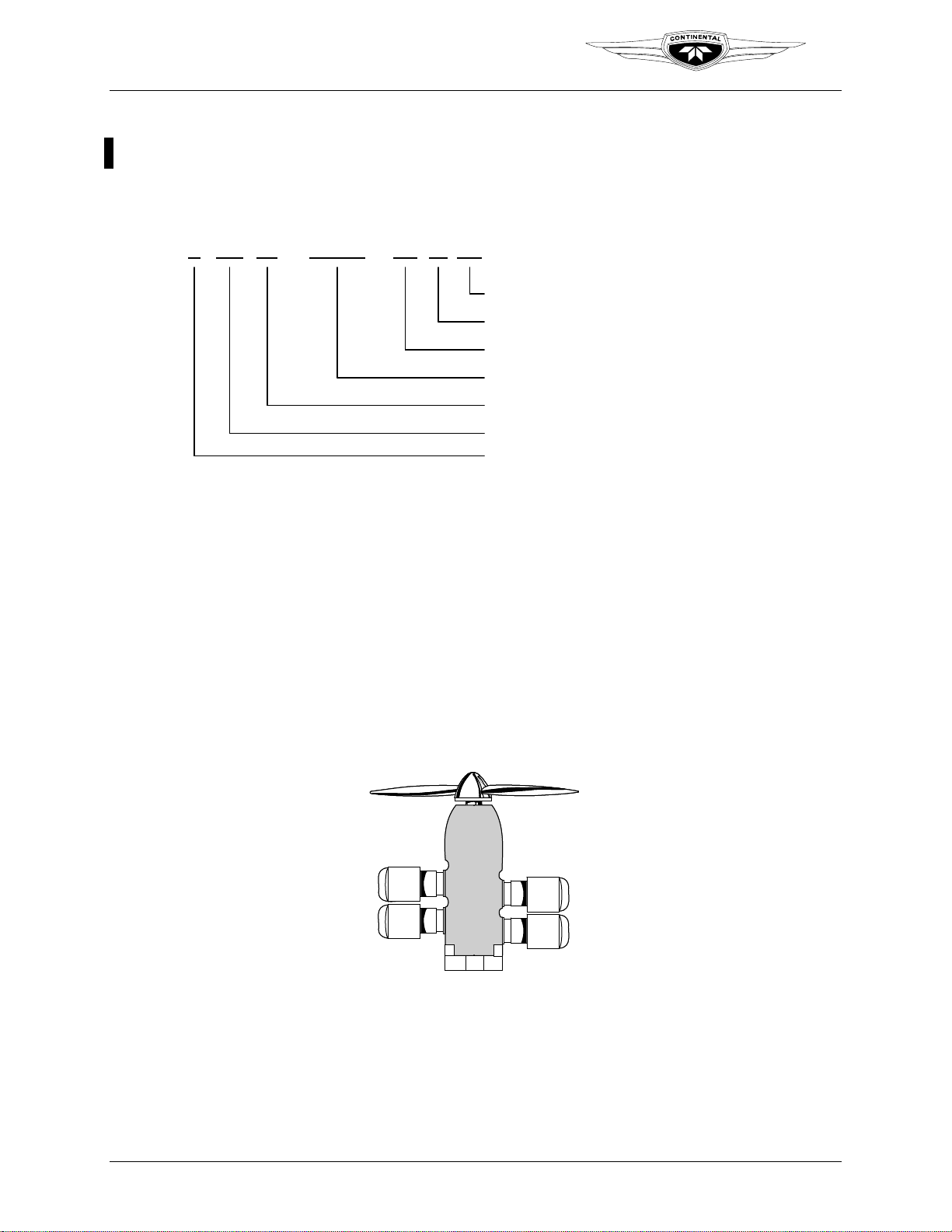

2-1.1. Engine Model Number Definition

The description of each alphanumeric character in the engine model number is given

below for the example engine model number IOF-240-B1B (Figure 2-1).

TM

I O F-240-B 1

I O F-240-B 1

Figure 2-1. Engine Model Identifier

2-1.2. Cylinder Number Designations

Refer to Figure 2-2:

• The front of the engine is the end closest to the propeller and the rear of the engine

is the accessory end

• Viewed from the rear of the engine, the left-side cylinders are designated by even

numbers 2-4, with Cylinder 2 being closest to the rear.

• The right side cylinders have odd number sequential designation 1-3, with Cylinder

1 being closest to the rear.

• Firing order of the engine is 1-3-2-4.

B

B

Shipping Designation

Shipping Designation

Specification Number

Specification Number

Model Identifier

Model Identifier

Cubic Inch Displacement

Cubic Inch Displacement

FADEC-equipped

FADEC-equipped

Horizontally Opposed Cylinders

Horizontally Opposed Cylinders

Fuel Injected

Fuel Injected

2-4 IOF-240 Series Engine Maintenance Manual

Change 1 31 August 2007

4

4

2

2

Figure 2-2. Cylinder Number Designation

3

3

1

1

Teledyne Continental Motors, Inc.

TM

Engine Description

2-2. Detailed Engine Description

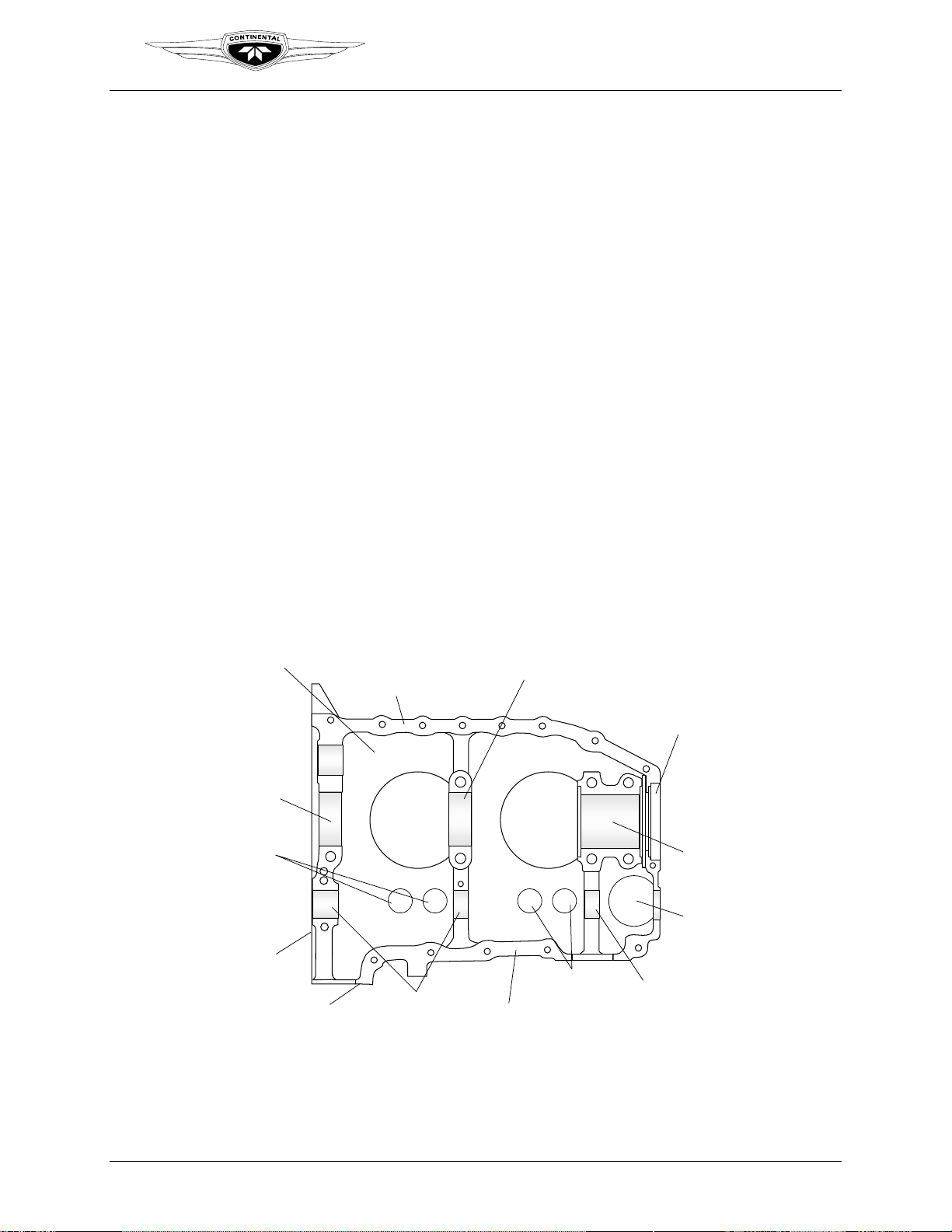

2-2.1. Crankcase

Two aluminum alloy castings are joined along the vertical center plane to form the

crankcase. The individual castings (with studs and inserts) are referred to as the "left

crankcase" and "right crankcase."

The crankcase provides:

• A tight enclosure, sufficiently rigid to provide support for the crankshaft, camshaft

and bearings.

• Oil galleries for lubrication.

Bosses molded in the crankcase castings are line bored in the assembled crankcase halves

to form bearings for the camshaft and saddles for precision crankshaft main bearing

inserts. Guides are bored through lateral bosses for hydraulic tappets. There are six studs

and two through-bolts for attaching cylinder base flanges. The fuel pump mounting pad is

located on the left crankcase half, forward of Cylinder 4.

Cylinder mounting pads on the left crankcase, beyond the corresponding pads on the right

crankcase, permit each connecting rod to work on a separate crankpin. The crankcase

interior is vented by a breather assembly comprised of a tube and baffle assembly with a

side extension for a hose attachment. The breather assembly is pressed into a boss on the

top side of the right crankcase half, forward of Cylinder 3.

2-4 OR L/H

CRANKCASE HALF

REAR CRANKSHFT

BEARING BORE

TAPPET

GUIDES

ACCESSORY CASE

MOUNT FLANGE

CRANKSHAFT BEARING BORE

BACKBONE

Cyl #2 Cyl #4

OIL SUMP

MOUNT FLANGE

CAMSHAFT

BEARING BORE

SPINE BELOW

CAMSHAFT

Figure 2-3. IOF-240 Crankcase

INTERMEDIATE

TAPPET

GUIDES

CRANKSHAFT NOSE

SEAL LAND

CRANKSHAFT

BEARING BORE

FUEL PUMP

CAMSHAFT

BEARING BORE

FRONT

ACCESS

IOF-240 Series Engine Maintenance Manual 2-5

31 August 2007 Change 1

Engine Description

Teledyne Continental Motors, Inc.

2-2.2. Engine Drive Train

The engine drive train consists of the crankshaft and camshaft.

Starter

Starter

Oil Pump

Oil Pump

Driven Gear

Driven Gear

Crankshaft

Crankshaft

Camshaft

Camshaft

Camshaft Gear

Camshaft Gear

Fuel pump and

Fuel pump and

vacuum pump

vacuum pump

drive shaft

drive shaft

TM

Alternator

Alternator

2-2.2.1. Crankshaft

The crankshaft (Figure 2-5) is made of aircraft quality steel and has three machined, main

journals which are supported by precision-bearing inserts in each of the three bearing

saddles machined in the crankcase. Four machined rod journals provide attachment of the

connecting rod assemblies. The crankshaft gear is indexed on the crankshaft by a dowel

and secured by machined bolts. A neoprene oil seal over the crankshaft flange is seated

between the crankcase castings in the front shaft exit area, and is sealed to the crankshaft

by a helical spring inside the seal's cavity.

CRANKSHAFT

FLANGE

Oil Pump Drive Gear

Oil Pump Drive Gear

Tachometer

Tachometer

Drive Shaft

Drive Shaft

Figure 2-4. Engine Drive Train

ROD JOURNAL

OIL

PASSAGE

#3

#2

OIL

PASSAGE

2-6 IOF-240 Series Engine Maintenance Manual

Change 1 31 August 2007

FRONT MAIN

JOURNAL

#4

ROD JOURNAL ROD JOURNAL

MIDDLE MAIN

JOURNAL

Figure 2-5. Crankshaft

#1

REAR MAIN

JOURNAL

Teledyne Continental Motors, Inc.

2-2.2.2. Connecting Rods

The connecting rods halves are machined from a single forging of aircraft quality steel

and cut into two pieces, splitting the center of the larger opening of the connecting rod

assembly. The resulting pieces, called the rod and cap are fitted with a two piece bearing

and attach to the crankpin or rod journal with special bolts and nuts.

The portion of the rod between the rod and the crankpin and piston pin ends is called the

“I” beam. A split steel-backed bronze bushing is pressed into the piston pin end and

machined for a precision pin-to-bushing fit. Weight variations between opposing

crankshaft positions is limited to ½ ounce (14.175 grams).

NOTE: Some older models use castellated nut with cotter pin

CONNECTING ROD

CAP

TM

CONNECTING ROD

Engine Description

BRONZE BUSHING

SPIRAL LOCK NUT

ROD BOLT

2-2.2.3. Camshaft

The camshaft forging is machined on three main journals, six cam lobes and the gear

mount flange at the rear of the camshaft. The lobes and journals are ground and hardened.

The main journals of the camshaft are supported in the crankcase by machined bearing

saddles. Hydraulic tappets move inward and outward in their bores, following the

eccentric shape of the cam lobes. Four unequally spaced bolts secure the gear to the

camshaft and ensure proper positioning, locating the gears’ timing mark in relation to the

cam lobes. The camshaft gear has internal teeth for driving the alternator. A frontmounted, keyed bevel gear drives the accessory drive bevel gear which drives the fuel

pump through a common shaft.

FRONT REAR

SHELL

BEARING

#4 EXH #3 EXH #2 EXH #1 EXH

#3 & 4

INTAKE

#1 & 2

INTAKE

M/J

IOF-240 Series Engine Maintenance Manual 2-7

31 August 2007 Change 1

C/L C/L C/L C/L C/L C/L

M/J M/J

M/J - MAIN JOURNAL

C/L - CAM LOBE

Figure 2-6. Camshaft

Teledyne Continental Motors, Inc.

TM

Engine Description

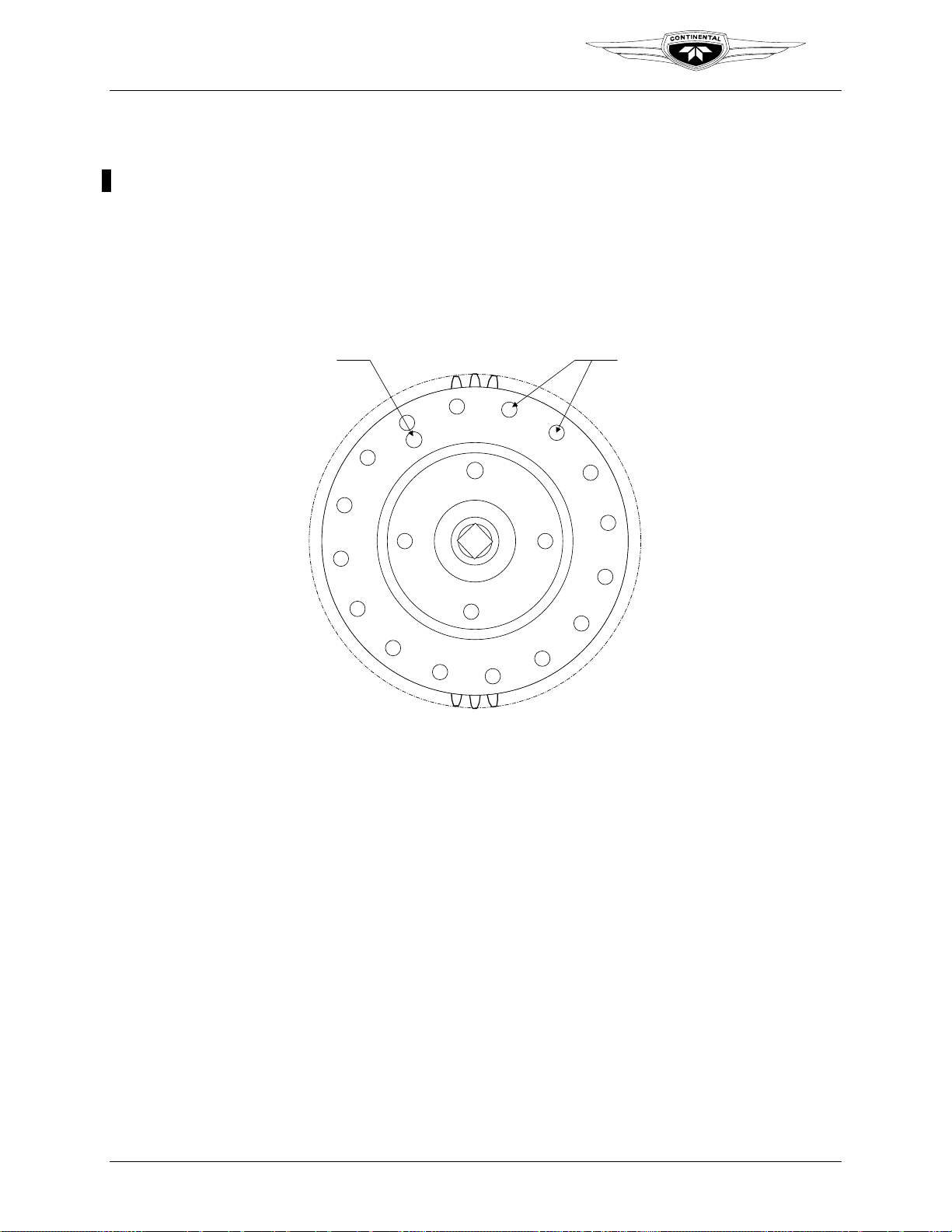

The camshaft gear (Figure 2-7) has 16 holes drilled in the outer track and one hole drilled in the

inner track. The speed pulse generated by the 16 hole-outer track is the Ne Pulse and the Nc

pulse is generated by the lone hole in top dead center inner track for Cylinder 1. As the camshaft

gear rotates, the holes in the gear are detected by the Speed Sensor Assembly (SSA).

The SSA consists of two pairs of sensors which detect steel density changes that occur when the

drilled holes in the camshaft gear pass by the sensor array. Detection of the open holes is sent as

a cam pulse signal to the FADEC Electronic Control Units (ECUs). The ECUs determine the

engine speed based on input from the SSA sensors signals which detect the speed pulses from the

camshaft gear outer track (Ne pulse) and the inner track (Nc pulse).

1 Nc Pulse

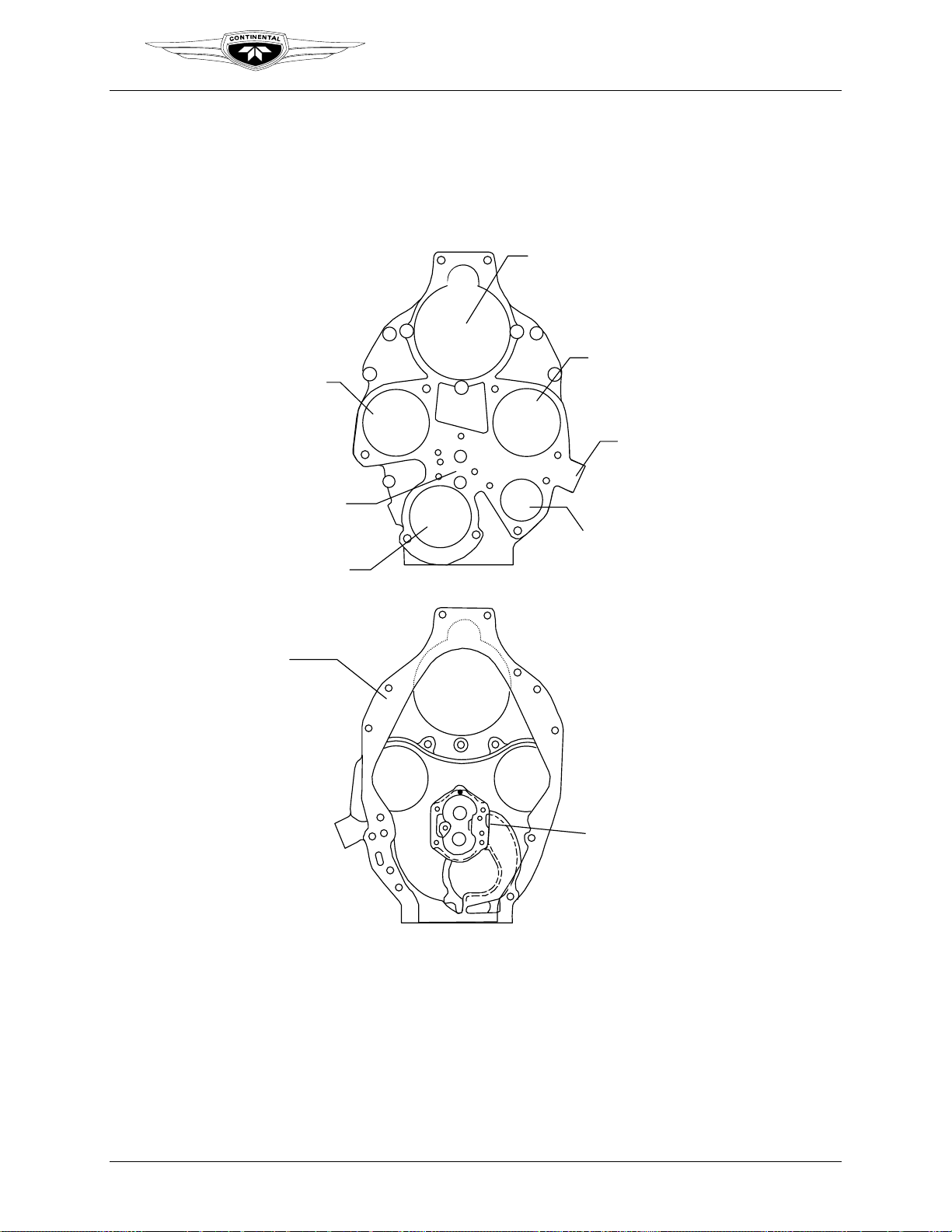

2-2.3. Accessory Case

The aluminum alloy casting of the accessory case is attached to the rear of the engine

crankcase, aligned with crankcase dowels; the accessory case is secured to the crankcase

by crankcase studs and various attaching hardware. Accessory mount pads on the rear

surface are machined in one plane parallel to the machined parting flange which

surrounds the front side of the casting. Mounting pads for the magnetos, alternator cover,

starter, tachometer drive, oil filter adapter, oil pressure relief valve and an oil suction

screen boss are provided. The accessory case casting has two holes above and three studs

to attach the starter and starter adapter. A mounting pad is provided for an oil screen

housing in lieu of the screw-on type oil filter.

The oil pump housing is machined into the internal portion of the accessory case. A

machined, threaded boss is located on the lower right side of the accessory case for

installation of a non-adjustable oil pressure relief valve. Oil pump gear chambers are

machined in the interior of the accessory case. The oil pump drive gear shaft hole is

machined in-line with the camshaft and the driven gear shaft hole is directly above it.

16 Ne Pulses

Figure 2-7. Camshaft Gear

2-8 IOF-240 Series Engine Maintenance Manual

Change 1 31 August 2007

Teledyne Continental Motors, Inc.

TM

Engine Description

A semicircular opening at the accessory case bottom is a machined threaded hole to

accommodate installation of the oil suction tube. Passages cast into the accessory case

allow oil to flow from the oil suction tube to the oil pump gears, pressure relief valve, and

main oil gallery. The tachometer drive shaft is the slotted end of the oil pump driven gear

shaft.

STARTER MOUNTING

STARTER MOUNTING

PAD

PAD

MAGNETO MOUNTING

MAGNETO MOUNTING

PAD COVERED

PAD COVERED

SPEED

SPEED

SENSOR

SENSOR

PAD

PAD

OIL PRESSURE

OIL PRESSURE

RELIEF VALVE

RELIEF VALVE

HOUSING

HOUSING

TACH DRIVE

TACH DRIVE

MOUNTING

MOUNTING

PAD

PAD

OIL SCREEN

ALTERNATOR

ALTERNATOR

MOUNTING

MOUNTING

PAD

PAD

OIL SCREEN

HOUSING

HOUSING

MOUNTING

MOUNTING

PAD

PAD

INSIDE VIEW

INSIDE VIEW

ACCESSORY

ACCESSORY

OF

OF

CASE

CASE

Figure 2-8. Accessory Case

OIL PUMP

OIL PUMP

IOF-240 Series Engine Maintenance Manual 2-9

31 August 2007 Change 1

Engine Description

Teledyne Continental Motors, Inc.

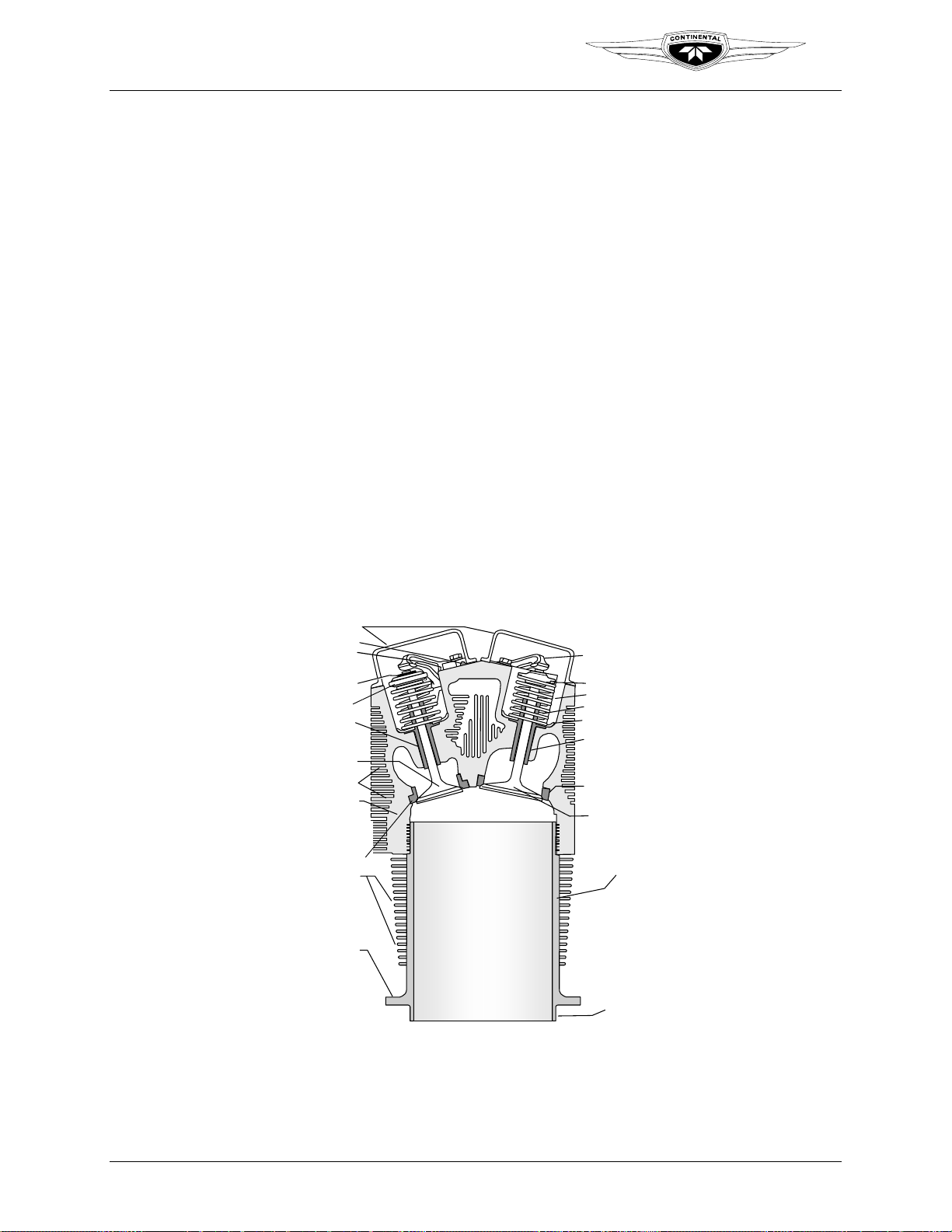

2-2.4. Cylinders

The IOF-240 engine has four, horizontally-opposed, air cooled cylinders, two on the left

side and two on the right side of the engine. The cylinders, pistons and valve drive train

provide the momentum to sustain crankshaft movement. Aviation fuel and air are drawn

into a cylinder during the intake stroke, compressed by the piston during the compression

stroke and then ignited by a high intensity spark from each spark plug (two per cylinder).

As the mixture is ignited, the expanding gases force the piston to move inward toward the

crankshaft during the power stroke.

The head and barrel assembly consists of externally finned aluminum alloy head casting

and a steel, nitrided cylinder barrel for wear resistance. Helical coil thread inserts are

installed in upper and lower spark plugs holes. A rotocoil assembly retains two concentric

springs surrounding the exhaust valve and is locked to the stem by tapered, semi-circular

keys which engage grooves around the valve stems. An outer retainer holds two

concentric springs which surround the intake valve and is locked to the stem by tapered,

semi-circular keys which engage grooves on the stem.

IOF-240 engines use a cross flow cylinder head design. The intake ports are located on

top of the cylinder head while the exhaust ports are located below. There are separate

intake and exhaust valve rocker covers made from zinc-plated stamped sheet steel. This

cylinder design is used in conjunction with a Balanced Induction System mounted above

the engine.

TM

ROCKER COVER

ROCKER SHAFT

THRUST WASHER

(ONE ON EACH SIDE

OF EACH ROCKER ARM)

VALVE RETAINER

KEYS

ROTOCOIL

EXHAUST

VALVE GUIDE

EXHAUST

VALVE

COOLING FINS

CYLINDER HEAD

EXHAUST

VALVE

SEAT

INSERT

CYLINDER BARREL

COOLING FINS

CYLINDER BASE

FLANGE

Figure 2-9. Cylinder Assembly

ROCKER ARM

RETAINER

OUTER SPRING

INNER SPRING

SPRING SEAT

INTAKE VALVE GUIDE

INTAKE VALVE

SEAT INSERT

INTAKE VALVE

CYLINDER BARREL

CYLINDER SKIRT

2-10 IOF-240 Series Engine Maintenance Manual

Change 1 31 August 2007

Teledyne Continental Motors, Inc.

2-2.4.1. Pistons

Pistons are aluminum alloy castings with a steel insert cast into the top ring groove. The

skirts are solid and have cylindrical relief cuts at the bottom. Pistons have three ring

grooves above the piston pin hole and one ring groove below. Compression rings are

installed in the top and second grooves. The groove below the pin hole contains an oil

scraper. A center grooved and slotted oil control ring is installed in the third groove

which has six oil drain holes to the interior. Weight differences are limited to ½ ounce

between opposing cylinders bays. Piston pins are full floating with permanently pressedin aluminum end plugs.

TM

Engine Description

MANGANESE PHOSPHATE COATING

PISTON PIN

GRAPHITE COATED SKIRT

2-2.4.2. Hydraulic Valve Tappets

The hydraulic lifter performs two functions. First, it provides an interface between the

camshaft lobe and the remaining valve train. Hydraulic valve lifters ride on the eccentric

cam lobes opening and closing the intake and exhaust valves mechanically via push rod

tubes and rocker arms. This allows conversion of the cam lobe profile into a linear

movement for actuation of the intake and exhaust valves. Secondly, the hydraulic

mechanism inside the lifter maintains zero clearance between the valve and its actuating

components.

The interface between a cam lobe and lifter is intended to wear to some degree as the

engine operates. This is similar to the piston ring / cylinder wall interface that must seat

together for proper operation and wear over time.

ST

COMPRESSION

1

RING

ND

2

COMPRESSION

RING

OIL CONTROL

RING

OIL SCRAPER

RING

IOF-240 Series Engine Maintenance Manual 2-11

31 August 2007 Change 1

Engine Description

Teledyne Continental Motors, Inc.

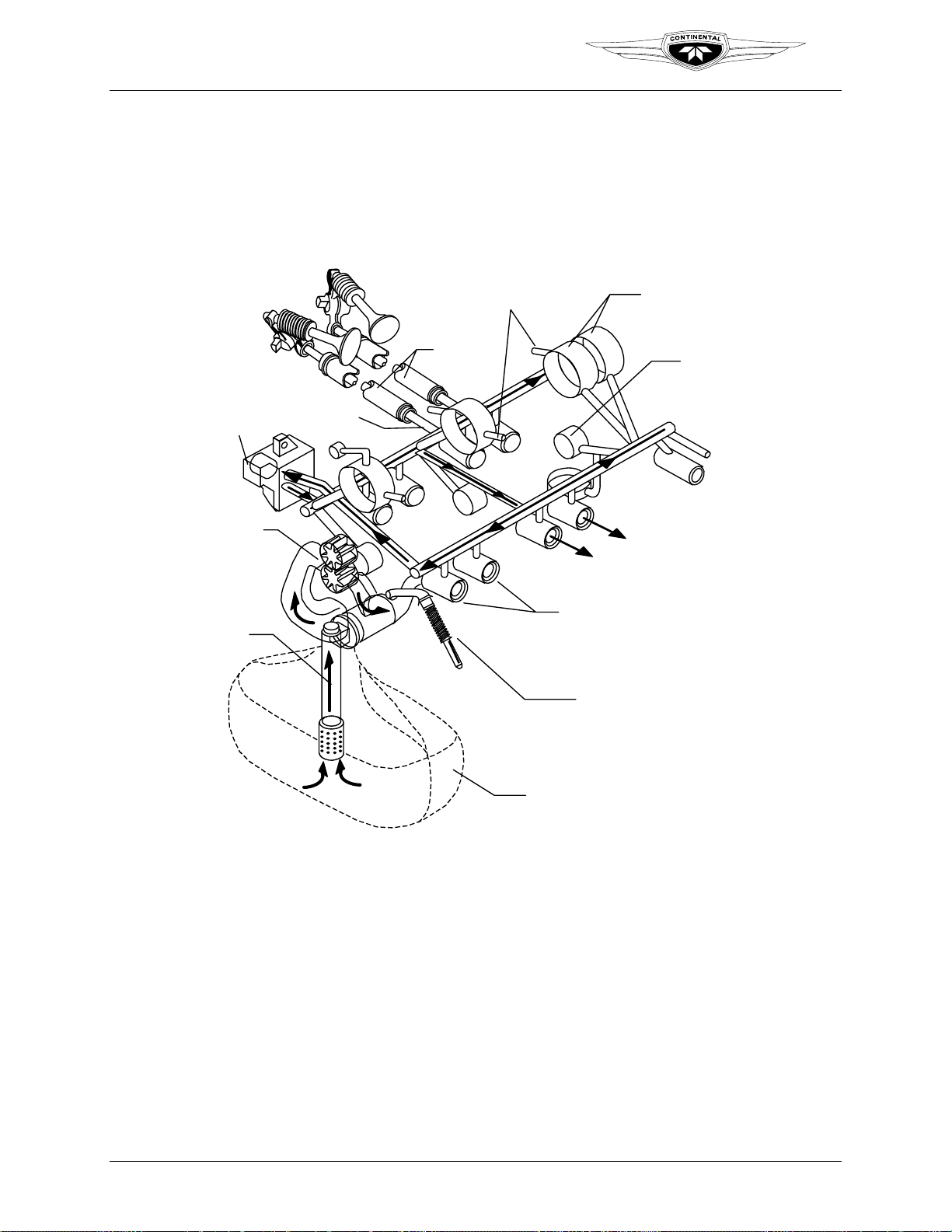

2-2.5. Lubrication System

The engine lubrication system delivers lubricating oil throughout the engine to various

bearings, bushings, and engine components. The wet sump, high pressure lubrication

system consists of an internal engine-driven oil pump, a non-adjustable pressure relief

valve, an oil sump, oil sensing ports. The oil cooler adapter is provided to connect an

optional remote mounted oil cooler.

TM

OIL COOLER

ADAPTER

OIL PUMP

GEARS

OIL

SUCTION

TUBE

INTAKE

PUSHROD

EXHAUST

OIL SQUIRT

NOZZLE

PUSHROD

HOUSING

CRANKSHAFT

BEARINGS

CAMSHAFT

BOSS

VACUUM

PUMP

BUSHING

HYDRAULIC

LIFTERS

OIL PRESSURE

RELIEF VALVE

2-2.5.1. Oil Pump

The engine-driven, gear type oil pump (

consists of two meshed steel gears that revolve inside the oil pump cavity machined in

the accessory case. The camshaft drives the oil pump drive gear, which drives the oil

pump driven gear. The oil pump driven gear is supported by a shaft pressed into the

accessory case and supported by the oil pump cover plate. The oil pump drive gear shaft

is supported by bushings pressed into the accessory case. The oil pump gear shaft

incorporates provisions to drive a mechanical tachometer.

The oil pump housing and oil pump gear chambers are machined in the interior of the

accessory case. The oil pump drive gear shaft hole is machined in-line with the camshaft

and the driven gear shaft hole is directly above it.

2-12 IOF-240 Series Engine Maintenance Manual

Change 1 31 August 2007

OIL SUMP

Figure 2-10. Lubrication Schematic

Figure 2-11) is a positive displacement pump that

Loading...

Loading...