Page 1

IO-240-A

CONTINENTAL® AIRCRAFT ENGINE

B

INSTALLATION

AND

OPERATION

MANUAL

FAA APPROVED

Publication OI-6

©

2011 CONTINENTAL MOTORS, INC. OCT 2011

Page 2

Supersedure Notice

This manual is a revision of the Continental Motors IO-240 Operation and Installation Manual, Part No. X30620,

released on January 1996. Upon FAA Approval, this manual supersedes X30620 in its entirety.

Effective Changes for this Manual

0..........31 October 2011

List of Effective Pages

Document Title: IO-240 Series Engine Installation & Operation Manual

Publication Number: OI-6 Initial Publication Date: 31 October 2011

Page Change Page Change Page Change Page Change

Cover............................0

A...................................0

i-xii................................0

1-1 thru 1-10.................0

2-1 thru 2-32.................0

3-1 thru 3-30.................0

4-1 thru 4-28.................0

A-1 thru A-4..................0

B-1 thru B-10................0

C-1 thru C-20 ...............0

Published and printed in the U.S.A. by Continental Motors, Inc.

Available exclusively from the publisher: P.O. Box 90, Mobile, AL 36601

Copyright © 2011 Continental Motors, Inc. All rights reserved. This material may not be reprinte d, republished, broadcast, or o therwise

altered without the publisher's written permission. This manual is provided without express, statutory, or implied warranties. The publisher will

not be held liable for any damages caused by or alleged to be caused by use, misuse, abuse, or misinterpretation of the contents. Content is

subject to change without notice. Other products and companies mentioned herein may be trademarks of the respective owners.

A IO-240 Series Engine Installation & Operation Manual

31 October 2011

Page 3

Service Document and Technical References

Technical information in the service documents listed below relevant to the engine models

covered by this engine manual have been incorporated in the manual. The full content of active

Continental Motors engine service documents is available http://continentalmotors.aero. Refer to

Section 1-3, “Contact Information” for Continental Motors web site details.

Service Document Subject Affected Chapter

M64-18, Turbocharger Field Conversion Engine Modification N/A

M72-17R1, Maximum Weight Difference Allowance Between

Connecting Rods and Pistons in the Same Engi ne

M73-13, Reaming and Bushing Rocker Shaft Bosses

M75-6R1, Conversion of Engines From One Model to Another Engine Configuration N/A

M76-4, Installation Of Propeller Shaft Or Nose Oil Seals Oil Seal Replacement N/A

M76-5R1, Remote Mounted Oil Coolers

M76-8, Intake Valve Change

M76-15, Fuel Pumps

M77-19, Intake and Exhaust Rocker Arm Identification and

Application

M81-8R1, Fuel Pump Screen Restriction

M81-25, Exhaust Flange to Cylinder Installation Procedures Engine Installation N/A

M86-9, Crankcase Modification Engine Overhaul N/A

M87-15, Alternator Ground Strap Alternator Replacement N/A

M88-9, Lightning Strikes Unscheduled Maintenance 4

M88-10, Contaminated Fuels Unscheduled Maintenance 3 & 4

M89-7R1, Engine Operation after Cylinder Replacement and/or

Major Overhaul

M89-9, Excessive Crankcase Pressure Unscheduled Maintenance 4

M89-18, EGT Recommendations EGT Leaning 4

M90-9, New TCM Magneto and Harness Applications

M90-13, Exhaust Valve Stem Corrosion/Erosion Inspection & Overhaul N/A

M90-17, Crankcase Inspection Criteria Inspection N/A

M91-4, Piston Identification and Piston Ring Application Bulletin Piston Replacement N/A

M91-9, Cam and Lifter Lubrication during Rebuild Overhaul N/A

M93-8, Rocker Arm to Rotocoil Clearance Rocker Arm Clearance N/A

M93-10, TCM Ignition Systems Service Bulletin 639 Inspection N/A

SIL93-11A, New Service Document Format Service Documents 1

MSB93-12, Valve Retainer Key Installation Inspection Inspection N/A

SIL93-14, CFC Compliance N/A N/A

Engine Assembly and

Overhaul

Cylinder Repair and

Overhaul

Engine Installation and Oil

Servicing

Engine Maintenance and

Overhaul

Fuel Pump and Camshaft

Replacement

Engine Assembly N/A

Fuel Pump Inspection and

Parts Replacement

Engine Operation-break-in 4

Magneto and Ignition

Harness Replacement

N/A

N/A

N/A

N/A

N/A

N/A

N/A

IO-240 Series Engine Installation & Operation Manual i

31 October 2011

Page 4

Service Document Subject Affected Chapter

SIL93-15, General Practices for Installation of Lock Wire, Tab

Washers, and Cotter Pins

CSB94-1, TCM Ignition CSB641 Magneto Coil N/A

SIL94-5, Mobil AV-1 Oil Authorized Lubricants N/A

MSB94-8D, Magneto to Engine Timing Service N/A

SB95-2, Inspection and Maintenance of Engine Control Cables

and Linkage

SB95-3B, Alternator/Generator Drive Couplings Inspection N/A

CSB95-4, Intake Valve Guide Seal Inspection N/A N/A

SIL95-5, Hose and Tubing Installation Hose and tubing installation Appendix C

CSB96-1, Starter Gear and Clutch Assembly, P/N 653575 Starter Replacement N/A

SID96-6, TCM Ignition SB653

SB96-7C, Torque Limits fastener torque Appendix B

MSB96-10, Requirements for Ultrasonic Inspection

SB96-11B, Propeller Strikes and Hydraulic Lock Scheduled Inspection 4

SB96-12, Continued Airworthiness for TCM Cylinders Scheduled Inspection N/A

SIL97-1, Airworthiness Limitations Airworthiness Limitations N/A

SID97-2B, TCM Cylinder Warranties N/A N/A

SID97-3E,Procedures and Specifications for Adjustment of TCM

Continuous Flow Fuel Injection Systems

SID97-4C, Cylinder Bore and Piston Fit Specifications Overhaul & Service Limits N/A

SB97-6B, Mandatory Replacement Parts

CSB97-10A, Piston Pin Plug Wear Service Limits N/A

SIL97-14, Replacement Cylinder Assembly Cylinder Replacement N/A

SB97-15, TCM Ignition Service Bulletin SB660 N/A N/A

CSB98-1B, Intake and Exhaust Valve Inspection Service Limits N/A

SIL98-9A, Time Between Overhaul Periods

SIL99-1, Engine Preservation for Active and Stored Aircraft

SIL99-2C, Current Listing of Sealants, Lubricants and Adhesives

Authorized by TCM

SB99-8, Engine Fuel Injection System Preservation

SB00-3A, Crankshaft, Counterweight and Connecting Rod

Repair Information

SB00-4A, Australian AVGAS Contamination Inspection and Operation N/A

SIL00-7A, Oil Gauge Rod Application Oil Servicing N/A

SIL00-9A, Engine Data Plates N/A N/A

SB00-10, Fuel Pump Seal Fuel Pump Installation N/A

Standard Practices Appendix C

Inspection N/A

Engine Operation-Hot

magneto Test

Crankshaft Removal &

Replacement

Engine Operational Check

and Engine Specifications

Engine Inspection &

Assembly

Engine Specifications,

Scheduled Maintenance

Engine preservation and

returning an engine to

service after storage

Materials Throughout

Fuel Injection system

storage

Repair Specifications N/A

4

N/A

3, 4

Appendix C

2

3

3

ii IO-240 Series Engine Installation & Operation Manual

31 October 2011

Page 5

Service Document Subject Affected Chapter

SIL00-11B, Release of new Cylinder Induction Port Drain

Connector

CSB02-8, TCM Ignition Systems CSB664 N/A N/A

SIL03-1, Cold Weather Operation – Engine Preheating Preheating procedures 4

SIL03-2B, Currently Active Approved Spark Plug Application Spark plugs 2 & 3

SIL03-3, Differential Pressure Test and Borescope Inspection Inspection Criteria N/A

SIL03-7, IO-240 Series Magneto Drive Gear Inspection Criteria N/A

SIL04-2, Cylinder Barrel Ultrasonic Inspection N/A N/A

SB04-4, Manifold Valve Spring Replacement Overhaul Repairs N/A

CSB04-5A, TCM Ignition Systems CSB665A Magneto Service N/A

SB04-10, Piston Pin Marking Overhaul Repairs N/A

SB04-11, Valve Guide Application, Installation and Reaming Valve Guide Repairs N/A

SIL04-1A, Installation of Optional Altitude Compensating Fuel

Pump on IO-240-B Series Engines

SIL04-8 Optional Replacement Starter fo IO-240 Series Engines

SIL04-9, IO240B13B Manifold Valve Replacement, Heat Isolation

Modifications, and Throttle Body Modifications

SIL04-12A, TCM Authorized Engine Adjustments, Component

Replacement and Repositioning

SID05-1, Design, Operation and Maintenance of TCM Camshafts

and Hydraulic Lifters

SB05-2, Overspeed Limitations Unscheduled Maintenance 4

SIL05-3, Engine Specification Numbers Engine Specification 2

SIL05-4A, IO-240 Series PN 656850 Inline Fuel Filter Installation

and Inspection Procedures

SIL05-5A, IO-240-B Series Manifold Valve Fuel Scavenge

System Installation

SIL05-6A, IO-240-B Series Product Upgrades

SB07-1, Connecting Rod Piston Pin Bushing Inspection Inspection N/A

SB07-3, Procedures and Specifications for adjustment of TCM

IO-240-B17B Fuel Injection System installed on Diamond DA20C1 Aircraft

SB07-8, Recommended Minimum RPM & Manifold Pressure

Cruise Operations Limits

SB08-3A, Throttle & Mixture Control Arms N/A 4

SB08-4, Fuel Injection System Contamination

SB08-8, Slick Service Bulletin SB2-08 Magneto Inspection N/A

SB08-9A, Slick Service Bulletin SB3-08A Magneto Inspection N/A

Cylinder Assembly N/A

Fuel System Specification

and Engine Operational

Check

Engine Specification and

Parts Replacement

Engine Specification 3, 4

Engine Specification N/A

Inspection Criteria N/A

Engine Specification,

Inspection, Component

Replacement

Engine Specification,

Inspection, Component

Replacement

Engine Specification,

Inspection, Component

Replacement

Engine Specification,

Inspection, Component

Replacement

Engine Operation 4

Engine Specification,

Inspection, Replacement

3, 4

3, 4

3

3

3

3 & 4

3

IO-240 Series Engine Installation & Operation Manual iii

31 October 2011

Page 6

Service Document Subject Affected Chapter

SB08-13, Induction System Hose and Clamp Installation

SB09-14, Camshaft Corrosion Treatmen Engine Inspection N/A

SIL640, Service Document Format Service Documents Preface & 1

SB643B, Maintenance Intervals for TCM Bendix Magnetos Inspection & Operation N/A

SB653, Hot Magneto Test Inspection & Operation 3 & 4

Induction System

Inspection & Assembly

Appendix C

Service Documents Released After Publication

Continental Motors strives to provide clear, concise, and accurate information and instructions

based on best known engineering data at the time of publication. Ongoing process improvements

may change a specification or procedure after a manual is released. Service documents, defined in

Chapter 1, expedite customer notification and serve as the prevailing instruction over conflicting

information until the new information is incorporated in the manual text. As service documents

are received, note the service document number , releas e date, title, a nd applicable sec tion af f ected

by the service document in the blank cells below and insert a copy of the service document behind

the last page of this section. Make pen & ink corrections, where appropriate, to the original text in

the manual with a citation to the service document; i.e. see SB9X-1. For paragraphs or entire

sections, draw an “X” through the affected information in the manual and reference the service

document containing the correction.

Service Bulletins Release After This Manual

Bulletin Number: Release Date:

Title:

Bulletin Number: Release Date:

Title:

Bulletin Number: Release Date:

Title:

Bulletin Number: Release Date:

Title:

Bulletin Number: Release Date:

Title:

Bulletin Number: Release Date:

Title:

Bulletin Number: Release Date:

Title:

Bulletin Number: Release Date:

/ /

/ /

/ /

/ /

/ /

/ /

/ /

/ /

Affected Sections:

Affected Sections:

Affected Sections:

Affected Sections:

Affected Sections:

Affected Sections:

Affected Sections:

Affected Sections:

Title:

iv IO-240 Series Engine Installation & Operation Manual

31 October 2011

Page 7

Service Bulletins Release After This Manual

Bulletin Number: Release Date:

Title:

Bulletin Number: Release Date:

Title:

Bulletin Number: Release Date:

Title:

Bulletin Number: Release Date:

Title:

Bulletin Number: Release Date:

Title:

Bulletin Number: Release Date:

Title:

Bulletin Number: Release Date:

Title:

Bulletin Number: Release Date:

/ /

/ /

/ /

/ /

/ /

/ /

/ /

/ /

Affected Sections:

Affected Sections:

Affected Sections:

Affected Sections:

Affected Sections:

Affected Sections:

Affected Sections:

Affected Sections:

Title:

Bulletin Number: Release Date:

Title:

Bulletin Number: Release Date:

Title:

Bulletin Number: Release Date:

Title:

Bulletin Number: Release Date:

Title:

Bulletin Number: Release Date:

Title:

Bulletin Number: Release Date:

Title:

Bulletin Number: Release Date:

Title:

/ /

/ /

/ /

/ /

/ /

/ /

/ /

Affected Sections:

Affected Sections:

Affected Sections:

Affected Sections:

Affected Sections:

Affected Sections:

Affected Sections:

Bulletin Number: Release Date:

IO-240 Series Engine Installation & Operation Manual v

31 October 2011

/ /

Affected Sections:

Page 8

PREFACE

Continental Motors provides Instructions for Continued Airworthiness based on the design,

testing, and certification of engines and parts for which Continental Motors is the holder of the

Type Certificate (TC) or Parts Manufacture Approval (PMA) issued by the Federal Aviation

Administration (FAA). Instructions in Continental Motors engine manuals, which include

maintenance, repair limits, overhaul, and installation, are applicable only to engines and parts

supplied by Continental Motors.

Except for F AR part 43.3 authorized owner preventive maintenance, Continental Motors ICAs are

written for exclusive use by FAA (or equivalent authority) licensed mechanics or FAA (or

equivalent authority) certified repair station employees working under the supervision of an FAA

licensed mechanic. Information and instructions contained in this manual anticipate the user

possesses and applies the knowledge, training, and experience commensurate with the

requirements to meet the prerequisite FAA license and certification requirements. No other use is

authorized.

Installation of aftermarket parts on a Continental Motors engine constitutes a deviation from FAA

approved type-design criteria. Continental Motors has not participated in design, test, or

certification of any aftermarket parts. Continental Motors does not provide product manufacturing

specifications to aftermarket parts manufacturers and accepts no liability for the suitability,

durability, longevity, or safety of such parts installed on Continental Motors engines. Installation

of aftermarket parts on a Continental Motors engine must be performed using Instructions for

Continued Airworthiness prepared by the manufacturer and accepted by the FAA for the subject

installation. Continental Motors ICAs must not be used for such parts.

Service documents may contain general information or information specific to a group of engines

or be in effect for a limited time frame. Service Documents may also contain advance changes to

the ICAs. It is the responsibility of the organization/person maintaining or operating the engine to

verify that current and complete information, including Service Documents, FAA Airworthiness

Directives (ADs), and publications are used.

To facilitate the use of current data, Continental Motors provides information on the Continental

Motors web site. The information available includes a listing of the latest manual versions,

service documents, FAA ADs, and other information applicable to the ICAs.

Manuals published since 2003 are available on the Continental Motors web site to Fixed Base

Operators (FBOs) who subscribe to Continental Motors Internet Services. Information available

to Continental Motors engine owners is also available to FBOs. Printed manuals and service

subscriptions are also available. Refer to “Publication Access” in Section 1-2.3.

vi IO-240 Series Engine Installation & Operation Manual

31 October 2011

Page 9

TAB LE OF CON TE NT S

Chapter 1. Introduction

1-1. Scope and Purpose of This Manual ................................................................. 1-1

1-1.1. Effectivity Symbols...................................................................................................... 1-1

1-1.2. Advisories .................................................................................................................... 1-1

1-1.3. Using this Manual...................... ......................................................................... ......... 1-1

1-2. Publications...................................................................................................... 1-3

1-2.1. Service Documents ...................................................................................................... 1-3

1-2.2. Related Publications.................................................. ..................................... .............. 1-4

1-2.3. Publication Access....................................................................................................... 1-5

1-2.4. Publication Changes..................................................................................................... 1-5

1-2.4.1. Update/Change Distribution..............................................................................1-5

1-2.4.2. Suggestions and Corrections .............................................................................1-7

1-3. Contact Information......................................................................................... 1-8

Chapter 2. Engine Description

2-1. General Engine Description............................................................................. 2-1

2-1.1. Engine Model Number Definition ............................................................................... 2-2

2-1.2. Cylinder Number Designations.................................................................................... 2-2

2-2. Detailed Engine Description............................................................................ 2-3

2-2.1. Crankcase..................................................................................................................... 2-3

2-2.2. Engine Drive Train...................................................................................................... 2-4

2-2.2.1. Crankshaft..........................................................................................................2-4

2-2.2.2. Connecting Rods................................................................................................2-5

2-2.2.3. Camshaft...........................................................................................................2-6

2-2.3. Accessory Case........................................................................................................... 2-6

2-2.4. Cylinders...................................................................................................................... 2-7

2-2.4.1. Pistons................................................................................................................2-9

2-2.4.2. Hydraulic Valve Tappets...................................................................................2-9

2-2.5. Lubrication System.................................................................................................... 2-10

2-2.5.1. Oil Pump................................................................... ..................................... ..2-11

2-2.5.2. Oil Sump................................................................... ..................................... ..2-12

2-2.5.3. Oil Pressure Relief Valve ................................. .................................... ... ........2-12

2-2.5.4. Oil Cooler Adapter ................................................... ..................................... ..2-12

2-2.6. Ignition System .......................................................................................................... 2-14

2-2.7. Fuel System................................................................................................................ 2-16

2-2.7.1. Fuel Pump........................................................................................................2-16

2-2.7.2. Fuel Injectors...................................................................................................2-18

2-2.8. Starter Assembly........................................................................................................ 2-18

2-2.9. Alternator ................................................................................................................... 2-18

2-2.10. Engine Cooling ............ ......................................................................... ..................... 2-19

2-2.11. Induction System........................................................................................................ 2-20

2-3. Engine Specifications and Operating Limits ................................................. 2-21

2-3.1. Accessory Drive Ratios........................................................ ...................................... 2-25

2-3.2. Performance Data....................................................................................................... 2-25

IO-240 Series Engine Installation & Operation Manual vii

31 October 2011

Page 10

2-3.2.1. IO-240-A Performance Charts ........................................................................2-26

2-3.2.2. IO-240-B Performance Charts.........................................................................2-28

Chapter 3.Engine Installation

3-1. Engine Installation........................................................................................... 3-1

3-1.1. Common Tools and Consumable Supplies Required .................................................. 3-1

3-1.2. Engine Receipt and Handling...................................................................................... 3-1

3-1.2.1. Uncrating the Engine.........................................................................................3-2

3-1.2.2. Crating an Engine for Shipping.........................................................................3-2

3-1.2.3. Acceptance Inspection....................................................................................... 3-2

3-1.3. Engine Transport.......................................................................................................... 3-2

3-2. Installation Procedures..................................................................................... 3-4

3-2.1. Prepare the Airframe for Engine Installation............................................................... 3-4

3-2.2. Prepare the Engine for Installation .............................................................................. 3-4

3-2.3. Installation Sequence................................................................................................... 3-5

3-2.3.1. Engine Pre-oiling............................................................................................... 3-7

3-2.3.2. Fuel Purge and Leak Check............................................................................... 3-8

3-2.4. Installation Inspection.................................................................................................. 3-9

3-2.5. Preflight and Run-up.................................................................................................... 3-9

3-3. Engine Installation Drawings ......................................................................... 3-11

3-3.1. IO-240-A Installation Drawings ................................................................................ 3-11

3-3.2. IO-240-B Installation Drawings ................................................................................ 3-15

3-3.3. IO-240 Common Installation Drawings .................................................................... 3-22

Chapter 4. Engine Operation

4-1. Introduction...................................................................................................... 4-1

4-2. Flight Prerequisites .......................................................................................... 4-1

4-2.1. Oil Change Interval........................................................................................... ........... 4-2

4-2.2. Engine Fuel Requirements........................................................................................... 4-2

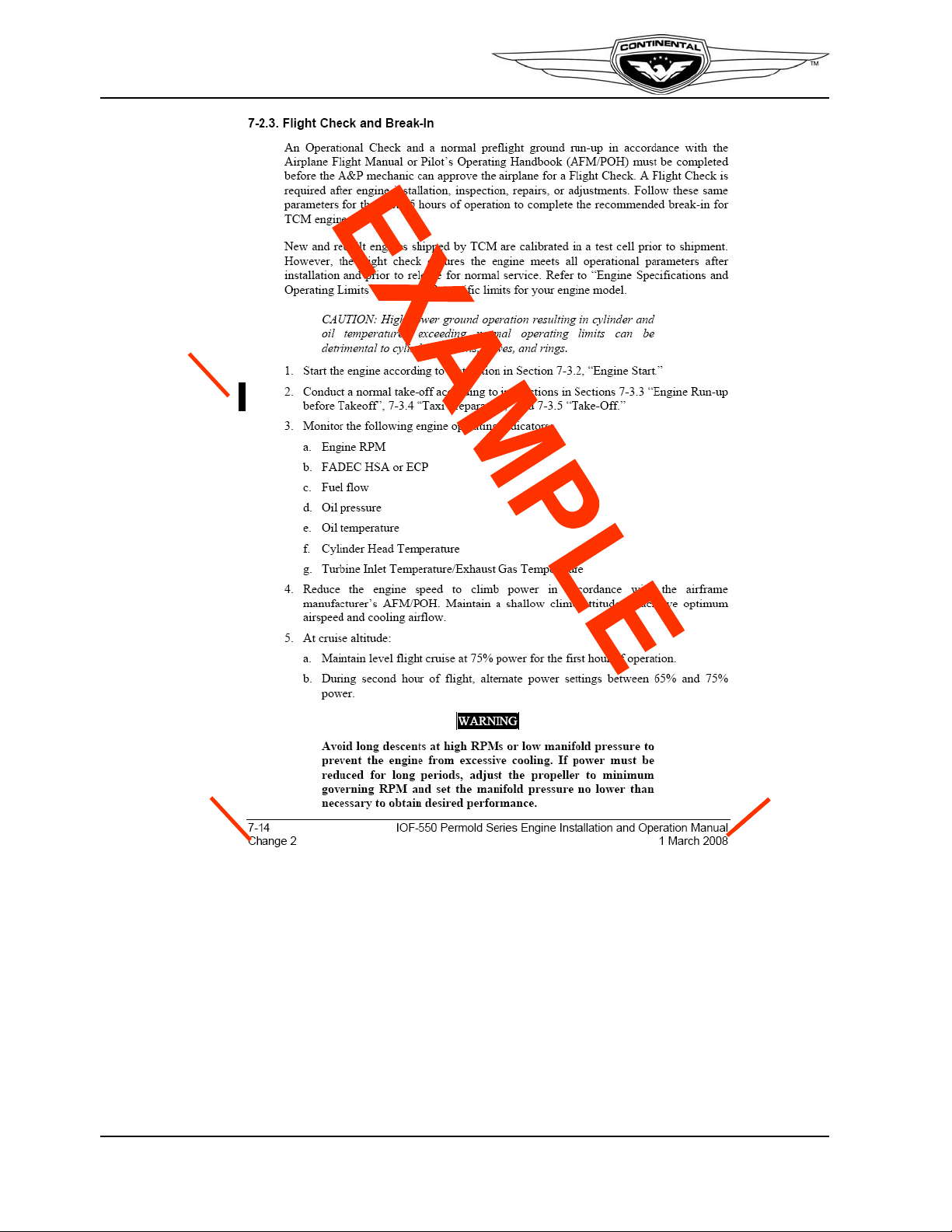

4-2.3. Flight Check and Break-In........................................................................................... 4-2

4-2.3.1. Engine Break-In ................................................................................................4-3

4-2.3.2. Flight Check ......................................................................................................4-5

4-3. Normal Operation ............................................................................................ 4-7

4-3.1. Pre-operational Requirements...................................................................................... 4-7

4-3.2. Engine Start..................................................................... ..................................... ........ 4-8

4-3.2.1. Cold Start...........................................................................................................4-9

4-3.2.2. Flooded Engine................................................................................................4-10

4-3.2.3. Hot Start ............................................................................................. ............. 4-10

4-3.3. Ground Run-up .......................................................................................................... 4-10

4-3.4. Taxi Preparation.................................................................................. ....................... 4-12

4-3.5. Power Control............................................................................................................ 4-12

4-3.6. Take-Off..................................................................................................................... 4-13

4-3.7. Climb ......................................................................................................................... 4-14

4-3.8. Cruise......................................................................................................................... 4-15

4-3.9. Descent....................................................................................................................... 4-16

4-3.10. Landing ...................................................................................................................... 4-16

viii IO-240 Series Engine Installation & Operation Manual

31 October 2011

Page 11

4-3.11. Engine Shutdown .................................. ..................................................................... 4-17

4-4. Emergency Operation .................................................................................... 4-18

4-4.1. Engine Fire During Start............................................................... ............................. 4-18

4-4.2. Engine Fire During Flight............................................................. ............................. 4-18

4-4.3. In-Flight Restart......................................................................................................... 4-19

4-4.4. Engine Roughness...................................................................................................... 4-19

4-4.5. High Cylinder Head Temperature..................................... ......................................... 4-19

4-4.6. High Oil Temperature ................................................................................................ 4-20

4-4.7. Low Oil Pressure........................................................................................................ 4-20

4-5. Engine Operation in Abnormal Environments .............................................. 4-21

4-5.1. Engine Operation in Extreme Cold................................................. ........................... 4-21

4-5.1.1. Engine Preheating................................. ..................................... ... ...................4-22

4-5.2. Engine Operation in Hot Weather............................................................ .................. 4-26

4-5.2.1. Cooling an Engine in Hot Weather..................................................................4-26

4-5.2.2. Engine Restart in Hot Weather........................................................................4-27

4-5.2.3. Ground Operation in Hot Weather ..................................................................4-27

4-5.2.4. Take-off and Initial Climb Out in Hot Weather ..............................................4-27

4-5.3. Ground Operation at High Density Altitude.............................................................. 4-28

4-6. Troubleshooting ............................................................................................. 4-28

Appendix A. Glossary

A-1. Acronyms........................................................................................................ A-1

A-2. Glossary.......................................................................................................... A-2

Appendix B.Torque Specifications

B-1. General Information......................................................................................... B-1

B-1.1. Torque Tips ................................................................................................................. B-1

B-2. Cylinder Torque Procedure.............................................................................. B-2

B-3. Torque Wrench and Extension Calculations.................................................... B-3

Appendix C.Standard Practices

C-1. Handling Parts.................................................................................................. C-1

C-2. Replacement Parts............................................................................................ C-2

C-2.1. Background................................................................................................................. C-2

C-2.2. Acceptable Replacement Parts.................................................................................... C-2

C-2.2.1. Know Your Supplier......................................................................................... C-3

C-2.3. 100% Parts Replacement Requirements..................................................................... C-3

C-2.4. Mandatory Overhaul Replacement Parts .................................................................... C-4

C-2.5. Authorized Oversize/Undersize Parts......................................................................... C-4

C-3. Torque.............................................................................................................. C-4

C-4. Safety Wiring Hardware .................................................................................. C-5

C-5. Tab Washer Installation.................................................................................... C-7

IO-240 Series Engine Installation & Operation Manual ix

31 October 2011

Page 12

C-6. Helical Coil Insert Replacement...................................................................... C-8

C-6.1. Helical Coil Removal................................................................................................... C-9

C-6.2. Helical Coil Insertion................................................................................................. C-10

C-7. Stud Replacement.......................................................................................... C-11

C-7.1. Stud Removal............................................................................................................. C-11

C-7.1.1. Size-on-Size Rosan® Stud Removal...............................................................C-11

C-7.1.2. Step-Type Rosan® Stud Removal...................................................................C-12

C-7.2. Stud Installation......................................................................................................... C-13

C-7.2.1. Rosan® Stud Installation.................................................................................C-14

C-8. Cotter Pin Installation.................................................................................... C-15

C-9. Fuel System Service ...................................................................................... C-16

C-9.1. Fuel System Purge..................................................................................................... C-16

C-10. Gasket Maker® Application.......................................................................... C-17

C-11. Gasket Installation......................................................................................... C-18

C-12. Hose and Tubing Installation......................................................................... C-19

C-13. Harness Routing............................................................................................. C-20

LIST OF TABLES

Table 1-1. Related Publications .................................................................................... 1-4

Table 2-1. IO-240-A Specifications and Operating Limits .......................................... 2-21

Table 2-2. IO-240-B Specifications and Operating Limits .......................................... 2-23

Table 2-3. Accessory Drive Ratios .............................................................................. 2-25

Table 4-1. IO-240 Operating Limits .............................................................................. 4-4

Table B-1. General Torque Specification .......................................................................B-5

Table B-3. Hose Fitting (“B” Nut) Torque Specification ...............................................B-6

Table B-2. Tube Fitting Torque Specifications ..............................................................B-6

Table B-4. Component Specific Torque Specifications .................................................B-7

Table B-5. Specific Torque for Non-Lubricated Hardware ..........................................B-10

Table C-1. Rosan® Stud Primary & Secondary Bore Specifications ..........................C-12

x IO-240 Series Engine Installation & Operation Manual

31 October 2011

Page 13

LIST OF ILLUSTRATIONS

Figure 1-1. Figure and Index Reference ................................................................... 1-2

Figure 1-2. Change Page Identification .................................................................... 1-6

Figure 1-3. List of Effective Pages ........................................................................... 1-7

Figure 2-1. Engine Model Definition .......................................................................2-2

Figure 2-2. Cylinder Number Designation ............................................................... 2-2

Figure 2-3. IO-240 Crankcase Features .................................................................... 2-3

Figure 2-4. Engine Drive Train ................................................................................ 2-4

Figure 2-5. Crankshaft .............................................................................................. 2-5

Figure 2-6. Connecting Rod ..................................................................................... 2-5

Figure 2-7. Camshaft ................................................................................................ 2-6

Figure 2-8. Accessory Case Features ....................................................................... 2-7

Figure 2-9. Cylinder Features ................................................................................... 2-8

Figure 2-10. Piston Features ....................................................................................... 2-9

Figure 2-11. IO-240-A Lubrication .........................................................................2-10

Figure 2-12. IO-240-B Lubrication ......................................................................... 2-11

Figure 2-13. Oil Pump ..............................................................................................2-12

Figure 2-14. IO-240-A Oil Cooler Adapter ............................................................. 2-13

Figure 2-15. IO-240-B Oil Cooler Adapter .............................................................2-13

Figure 2-16. IO-240-B Oil Cooler/Filter Adapter ................................................... 2-13

Figure 2-17. Continental Motors Magneto Part Number Structure .......................... 2-14

Figure 2-18. Continental Motors Ignition Distribution ............................................ 2-15

Figure 2-19. Slick Ignition Distribution ................................................................... 2-15

Figure 2-20. IO-240 Standard Fuel Injection System ............................................... 2-16

Figure 2-21. Standard Fuel Pump ............................................................................. 2-17

Figure 2-22. Altitude Compensating Fuel Pump ...................................................... 2-17

Figure 2-23. Fuel Injector ......................................................................................... 2-18

Figure 2-24. Engine Cooling .................................................................................... 2-19

Figure 2-25. IO-240-A Induction System ................................................................. 2-20

Figure 2-26. IO-240-B Crossflow Induction System ............................................... 2-20

Figure 2-27. IO-240-A Fuel Flow vs. Brake Horsepower ........................................ 2-26

Figure 2-28. IO-240-A Sea Level Performance ....................................................... 2-27

Figure 2-29. IO-240-B Fuel Flow vs. Brake Horsepower ........................................ 2-28

Figure 2-30. IO-240-B Sea Level Performance ........................................................ 2-29

Figure 3-1. IO-240-A Top View .............................................................................3-11

Figure 3-2. IO-240-A Left Side View ....................................................................3-12

Figure 3-3. IO-240-A Front View .......................................................................... 3-13

Figure 3-4. IO-240-A Rear View ........................................................................... 3-14

Figure 3-5. IO-240-B Top View ............................................................................. 3-15

Figure 3-6. IO-240-B Left Side View .................................................................... 3-16

Figure 3-7. IO-240-B Front View ...........................................................................3-17

Figure 3-8. IO-240-B Rear View ............................................................................ 3-18

Figure 3-9. IO-240-B w/optional Oil Cooler-Filter Adapter Top View ................. 3-19

Figure 3-10. IO-240-B w/optional Oil Cooler-Filter Adapter Left Side View ........ 3-20

Figure 3-11. IO-240-B w/optional Oil Cooler-Filter Adapter Rear View ................ 3-21

IO-240 Series Engine Installation & Operation Manual xi

31 October 2011

Page 14

Figure 3-12. Propeller Flange ................................................................................... 3-22

Figure 3-13. Exhaust Flange Dimensions ................................................................ 3-23

Figure 3-14. Standard Fuel Pump Installation .......................................................... 3-23

Figure 3-15. Standard Fuel Pump Adjustments ....................................................... 3-24

Figure 3-16. IO-240-B Altitude Compensating Fuel Pump Adjustments ................ 3-24

Figure 3-17. Throttle Lever Installation ................................................................... 3-25

Figure 3-18. Oil Cooler Adapter Connections ......................................................... 3-25

Figure 3-19. Oil Cooler Adapter Connections ......................................................... 3-26

Figure 3-20. Oil Cooler-Filter Adapter Connections ............................................... 3-26

Figure 3-21. IO-240-A Air Intake Flange ................................................................ 3-27

Figure 3-22. Alternator Connections ........................................................................ 3-27

Figure 3-23. Engine Mounts ..................................................................................... 3-28

Figure 3-24. Continental Motors Magneto Ignition Schematic ............................... 3-29

Figure 3-25. Champion (Slick) Magneto Ignition Schematic .................................. 3-29

Figure 3-26. Airframe Ignition Switch Connections to Magneto ............................. 3-30

Figure B-1. Torque Wrench ......................................................................................B-3

Figure B-2. Drive extensions ....................................................................................B-3

Figure B-3. Extension increases applied torque ........................................................B-4

Figure B-4. Extension decreases applied torque .......................................................B-4

Figure C-1. Right-hand-thread safety wire installation .............................................C-5

Figure C-2. Safety wire Patterns for Right-Hand Threads ........................................C-6

Figure C-3. Tab Washer Installation .........................................................................C-7

Figure C-4. Helical Coil Extraction Tool ..................................................................C-9

Figure C-5. Installing a Helical Coil Insert .............................................................C-10

Figure C-6. Rosan® Stud Removal Tool ................................................................C-12

Figure C-7. Rosan® stud removal tool installed on stud ........................................C-12

Figure C-8. Stud Sizes ............................................................................................C-13

Figure C-9. Minimum Material Thickness for Helical Coil insertion ....................C-14

Figure C-10. Rosan® Stud Installation Dimensions .................................................C-14

Figure C-11. Cotter Pin Installation ..........................................................................C-15

Figure C-12. Installing Hoses and Fittings ...............................................................C-19

xii IO-240 Series Engine Installation & Operation Manual

31 October 2011

Page 15

Chapter 1 . Introduction

AA

BB

1-1. Scope and Purpose of This Manual

This manual is part of the interface control document for IO-240-A and B engine models.

This manual provides airframe interface requirements, installation instructions and engine

operating instructions to supplement the Airplane Flight Manual (POH)/Pilot’s Operating

Handbook (POH).

Instructions in this manual are specific to the IO-240 Series engines. For information

specific to other Continental Motors engine series, accessories, or the airplane, refer to the

appropriate manual. Chapters are arranged in sequential order to install, test, and operate

the engine.

1-1.1. Effectivity Symbols

Va riations in IO-240 Series engine models require specific instructions or illustrations. If

peculiar information pertains to only a specific engine model in the series, an effectivity

symbol will accompany the information. Effectivity symbols found in this publication are:

IO-240-A IO-240-B

IO-240-B with altitude compensating fuel pump

Introduction

1-1.2. Advisories

This manual utilizes three types of advisories; defined as follows:

A warning emphasizes information which, if disregarded, could

result in severe injury to personnel or equipment failure.

CAUTION: Emphasizes certain information or instructions, which if

disregarded, may result in damage to the engine or accessories.

NOTE: Provides special interest information, which may facilitate

performance of a procedure or operation of equipment.

Warnings and cautions precede the steps to which they apply; notes are placed in the

manner which provides the greatest clarity. Warnings, cautions, and notes do not impose

undue restrictions. Failure to heed advisories will likely result in the undesirable or unsafe

conditions the advisory was intended to prevent. Advisories are inserted to ensure

maximum safety , ef ficiency, and performance. Abuse, misuse, or neglect of equipment can

cause eventual engine malfunction or failure.

1-1.3. Using this Manual

Except for engine installation drawings, illustrations in this manual are for reference only,

depicting the most prominent configuration in the engine series. Consult the parts catalogs

for engine model-specific illustrated parts breakdowns.

WARNING

This manual and the accessory manuals listed in Table 1-1 and certain service documents,

and other related publications constitute the Instructions for Continued Airworthiness

IO-240 Series Engine Installation & Operation Manual 1-1

31 October 2011

Page 16

Introduction

(ICAs) prepared by Continental Motors and accepted by the Federal Aviation

Administration (FAA). This manual is prepared in a user -friendly format suited equally for

electronic viewing and print.

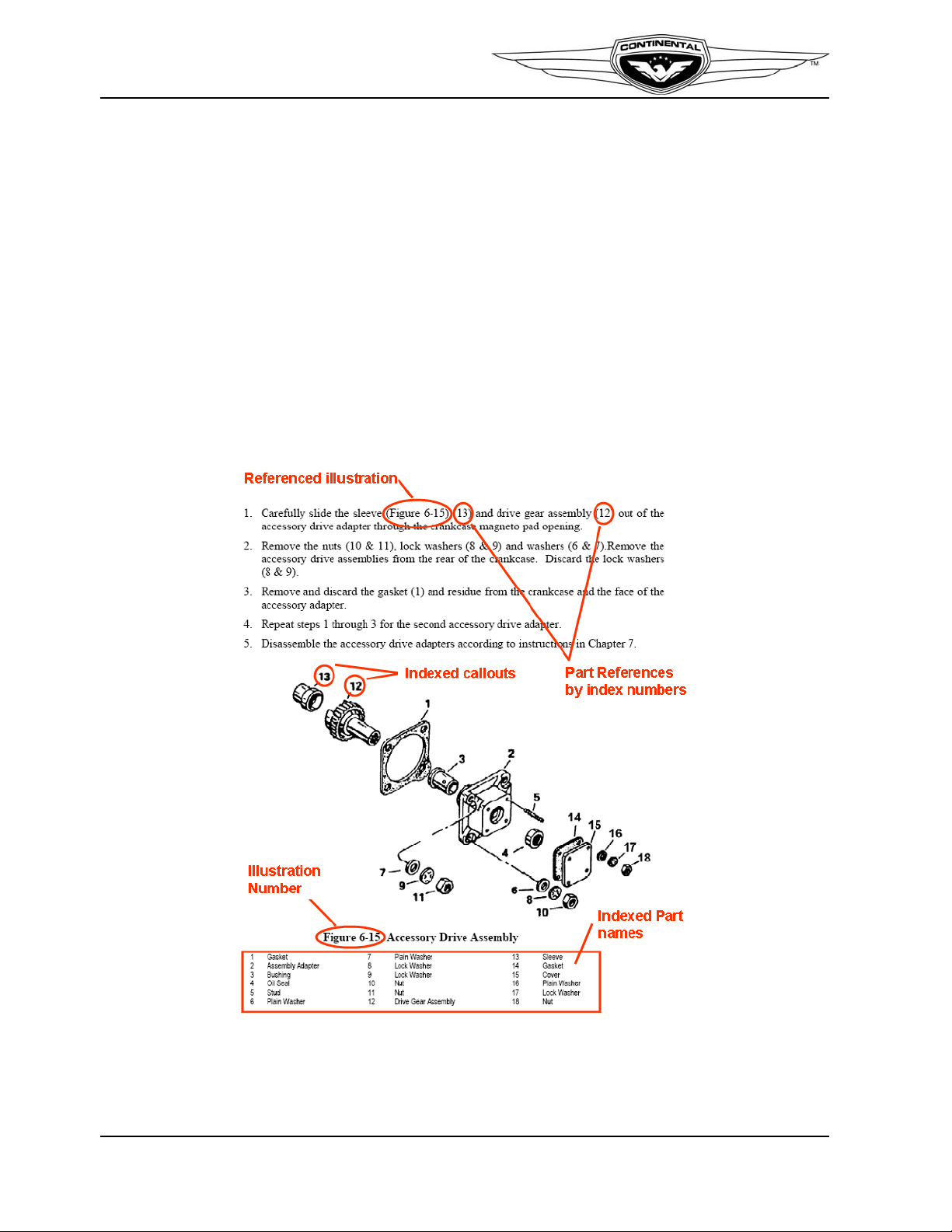

Exploded assembly illustrations accompany instructions throughout the manual. Parts in

illustrations (Figure 1-1.) are identified with numerical callouts (indexes). Corresponding

parts listings follow the illustrations for reference. The first time instructions refer to an

illustration, the figure number is identified in parentheses, followed by the callout. In

subsequent parts references, only the callout will be specified unless the referenced

illustration changes.

WARNING

Continental Motors ICAs are applicable only to Continental

Motors engines conforming to the approved, type certified

engine model configuration. Continental Motors ICAs must not

be used for aftermarket parts.

Figure 1-1. Figure and Index Reference

1-2 IO-240 Series Engine Installation & Operation Manual

31 October 2011

Page 17

1-2. Publications

1-2.1. Service Documents

Continental Motors may issue Service Documents in one of six categories ranging from mandatory

(Category 1) to informational (Category 6). Definitions of the categories are listed below:

NOTE: Upon FAA approval, Continental Motors publishes service

documents for immediate availability on our web site. The service

document cover page indicates the engine models affected by the service

document. Service documents may alter or replace manufacturer’s ICAs.

Insert a copy of applicable Service Documents in affected manuals until

the service document instructions are incorporated in the manual, or the

service document is cancelled or superseded.

1Procedure

Category 1: Mandatory Service Bulletin (MSB)

Used to identify and correct a known or suspected safety hazard which has b een incorporated in whole or in

part into an Airworthiness Directive (AD) issued by the FAA or have been issued at the direction of the FAA

by the manufacturer requiring compliance with an already-issued AD (or an equivalent issued by another

country’s airworthiness authority). May contain updates to Instructions for Continued Airworthiness (ICAs)

to address a safety issue.

Category 2: Critical Service Bulletin (CSB)

This category identifies a condition that threatens continued safe operation of an aircraft, persons or property

on the ground unless some specific action (inspection, repair, replacement, etc.) is taken by the owner or

operator. Documents in this category are candidates for incorporation into an FAA Airworthiness Directive.

May contain updates to ICAs to address a safety issue.

Introduction

Category 3: Service Bulletin (SB)

Information which the product manufacturer believes may improve the i nherent safety of an aircraft or

aircraft component; this category includes the most recent updates to ICAs.

Category 4: Service Information Directive (SID)

The manufacturer directs the owner/operator/mechanic in the use of a product to enhance safety,

maintenance or economy. May contain updates to ICAs in the form of maintenance procedures or

specifications.

Category 5: Service Information Letter (SIL)

This category includes all information (not inclu ded in categories 1 through 4) that may be useful to the

owner/operator/technician. May contain updates to ICAs for optional component installations, which are not

covered in the Applicable Operator, Maintenance, or Overhaul Manuals.

Category 6: Special Service Instruction (SSI)

This category is used to address an issue limited to specific model and/or serial number engines. We will

distribute SSI notification directly to the affected engine’s owners.

service document set but will be made available through our Customer Service Department to owners of the

affected engines only . An SSI may update the applicable engine’s Instructions for Continued Airworthiness.

SSIs will not be included in the general

IO-240 Series Engine Installation & Operation Manual 1-3

31 October 2011

Page 18

Introduction

1-2.2. Related Publications

The table below lists related publications, source, and accessibility relevant to IO-240

Series engine installation and operation.

WARNING

Use only the latest revision of all publications. Using superseded

information may jeopardize engine airworthiness

Table 1-1. Related Publications

Supplied

With

Publication

Engine

Maintenance and Overhaul Manual (M-6) Yes

S-20/S-200 Magneto Service Manual (X42002) Yes Yes Yes

Service Documents No Yes Yes

Parts Catalog No Yes (view only)No

Available

download at

web site

1

Yes

Printed

Manual

Available

for

Purchase

Yes

1. Our web site (http://continentalmotors.aero) provides 24-hour access to engine technical data via the Internet. If you are an internet service subscriber, you can access our web site to confirm and review the latest revision of this manual. If you have not subscribed to internet service and are using printed manuals, contact using the “Contact Information” on page 8. to confirm you have the latest revision of

the manual.

1-4 IO-240 Series Engine Installation & Operation Manual

31 October 2011

Page 19

1-2.3. Publication Access

Contact an authorized Continental Motors distributor to discuss service subscription

options and pricing or visit the Continental Motors web site. Printed technical publications

may be ordered through authorized Continental Motors distributors or via the Internet at

http://continentalmotors.aero.

1-2.4. Publication Changes

The instructions in this manual represent the best and most complete information available

at the time of publication. Product or process improvements may trigger changes to

existing product design specifications or procedures contained in publications. As new

technical information becomes available, Continental Motors will make the information

available to the customer.

New information may be contained in Continental Motors

service documents. Service documents applicable to engines

and accessories within the scope of this manual must be

complied with as defined in these documents. This manual and

other related publications noted herein constitute the ICAs

prepared by Continental Motors and accepted by the FAA.

Introduction

WARNING

Continental Motors releases publication changes in the form of either change pages or

complete publication revisions, depending upon the extent of change. Service Documents

may supplement or replace technical information contained in one publication or an entire

series of publications. Such Service Documents represent a change to the published ICA

until the individual publications incorporate the latest technical information.

1-2.4.1. Update/Change Distribution

Document updates are available on our web site upon notification of FAA document

approval. Printed publication subscribers receive printed changes and revisions as they are

released.

Document revisions are released if the update changes more than 50% of the contents of a

publication. Revisions replace the previous version of a publication from cover to cover.

Minor corrections are released as change pages to the original publication, identified with

a change number and effective change date in the page footer. Information on the page that

changed from the previous edition is identified by a vertical, six-point black line (Figure

1-2.), referred to as a “change bar” in the outside margin of the page. A change page

replaces only the previous edition of the affected page.

IO-240 Series Engine Installation & Operation Manual 1-5

31 October 2011

Page 20

Introduction

Change Bar

Change

Number

Change

Date

Change Bar

Change

Number

Change

Date

Change Bar

Change

Number

Change

Date

1-6 IO-240 Series Engine Installation & Operation Manual

Figure 1-2. Change Page Identification

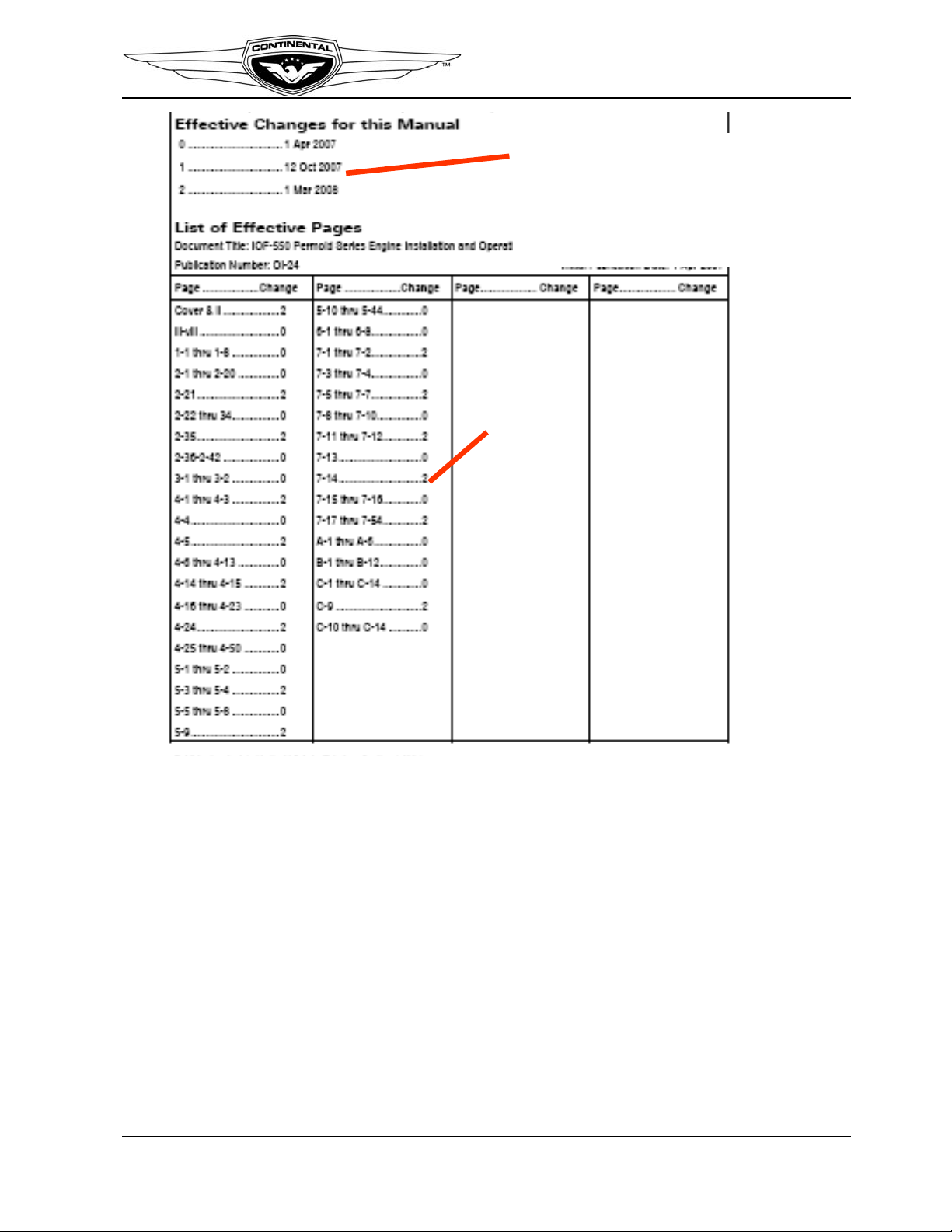

Page A of the manual contains the original publication date and an itemized list of changes

issued for the technical manual (Figure 1-3.). If change pages are issued for the manual,

the change will be identified, with an effective date under the heading “Effective Changes

for This Manual.” The list of effective pages, itemizes the pages in each section, by

change number. Original pages are designated by a 0 in the List of Effective Pages

“Change” column.

31 October 2011

Page 21

Introduction

Effective Manual

Changes and

Change Dates

Itemized List

of Effective

Pages

Effective Manual

Changes and

Change Dates

Itemized List

of Effective

Pages

Figure 1-3. List of Effective Pages

1-2.4.2. Suggestions and Corrections

Continental Motors solicits and encourages user comments regarding suggested changes

to this manual. Direct recommended changes or questions to the attention of

“Publications” at the address listed in Section 1-3, “Contact Information” or send

comments via email to CM.techpubs@continental.aero.

Notify our Customer Service Department immediately, using our toll-free number, if you

discover incorrect information which adversely affects safety.

IO-240 Series Engine Installation & Operation Manual 1-7

31 October 2011

Page 22

Introduction

1-3. Contact Information

Continental Motors is available to answer technical questions and encourages suggestions

regarding products, parts, or service. If customers have an inquiry or require technical

assistance, they should contact their local Continental Motors distributor or field

representative. To contact a factory representative, refer to the contact information below:

Continental Motors, Inc.

P. O. Box 90

Mobile, AL 36601

Customer Service:

Toll free within the Continental United States: 1-888-826-5465

International: 1-251-438-8299

Internet: http://continentalmotors.aero.

1-8 IO-240 Series Engine Installation & Operation Manual

31 October 2011

Page 23

Chapter 2 . Engine Description

2-1. General Engine Description

IO-240 engines are four-cylinder, four-stroke reciprocating aircraft engines. IO-240-A &

B engines are designed for fixed pitch, ground adjustable, or electric constant speed

propellers. There is no provision for a hydraulic propeller governor. Cylinder

displacement of 240 cubic inches is achieved with a 4.44 inch bore and a 3.88 inch stroke.

IO-240 series engines are equipped with continuous flow fuel injection and a either an

updraft or a downdraft induction system, depending on the engine model.

IO-240 series engines are designed with a wet sump, positive displacement oil pump

installed in the accessory case. When properly maintained, under normal operating

conditions, the desired oil pressure is maintained by a pressure relief valve located in the

accessory case. Engine cranking is accomplished by a geared starter mounted on the

accessory case.

A gear driven alternator is installed on the accessory case. The engine is equipped with

two gear-driven magnetos. The downdraft exhaust system is supplied by the airframe

manufacturer.

IO-240 series engines have a doweled, six bolt propeller flange.

Engine Description

IO-240 Series Engine Installation & Operation Manual 2-1

31 October 2011

Page 24

Engine Description

I O-240-B1

Specification Number

Model Identifier

Cubic Inch Displacement

Horizontally Opposed Cylinders

Fuel Injected

B

Shipping Designation

I O-240-B1

Specification Number

Model Identifier

Cubic Inch Displacement

Horizontally Opposed Cylinders

Fuel Injected

B

Shipping Designation

4

2

3

1

4

2

3

1

2-1.1. Engine Model Number Definition

The description of each alphanumeric character in the engine model number is given

below for the example engine model number IO-240-B1B (Figure 2-1).

Figure 2-1. Engine Model Definition

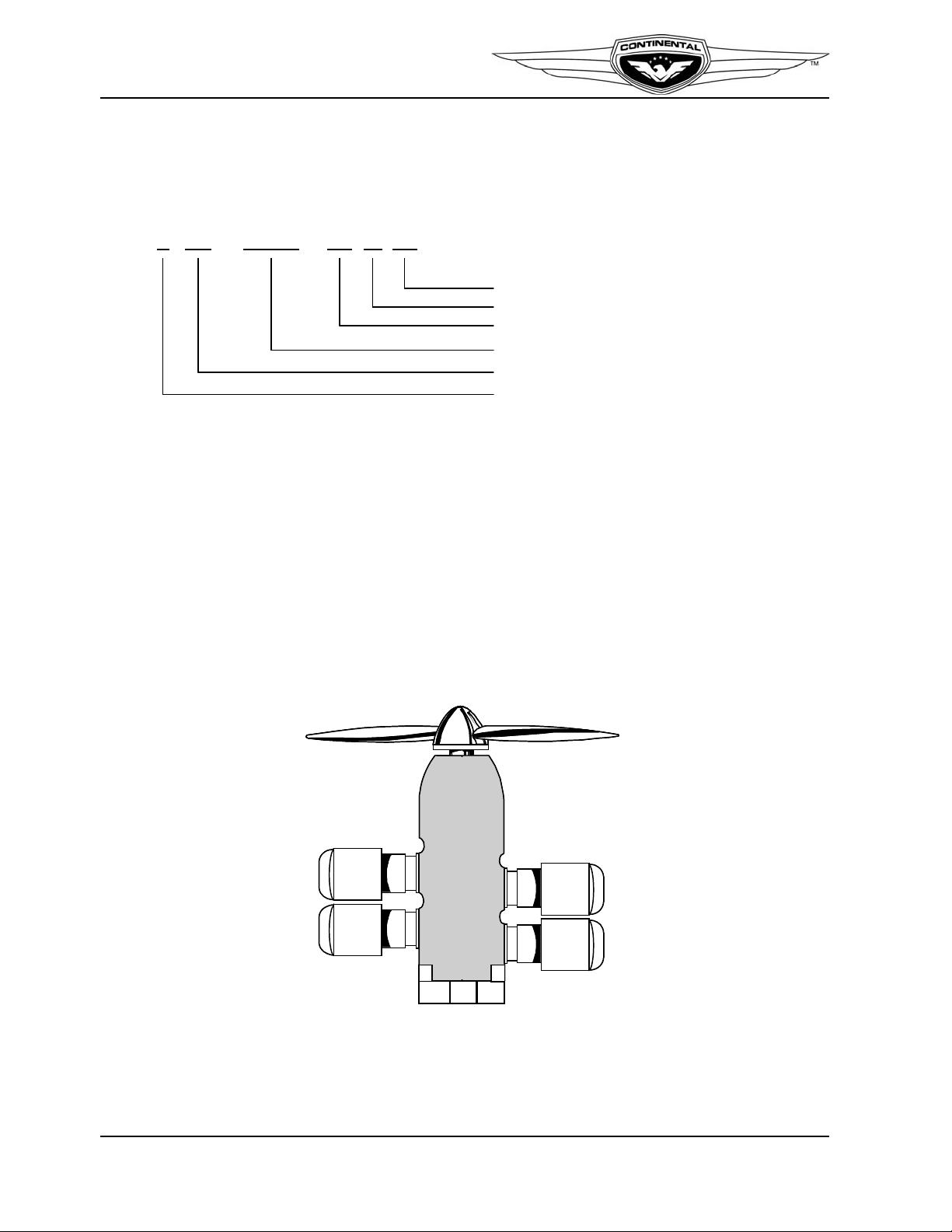

2-1.2. Cylinder Number Designations

Refer to Figure 2-2:

• The front of the engine is the end closest to the propeller and the rear of the engine is

the accessory end.

• V iewed from the rear of the engine, the left-side cylinders are designated by even num-

bers 2-4, with Cylinder 2 being closest to the rear.

• The right side cylinders have odd number sequential designation 1-3, with Cylinder 1

being closest to the rear.

• Firing order of the engine is 1-3-2-4.

Figure 2-2. Cylinder Number Designation

2-2 IO-240 Series Engine Installation & Operation Manual

31 October 2011

Page 25

2-2. Detailed Engine Description

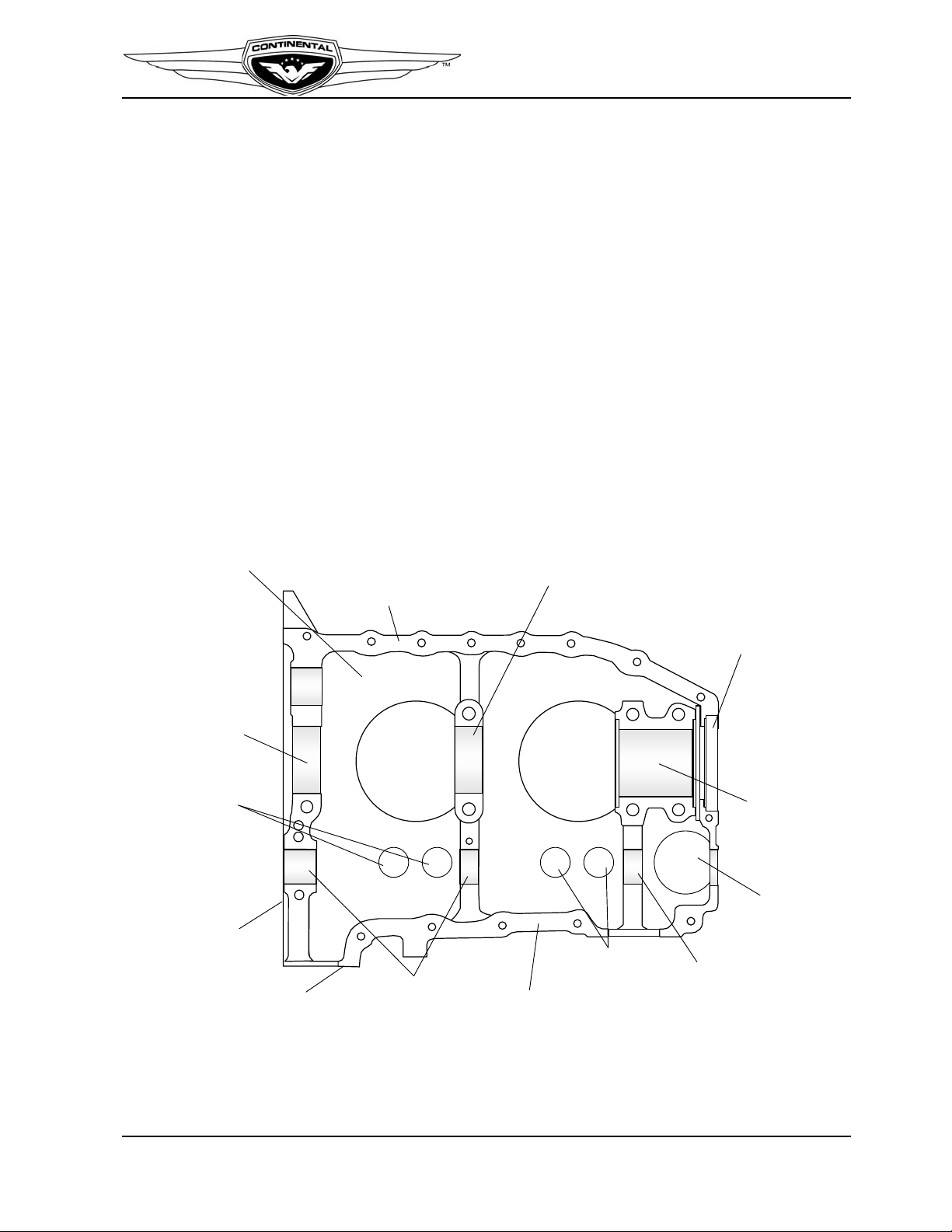

REAR CRANKSHFT

BEARING BORE

Cyl #2 Cyl #4

2-4 OR L/H

CRANKCASE HALF

INTERMEDIATE

CRANKSHAFT BEARING BORE

BACKBONE

CRANKSHAFT NOSE

SEAL LAND

FRONT

CRANKSHAFT

BEARING BORE

CAMSHAFT

BEARING BORE

TAPPET

GUIDES

SPINE BELOW

CAMSHAFT

CAMSHAFT

BEARING BORE

OIL SUMP

MOUNT FLANGE

ACCESSORY CASE

MOUNT FLANGE

TAPPET

GUIDES

FUEL

PUMP

MOUNTING

PAD

REAR CRANKSHFT

BEARING BORE

Cyl #2 Cyl #4

REAR CRANKSHFT

BEARING BORE

Cyl #2 Cyl #4

2-4 OR L/H

CRANKCASE HALF

INTERMEDIATE

CRANKSHAFT BEARING BORE

BACKBONE

CRANKSHAFT NOSE

SEAL LAND

FRONT

CRANKSHAFT

BEARING BORE

CAMSHAFT

BEARING BORE

TAPPET

GUIDES

SPINE BELOW

CAMSHAFT

CAMSHAFT

BEARING BORE

OIL SUMP

MOUNT FLANGE

ACCESSORY CASE

MOUNT FLANGE

TAPPET

GUIDES

FUEL

PUMP

MOUNTING

PAD

2-2.1. Crankcase

Two aluminum alloy castings are joined along the vertical center plane to form the

crankcase. The individual castings (with studs and inserts) are referred to as the “left

crankcase” and “right crankcase.” The crankcase provides a tight enclosure, sufficiently

rigid to support the crankshaft, camshaft and bearings, with oil galleries for lubrication.

Bosses molded in the crankcase castings are line bored in the assembled crankcase halves

to form bearings for the camshaft and saddles for precision crankshaft main bearing

inserts. Guides are bored through lateral bosses for hydraulic tappets. There are six studs

and two through-bolts for attaching cylinder base flanges. The fuel pump mounting pad is

located on the left crankcase half, forward of Cylinder 4 (Figure 2-3).

Cylinder mounting pads on the left and right crankcase are offset to permit each crankpin

to transmit the rotational force to the piston through the connecting rod. The crankcase

interior is vented by a breather assembly comprised of a tube and baffle assembly with a

side extension for a hose attachment. The breather assembly is pressed into a boss on the

top side of the right crankcase half, forward of Cylinder 3.

Engine Description

Figure 2-3. IO-240 Crankcase Features

IO-240 Series Engine Installation & Operation Manual 2-3

31 October 2011

Page 26

Engine Description

Starter

Alternator

Crankshaft

Camshaft

Fuel Pump &

Vacuum

Pump Driv e

Shaft

Camshaft

GearTachometer

Drive Shaft Oil Pump

Drive Gear

Oil Pump

Driven Gear

Starter

Alternator

Crankshaft

Camshaft

Fuel Pump &

Vacuum

Pump Driv e

Shaft

Camshaft

GearTachometer

Drive Shaft Oil Pump

Drive Gear

Oil Pump

Driven Gear

2-2.2. Engine Drive Train

The engine drive train (Figure 2-4) consists of the crankshaft, camshaft and drive gears.

The crankshaft has a propeller flange at one end to attach a propeller for thrust. The starter

gear meshes with the outer teeth of the rear crankshaft gear to turn the crankshaft until the

fuel mixture in the cylinder is ignited by the spark plugs. A drive gear at the rear end of the

crankshaft interfaces with a gear mounted on the rear end of the camshaft to synchronize

intake and exhaust valve movement and magneto rotation, as well as supply driving force

to the gear driven alternator. The oil pump driven gear, along with the optional tachometer

drive are gear driven by the inner row of teeth on the camshaft. The engine driven fuel

pump, and the optional vacuum pump drive are driven by a gear on the forward end of the

camshaft.

Figure 2-4. Engine Drive Train

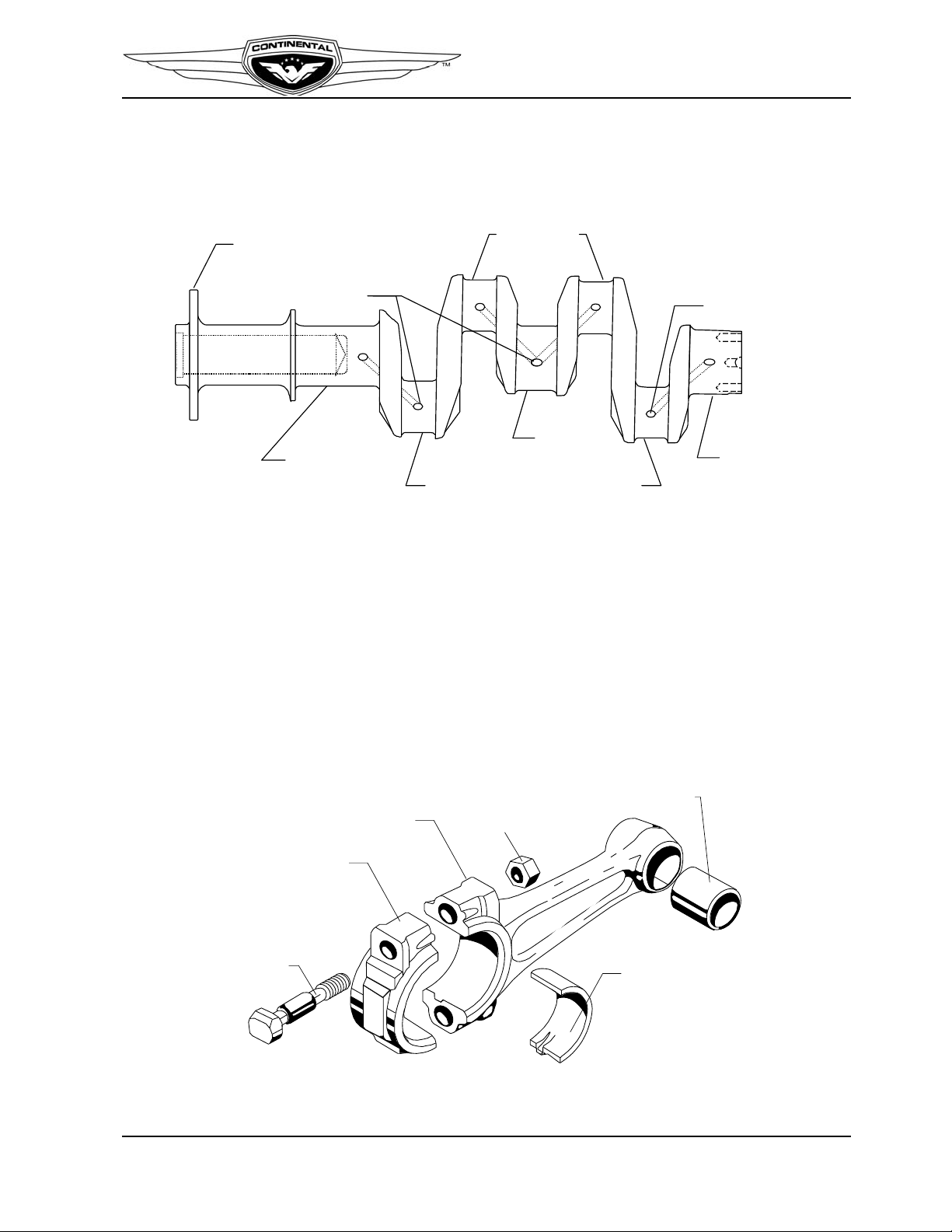

2-2.2.1. Crankshaft

The crankshaft (Figure 2-5) is an aircraft quality steel forging with three machined, main

journals supported by precision-bearing inserts in each of the three bearing saddles

machined in the crankcase. Four machined rod journals provide attachment of the

connecting rod assemblies.

The crankshaft gear is indexed on the crankshaft by a dowel and secured by machined

bolts. A neoprene oil seal over the crankshaft flange is seated between the crankcase

castings in the front shaft exit area, and is sealed to the crankshaft by a helical spring

inside the seal's cavity.

2-4 IO-240 Series Engine Installation & Operation Manual

31 October 2011

Page 27

Engine Description

CRANKSHAFT

FLANGE

FRONT MAIN

JOURNAL

ROD JOURNAL

ROD JOURNAL ROD JOURNAL

REAR MAIN

JOURNAL

MIDDLE MAIN

JOURNAL

OIL

PASSAGE

#1

#2

#3

#4

OIL

PASSAGE

CRANKSHAFT

FLANGE

FRONT MAIN

JOURNAL

ROD JOURNAL

ROD JOURNAL ROD JOURNAL

REAR MAIN

JOURNAL

MIDDLE MAIN

JOURNAL

OIL

PASSAGE

CRANKSHAFT

FLANGE

FRONT MAIN

JOURNAL

ROD JOURNAL

ROD JOURNAL ROD JOURNAL

REAR MAIN

JOURNAL

MIDDLE MAIN

JOURNAL

OIL

PASSAGE

#1

#2

#3

#4

OIL

PASSAGE

NOTE: Some older models use castellated nut with cotter pin

SPIRAL LOCK NUT

BRONZE BUSHING

CONNECTING ROD

CONNECTING ROD

CAP

ROD BOLT

SHELL

BEARING

The flange type crankshaft has a propeller mount flange forged on the front end with six

tapped bushings pressed into holes spaced equally around the flange. Six bolts, screwed

into the shaft flange bushings, clamp the propeller between a loose front flange and the

shaft flange.

Figure 2-5. Crankshaft

2-2.2.2. Connecting Rods

The connecting rods halves (Figure 2-6) are machined from a single forging of aircraft

quality steel and cut into two pieces, splitting the center of the larger opening of the

connecting rod assembly. The resulting pieces, called the rod and cap are fitted with a two

piece bearing and attach to the crankpin or rod journal with special bolts and nuts.

The portion of the rod between the rod and the crankpin and piston pin ends is called the

“I” beam. A split steel-backed bronze bushing is pressed into the piston pin end and

machined for a precision pin-to-bushing fit.

Figure 2-6. Connecting Rod

IO-240 Series Engine Installation & Operation Manual 2-5

31 October 2011

Page 28

Engine Description

FRONT REAR

#4 EXH #3 EXH #2 EXH #1 EXH

#3 & 4

INTAKE

#1 & 2

INTAKE

M/J

C/L C/L C/L C/L C/L C/L

M/J M/J

C/L - CAM LOBE

M/J - MAIN JOURNAL

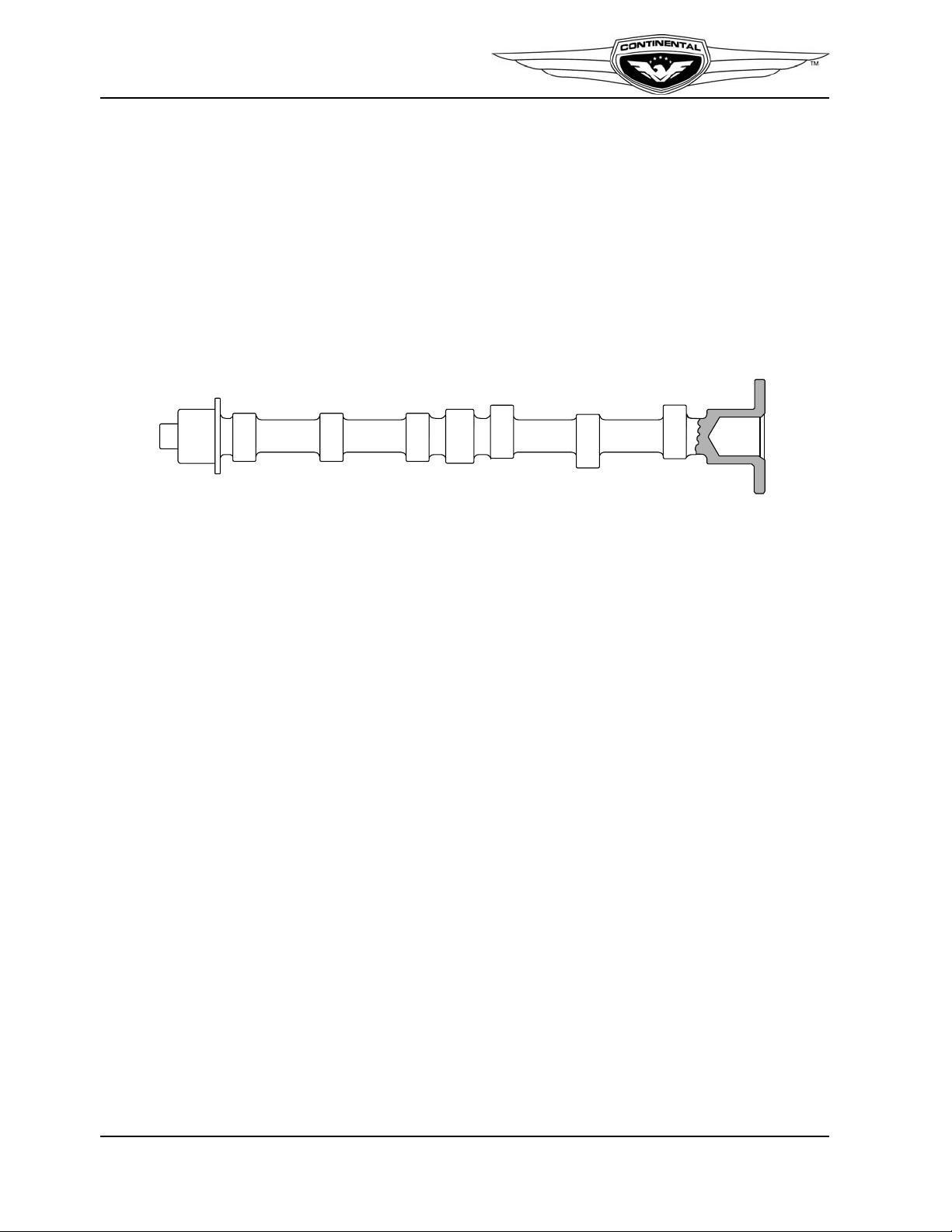

2-2.2.3. Camshaft

The camshaft forging is machined on three main journals, six cam lobes and the gear

mount flange at the rear of the camshaft (Figure 2-7). The lobes and journals are ground

and hardened. Camshaft main journals are supported in the crankcase by machined

bearing saddles. Hydraulic tappets move inward and outward in their bores, following the

eccentric shape of the cam lobes. Four unequally spaced bolts secure the gear to the

camshaft and ensure proper positioning, locating the gears' timing mark in relation to the

cam lobes. The camshaft gear has internal teeth to drive the alternator. A front-mounted

bevel gear drives the accessory drive bevel gear and fuel pump through a common shaft.

Figure 2-7. Camshaft

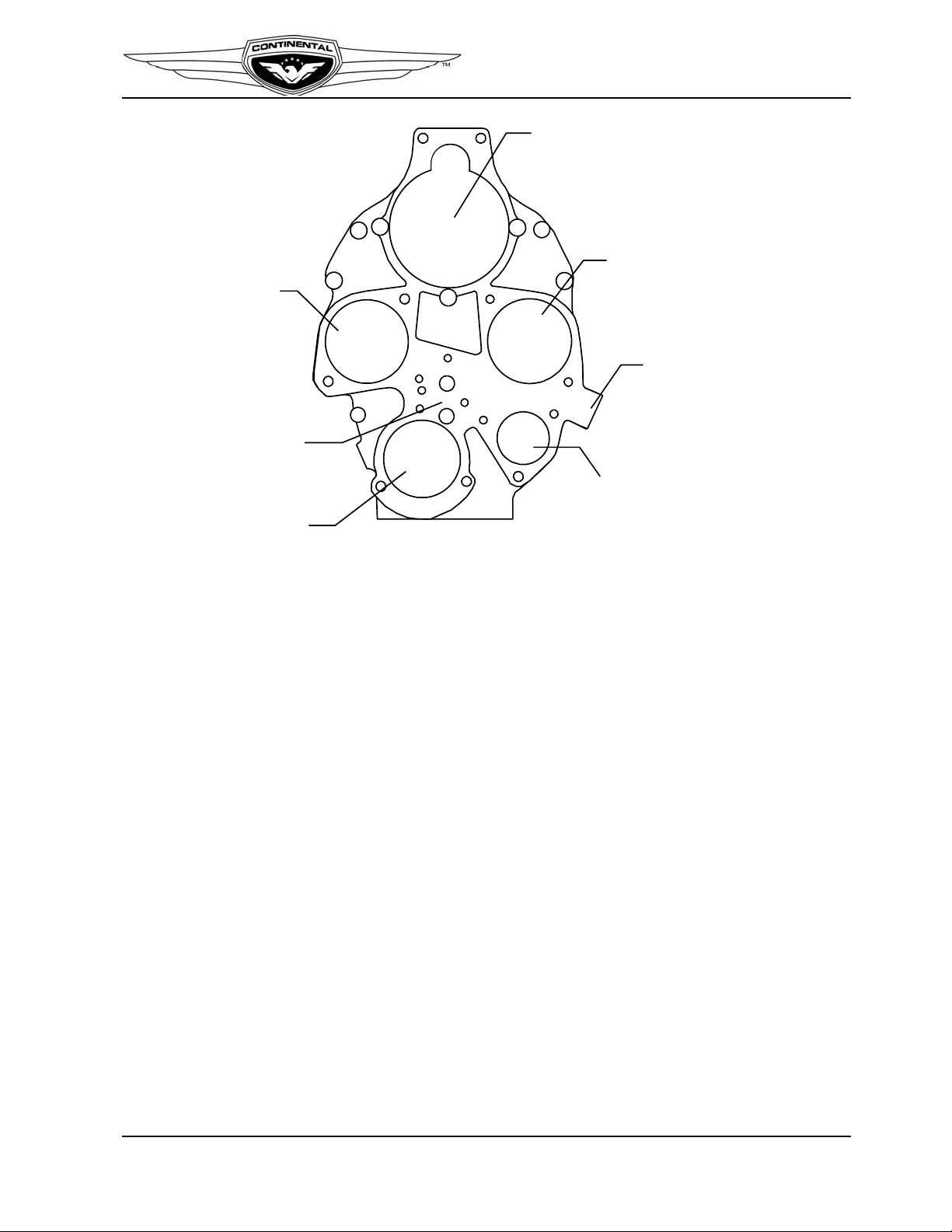

2-2.3. Accessory Case

The accessory case (Figure 2-8) aluminum alloy casting is attached to the rear of the

engine crankcase, aligned with crankcase dowels. The accessory case is secured to the

crankcase by crankcase studs and various attaching hardware. Accessory mount pads on

the rear surface are machined in one plane parallel to the machined parting flange which

surrounds the front side of the casting. Mounting pads for the magnetos, alternator cover,

starter, tachometer drive, oil filter adapter, oil pressure relief valve and an oil suction

screen boss are provided. The accessory case casting has two holes above and three studs

to attach the starter. A mounting pad is provided for a permanent oil screen housing. In

lieu of the oil screen housing, an oil filter adapter, with a screw-on type oil filter is also

available.

The oil pump housing is machined into the internal portion of the accessory case. A

machined, threaded boss is located on the lower right side of the accessory case for

installation of a non-adjustable oil pressure relief valve. Oil pump gear chambers are

machined in the interior of the accessory case. The oil pump drive gear shaft hole is

machined in-line with the camshaft and the driven gear shaft hole is directly above it.

A semicircular opening at the accessory case bottom is a machined threaded hole to

accommodate installation of the oil suction tube. Passages cast into the accessory case

allow oil to flow from the oil suction tube to the oil pump gears, pressure relief valve, and

main oil gallery. The tachometer drive shaft is the slotted end of the oil pump driven gear

shaft.

2-6 IO-240 Series Engine Installation & Operation Manual

31 October 2011

Page 29

Engine Description

STARTER MO UNTING

PAD

MAGNETO MOUNTIN G

PAD

TACH DRIVE

MOUNTING

PAD

ALTERNATOR

MOUNTING

PAD

OIL SCREEN

HOUSING

MOUNTING

PAD

OIL PRESSURE

HOUSING

MAGNETO

MOUNTING

PAD

RELIEF VALVE

2-2.4. Cylinders

The IO-240 engine have four, horizontally-opposed, air cooled cylinders, two on the left

side and two on the right side of the engine. The cylinders, pistons and valve drive train

provide the momentum to sustain crankshaft movement. Aviation fuel and air are drawn

into a cylinder during the intake stroke, compressed by the piston during the compression

stroke and then ignited by a high intensity spark from each spark plug (two per cylinder).

As the mixture is ignited, the expanding gases force the piston to move inward toward the

crankshaft during the power stroke.

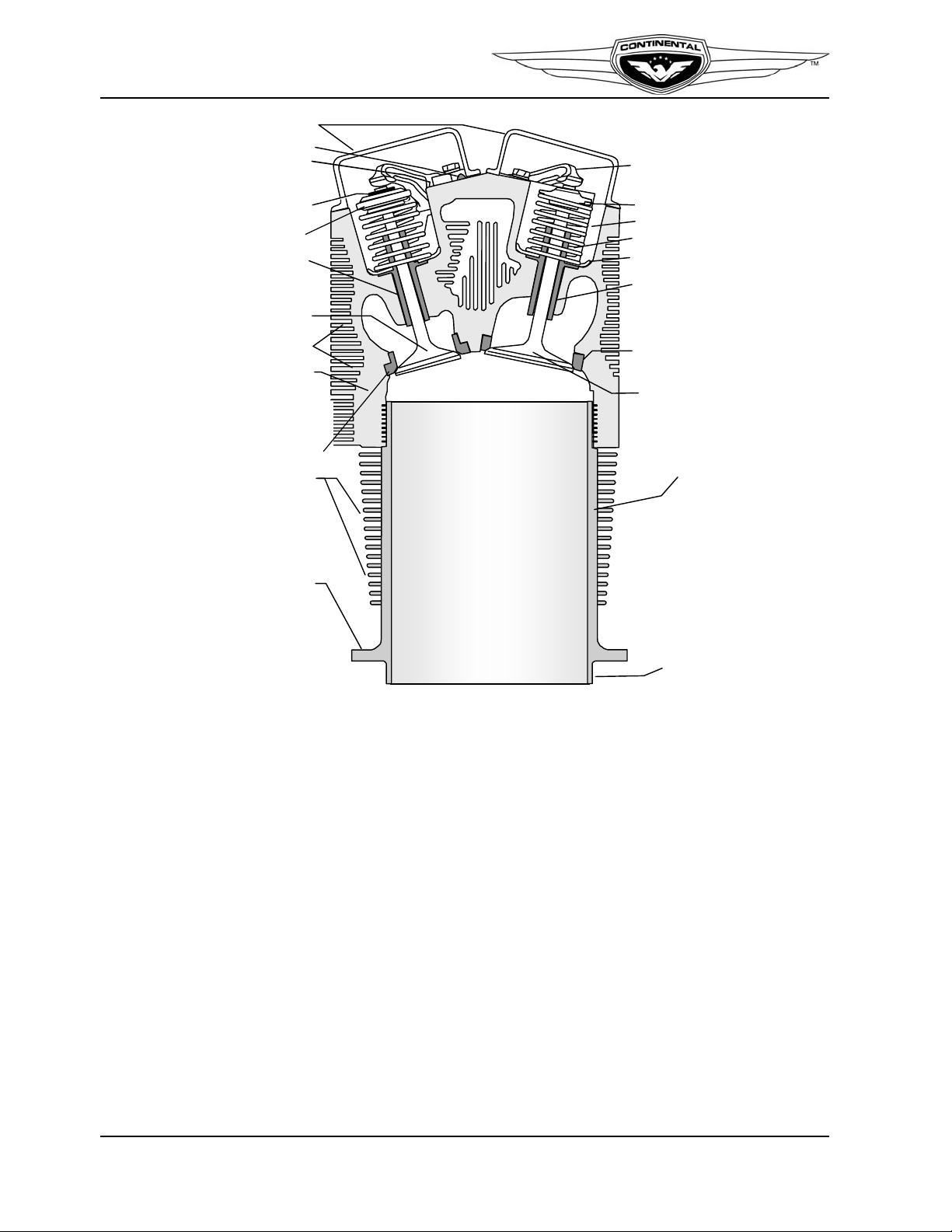

The head and barrel assembly (Figure 2-9) consists of externally finned aluminum alloy

head casting and a steel, nitrided cylinder barrel for wear resistance. Helical coil thread

inserts are installed in upper and lower spark plugs holes. A rotocoil assembly retains two

concentric springs surrounding the exhaust valve and is locked to the stem by tapered,

semi-circular keys which engage grooves around the valve stems. An outer retainer holds

two concentric springs which surround the intake valve and is locked to the stem by

tapered, semi-circular keys which engage grooves on the stem.

IO-240 Series engines use a cross flow cylinder head design. The intake ports are located

on top of the cylinder head while the exhaust ports are located below. There are separate

intake and exhaust valve rocker covers made from zinc-plated stamped sheet steel. This

cylinder design is used in conjunction with a Balanced Induction System mounted above

the engine.

Figure 2-8. Accessory Case Features

IO-240 Series Engine Installation & Operation Manual 2-7

31 October 2011

Page 30

Engine Description

ROCKER SHAFT

ROCKER ARM

VALVE RETAIN ER

KEYS

ROTOCOIL

EXHAUST

VALVE GUIDE

OUTER SPRING

INNER SPRING

SPRING SEAT

INTAKE VALVE GUIDE

INTAKE VALVE

SEAT INSERT

INTAKE VALVE

CYLINDER BARREL

EXHAUST

VALVE

COOLING FINS

CYLINDER HEAD

CYLINDER BARREL

COOLING FINS

CYLINDER BASE

FLANGE

CYLINDER SKIRT

ROCKER COVER

RETAINER

EXHAUST

VALVE

SEAT

INSERT

THRUST WASHER

(ONE ON EACH SIDE

OF EACH ROCKER ARM)

Figure 2-9. Cylinder Features

2-8 IO-240 Series Engine Installation & Operation Manual

31 October 2011

Page 31

2-2.4.1. Pistons

PISTON PIN

MANGANESE PHOSPHATE COATING

GRAPHITE COATED SKIRT

1

ST

COMPRESSION

RING

2

ND

COMPRESSION

RING

OIL CONTROL

RING

OIL SCRAPER

RING

Pistons (Figure 2-10) are aluminum alloy castings with a steel insert cast into the top ring

groove. The skirts are solid and have cylindrical relief cuts at the bottom. Pistons have

three ring grooves above the piston pin bore and one ring groove below. Compression

rings are installed in the top and second grooves. The groove below the piston pin bore

contains an oil scraper . A center grooved and slotted oil control ring is installed in the third

groove which has six oil drain holes to the interior. Weight differences are limited to ½

ounce between opposing cylinders bays. Piston pins are full floating with permanently

pressed-in aluminum end plugs.

Engine Description

2-2.4.2. Hydraulic Valve Tappets

Figure 2-10. Piston Features

The hydraulic valve tappet (lifter) provides an interface between the camshaft lobe and the

remaining valve train. Lifters ride on the eccentric cam lobes, opening and closing the

intake and exhaust valves mechanically via push rod tubes and rocker arms, converting the

cam lobe profile into a linear movement for intake and exhaust valves actuation. The

hydraulic mechanism inside the hydraulic mechanism maintains zero clearance between

the valve and actuating components.

IO-240 Series Engine Installation & Operation Manual 2-9

31 October 2011

Page 32

Engine Description

AA

OIL

SUCTION

TUBE

OIL PRESSURE

RELIEF VALVE

CRANKSHAFT

BEARINGS

CAMSHAFT

BOSS

INTAKE

EXHAUST

PUSHROD

HOUSING

PUSHROD

HYDRAULIC

LIFTERS

OIL SUMP

OIL PUMP GEARS

OIL FILTER

SCREEN

OIL COOLER

ADAPTER

OIL

SUCTION

TUBE

OIL PRESSURE

RELIEF VALVE

CRANKSHAFT

BEARINGS

CAMSHAFT

BOSS

INTAKE

EXHAUST

PUSHROD

HOUSING

PUSHROD

HYDRAULIC

LIFTERS

OIL SUMP

OIL PUMP GEARS

OIL FILTER

SCREEN

OIL COOLER

ADAPTER

2-2.5. Lubrication System

The engine lubrication system (Figure 2-11 and Figure 2-12) delivers lubricating oil

throughout the engine to various bearings, bushings, and engine components. The wet

sump lubrication system consists of an internal engine-driven oil pump, a fixed, nonadjustable pressure relief valve, an oil sump and oil sensing ports. Various optional oil

cooler adapters allow connection of an optional remote mounted oil cooler.

2-10 IO-240 Series Engine Installation & Operation Manual

Figure 2-11. IO-240-A Lubrication

31 October 2011

Page 33

Engine Description

BB

OIL

SUCTION

TUBE

OIL PRESSURE

RELIEF VALVE

CRANKSHAFT

BEARINGS

CAMSHAFT

BOSS

INTAKE

EXHAUST

PUSHROD

HOUSING

PUSHROD

HYDRAULIC

LIFTERS

OIL SUMP

OIL PUMP GEARS

OIL FILTER AND

BYPASS

ASSEMBLY

OIL COOLER

ADAPTER

OIL

SUCTION

TUBE

OIL PRESSURE

RELIEF VALVE

CRANKSHAFT

BEARINGS

CAMSHAFT

BOSS

INTAKE

EXHAUST

PUSHROD

HOUSING

PUSHROD

HYDRAULIC

LIFTERS

OIL SUMP

OIL PUMP GEARS

OIL FILTER AND

BYPASS

ASSEMBLY

OIL COOLER

ADAPTER

2-2.5.1. Oil Pump

IO-240 Series Engine Installation & Operation Manual 2-11

31 October 2011

Figure 2-12. IO-240-B Lubrication

The engine-driven, gear type oil pump (Figure 2-13) is a positive displacement pump that

consists of two meshed steel gears that revolve inside the oil pump cavity machined in the

accessory case. The camshaft drives the oil pump drive gear, which drives the oil pump

driven gear. The oil pump driven gear is supported by a shaft pressed into the accessory

case and the oil pump cover plate. The oil pump drive gear shaft is supported by bushings