Continental Refrigerator DLRB42-SS-F-BS, DLRB67-SS-F, DLRB67-SS-F-BS Specifications

FISH FILE

REFRIGERATED BASE

REFRIGERATORS

Utilizing Environmentally Safe, CFC-free R-134a Refrigerant

Standard Features

•Stainless Steel Exterior and Interior

•Modern, State-of-the-Art Styling

•Performance Rated Refrigeration System Utilizing

Environmentally Safe R-134a Refrigerant

•Automatic, Energy Saving, Non-Electric Condensate

Disposal System

•High Density, Non-CFC Polyurethane Foamed-In-Place

Insulation

•Easily Accessible and Serviceable Front Slide-Out

Condensing Unit

•Completely Enclosed, Vented, and Removable Case Back

•Plasticized Fin Coil

•Capillary Dial Thermometer

•Chrome-Plated Hardware

•Reinforced Rigid Work Table

•Easy Glide Drawers

•One Piece Snap-In Magnetic Gaskets

•Adjustable 6" Stainless Steel Legs

•

Specially Designed for Fresh Fish Storage on Crushed Ice

Models Available

•DLRB42-SS-F

•DLRB67-SS-F

DLRB42-SS-F

Optional Features & Accessories

•Remote Models - R •Back Splash - BS

•Electric Condensate •Casters

•Stainless Steel Rear •Front Breathing Kit (-FB)

Cover

REFRIGERATION SYSTEM

A “Performance Rate”, air-cooled, hermetically

sealed, capillary type refrigeration system is

installed on the top of each model. Plasticized

finned coil and air circulating fans are contained

within an easily accessible, low profile, interior

ceiling mounted housing. Our refrigeration system, fully charged with R-134a refrigerant, is

designed to maintain 38°-40° Fahrenheit while

operating with an unrestricted air supply in an

ambient temperature of 100° Fahrenheit. All

evaporator condensate water is directed to the

bottom where there is an automatic electric

condensate vaporizer. a strict quality assurance team inspects all materials and components to certify that each model conforms to the

most exacting standards. All models are performance tested for a minimum of 16 hours

prior to crating.

CABINET CONSTRUCTION

All materials are of top quality, and are assembled under rigid supervision conforming to strict

quality assurance requirements. Case is of all

metal welded construction and is internally supported and braced for rigid unit construction.

Exterior cabinet back and bottom are heavy

gauge galvanized steel. Work top is constructed of heavy gauge polished stainless steel for

durability. Cabinet design eliminates overlapping panels with raw edges. Interior corners

are rounded with a 1/4" radius for cleaning

ease. All cabinet joints and seams are vaportight sealed. Easily removable anti-sweat drawer heaters, concealed by a non-metallic, nonconductive, high impact thermal breaker strip,

eliminates condensation build-up on case front.

INSULATION

All cabinet walls, top, and bottom have high

density insulation. Foamed-in-place, non-CFC

polyurethane insulation.

DRAWER CONSTRUCTION

Door fronts and backs are constructed of heavy

gauge, polished stainless steel with heavy duty,

safety grip, chrome plated handles. All drawer

fronts are insulated with non-CFC polyurethane

foam insulation. Full extension, lift-out type

drawer frames are of heavy gauge, welded

stainless steel mounted on heavy duty, easy

glide, self closing drawer slides. Each drawer is

supplied with a sturdy removable pan 24" wide

x 18

1

/2 long x 6" deep. Self adjusting, full

perimeter, magnetic snap-in gaskets guarantee

a positive seal. Condensation from pans and

water from ice is drained by drawer gutters to

the floor of the cabinet where a 1" male pipe

connection can be made to the floor drain.

DLRBSF305

REFRIGERATORS

A Division of National Refrigeration & A/C Products, Inc.

539 Dunksferry Road Bensalem, PA 19020

(800) 523-7138 Fax: (215) 244-9579

www.continentalrefrigerator.com

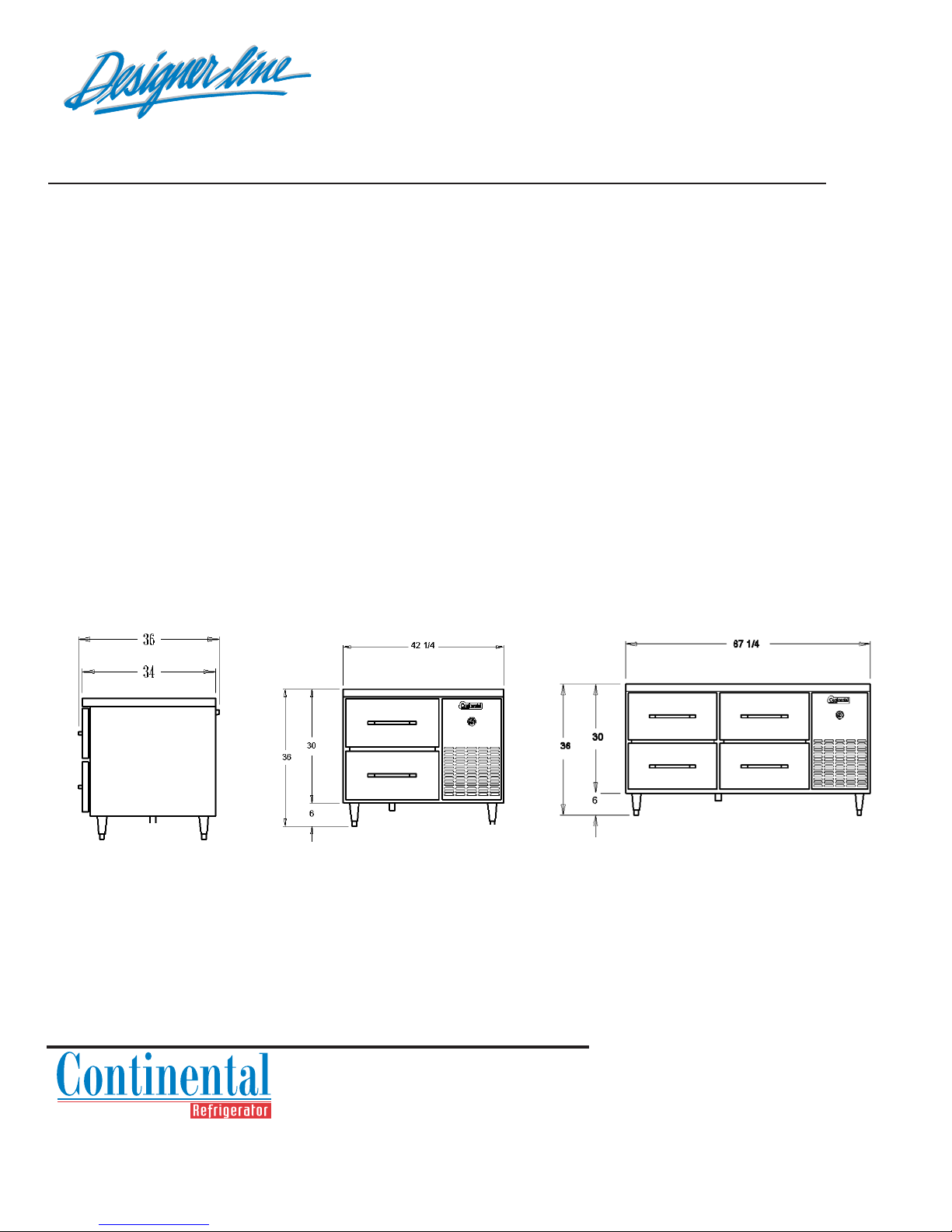

CHARACTERISTICS DLRB42-SS-F DLRB42-SS-F-BS DLRB67-SS-F DLRB67-SS-F-BS

DIMENSIONAL DATA

Net Capacity (cu.ft.) 8.0 8.0 17.0 17.0

Width, Overall (in.) 42

1

/4 421/4 671/4 671/4

Depth, Overall (incl. Hdls. (in.) 36 36 36 36

Depth, Body Only (Less Drawer(s)) (in.) 34 34 34 34

Height, Overall (incl. 6" Legs) (in.) 36 42 36 42

No. of Drawers 2 2 4 4

Drawer Pans (WxLxD) (in.) 24x18

1

/2x6 24x181/2x6 24x181/2x6 24x181/2x6

Interior Depth (in.) 28

1

/2 281/2 281/2 281/2

Interior Height (in.) 26 26 26 26

Interior Width (in.) 22 22 47 47

Condensing Unit Size (H.P.)

1

/

4

1

/

4

1

/

3

1

/

3

Refrigerant R-134a R-134a R-134a R-134a

Cabinet Electrical 115/60/1 115/60/1 115/60/1 115/60/1

Amps 6.1 6.1 8.8 8.8

Fans 1 1 2 2

Shipping Weight (lbs.) 355 470 495 495

Shipping Height (in.) 43 43 43 43

Shipping Length (in.) 54 54 77 77

Shipping Depth (in.) 41 41 41 41

SIDE VIEW

DLRB42-SS-F

DLRB67-SS-F

Note: All specifications subject to change without notice

Loading...

Loading...