Page 1

OVER/UNDER

DUAL TEMP

REFRIGERATOR/FREEZER

REFRIGERATOR/FREEZER

Utilizing Environmentally Safe, CFC-free R-134a/ R-404a Refrigerant

Standard Features

• Modern, State-of-the-Art Styling

• Performance Rated Refrigeration Systems

• 3" Non-CFC Polyurethane Foam Insulation

• Chrome Plated Flow Line Handles

• Cam-Action Lift-Off Hinges

• Self-Closing Doors

• Magnetic Snap-In Door Gaskets

• Cylinder Lock In Each Door

• Automatic Electric Condensate Evaporator

• Adjustable 6" Stainless Steel Legs

• Heavy-Duty, Epoxy-Coated Steel Shelves

• External Digital Thermometers

• Automatic Electric Defrost On Freezer Systems

• Automatic Interior Lighting

Models Available

Standard (S/S Front, Aluminum Ends & Interior)

Suffix SA (S/S Exterior, Aluminum Interior)

Suffix SS (S/S Exterior & Interior)

DL1RF-SS

DL1RFE-SS

OTHER MODELS

AVAILABLE

• DL1RFX-SS

• Remote

• Consult Factory

• Hinged Glass Door

Refrigeration System

Two”performance rated”, air cooled, hermetically

sealed, capillary-type refrigeration systems are

installed on the top of each dual temp. Plasticized fin

coil and air circulating fans are contained within an easily accessible, low-profile, interior ceiling mounted

housing. Both refrigeration systems are fully charged

with refrigerant and evenly matched providing equal air

distribution. Refrigerator sections are designed to maintain 38-40 degrees Fahrenheit (3 to 5 degrees

Centigrade), and Freezer sections 0 degrees

Fahrenheit (-18 degrees Centigrade) while operating

with an unrestricted air supply in a maximum ambient

temperature of 100 degrees Fahrenheit. Freezer systems have an automatic electric defrost timer which initiates defrost cycles at pre-determined intervals. All

condensate water is directed to the cabinet bottom for

connection to an automatic thermostatically controlled

evaporator which is supplied with each model. A strict

quality-assurance team inspects all materials and components to certify that each model conforms to the most

exacting standards. All models are factory performance tested for a minimum of 16 hours prior to crating.

Cabinet Construction

All materials are of top quality, assembled to conform

with strict quality-assurance requirements. The cabinet

front and doors are constructed of heavy-gauge polished stainless steel for durability. All cabinet joints and

seams are sealed vapor tight. Case is of all metal, welded construction and internally supported and braced for

a rigid unit construction. Cabinet design eliminates

overlapping panels with raw edges. Cabinet body, and

doors are insulated with non-CFC, foamed-in-place

polyurethane foam with an average thickness of 3 inches to ensure increased energy efficiency. Full length

louvered air grille located above the doors allows equal

air circulation to the condensing units. Easily removable, low wattage, anti-sweat door heaters concealed

by a non-metallic, non-conductive, high-impact thermal

breaker strip eliminate condensate build up on the cabinet front. Automatic interior lighting is controlled by

door openings. Cabinets are equipped with 6-inch

adjustable stainless steel legs.

Shelving

Shelves are designed for heavy-duty use with .306"

diameter frame and brace members and .140" diameter

fill wires spaced 3/4" apart. Shelves are welded steel

and epoxy-coated for a durable, long, rust-free service

life. Adjustments are in 1/2 inch increments and a wide

door opening allows the use of a variety of optional pan

and tray slide types.

Door Construction

Door shells are constructed of heavy-gauge stainless

steel and are internally braced and urethane-foaminsulated for rigidity. Door corners are of welded construction and polished. Replaceable snap-in door gaskets are self-adjusting, heavy-duty, magnetic type. Door

handles and hinges are chrome-plated and non-corrosive. Doors are provided with built-in cylinder locks

which are keyed alike. Hinges are cam

- action, lift-off

type featuring positive safety stop at 120

degrees.

Page 2

REFRIGERATOR/FREEZER

A Division of National Refrigeration & A/C Products, Inc.

539 Dunksferry Road Bensalem, PA 19020

(800) 523-7138 Fax: (215) 244-9579

www.continentalrefrigerator.com

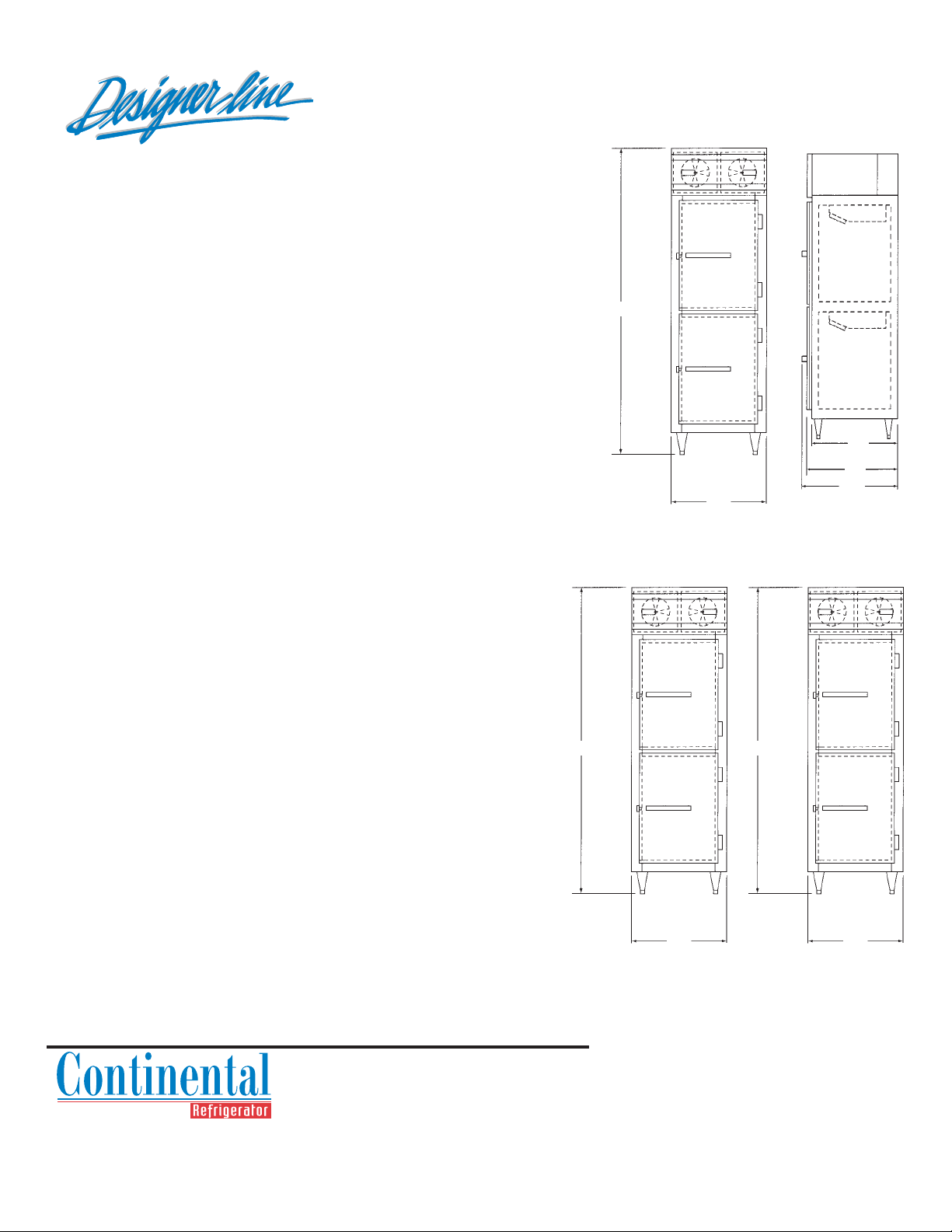

MODEL DL1RF-SS MODEL DL1RFX-SS MODEL DL1RFE-SS

ONE SECTION ONE SECTION ONE SECTION

Reach-In Reach-In Reach-In

CHARACTERISTICS

DIMENSIONAL DATA

Net Capacity (cu. ft.) Refrigerator 10 16 11

Net Capacity (cu.ft.) Freezer 10 16 11

Width, Overall (in.) 26 36

Depth, Overall (Incl. Hdls.) (in.) 351/

2

351/

/

2

281/

351/

1

4

Depth (Less Door(s) (in.) 32 32 32

Depth (Doors(s) Open 90°) (in.) 55

Clear Door Width (in.) 19

Clear Half-Door Height (in.) 271/

Height, Overall (Incl. 6" Legs)(in.) 831/

/

3

8

/

2

4

66 58

8

295/

2

271/

4

831/

217/

271/

831/

1

2

Half Doors 2 2 2

Shelves 4 4 4

Shelf Area (sq. ft.) 10.2 24.4 10.2

Tray Slide Capacity (Half) 11ea. 11ea. 11ea.

REFRIGERATION DATA

1

Condensing Unit Size (H.P.) Ref.

Condensing Unit Size (H.P.) Frz.

5

/

1

4

/

Capacity (BTU/hr)*Ref. 1725 1940 1725

Capacity (BTU/hr)*Frz. 1250 1590 1250

1

4

/

1

3

/

1

5

/

1

4

/

2

2

8

2

4

831/4"

1

/4"

36

DL1RFX-SS

32"

24"

1

35

/2"

SIDE VIEW

FRONT VIEW

ELECTRICAL DATA

Cabinet Specifications

Feed Wires (Incl. Ground) 3/3 3/3 3/3

Condensing Unit Specs.

Total Amperes 5.3/5.4 6.9/7.6 5.3/5.4

Cabinet Amperes .9/.9 1.6/1.6 .9/.9

Defrost Amperes 5.2 6.5 5.2

Power Supply Cord yes/yes yes/yes yes/yes

115/60/1 115/60/1 115/60/1

115/60/1 115/60/1 115/60/1

831/4"

831/4"

SHIPPING DATA

Height – crated (in.) 851/

Width – crated (in.) 315/

2

8

Depth – crated (in.) 42 42 42

Volume – crated (cu.ft.) 66 87 66

Weight Std – crated (lbs.) 420 440 420

Weight SS – crated (lbs.) 480 500 480

Weight Std – uncrated (lbs.) 320 340 320

Weight SS – uncrated (lbs.) 380 400 380

*Rating @ +25° F Evaporator, 90° Ambient (Refrigerator)

*Rating @ -15° F Evaporator, 90° Ambient (Freezer)

Note: All specifications subject to change without notice

2

851/

42 315/

851/

2

8

26"

DL1RF-SS

FRONT VIEW

DL1RFE-SS

FRONT VIEW

Note: If the cabinet is located directly against wall and/or under low ceiling, a minimum clearance of 12" is required.

1

/2"

28

DL1RF810

Loading...

Loading...