Page 1

EXTRA-WIDE

FREEZERS

FREEZERS

Utilizing Environmentally Safe, CFC-free R-404a Refrigerant

Standard Features

• Modern, State-of-the-Art Styling Performance

Rated “Plug” Refrigeration System

• 3" Non-CFC Polyurethane Foam Insulation

• Chrome-Plated Flow Line Handles

• Cam-Action Lift-Off Hinges

• Self-Closing Doors

• Magnetic Snap-In Door Gasket

• Cylinder Lock in Each Door

• Automatic Hot Gas Condensate Evaporator

• Adjustable 6" Stainless Steel Legs

• Heavy-Duty, Epoxy-Coated Steel Shelves

• External Digital Thermometer

• Automatic Electric Defrost

Optional Features & Accessories

• Half Door • Pass-Thru

• Remote • Consult Factory

• Hinged Glass Display Door

Standard (S/S Front, Aluminum Ends & Interior)

Suffix SA (S/S Exterior, Aluminum Interior)

Suffix SS (S/S Exterior & Interior)

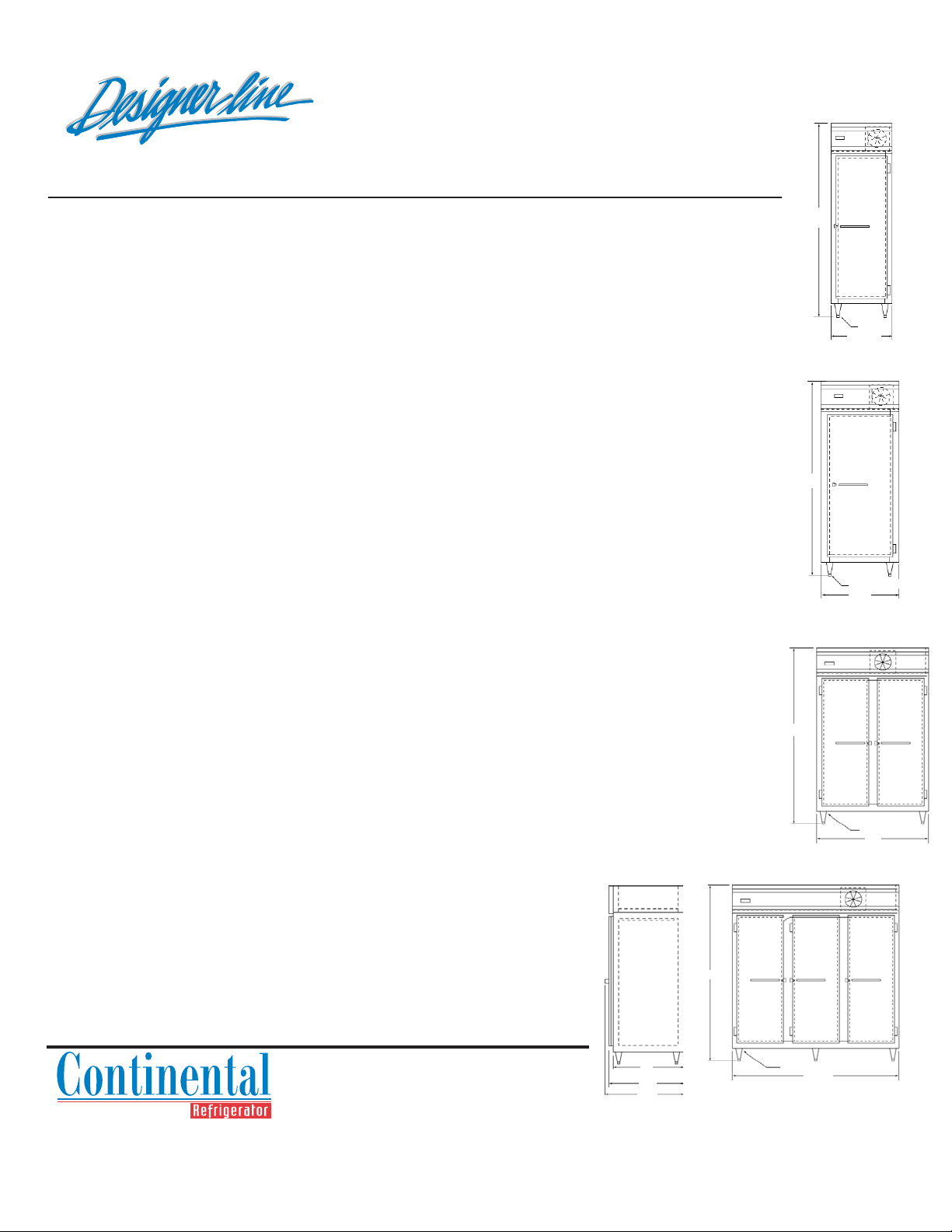

DL2FE-SS

DL3FE-SS

DL1FE-SS

DL1FX-SS

Refrigeration System

A “performance rated” air cooled hermetically sealed,

capillary type refrigeration system is installed on the

top of each freezer. Plasticized fin coil and air circulating fans are contained within a concealed “plug”

type insulated housing, readily accessible on the top

of the cabinet and separate from the food zone to

increase food storage capacity. The entire “plug” system is fully charged with refrigerant and mounted on

a sturdy steel, rail-type base which can be easily

removed if refrigerator conversion is desired.

Freezers are designed to maintain 0 degrees

Fahrenheit (-18

°

Centigrade) while operating with an

unrestricted air supply in a maximum ambient temperature of 100

°

Fahrenheit Automatic electric defrost

timer initiates defrost cycles at predetermined intervals. All condensate water is evaporated by an automatic, non-electric, corrosion-resistant condensate

evaporator. A strict quality-assurance team inspects

all materials and components to certify that each

model conforms to the most exacting standards. All

models are factory performance tested for a minimum

of 16 hours prior to crating.

Cabinet Construction

All materials are of top quality, assembled to conform

with strict quality-assurance requirements. The cabinet front and doors are constructed of heavy-gauge

polished stainless steel for durability. All cabinet joints

and seams are sealed vapor tight. Case is of all

metal, welded construction and internally supported

and braced for a rigid unit construction. Cabinet

design eliminates overlapping panels with raw edges.

Cabinet body and doors are insulated with non-CFC,

foamed- in-place polyurethane foam with an average

thickness of 3 inches to ensure increased energy efficiency. Full-length louvered air grille located above

the doors allows equal air circulation to the condensing unit. Easily removable, low-wattage, anti-sweat

door heaters concealed by a non-metallic, non-conductive, high-impact thermal breaker strip eliminate

condensate build up on the cabinet front. Automatic

interior lighting is controlled by door openings.

Cabinets are equipped with 6-inch adjustable stainless steel legs.

Shelving

Shelves are designed for heavy-duty use with .306"

diameter frame and brace members and .140" diameter fill wires spaced 3/4" apart. Shelves are welded

steel and epoxy-coated for a durable, long, rust-free

service life. Adjustments are in

1

/

2" increments and a

wide door opening allows the use of a variety of

optional pan and tray slide types.

Door Construction

Door shells are constructed of heavy-gauge stainless

steel and are internally braced and urethane-foaminsulated for rigidity. Door corners are of welded construction and polished. Replaceable snap-in door

gaskets are self-adjusting, heavy-duty, magnetic type.

Door handles and hinges are chrome-plated and noncorrosive. Doors are provided with built-in cylinder

locks which are keyed alike. Hinges are cam action,

lift-off type featuring positive safety stop at 120

degrees.

Page 2

DLFE305

FREEZERS

A Division of National Refrigeration & A/C Products, Inc.

539 Dunksferry Road Bensalem, PA 19020

(800) 523-7138 Fax: (215) 244-9579

www.continentalrefrigerator.com

DL1FE-SS DL1FX-SS DL2FE-SS DL3FE-SS

One Section One Section-Extra Wide Two Section Three Section

CHARACTERISTICS

Reach-In Pass-Thru Reach-In Pass-Thru Reach-In Pass-Thru Reach-In Pass-Thru

DIMENSIONAL DATA

Net Capacity (cu.ft.) 22 22 32 32 52 52 75 75

Width, Overall (in.) 281/

2

281/

2

361/

4

361/

4

57 57 851/

2

851/

2

Depth, Overall (Incl. Hdls.) (in.) 351/

2

39 351/

2

39 35

1

/

2

39 351/

2

39

Depth (Less Door(s)) (in.) 32 32 32 32 32 32 32 32

Depth (Door(s) Open 90°) (in.) 58 84 66 100 58 84 58 84

Clear Door Width (in.) 217/

8

217/

8

295/

8

295/

8

217/

8

217/

8

217/

8

217/

8

Clear Full-Door Height (in.) 585/

8

585/

8

585/

8

585/

8

585/

8

585/

8

585/

8

585/

8

Clear Half-Door Height (in.) 271/

2

271/

2

271/

2

271/

2

271/

2

271/

2

271/

2

271/

2

Height, Overall (Incl. 6" Legs) (in.) 831/

4

831/

4

863/4 863/4 863/4 871/

4

871/

4

871/

4

No. of Full Door(s) 1 2 1 2 2 4 3 6

No. of Half Door(s) 2 4 2 4 4 8 6 12

No. of Shelves 3 3 3 3 6 6 9 9

Shelf Area (sq. ft.) 20.4 20.4 24.4 24.4 40.8 40.8 61.2 61.2

Tray Slide Capacity (Half) 11 ea. 11 ea. 11 ea. 11 ea. 11 ea. 11 ea. 11 ea. 11 ea.

Tray Slide Capacity (Full) 24 ea. 24 ea. 24 ea. 24 ea. 24 ea. 24 ea. 24 ea. 24 ea.

REFRIGERATION DATA

Condensing Unit Size (H.P.)

1

/

3

1

/

3

1

/

2

1

/

2

1

/

2

3

/

4

3

/

4

1

Capacity (BTU/Hr)* 1590 1590 1840 1840 2470 3575 3575 4325

ELECTRICAL DATA

Cabinet Specifications

115/60/1 115/60/1 115/60/1 115/60/1 115/60/1 115/208-230/60/1 115/208-230/60/1 115/208-230/60/1

Feed Wires (Incl. Ground) 3 3 3 3 3 4 4 4

Condensing Unit Specs.

115/60/1 115/60/1 115/60/1 115/60/1 115/60/1 208-230/60/1 208-230/60/1 208-230/60/1

Total Amperes 7.6 8.0 12.5 12.8 12.8 9.3 9.3 12.1

Cabinet Amperes 1.6 1.9 1.8 2.1 1.9 2.9 2.9 3.9

Defrost Amperes 4.3 4.3 9.6 9.6 9.6 9.6 9.6 9.6

Power Supply Cord yes yes yes yes yes no no no

SHIPPING DATA

Height – crated (in.) 851/2 851/2 851/2 851/2 851/2 851/2 851/2 851/2

Width – crated (in.) 315/

8

315/

8

42 42 64 64 90 90

Depth – crated (in.) 42 42 42 42 42 42 42 42

Volume – crated (cu. ft.) 63 63 87 87 129 129 181 181

Weight Std – crated (lbs.) 355 385 455 460 610 720 865 960

Weight SS – crated (lbs.) 415 445 515 520 690 800 985 1075

Weight Std – uncrated (lbs.) 255 285 355 360 440 550 655 750

Weight SS – uncrated (lbs.) 315 345 415 420 520 630 770 865

*Rating @ -15°F Evaporator, 90° Ambient

Note: All specifications subject to change without notice.

Note: If the cabinet is located directly against wall and/or under low ceiling,

a minimum clearance of 2" is required.

Cabinet upper side panels and refrigeration plug system can be easily removed

and reinstalled at installation site where space limitations are confining.

83 1/4"

281/2"

6" ADJUSTABLE LEGS

32"

34"

35 1/2"

6" ADJUSTABLE LEGS

86 3/4"

57"

87 1/4"

851/

2"

6" ADJUSTABLE LEGS

DL1FE-SS

FRONT VIEW

SIDE VIEW

DL2FE-SS

FRONT VIEW

DL3FE-SS

FRONT VIEW

86 3/

4"

361/4"

DL1FX-SS

FRONT VIEW

6" ADJUSTABLE LEGS

Loading...

Loading...