Continental Refrigerator C75, C85, C90, O-200 Overhaul Manual

C75

C85

C90

O-200

CONTINENTAL® AIRCRAFT ENGINE

OVERHAUL

MANUAL

FAA APPROVED

Publication X30010

©

2011 CONTINENTAL MOTORS, INC. AUG 2011

Supersedure Notice

This manual revision replaces the front cover and list of effective pages for Pub lication Part No. X30010, dated

January 1984. Previous editions are obsolete upon release of this manual.

Effective Changes for this Manual

0...............January 1984

1............31 August 2011

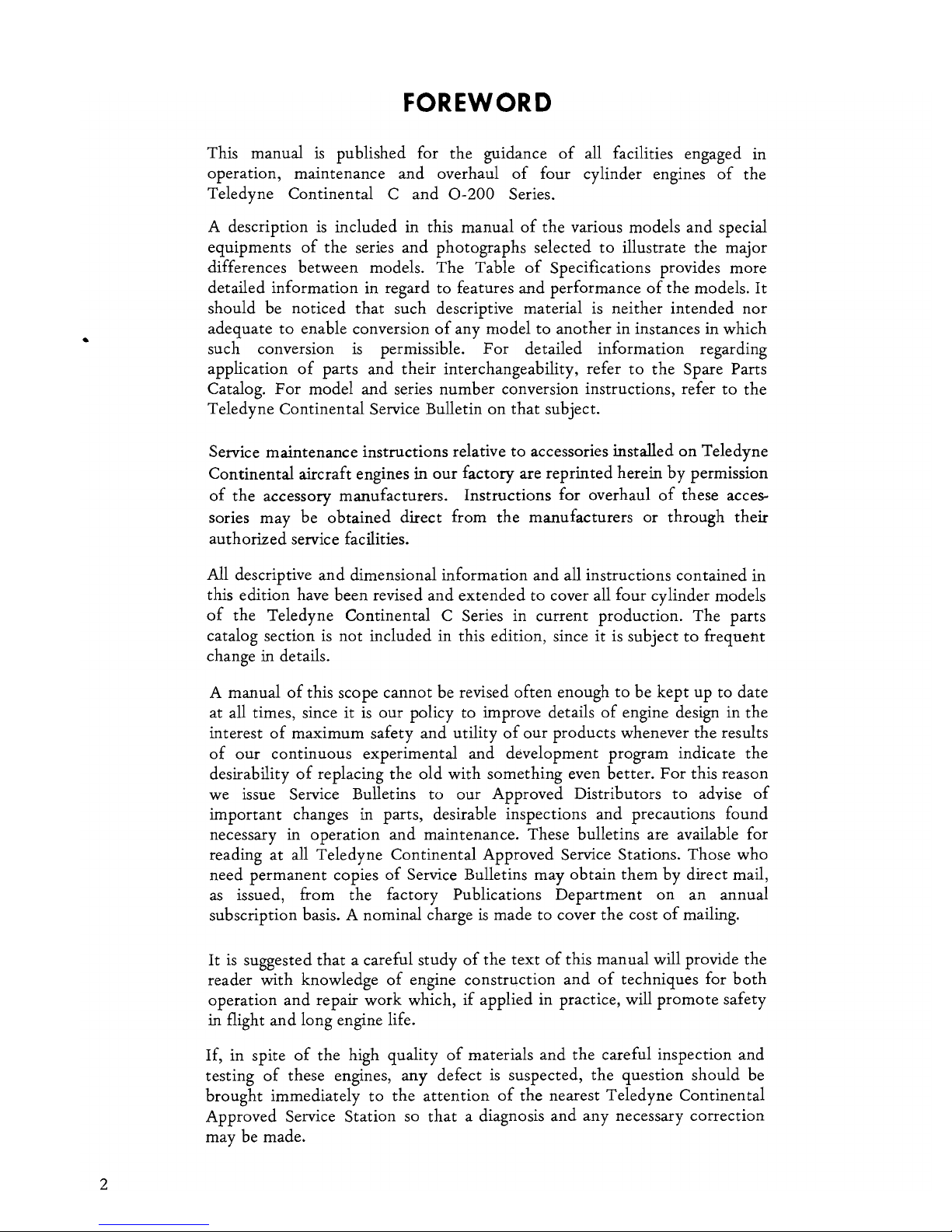

List of Effective Pages

Document Title: C75, C85, C90 & O-200 Series Engines Overhaul Manual

Publication Number: X30010 Initial Publication Date: January 1984

Page Change Page Change Page Change Page Change

Cover............................1

A...................................1

1 - blank added............1

2 thru 124.....................0

Published and printed in the U.S.A. by Continental Motors, Inc.

Available exclusively from the publisher: P.O. Box 90, Mobile, AL 36601

Copyright © 2011 Continental Motors, Inc. All rights reserved. This material may not be reprinted, republished, broadcast, or otherwise

altered without the publisher's written permission. This manual is provided without express, statutory, or implied warranties. The publisher will

not be held liable for any damages caused by or alleged to be caused by use, misuse, abuse, or misinterpretation of the contents. Content is

subject to change without notice. Other products and companies mentioned herein may be trademarks of the respective owners.

A C75, C85, C90 & O-200 Series Engines Overhaul Manual

31 August 2011

INTENTIONALLY

LEFT

BLANK

2

FOREWORD

This manual

is

published for the guidance

of

all facilities engaged in

operation, maintenance and overhaul

of

four cylinder engines

of

the

Teledyne Continental C

and

0-200

Series.

A description

is

included in this manual

of

the various models

and

special

equipments

of

the

series

and

photographs selected

to

illustrate

the

major

differences between models. The Table

of

Specifications provides more

detailed information in regard

to

features

and

performance

of

the

models.

It

should be noticed

that

such descriptive material

is

neither intended

nor

adequate

to

enable conversion

of

any model

to

another

in instances in which

such conversion

is

permissible.

For

detailed information regarding

application

of

parts

and

their interchangeability, refer

to

the

Spare Parts

Catalog.

For

model

and

series number conversion instructions, refer

to

the

Teledyne Continental Service Bulletin

on

that

subject.

Service maintenance instructions relative

to

accessories installed

on

Teledyne

Continental aircraft engines in

our

factory are reprinted herein

by

permission

of

the

accessory manufacturers. Instructions for overhaul

of

these acces-

sories may be obtained direct from

the

manufacturers

or

through their

authorized service facilities.

All descriptive

and

dimensional information

and

all instructions contained in

this edition have been revised and extended

to

cover all four cylinder models

of

the Teledyne Continental C Series in current production. The parts

catalog section

is

not

included in this edition, since

it

is subject

to

frequeht

change in details.

A manual

of

this scope cannot be revised

often

enough

to

be kept up

to

date

at all times, since

it

is

our

policy

to

improve details

of

engine design

in

the

interest

of

maximum safety and utility

of

our

products whenever the results

of

our

continuous experimental and development program indicate the

desirability

of

replacing the old

with

something even better.

For

this reason

we issue Service Bulletins

to

our

Approved Distributors

to

advise

of

important changes in parts, desirable inspections

and

precautions found

necessary in operation and maintenance. These bulletins are available for

reading

at

all Teledyne Continental Approved Service Stations. Those who

need permanent copies

of

Service Bulletins may obtain

them

by

direct mail,

as

issued, from the factory Publications Department

on

an

annual

subscription basis. A nominal charge

is

made

to

cover

the

cost

of

mailing.

It

is

suggested

that

a careful study

of

the

text

of

this manual will provide the

reader with knowledge

of

engine constrq.ction

and

of

techniques for

both

operation

and

repair work which,

if

applied in practice, will

promote

safety

in flight

and

long engine life.

If,

in

spite

of

the

high quality

of

materials

and

the careful inspection

and

testing

of

these engines, any defect

is

suspected,

the

question should be

brought immediately

to

the

attention

of

the nearest Teledyne Continental

Approved Service Station so

that

a diagnosis

and

any necessary correction

may be made.

Section

&

Para.

1-1

1-2

1-3

1-4

II

III

3-1

3-2

3-3

3-4

3-5

3-6

3-7

3-8

3-9

3-10

3-11

3-12

3-13

3-17

3-18

3-19

3-25

3-26

3-27

3-28

3-29

3-30

3-36

3-37

3-38

3-39

3-40

3-41

IV

4-1

4-2

4-3

4-4

V

5-1

5-2

5-3

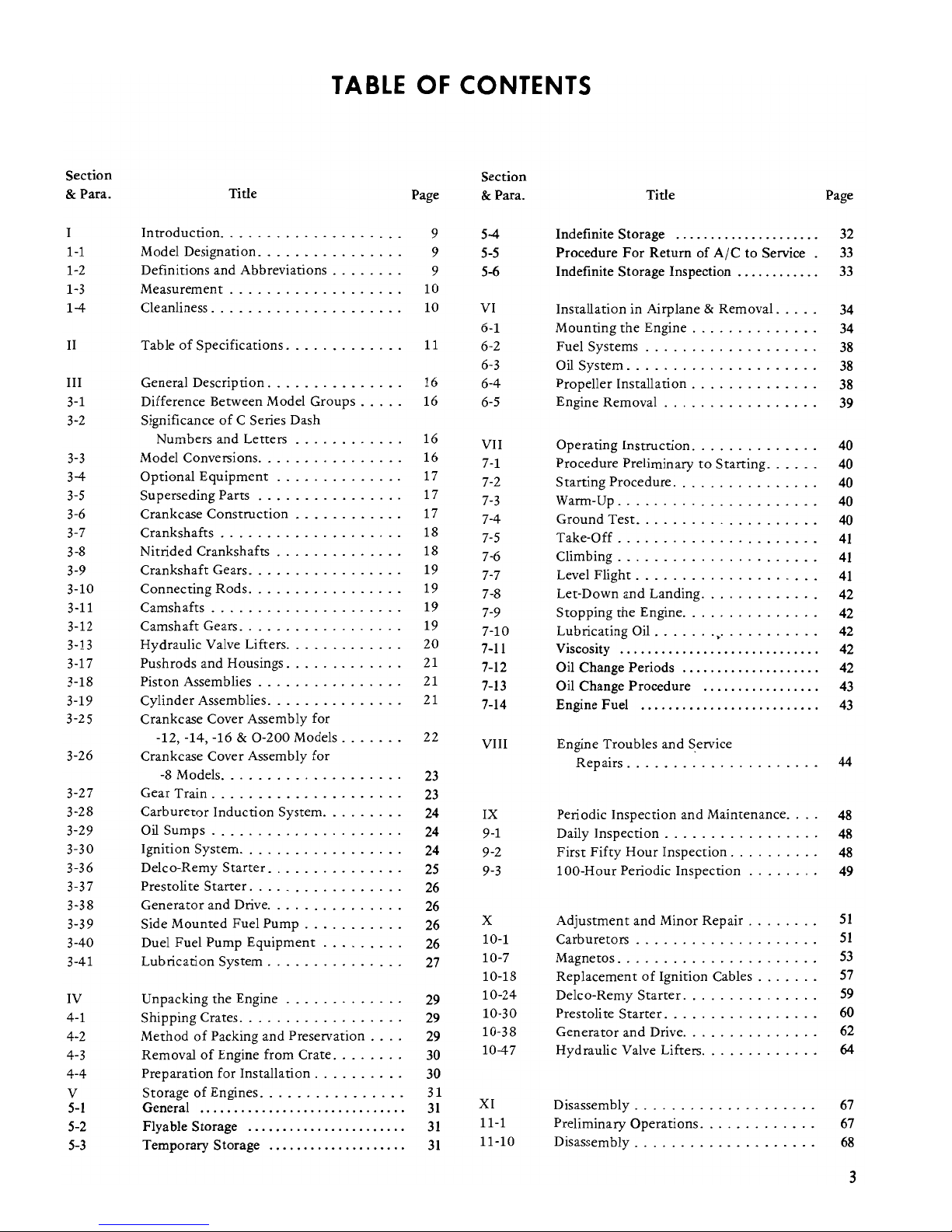

TABLE

OF

CONTENTS

Tide

Page

Introduction.

. . . . . . . . . . . . . . . . . . . 9

Model Designation. . . . . . . . . . . . . . . . 9

Definitions

and

Abbreviations.

. . . . . . . 9

Measurement.

. . . . . . . . . . . . . . .

... . 10

Cleanliness. . . . . . . . . . . . . . . . . . . . .

10

Table

of

Specifications.

. . . . . . . . . . . . 11

General

Description.

. . . . . . . . . . . . . . 16

Difference Between Model

Groups.·.

. . . 16

Significance

of

C Series Dash

Numbers

and

Letters

. . . . . . . . . .

..

16

Model Conversions. . . . . . . . . . . . . . . .

16

Optional

Equipment

. . . . . . . . . . . . . . 17

Superseding

Parts

. . . . . . . . . . . . . . . .

17

Crankcase

Construction

. . . . . . . . . . . . 17

Crankshafts . . . . . . . . . . . . . . . . . . . . 18

Nitrided

Crankshafts.

. . . . . . . . . . .

..

18

Crankshaft

Gears. . . . . . . . . . . . . . . . . 19

Connecting

Rods.

. . . . . . . . . . . . . . . . 19

Camshafts.

. . . . . . . . . . . . . . . . . . . . 19

Camshaft

Gears. . . . . . . . . . . . . . . . . . 19

Hydraulic Valve Lifters. . . . . . . . . . . . .

20

Push rods

and

Housings.

. . . . . . . . . .

..

21

Piston

Assemblies.

. . . . . . . . . . . . . . . 21

Cylinder

Assemblies. . . . . . . . . . . . .

..

21

Crankcase Cover Assembly

for

-12, -14, -16 &

0-200

Models.

. . . .

..

22

Crankcase Cover Assembly

for

-8 Models. . . . . . . . . . . . . . . . . . . . 23

Gear

Train.

. . . . . . . . . . . . . . . . . . . . 23

Carburetor

Induction

System. . . . . . . . . 24

Oil

Sumps

. . . . . . . . . . . . . . . . . . .

..

24

Ignition System. . . . . . . . . . . . . . . . . . 24

Deko-Remy

Starter.

. . . . . . . . . . . . . . 25

Prestolite

Starter.

. . . . . . . . . . . . . . . . 26

Generator

and

Drive. . . . . . . . . . . . .

..

26

Side

Mounted

Fuel

Pump.

. . . . . . . . . . 26

Duel

Fuel

Pump

Equipment

. . . . . . .

..

26

Lubrication

System.

. . . . . . . . . . . . . . 27

Unpacking

the

Engine . . . . . . . . . . . . . 29

Shipping

Crates. . . . . . . . . . . . . . . . . . 29

Method

of

Packing

and

Preservation . . . . 29

Removal

of

Engine

from

Crate.

. . . . . . .

30

Preparation

for

Installation.

. . . . . . . . .

30

Storage

of

Engines. . . . . . . . . . . . . . . . 31

General

..............................

31

Flyable Storage

.......................

31

Temporary

Storage

....................

31

Section

& Para.

5-4

5-5

5-6

VI

6-1

6-2

6-3

6-4

6-5

VII

7-1

7-2

7-3

7-4

7-5

7-6

7-7

7-8

7-9

7-10

7-11

7-12

7-13

7-14

VIII

IX

9-1

9-2

9-3

X

10-1

10-7

10-18

10-24

10-30

10-38

10-47

XI

11-1

11-10

Tide

Page

Indefinite Storage

.....................

32

Procedure

For

Return

of

AIC

to

Service 33

Indefinite Storage Inspection

............

33

Installation

in Airplane &

Removal.

. . . .

34

Mounting

the

Engine.

. . . . . . . . . . . . .

34

Fuel

Systems . . . . . . . . . . . . . . . . . . .

38

Oil

System.

. . . . . . . . . . . . . . . . . .

..

38

Propeller

Installation.

. . . . . . . . . . . . . 38

Engine Removal . . . . . . . . . . . . . . .

..

39

Operating

Instruction.

. . . . . . . . . . .

..

40

Procedure

Preliminary

to

Starting.

. . .

..

40

Starting

Procedure.

. . . . . . . . . . . . . . .

40

Warm-Up.

. . . . . . . . . . . . . . . . . . .

..

40

Ground

Test.

. . . . . . . . . . . . . . . . .

..

40

Take-Off.

. . . . . . . . . . . . . . . . . . .

..

41

Climbing.

. . . . . . . . . . . . . . . . . . .

..

41

Level

Flight.

. . . . . . . . . . . . . . . . .

..

41

Let-Down

and

Landing. . . . . . . . . . .

..

42

Stopping

the

Engine. . . . . . . . . . . . .

..

42

Lubricating

Oil

......

'.'

. . . . . . . .

..

42

Viscosity

.............................

42

Oil Change Periods

....................

42

Oil Change

Procedure

.................

43

Engine Fuel

..........................

43

Engine

Troubles

and

S.ervice

Repairs

...........

, . . . . . . .

..

44

Periodic

Inspection

and

Maintenance. .

..

48

Daily

Inspection.

. . . . . . . . . . . . . .

..

48

First

Fifty

Hour

Inspection

.........

, 48

100-Hour

Periodic

Inspection

. . . . . .

..

49

Adjustment

and

Minor

Repair.

. . . . . . .

51

Carburetors.

. . . . . . . . . . . . . . . . . . .

51

Magnetos.

. . . . . . . . . . . . . . . . . . . . .

53

Replacement

of

Ignition

Cables.

. . . . . .

57

Delco-Remy

Starter.

. . . . . . . . . . . .

..

59

Prestolite

Starter.

. . . . . . . . . . . . . .

..

60

Generator

and

Drive. . . . . . . . . . . . . . . 62

Hydraulic Valve Lifters. . . . . . . . . . . . .

64

Disassembly.

. . . . . . . . . . . . . . . . . . . 67

Preliminary

Operations.

. . . . . . . . . . . . 67

Disassembly.

. . . . . . . . . . . . . . . . . . . 68

3

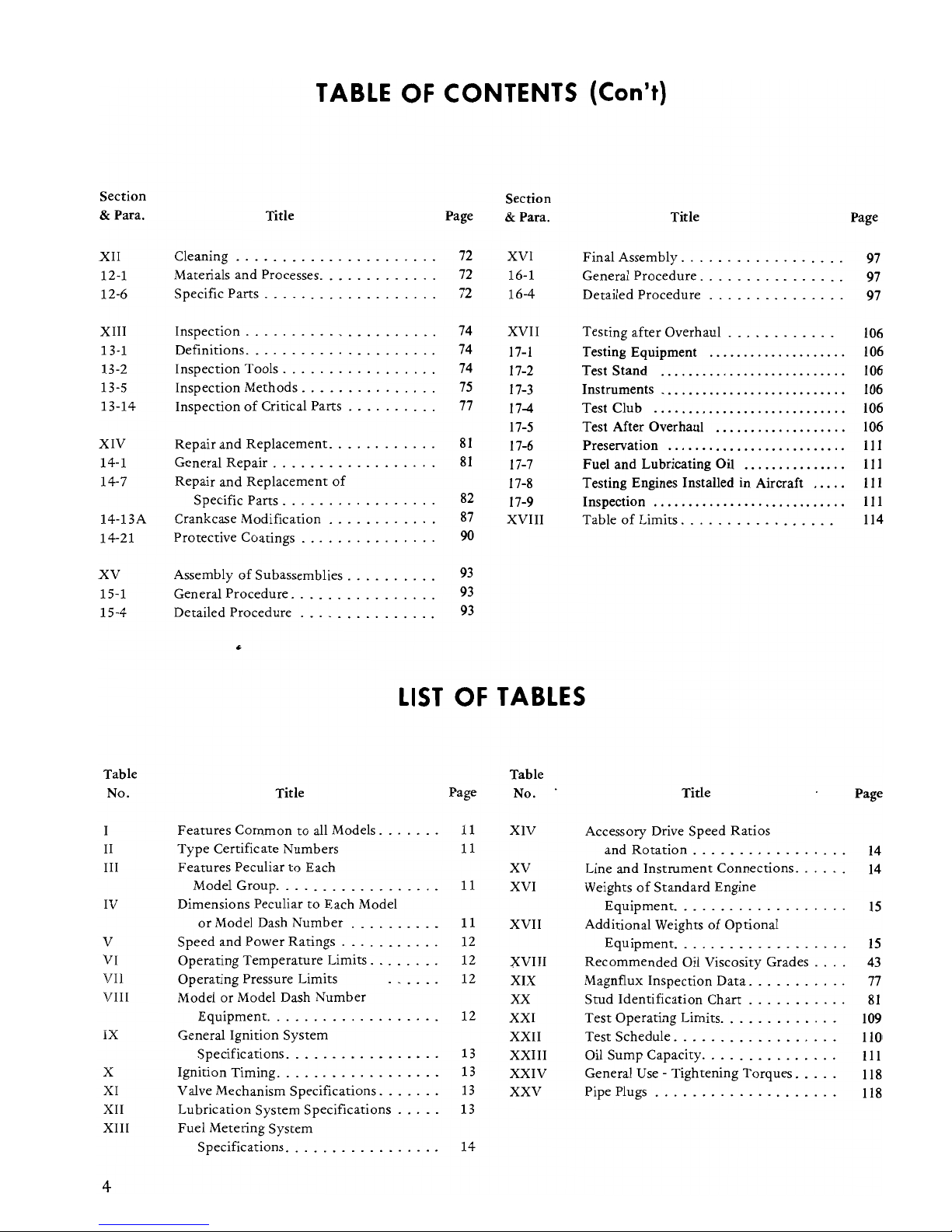

TABLE

OF

CONTENTS

(Con't)

Section

Section

& Para. Title Page

& Para.

Title Page

XII

Cleaning

............................................

72

XVI

Final Assembly. . . . . . . . . . . . . . . . . .

97

12-1

Materials and Processes

.............

72

16-1 General

Procedure.

. . . . . . . . . . . . . . .

97

12-6

Specific Parts

...................

72

16-4 Detailed Procedure . . . . . . . . . . . . . . .

97

XIII

Inspection

.....................

74

XVII Testing

after

Overhaul . . . . . . . . . . . .

106

13-1

Definitions

.....................

74

17-1

Testing Equipment

....................

106

13-2

Inspection Tools

.................

74

17-2

Test Stand

...........................

106

13-5

Inspection Methods

...............

75

17-3

Instruments.

. . . . . . . .

.. . .. . ..

. . . . . . . . . .

106

13-14

Inspection

of

Critical Parts

..........

77

17-4

Test Club

............................

106

17-5

Test After Overhaul

...................

106

XIV

Repair and Replacement. . . . . . .

.....

81

17-6

Preservation

..........................

111

14-1

General Repair

..................

81

17-7

Fuel

and

Lubricating Oil

...............

111

14-7

Repair

and

Replacement

of

17-8

Testing Engines Installed in Aircraft

.....

111

Specific Parts

.................

82

17-9

Inspection

............................

111

14-13A

Crankcase Modification

........................

87

XVIII Table

of

Limits.

. . . . . . . . . . . . . . . .

114

14-21

Protective Coatings . . . . . . . .

.......

90

XV Assembly

of

Subassemblies

..........

93

15-1 General Procedure

................

93

15-4 Detailed Procedure

..............................

93

•

LIST

OF

TABLES

Table

Table

No.

Title

Page

No.

Title

Page

Features Common

to

all

Models

.......

11 XIV

Accessory Drive Speed Ratios

II

Type

Certificate Numbers

11 and

Rotation

.................

14

III

Features Peculiar

to

Each

XV

Line and

Instrument

Connections

......

14

Model Group

..................

11

XVI

Weights

of

Standard Engine

IV

Dimensions Peculiar

to

Each Model

Equipment

...................

15

or

Model Dash

Number

..........

11

XVII

Additional Weights

of

Optional

V

Speed and Power Ratings

...........

12

Equipment

...................

15

VI

Operating Temperature Limits

........

12

XVIII

Recommended

Oil Viscosity Grades

....

43

VII

Operating Pressure Limits

............

12

XIX

Magnflux Inspection Data

.. , ........

77

VIII

Model

or

Model Dash Number

XX

Stud

Identification Chart

...........

81

Equipment

...................

12

XXI

Test

Operating Limits

.............

109

IX

General Ignition System

XXII

Test Schedule

..................

110

Specifications

.................

13

XXIII

Oil Sump Capacity

...............

III

X

Ignition Timing

..................

13

XXIV

General Use - Tightening Torques

.....

118

XI

Valve Mechanism Specifications

.......

13

XXV

Pipe Plugs

........................................

118

XII

Lubrication System Specifications

.....

13

XIII Fuel Metering System

Specifications

.................

14

4

Figure

No.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

II.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

27.

28.

29.

30.

31.

32.

33.

34.

35.

36.

37.

38.

39.

40.

41.

42.

43.

44.

45.

39.

40.

LIST

OF

ILLUSTRATIONS

Page

Left

Side View, Model

C85-12F.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

6

Three-Quarter

Right

Rear

View, Model

C85-12.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

6

Three-Quarter

Left

Front

View, Model C90-16F . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

7

Three-Quarter

Right

Rear View, Model C90-16F . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

7

Right

Front

View, Model C-90. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

8

Left

Front

View, Model

0-200.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

8

Cylinder Arrangement Diagram (Top View)

.......................................

10

Section Through Hydraulic Valve Lifter

..........................................

20

Crankcase Cover and Accessories

of

-12, -14, -16 and

0-200

Models

.......................

22

Gear Train

of

-12, -14, -16

and

0-200

Models

......................................

24

Hoisting Engine

by

Crankshaft Lifting Eye

........................................

29

Typical Installation Diagram

for

-12, -14 & -16 Models, Side View

........................

35

Installation Drawing

for

-12,

-14

& -16 Models,

Front

View

.............................

35

Installation Drawing

for

-12,

-14

& -16 Models, Rear View

.............................

36

Installation Drawing

for

-12,

-14

& -16 Models, Side and Top Views

.......................

37

Engine Mounting

Equipment

of

Models C90-14 & 16 and

0-200

.........................

38

Ignition Wiring

Diagram.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

57

Removal

of

Hydraulic

Unit

from Valve Lifter Body

..................................

69

Compressing Valve Spring

to

Remove Locks

.......................................

71

Removing Plunger from Hydraulic

Unit

with

Taped

Pliers

..............................

71

Installing Helical Coil

Inserts.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

82

Dimensions

of

Rocker

Shaft

Boss Bushings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

. . . . .

..

84

Drill

Fixture.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

87

Drilling Hole in Bearing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

88

Drilling

Adapter

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

88

Plug

Detail.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

89

Drill

Fixture.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

89

Drill

Fixture

Installed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

89

Name Plate Change

.......................................................

89

Tightening

No.1

Connecting

Rod

Bolts

..........................................

95

Installing Crankshaft Bearing and Old

Type

Thrust

Washer.

. . . . . . . . . . . . . . . . . . . . . . . . . .

..

97

Installing Crankshaft and Connecting Rods. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

98

Installing Dowel

Type

Thrust

Washers and Split Oil

Seal.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

98

Installing

Starter

Pinion Pivot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

99

Installing Crankcase 1, 3 Side on

2,4

Side.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

99

Installing Crankcase Cover

on

-12, -14, -16 and

0-200

Models

.........

'

..................

102

Installing No. 3 Cylinder

....................................................

103

Installing

"0"

Rings

on

Intake Manifold Studs

..............•......................

103

placing Crankshaft in Firing Position

of

No.1

Piston

.................................

104

Placing Flange Crankshaft in Firing Position

of

No.1

Piston

............................

104

Fuel Flow Limits

vs.

RP.M.

at

Propeller Load, Model C90

.............................

112

Fuel Flow Limits vs. R.P.M.

at

Propeller Load, Models C75

and

C85

.......................

112

Fuel

Flow

Limits vs.

RP.M.

at

Propeller Load, Model

0-200

............................

113

Limits and Lubrication

Chart

(Sheet 1

of

4)

- Cross Section View

.........................

120

Limits and Lubrication

Chart

(Sheet 2

of

4)

- Longitudinal Section View

....................

121

Limits and Lubrication

Chart

(Sheet 3

of

4)

- Rear View & Horizontal Section - 8 Models

.........

122

Limits and Lubrication

Chart

(Sheet 4

of

4)

- Rear View & Sections,

-12, -14 and

0-200

Models

.................................................

123

Figure

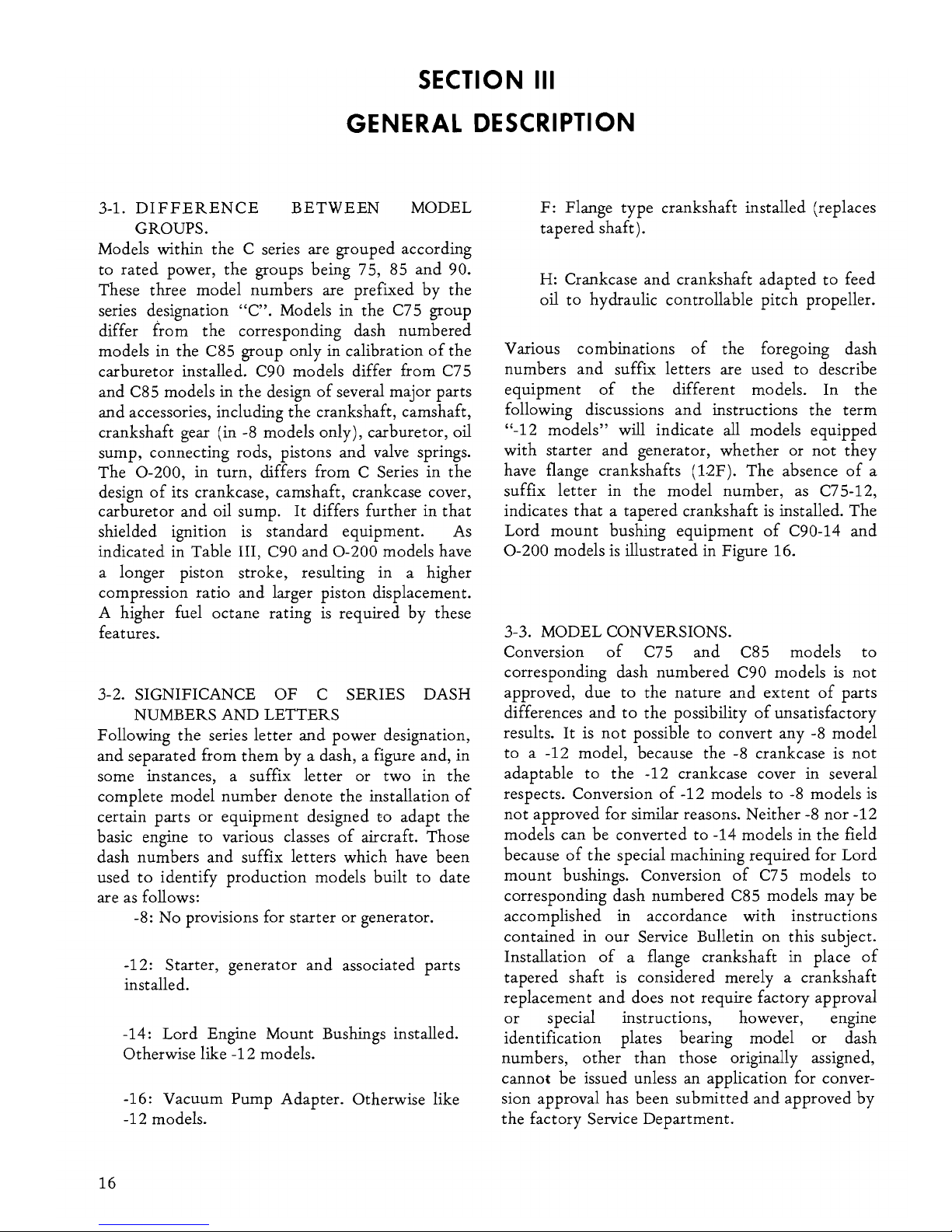

1.

Left Side View, Model C85-12F.

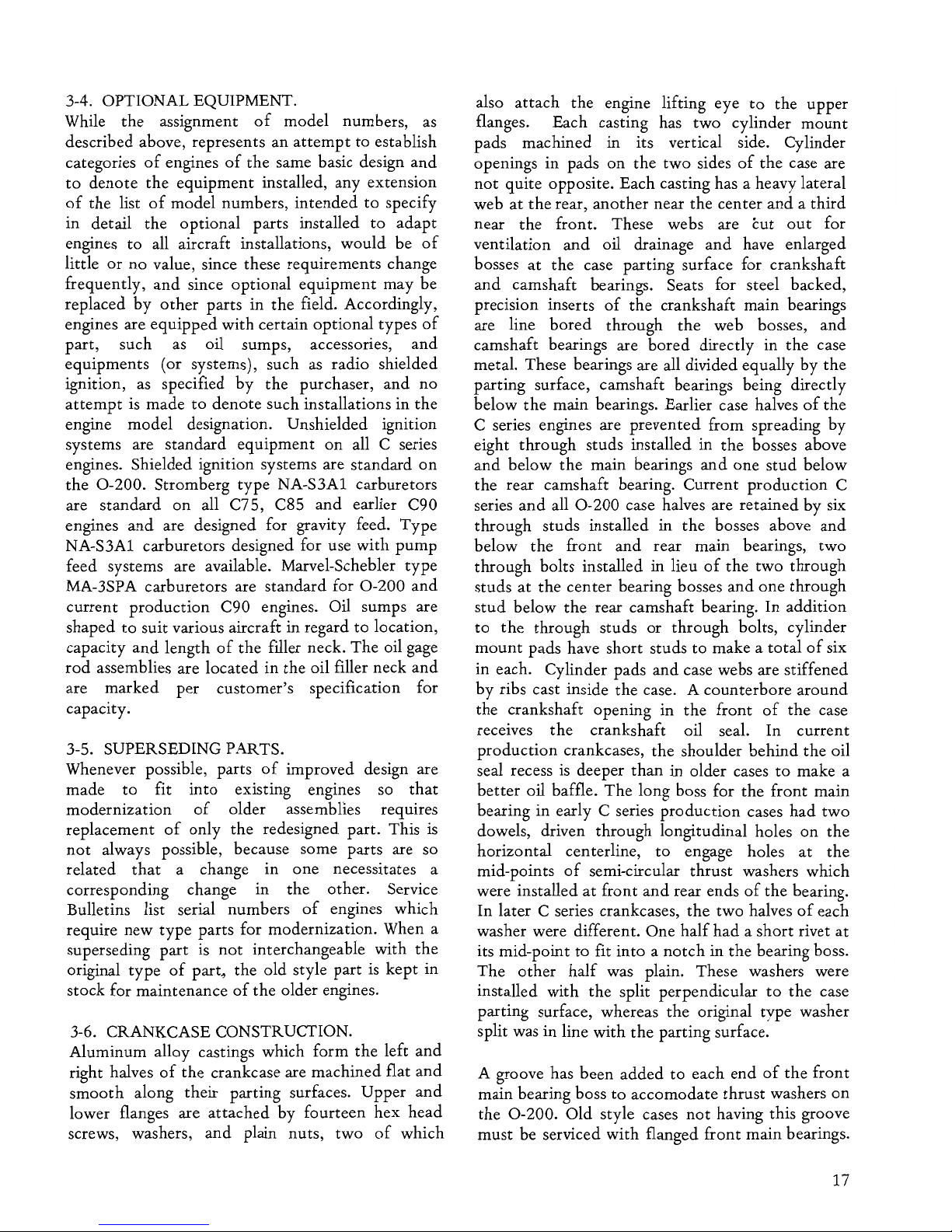

Figure

2.

Three-Quarter Right Rear View, Model C85-12.

Figure 3. Three-Quarter Left

Front

View, Model C90-16F.

Figure 4. Three-Quarter Right Rear View, Model C90-16F.

7

Figure 5. Right

Front

View, Model C90.

Figure 6. Left Rear View, Model

0-200.

8

SECTION I

INTRODUCTION

1.1 MODEL DESIGNATIONS.

This publication covers

the

maintenance

and

overhaul instructions applicable

to

the

four

cylinder C Series

and

the

0-200

Aircraft Engines. C

Series Engines covered

by

this publication fall

into

three model groups, namely, C75,C85

and

C90,

according

to

normal

rated

horsepower. Within each

C model group, variations in

equipment

of

the

basic engine are

denoted

by

suffix dash numbers,

as

explained in

the

Table

of

Specifications.

Further

explanation

of

the

meaning

of

model

dash

numbers

applicable

to

C models will be

found

in Section III.

Each engine bears an identification plate,

on

which

is

stamped

the

information

peculiar

to

that

particular model, including

the

exact

model

and

dash

number

designation

and

the

engine serial

number.

NOTE

If a new

nameplate

is required,

refer

to

Service Bulletin M7S-S.

All

correspondence

with

Teledyne

Continental

Distributors

and

with

the

factory

Service De-

partment

in

regard

to

specific engines

should

refer

to

the

exact

model

designation

and

serial

number.

1-2. DEFINITIONS & ABBREVIATIONS

A.B.e.

Approx.

A.T.e.

Bar.

B.B.C.

B.

H.

P.

B.

T.

e.

F.

A. A.

After

Bottom

Center

Approximately

After

Top

Center

Barometric

Before

Bottom

Center

Brake Horsepower

Before

Top

Center

Federal Aviation

Administration

e.

F.

M.

e.G.

Dia.

o

o

F.

Fig.

Front

Ft.

G.P.M.

H20

Hg.

I.D.

In. (")

Hex.

Hr.

Left

Side

Lbs.

Lockwire

Man.

Max.

Min.

30'

N.P.T.

N.C.

N.F.

O.D.

Press.

P.

S.1.

Rear

Right Side

R.P.M.

Std.

T.D.e.

Temp.

Torque

Cubic

Feet

Per Minute

Center

of

Gravity

Diameter

Degree

of

Angle

Degrees

Fahrenheit

Figure (Illustration)

Propeller

End

Foot

or

Feet

Gallons Per Minute

Water

Mercury

Inside

Diameter

Inches

Hexagon

Hour

Side

on

Which

No's

2 & 4 Cylinders

Located

Pounds

Soft Steel Wire Used

to

Safety

Connections, Etc.

Manifold

or

Manometer

Maximum

Minimum

Thirty

Minutes

of

Angle

(60'

Equals One

0)

National Pipe

Thread

(Tapered)

National Coarse (Thread)

National Fine (Thread)

Outside Diameter

Pressure

Pounds

Per

Square

Inch

Accessory

End

of

Engine

Side

on

Which

No's

1 & 3 Cylinders

Located

Revolution Per Minute

Standard

Top

Dead

Center

Temperature

Force

X Lever

Arm

(125 ft. lbs.

torque

= 1251bs.

Force

Applied

One

Ft.

From

Bolt

Center

or

62-1/2

lbs. Applied 2

Ft.

From

Center)

9

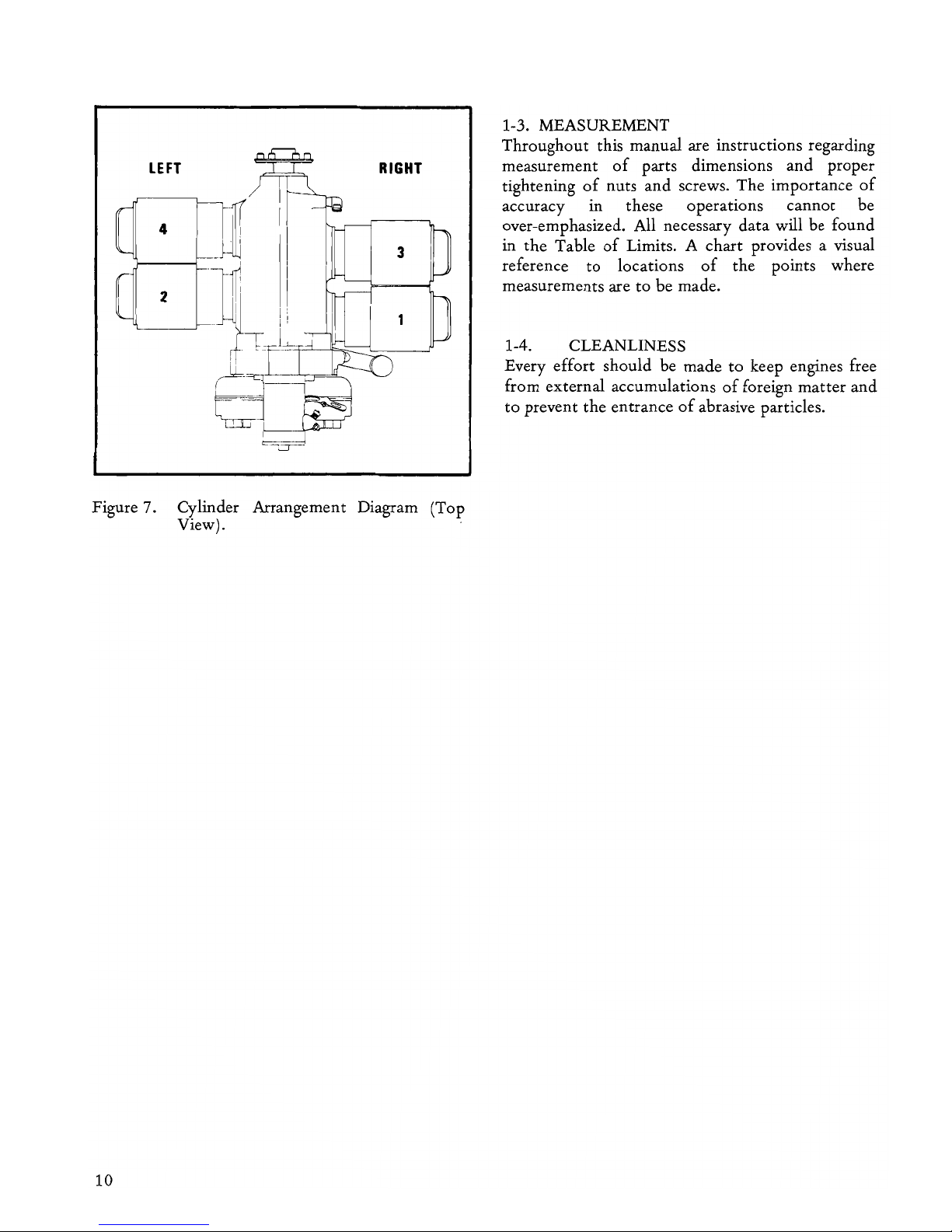

LEFT

RIGHT

4

3

2

1

Figure 7. Cylinder Arrangement Diagram (Top

View).

10

1-3. MEASUREMENT

Throughout

this manual are instructions regarding

measurement

of

parts dimensions

and

proper

tightening

of

nuts

and

screws. The importance

of

accuracy in these operations

cannot

be

over-emphasized. All necessary

data

will be found

in

the

Table

of

Limits. A chart provides a visual

reference

to

locations

of

the

points where

measurements are

to

be made.

1-4. CLEANLINESS

Every effort should be made

to

keep engines free

from external accumulations

of

foreign

matter

and

to

prevent

the

entrance

of

abrasive particles.

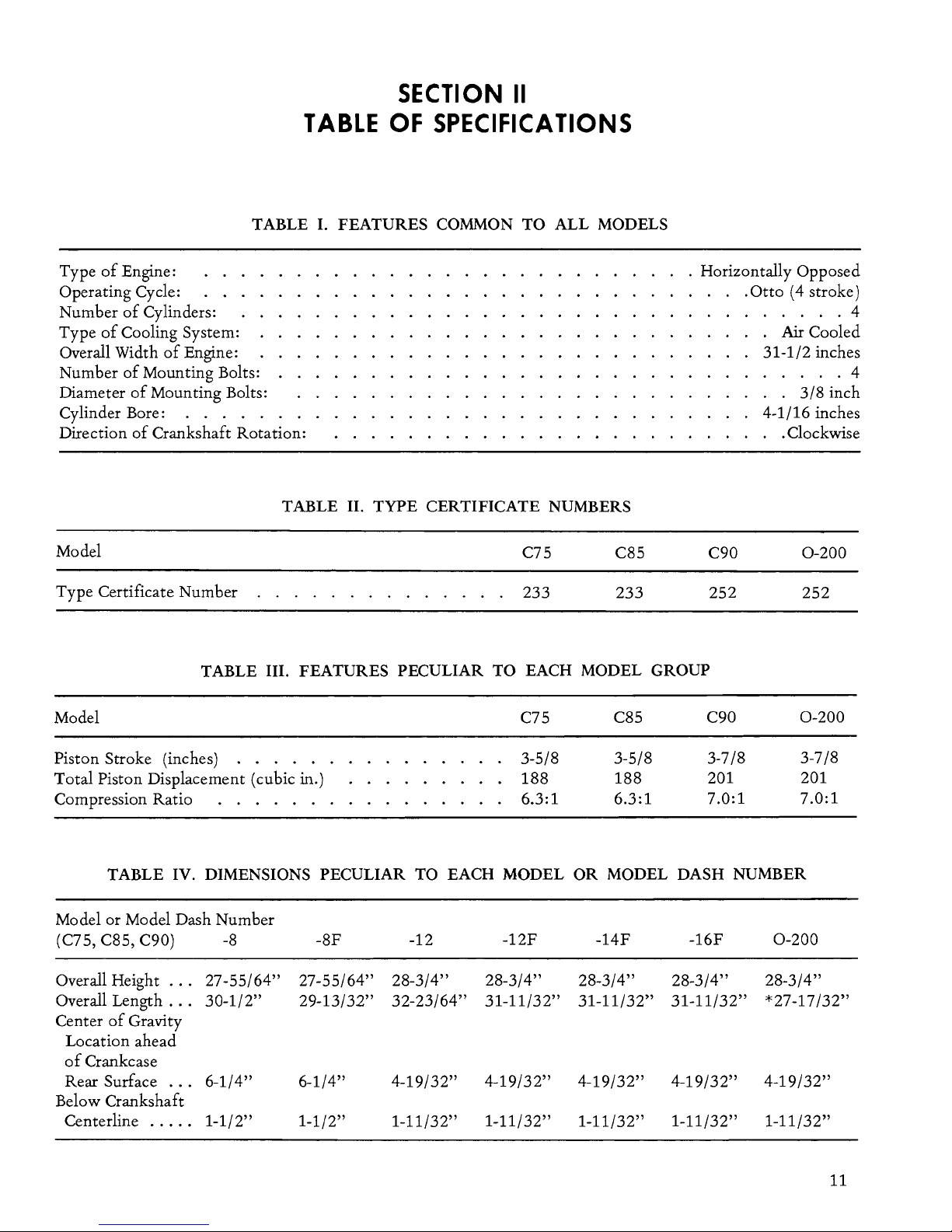

SECTION

II

TABLE

OF

SPECIFICATIONS

TABLE

I.

FEATURES

COMMON

TO

ALL

MODELS

Type

of

Engine:

Operating Cycle:

Number

of

Cylinders:

Type

of

Cooling System:

Overall Width

of

Engine:

Number

of

Mounting Bolts:

Diameter

of

Mounting Bolts:

Cylinder Bore: . . . . .

Direction

of

Crankshaft Rotation:

TABLE II.

TYPE

CERTIFICATE NUMBERS

Model

C75 C85

Type Certificate Number

233 233

. Horizontally Opposed

C90

252

.

Otto

(4 stroke)

·

....

4

·

Air

Cooled

31-1/2 inches

·

....

4

· .

3/8

inch

4-1/16 inches

· .Clockwise

0-200

252

TABLE III. FEATURES PECULIAR

TO

EACH

MODEL

GROUP

Model C75

C85 C90

0-200

Piston Stroke (inches) . . . .

3-5/8 3-5/8

3-7/8 3-7/8

Total Piston Displacement (cubic

in.)

188 188

201

201

Compression Ratio

.

6.3:1 6.3:1

7.0:1 7.0:1

TABLE IV. DIMENSIONS PECULIAR

TO

EACH

MODEL

OR

MODEL

DASH NUMBER

Model or Model Dash Number

(C75, C85, C90)

-8 -8F -12

-12F

-14F

-16F

0-200

Overall Height

...

27-55/64" 27-55/64"

28-3/4" 28-3/4" 28-3/4" 28-3/4" 28-3/4"

Overall Length

...

30-1/2" 29-13/32" 32-23/64"

31-11/32"

31-11/32"

31-11/32"

*27

-17/32"

Center

of

Gravity

Location ahead

of

Crankcase

Rear Surface

...

6-1/4"

6-1/4"

4-19/32" 4-19/32"

4-19/32"

4-19/32"

4-19/32"

Below Crankshaft

Centerline

.....

1-1/2"

1-1/2" 1-11/32"

1-11/32"

1-11/32"

1-11/32" 1-11/32"

11

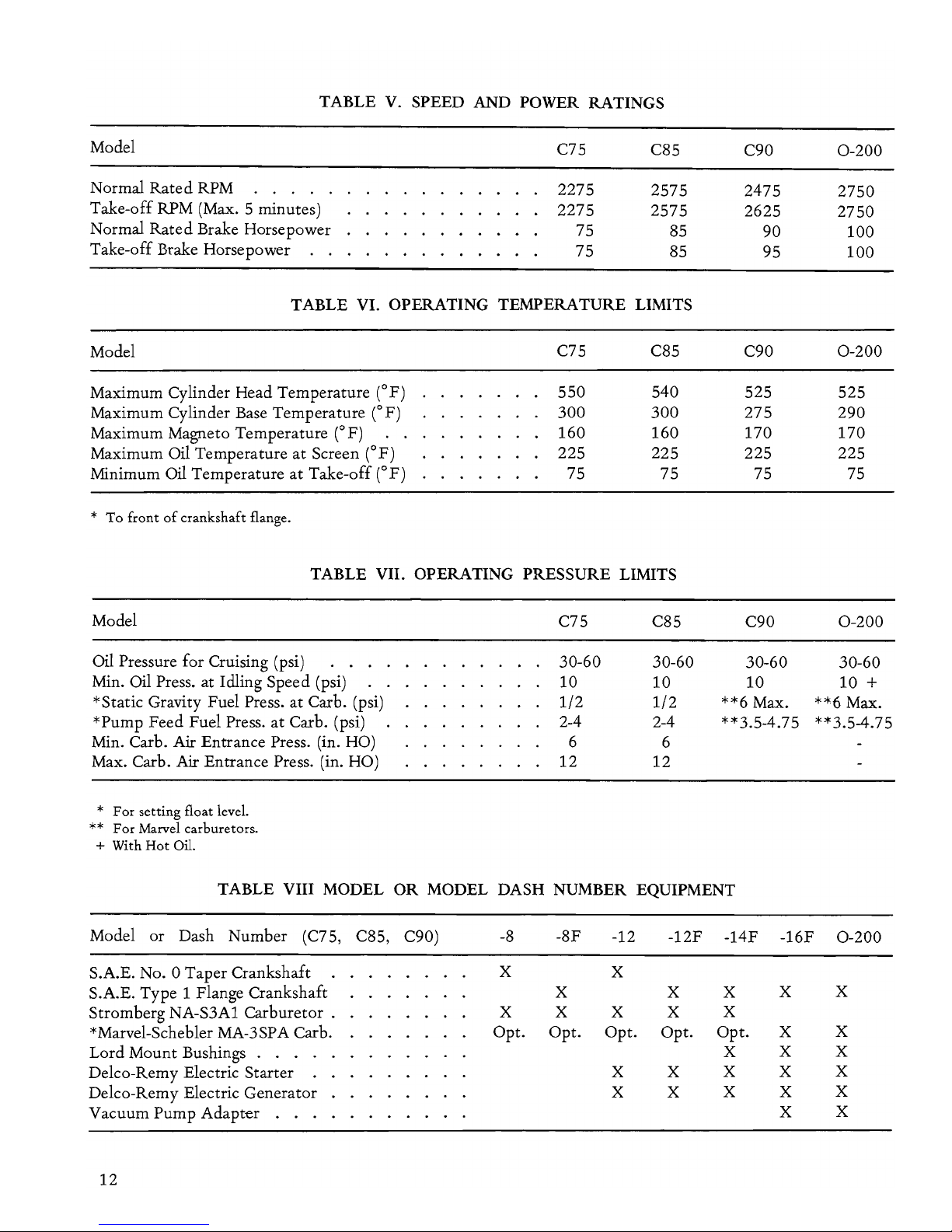

TABLE V. SPEED AND POWER RATINGS

Model

C75

C85

Normal

Rated

RPM

.

2275

2575

Take-off RPM (Max. 5 minutes)

2275

2575

Normal

Rated

Brake Horsepower

75

85

Take-off Brake Horsepower

75

85

TABLE VI. OPERATING TEMPERATURE LIMITS

Model

C75

C85

Maximum Cylinder Head Temperature (oF) 550 540

Maximum Cylinder Base Temperature

(OF)

300 300

Maximum Magneto Temperature

(0

F) 160 160

Maximum

Oil Temperature

at

Screen

(0

F)

225 225

Minimum Oil Temperature

at

Take-off

(0

F)

75 75

*

To front

of

crankshaft flange.

TABLE VII. OPERATING PRESSURE LIMITS

Model

Oil Pressure for Cruising (psi)

....

Min. Oil Press. at Idling Speed (psi)

*Static Gravity Fuel Press.

at

Carbo

(psi)

*Pump Feed Fuel Press.

at

Carbo

(psi)

Min.

Carbo

Air Entrance Press. (in. HO)

Max.

Carbo

Air

Entrance Press. (in. HO)

*

For

setting float level.

**

For

Marvel carburetors.

+ With

Hot

Oil.

C75

30-60

10

1/2

2-4

6

12

C85

30-60

10

1/2

2-4

6

12

C90

2475

2625

90

95

C90

525

275

170

225

75

C90

30-60

10

**6 Max.

**3.5-4.75

TABLE VIII MODEL

OR

MODEL DASH NUMBER EQUIPMENT

Model

or Dash Number

(C75,

C85, C90)

-8

-8F -12

-12F

-14F -16F

S.A.E. No. 0 Taper Crankshaft

X X

S.A.E. Type 1 Flange Crankshaft

X

X

X

X

Stromberg NA-S3A1 Carburetor .

X X X

X

X

*Marvel-Schebler MA-3SPA

Carbo

Opt. Opt. Opt. Opt. Opt.

X

Lord Mount Bushings . . .

X

X

Delco-Remy Electric Starter

.

X X X X

Delco-Remy Electric Generator

X X X X

Vacuum Pump Adapter .

X

12

0-200

2750

2750

100

100

0-200

525

290

170

225

75

0-200

30-60

10

+

**6 Max.

**3.5-4.75

0-200

X

X

X

X

X

X

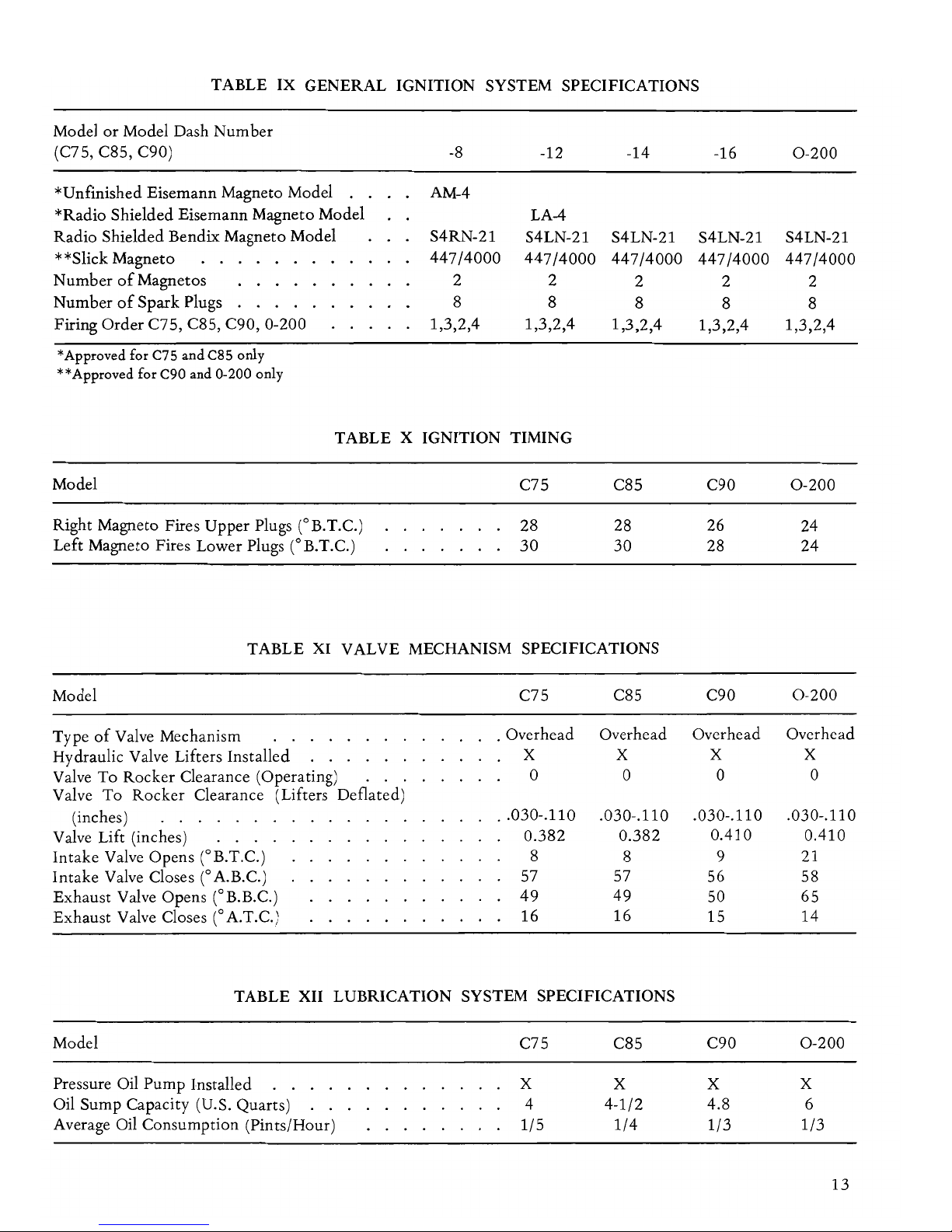

TABLE IX GENERAL IGNITION SYSTEM SPECIFICATIONS

Model

or

Model Dash Number

(C75, C85, C90)

-8

-12

*Unfmished Eisemann Magneto Model

AM-4

*Radio Shielded Eisemann Magneto Model LA-4

Radio Shielded Bendix Magneto Model

S4RN-21 S4LN-21

**Slick Magneto

447/4000

447/4000

Number

of

Magnetos

.

2

2

Number

of

Spark Plugs 8 8

Firing Order C75, C85, C90, 0-200 1,3,2,4 1,3,2,4

*Approved for

C7S

and

C8S

only

**Approved for C90 and 0-200 only

TABLE X IGNITION TIMING

Model

Right Magneto Fires Upper Plugs (OB.T.C.)

Left Magneto Fires Lower Plugs (OB.T.e.)

C75

28

30

-14

S4LN-21

447/4000

2

8

1,3,2,4

C85

28

30

TABLE XI VALVE MECHANISM SPECIFICATIONS

Model

C75

C85

Type

of

Valve Mechanism

. Overhead

Overhead

Hydraulic Valve Lifters Installed

X X

Valve To Rocker Clearance (Operating)

...

0 0

Valve To Rocker Clearance (Lifters Deflated)

(inches)

..

030-.110 .030-.110

Valve Lift (inches)

0.382

0.382

Intake Valve Opens (OB.T.e.)

8

8

Intake Valve Closes

(0

A.B.e.) 57

57

Exhaust Valve Opens (OB.B.e.)

49 49

Exhaust Valve Closes C A.T.e.)

16 16

TABLE XII LUBRICATION SYSTEM SPECIFICATIONS

Model

Pressure Oil Pump Installed . . . .

Oil Sump Capacity (U.S. Quarts)

Average Oil Consumption (Pints/Hour)

C75

X

4

1/5

C85

X

4-1/2

1/4

-16

S4LN-21

447/4000

2

8

1,3,2,4

C90

26

28

C90

Overhead

X

0

.030-.110

0.410

9

56

50

15

C90

X

4.8

1/3

0-200

S4LN-21

447/4000

2

8

1,3,2,4

0-200

24

24

0-200

Overhead

X

0

.030-.110

0.410

21

58

65

14

0-200

X

6

1/3

13

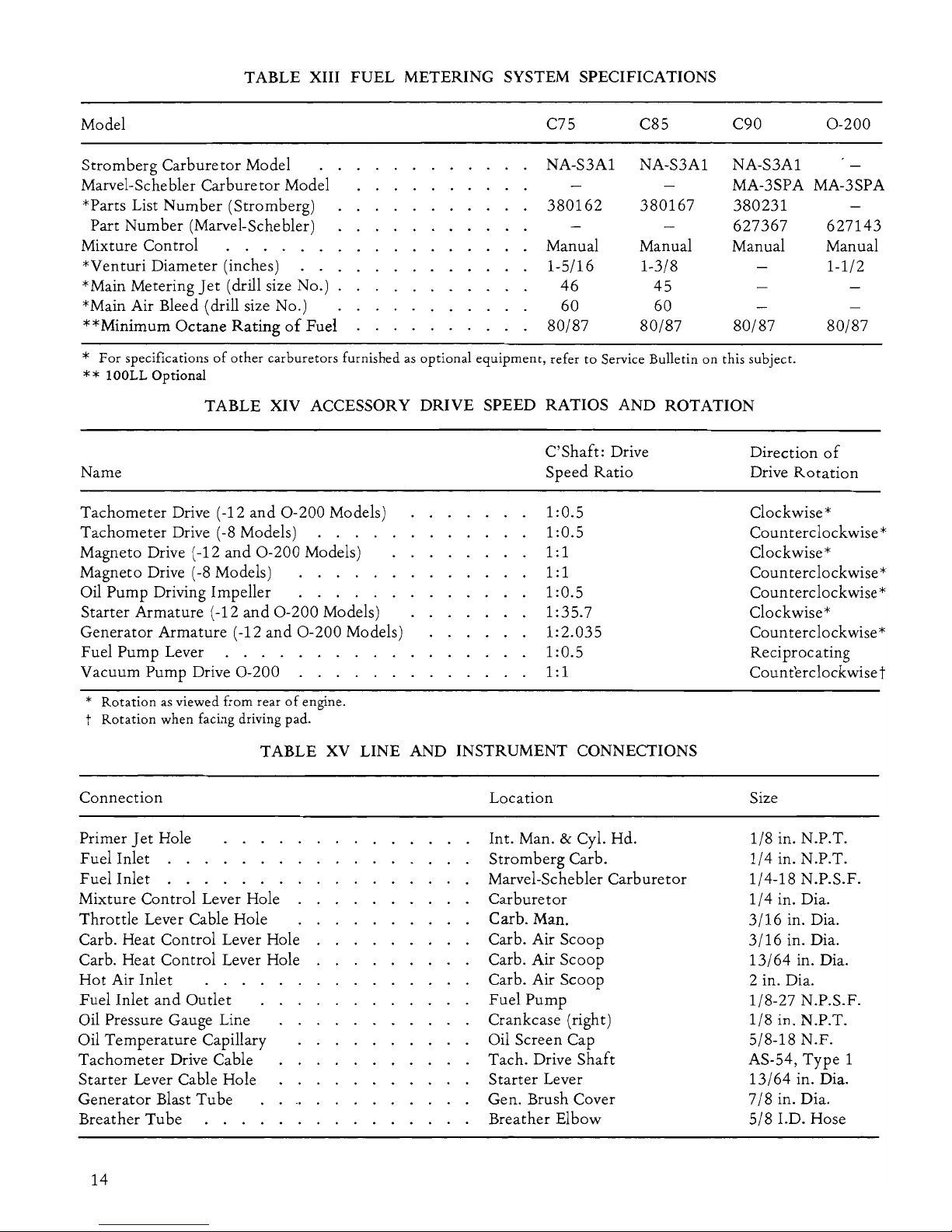

TABLE XIII FUEL METERING SYSTEM SPECIFICATIONS

Model

C75 C85 C90

0-200

Stromberg Carburetor Model

NA-S3A1 NA-S3A1 NA-S3A1

Marvel-Schebler Carburetor Model

MA-3SPA MA-3SPA

*Parts List Number (Stromberg)

380162

380167

380231

Part Number (Marvel-Schebler)

627367 627143

Mixture Control Manual Manual Manual Manual

*Venturi Diameter (inches)

1-5/16

1-3/8 1-1/2

* Main Metering

Jet

(drill size No.)

46

45

*Main Air Bleed (drill size No.)

60 60

**Minimum Octane Rating

of

Fuel

80/87

80/87 80/87

80/87

*

For

specifications

of

other

carburetors

furnished

as

optional

equipment,

refer

to

Service Bulletin

on

this subject.

** lOOLL

Optional

TABLE XIV ACCESSORY DRIVE SPEED RATIOS AND ROTATION

Name

Tachometer Drive (-12

and

0-200

Models)

Tachometer Drive

(-8

Models)

Magneto Drive (-12

and

0-200

Models)

Magneto Drive

(-8

Models)

...

.

Oil Pump Driving Impeller

...

.

Starter Armature (-12

and

0-200

Models)

Generator Armature (-12

and

0-200

Models)

Fuel Pump Lever . . . . . . .

Vacuum Pump Drive

0-200

*

Rotation

as

viewed

from

rear

of

engine.

t

Rotation

when

facing driving pad.

C'Shaft: Drive

Speed Ratio

1:0.5

1:0.5

1:1

1:1

1:0.5

1:35.7

1:2.035

1:0.5

1:1

TABLE

XV LINE AND INSTRUMENT CONNECTIONS

Connection

Location

Primer

Jet

Hole

Int. Man.

& Cyl. Hd.

Fuel Inlet

Stromberg

Carbo

Fuel Inlet

Marvel-Schebler Carburetor

Mixture Control Lever Hole

Carburetor

Throttle

Lever Cable Hole

Carbo Man.

Carbo

Heat Control Lever Hole

Carbo

Air Scoop

Carbo

Heat Control Lever Hole

Carbo

Air Scoop

Hot

Air Inlet

Carbo

Air Scoop

Fuel Inlet

and

Outlet

Fuel Pump

Oil Pressure Gauge Line

Crankcase (right)

Oil Temperature Capillary Oil Screen Cap

Tachometer Drive Cable

Tach. Drive

Shaft

Starter Lever Cable Hole

Starter Lever

Generator Blast Tube Gen. Brush Cover

Breather Tube

Breather Elbow

14

Direction

of

Drive

Rotation

Clockwise*

Coun terclockwise *

Clockwise *

Coun terclockwise *

Coun terclockwise *

Clockwise*

Co

un

terclockwise *

Reciprocating

Counterclockwise t

Size

1/8

in. N.P.T.

1/4

in. N.P.T.

1/4-18 N.P.S.F.

1/4

in. Dia.

3/16

in. Dia.

3/16

in. Dia.

13/64

in. Dia.

2 in. Dia.

1/8-27 N.P.S.F.

1/8

in. N.P.T.

5/8-18 N.F.

AS-54,

Type

1

13/64

in. Dia.

7/8

in. Dia.

5/8

I.D. Hose

TABLE XVI WEIGHTS

OF

STANDARD ENGINE EQUIPMENT

Description

Basic Engine (Model C85-8) . . . .

Basic Engine (Models C85-8F, C90-8F)

Basic Engine (Models C75-12, C85-12)

Basic Engine (Models C75-12F, C85-12F, C90-12F, C90-14F)

Basic Engine (Model C90-16F,

0-200)

. . . . . . . . .

Stromberg Carburetor, Type NA-S3Al (C75-8-12)

....

Marvel-Schebler Carburetor, Type MA-3SPA (C85, C90-8-12-14-16F &

0-200)

Two Magnetos (Bendix S4RN-21

or

S4LN-21)

Eight Shielded Spark Plugs

........

.

unshielded Ignition Cable Assembly

....

.

Shielded Ignition Harness Assembly (Model

0-200)

Delco-Remy Starter (-12,-14,-16

and

0-200)

Delco-Remy Generator (-12,-14,-16

and

0-200)

(12 Volt, 20 Amp)

Propeller Hub Assembly

(-8

and

-12)

."..........

Carburetor Air Intake

and

Filter Assembly (used with Stromberg Carburetors)

Carburetor

Air Intake

and

Filter Assembly (used with Marvel-Schebler Carburetors)

Propeller Attaching Parts (-8F, -12F, -14F,

-16F & 0-200)

Eight Rubber Mount Bushings,

Four

Steel Washers

Domestic Shipping Crate

Export

Shipping Crate . . . . . . . . . . .

TABLE XVII ADDITIONAL WEIGHTS

OF

OPTIONAL EQUIPMENT

Description

Radio Shielded Ignition Cable Assembly

Eight Shielded Spark Plugs

.....

Harrison Oil Cooler Equipment (complete)

AC Fuel Pump . . . . . . . . . . .

Weight (in lbs.)

157.8

158.84

167.56

168.6

170.18

2.56

2.62

12.12

1.75

1.82

3.81

15.50

10.12

4.39

2.38

3.12

1.7

0.55

70

142

*Weight (in lbs.)

1.06

1.75

4.25

1.71

NOTE: (*)

Add

stated

weights

of

corresponding standard equipment (if any)

to

obtain weight

of

optional equipment.

15

SECTION

III

GENERAL

DESCRIPTION

3-1.

DIFFERENCE

BETWEEN

MODEL

GROUPS.

Models within the C series are grouped according

to

rated

power,

the

groups being 75, 85

and

90.

These three model numbers are prefixed

by

the

series designation

"C".

Models in the

C7s

group

differ from

the

corresponding dash numbered

models in the

C8s

group only in calibration

of

the

carburetor installed. C90 models differ from

C7s

and

C8s

models in

the

design

of

several major parts

and accessories, including the crankshaft, camshaft,

crankshaft gear (in -8 models only), carburetor, oil

sump, connecting rods, pistons

and

valve springs.

The

0-200,

in

turn,

differs from C Series in

the

design

of

its crankcase, camshaft, crankcase cover,

carburetor and oil sump.

It

differs further in

that

shielded ignition

is

standard equipment.

As

indicated in Table III, C90

and

0-200

models have

a longer piston stroke, resulting in a higher

compression ratio

and

larger piston displacement.

A higher fuel octane rating is required

by

these

features.

3-2. SIGNIFICANCE

OF

C SERIES DASH

NUMBERS AND LETTERS

Following

the

series letter

and

power

designati~n,

and

separated from

them

by

a dash, a figure and, in

some instances, a suffix letter

or

two in

the

complete model number denote the installation

of

certain parts

or

equipment designed

to

adapt

the

basic engine

to

various classes

of

aircraft. Those

dash numbers

and

suffix letters which have been

used

to

identify production models built

to

date

are as follows:

16

-8: No provisions for starter

or

generator.

-12: Starter, generator

and

associated parts

installed.

-14: Lord Engine Mount Bushings installed.

Otherwise like -12 models.

-16: Vacuum Pump Adapter. Otherwise like

-12 models.

F:

Flange

type

crankshaft installed (replaces

tapered shaft).

H: Crankcase

and

crankshaft

adapted

to

feed

oil

to

hydraulic controllable

pitch

propeller.

Various combinations

of

the foregoing dash

numbers

and

suffix letters are used

to

describe

equipment

of

the

different models. In the

following discussions

and

instructions

the

term

"-12 models" will indicate all models equipped

with

starter

and

generator, whether

or

not

they

have flange crankshafts (1.2F). The absence

of

a

suffix

letter

in

the

model number,

as

C7S-12,

indicates

that

a tapered crankshaft

is

installed. The

Lord

mount

bushing equipment

of

C90-14

and

0-200

models is illustrated in Figure 16.

3-3. MODEL CONVERSIONS.

Conversion

of

C7s

and

C8s

models

to

corresponding dash numbered C90 models is

not

approved, due

to

the nature

and

extent

of

parts

differences

and

to

the

possibility

of

unsatisfactory

results.

It

is

not

possible

to

convert any -8 model

to

a -12 model, because the -8 crankcase

is

not

adaptable

to

the

-12 crankcase cover in several

respects. Conversion

of

-12 models

to

-8 models is

not

approved for similar reasons. Neither -8

nor

-12

models can be converted

to

-14 models in the field

because

of

the

special machining required for Lord

mount

bushings. Conversion

of

C7s

models

to

corresponding dash numbered

C8s

models may be

accomplished in accordance with instructions

contained in

our

Service Bulletin on this subject.

Installation

of

a flange crankshaft in place

of

tapered shaft is considered merely a crankshaft

replacement

and

does

not

require factory approval

or

special instructions, however, engine

identification plates bearing model

or

dash

numbers,

other

than

those originally assigned,

cannot be issued unless an application for conver-

sion approval has been submitted and approved

by

the

factory Service Department.

3-4. OPTIONAL EQUIPMENT.

While

the

assignment

of

model numbers, as

described above, represents an

attempt

to

establish

categories

of

engines

of

the

same basic design

and

to

denote

the

equipment

installed, any extension

of

the

list

of

model numbers,

intended

to

specify

in detail

the

optional parts installed

to

adapt

engines

to

all aircraft installations, would

be

of

little

or

no

value, since these requirements change

frequently,

and

since optional

equipment

may

be

replaced

by

other

parts in

the

field. Accordingly,

engines are equipped

with

certain optional types

of

part,

such as oil sumps, accessories,

and

equipments (or systems), such

as

radio shielded

ignition,

as

specified

by

the

purchaser,

and

no

attempt

is made

to

denote

such installations in

the

engine model designation. Unshielded ignition

systems are standard

equipment

on

all C series

engines. Shielded ignition systems are standard

on

the

0-200.

Stromberg

type

NA-S3Al carburetors

are standard

on

all C75, C85

and

earlier C90

engines

and

are designed for gravity feed. Type

NA-S3Al carburetors designed for use

with

pump

feed systems are available. Marvel-Schebler

type

MA-3SPA carburetors are standard for

0-200

and

current

production

C90 engines. Oil sumps are

shaped

to

suit various aircraft in regard

to

location,

capacity

and

length

of

the

Hller neck.

The

oil gage

rod

assemblies are located in

the

oil filler neck

and

are marked per customer's specification for

capacity.

3-5.

SUPERSEDING PARTS.

Whenever possible, parts

of

improved design are

made

to

fit

into

existing engines so

that

modernization

of

older assemblies requires

replacement

of

only

the

redesigned part. This

is

not

always possible, because some parts are so

related

that

a change in

one

necessitates a

corresponding change in

the

other. Service

Bulletins list serial numbers

of

engines which

require new

type

parts for modernization. When a

superseding part

is

not

interchangeable with

the

original

type

of

part,

the

old

style

part

is

kept

in

stock for maintenance

of

the

older engines.

3-6. CRANKCASE CONSTRUCTION.

Aluminum alloy castings which form

the

left

and

right halves

of

the

crankcase are machined flat

and

smooth

along their parting surfaces. Upper

and

lower flanges are

attached

by

fourteen

hex

head

screws, washers,

and

plain nuts,

two

of

which

also

attach

the

engine lifting eye

to

the

upper

flanges. Each casting has

two

cylinder

mount

pads machined in its vertical side. Cylinder

openings in pads

on

the

two

sides

of

the

case are

not

quite opposite. Each casting has a heavy lateral

web

at

the

rear,

another

near

the

center

and a third

near

the

front. These webs are

cut

out

for

ventilation

and

oil drainage

and

have enlarged

bosses

at

the

case parting surface for crankshaft

and

camshaft bearings. Seats for steel backed,

preclSlon inserts

of

the

crankshaft main bearings

are line

bored

through

the

web bosses,

and

camshaft bearings are

bored

directly in

the

case

metal. These bearings are all divided equally

by

the

parting surface, camshaft bearings being directly

below

the

main bearings. Earlier case halves

of

the

C series engines are prevented from spreading

by

eight

through

studs installed in

the

bosses above

and

below

the

main bearings

and

one

stud

below

the

rear camshaft bearing. Current

production

C

series

and

all

0-200

case halves are retained

by

six

through

studs installed in

the

bosses above and

below

the

front

and

rear main bearings,

two

through bolts installed in lieu

of

the

two

through

studs

at

the

center

bearing bosses

and

one

through

stud

below

the

rear camshaft bearing. In addition

to

the

through

studs or

through

bolts, cylinder

mount

pads have short studs

to

make a

total

of

six

in each. Cylinder pads

and

case webs are stiffened

by

ribs cast inside

the

case. A

counterbore

around

the

crankshaft opening in

the

front

of

the

case

receives

the

crankshaft oil seal.

In

current

production

crankcases,

the

shoulder

behind

the

oil

seal recess

is

deeper

than

in older cases

to

make a

better

oil baffle.

The

long boss for

the

front

main

bearing in early C series

production

cases

had

two

dowels, driven through longitudinal holes

on

the

horizontal centerline,

to

engage holes

at

the

mid-points

of

semi-circular

thrust

washers which

were installed

at

front

and

rear ends

of

the

bearing.

In

later C series crankcases,

the

two

halves

of

each

washer were different. One

half

had a short

rivet

at

its mid-point

to

fit

into a notch

in

the

bearing boss.

The

other

half

was plain. These washers were

installed

with

the

split perpendicular

to

the

case

parting surface, whereas

the

original

type

washer

split was in line with

the

parting surface.

A groove has been

added

to

each

end

of

the

front

main bearing boss

to

accomodate

thrust

washers

on

the

0-200.

Old

style cases

not

having this groove

must be serviced

with

flanged

front

main bearings.

17

A

notch

is

provided

to

accept

the

tang

of

these

bearings. Below each cylinder pad,

and

on

the

horizontal plane

of

the

camshaft,

two

lateral bosses

inside

the

case are

bored

to

form valve lifter guides.

These bores emerge

at

the

case side surface,

and

a

pushrod housing adapter, installed over their

open

ends,

is

retained

by

three case studs

and

nuts.

Between

the

line

of

lifter guides

and

the

line

of

cylinder openings at each side

of

the

case are

the

main oil galleries extending from front

to

rear.

The

oil galleries are plugged

at

the front. Current

C series crankcases use a 5/8-18

hex

head

plug

and

annular gasket. Earlier C series

and

current

0-200

crankcases use (2)

3/8

NPT

countersunk

hex

pipe

plugs.

An

enlargement

of

each casting's lower

parting flange

at

the

front

end

forms

half

of

a boss

which

is

machined

and

studded

to

make a

mount

pad

for a vacuum

pump

on

the

-16

and

0-200.

A

semicircular flange

at

the

rear

of

the

crankcase

bottom

surface

is

machined flat

and

studded

to

form the

front

half

of

the

oil sump

mount

pad.

Two

studs driven

into

bosses

at

the

lower parting flanges are used for

attachment

of

the

intake manifold. The crankcase

breather

elbow

is

screwed

into a tapped

boss ahead

of

No. 3

cylinder.

An

upper

and

a lower arm

at

the

rear

of

each case casting affords an engine

mounting

point.

For

-8, -12

and

-16 models the

end

bosses

of

mounting

arms have

front

and

rear conical recesses

for

rubber

mount

bushings. The arm bosses

of

-14

and

0-200

model crankcases are

bored

through

and

counterbored

for Lord

mount

bushing assemblies.

Parts

of

the

Lord

mount

assembly are illustrated

in

Figure 16. The flange surrounding

the

rear

end

of

the crankcase

is

machined flat

and

studded

for

attachment

of

the crankcase cover. Locations

and

lengths

of

the

studs are different in

-8

and

-12

crankcases. The crankcase

of

-12, -14, -16

and

0-200

models has a hole

bored

through

the rear

web above

the

rear main bearing

to

hold

the

starter

pinion pivot. A dowel driven

into

the

left side

of

the

hole fits

into

the

pivot

to

hold

it

in position.

Some models have a

studded

mount

pad

for a fuel

pump

on

the

1-3 side

of

crankcase.

3-7. CRANKSHAFTS

Each

type

of

crankshaft

is

machined from a single

forging. The four crankpins are spaced

1800 apart.

Starting at

the

rear

and

proceeding forward,

the

crankpin numbers are 1, 2, 3

and

4, according

to

the

cylinders which

they

serve. Each crankshaft has

three main journals, the front one being

immediately ahead

of

No.4

front crankcheek. The

cheek

is

ground flat

around

the

journal

and

contacts the rear crankcase

thrust

washer

to

18

transfer propeller

thrust.

A small anti-thrust flange

at

the

front

end

of

the

front

journal

acts

as

an oil

slinger.

I

CAUTION

~

I

This design should

not

be used in

pusher

installations.

Older types

of

shaft

had a taper

on

the front side

of

the slinger flange. These

cannot

be installed in pres-

ent type crankcases because

of

interference between

the

taper

and

the case oil baffle.

The

slinger flange

of

present type cranksh,afts has parallel sides. All

crankshafts

are

center bored for lightness.

The

front

bore runs

out

at

the

front crankcheek

and

the

rear

end bore

at

the

rear crankcheek. Steel oil tubes

are

permanently installed in holes drilled from

the

front

and

rear journals

through

crankcheeks

to

Nos. 1

and

4 crankpins. Oil holes are drilled

through solid cheeks from the center

journal

to

Nos. 2

and

3 crankpins. The

tapered

type

shaft has

a slot along the propeller

hub

taper

for a square key

to

drive the steel

hub

used with it.

The

hub

fits

tightly

on

the

taper

and

is

retained by a

tube

nut,

which

is

locked by a flat head pin. A snap ring in a

hub

groove ahead

of

the

nut

flange acts

as a hub

puller.

The

propeller

is

clamped between

the

steel

hub

flange

and

a loose steel flange in

front

by six

bolts

and

nuts. The flange

type

shaft has a

propeller

mount

flange forged

on

its

front

end

with

six

tapped

bushings pressed

into

holes spaced

equally

around

the flange. Six bolts, screwed

into

the

shaft flange bushings, clamp

the

propeller

between a loose

front

flange

and

the

shaft flange.

The loose

front

flange

and

the

six bolts are

not

supplied as part

of

the

0-200

engine. A steel cased

oil seal

is

installed over

the

front

end

of

tapered

shafts

and

is

retained

in

the crankcase recess

around

the

shaft opening. With flange

type

crankshafts a split, composition seal

is

used.

It

is

made in one piece,

and

the

seal lip

is

held against

the shaft race

by

a spring. The gear pilot flange

at

the rear

end

of

the

crankshaft has four unequally

spaced

tapped

holes for gear retammg screws.

Current

production

shafts have a dowel between

two

of

the

screw holes.

3-8.

NITRIDED

CRANKSHAFTS

Latest

types

of

flanged

and

tapered

crankshafts

have nitrided main journals

and

crank

pins. Flange

shafts

for

C90

and

0-200

models have always

been

nitrided. These are identified

by a 1/4

inch hole

drilled

through

the

propeller

mount

flange.

Nitrided flange

type

shafts

for

C75

and

C85

models are identified

by

the

letter

"N"

stamped

on

the edge

of

the

propeller flange. Tapered shafts for

C7S

and

C8S models,

if

not

nitrided, have four

hub

nut

lock pin holes

at

the

front end. One additional

hole

is

drilled

to

identify nitrided shafts.

3-9. CRANKSHAFT GEARS

The

gear is piloted

on

the

small rear flange

of

the

crankshaft

and

aligned

by

the

crankshaft dowel.

It

is

retained

by

four screws. Screw holes are

unequally spaced

to

assure correct installation. The

space between

two

adjacent punch marked gear

teeth

points

to

the camshaft when

No.1

crankpin

is

at

T. D. C. Gears for -8 models are plain spur

gears. In -12, -16 and

0-200

models a cluster gear

is

installed. Its large wheel has beveled

teeth

and

is

driven

by

the

starter pinion.

3-10.CONNECTING RODS

Connecting

rod

assemblies

of

C90

and

0-200

models differ in dimensions from those

of

C7S

and

C8S models,

but

the

two

types are

of

similar

design.

The

rod

and

bearing cap assembly are made

from a single steel alloy forging, which is sawed

through the center

of

the big

end

before the

bearing seat is bored. Each

half

of

the

split big

end

bore

is

notched

to

accept

the

tang

of

the

semicircular bearing insert which fits in it. The

replaceable crankpin bearing inserts are

thin

steel-back shell type, lined

with

special alloy metal.

The

bearing cap is attached

to

the

rod

by

two

special bolts

and

hex

nuts. The cylinder number

is

stamped

on

the upper

bolt

boss

of

both

rod

and

cap. A tapered

"I"

beam connects

the

big

end

and

the piston pin boss. The piston pin bushing

is

a

plain bronze sleeve, pressed

into

the

rod

boss

and

bored

parallel

to

the big end bearing.

The

original

type solid piston pin bushing has been replaced

by

a single piece, split type bushing in

both

C7S, C8S,

C90

and

0-200

type rods.

3-11. CAMSHAFTS

All camshafts installed in C7S

and

C8S models are

flame hardened iron castings. The same material

was employed in early production C90 camshafts.

Present

type

C90

and

the original

0-200

camshafts

are alloy steel forgings. These are identified, when

new,

by

an over-all black Parko-Lubrite coating

and

an underlying copper plate

on

unfinished

surfaces. All C90

and

0-200

camshafts are reduced

in diameter between cam lobes

to

provide

connecting

rod

clearance. Standard camshafts for C

series carburetor engines have an eccentric

machined

at

the front fuel

pump

lever. A special

camshaft

with

two

eccentrics

is

available for

installations which require a second fuel pump.

Camshafts installed

with

vacuum

pump

equipment

in -16

and

0-200

engines have

no

pump

drive

eccentric.

The

front

end

of

this type has six

tapped

holes for screws which

attach

the vacuum

pump

drive bevel gear. A special combination gear

and

eccentric is also available for

the

vacuum

pump

and

side

mounted

fuel pump. The C90-16

and

0-200

also have a camshaft for a side

mounted

fuel

pump

with

no

provision for a vacuum drive gear. The gear

is

spaced from

the

shaft end, for correct backlash

with

the

vacuum

pump

gear,

by

one

or

more shims,

which are available in

two

thicknesses. A few

of

the

early

production

0-200

engines have these

shims installed. Current production engines do

not

require these shims

to

provide proper backlash. All

camshafts have three journals. The center

journal

is

plain, while the front

journal

has a deep groove

to

register with oil holes drilled from its bearing

into

the

main oil galleries.

The

rear

journal

has flanges

at its

front

and

rear ends

to

restrict camshaft

end

movement

in

the rear bearing.

The

rear flange has

four unequally spaced

tapped

holes for

the

camshaft drive gear retaining screws. Three cam

lobes between each

two

journals operate valve

lifters for

two

cylinders. In each group,

the

outer

lobes each operate one exhaust valve lifter,

and

the

center lobe operates two opposite intake valve

lifters. Lobes

of

0-200

camshafts have a greater lift

than others.

3-12. CAMSHAFT GEARS

Camshaft drive gears installed in -8 models are

single spur gears with the web at the rear, while

those in -12, -14, -16

and

0-200

models have

both

external

and

internal

teeth,

and

the web is at

the

front. The internal

teeth

drive

the

generator gear.

Both types

of

gears have a square hole in

the

center

to

receive

the

oil

pump

driving impeller shaft. A

ground recess in the front side

of

each gear web fits

closely over the camshaft pilot flange. The gear is

retained

by

four hex head screws in holes spaced

unequally

around

the web. Thus, the gear can be

installed in only one position in relation

to

the

cam

lobes. A

punch

marked

tooth

is meshed,

at

assembly, between

two

similarly marked

teeth

on

the

crankshaft gear,

and

this simple operation

assures correct valve timing

without

measurement.

19

3-13. HYDRAULIC VALVE LIFTERS

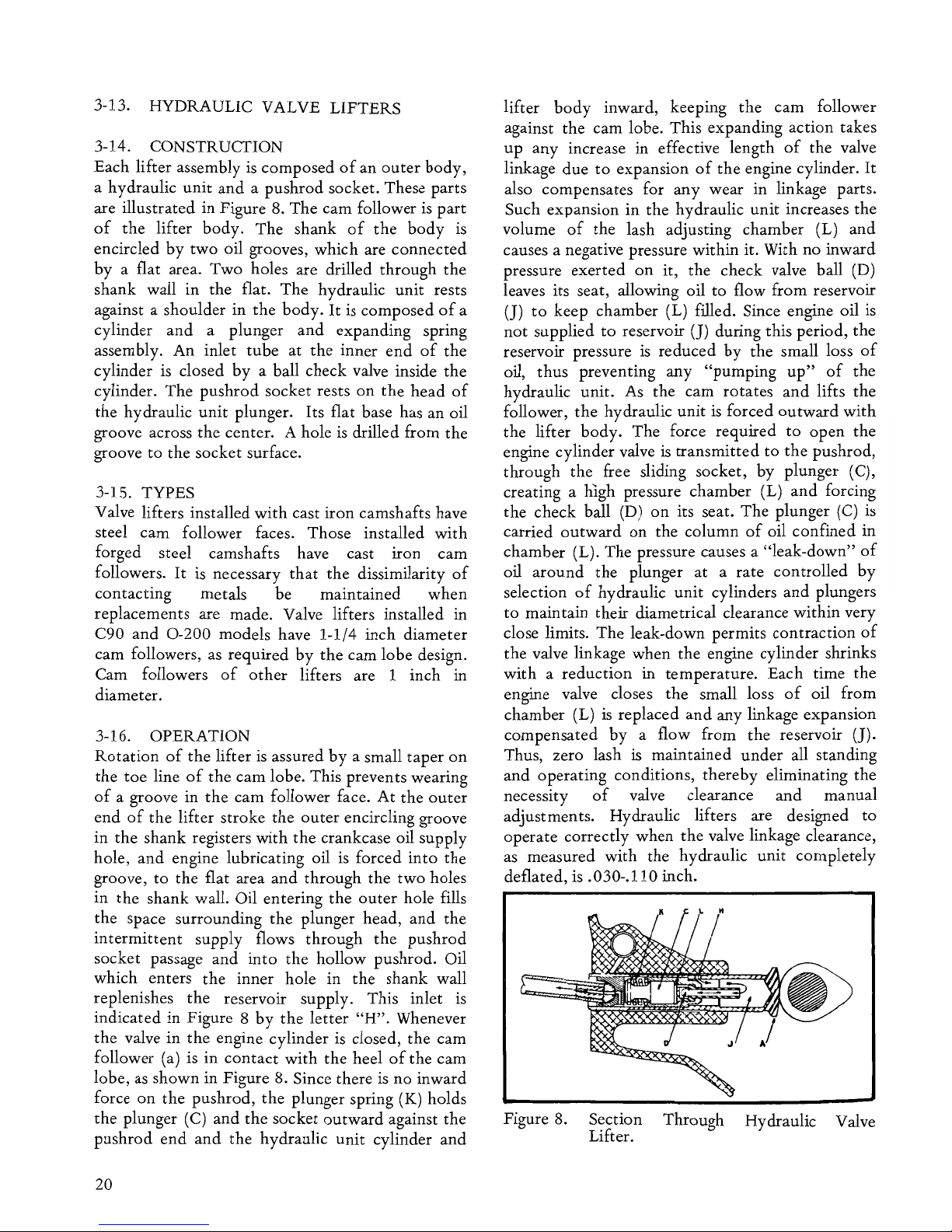

3-14. CONSTRUCTION

Each lifter assembly

is

composed

of

an

outer

body,

a hydraulic

unit

and

a pushrod socket. These parts

are illustrated in Figure 8. The cam follower

is

part

of

the

lifter

body.

The

shank

of

the

body

is

encircled

by

two

oil grooves, which are

connected

by

a flat area. Two holes are drilled through

the

shank wall in

the

flat.

The

hydraulic

unit

rests

against a shoulder in

the

body.

It

is composed

of

a

cylinder

and

a plunger

and

expanding spring

assembly. An inlet

tube

at

the

inner

end

of

the

cylinder

is

closed

by

a ball check valve inside

the

cylinder.

The

pushrod socket rests

on

the

head

of

the

hydraulic

unit

plunger. Its flat base has an oil

groove across

the

center. A hole

is

drilled from

the

groove

to

the

socket surface.

3-15. TYPES

Valve lifters installed

with

cast iron camshafts have

steel cam follower faces. Those installed

with

forged steel camshafts have cast

iron

cam

followers.

It

is

necessary

that

the

dissimilarity

of

contacting metals be maintained

when

replacements are made. Valve lifters installed in

C90

and

0-200

models have 1-1/4 inch diameter

cam followers,

as

required

by

the

cam lobe design.

Cam followers

of

other

lifters are 1 inch in

diameter.

3-16. OPERATION

Rotation

of

the

lifter

is

assured

by

a small

taper

on

the

toe

line

of

the

cam lobe. This prevents wearing

of

a groove in

the

cam follower face.

At

the

outer

end

of

the

lifter stroke

the

outer

encircling groove

in

the

shank registers

with

the

crankcase oil supply

hole, and engine lubricating oil

is

forced

into

the

groove,

to

the

flat area

and

through

the

two

holes

in

the

shank wall. Oil entering

the

outer

hole fills

the

space surrounding

the

plunger head,

and

the

intermittent

supply flows through

the

pushrod

socket passage

and

into

the

hollow pushrod. Oil

which enters

the

inner hole in

the

shank wall

replenishes

the

reservoir supply. This inlet

is

indicated in Figure 8

by

the

letter

"H".

Whenever

the

valve in

the

engine cylinder is closed,

the

cam

follower (a) is in

contact

with

the

heel

of

the

cam

lobe,

as

shown in Figure 8. Since there

is

no inward

force

on

the

pushrod,

the

plunger spring

(K)

holds

the

plunger

(C)

and

the

socket

outward

against

the

pushrod

end

and

the

hydraulic

unit

cylinder

and

20

lifter

body

inward, keeping

the

cam follower

against

the

cam lobe. This expanding action takes

up

any increase in effective length

of

the

valve

linkage due

to

expansion

of

the

engine cylinder.

It

also compensates for

any

wear in linkage parts.

Such expansion

in

the

hydraulic

unit

increases the

volume

of

the

lash adjusting chamber (L)

and

causes a negative pressure within it. With no inward

pressure

exerted

on

it,

the

check valve ball (D)

leaves its seat, allowing oil

to

flow from reservoir

(J)

to

keep chamber (L) filled. Since engine oil

is

not

supplied

to

reservoir

(J)

during this period,

the

reservoir pressure

is

reduced

by

the

small loss

of

oil,

thus

preventing any

"pumping

up"

of

the

hydraulic unit. As

the

cam rotates

and

lifts

the

follower,

the

hydraulic

unit

is

forced

outward

with

the

lifter

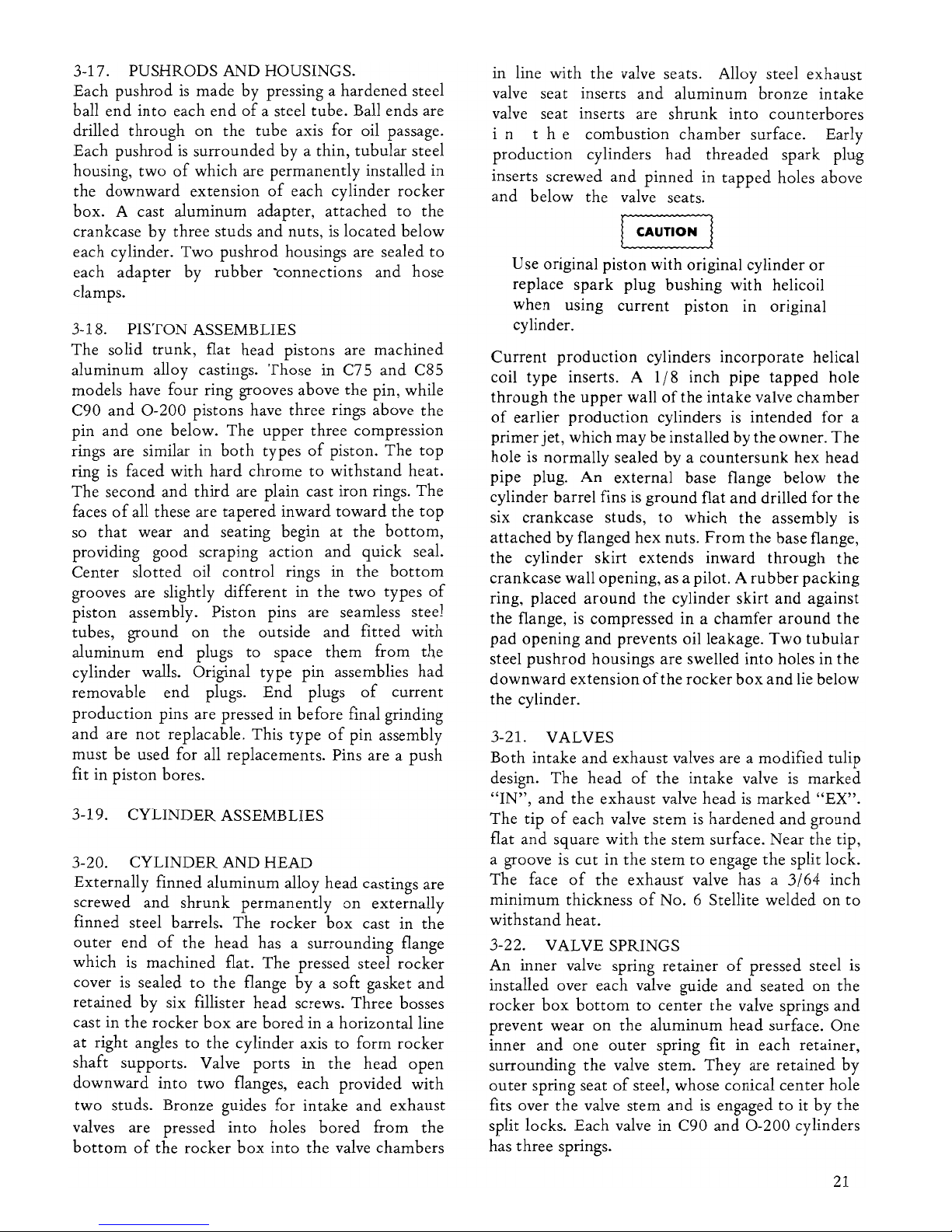

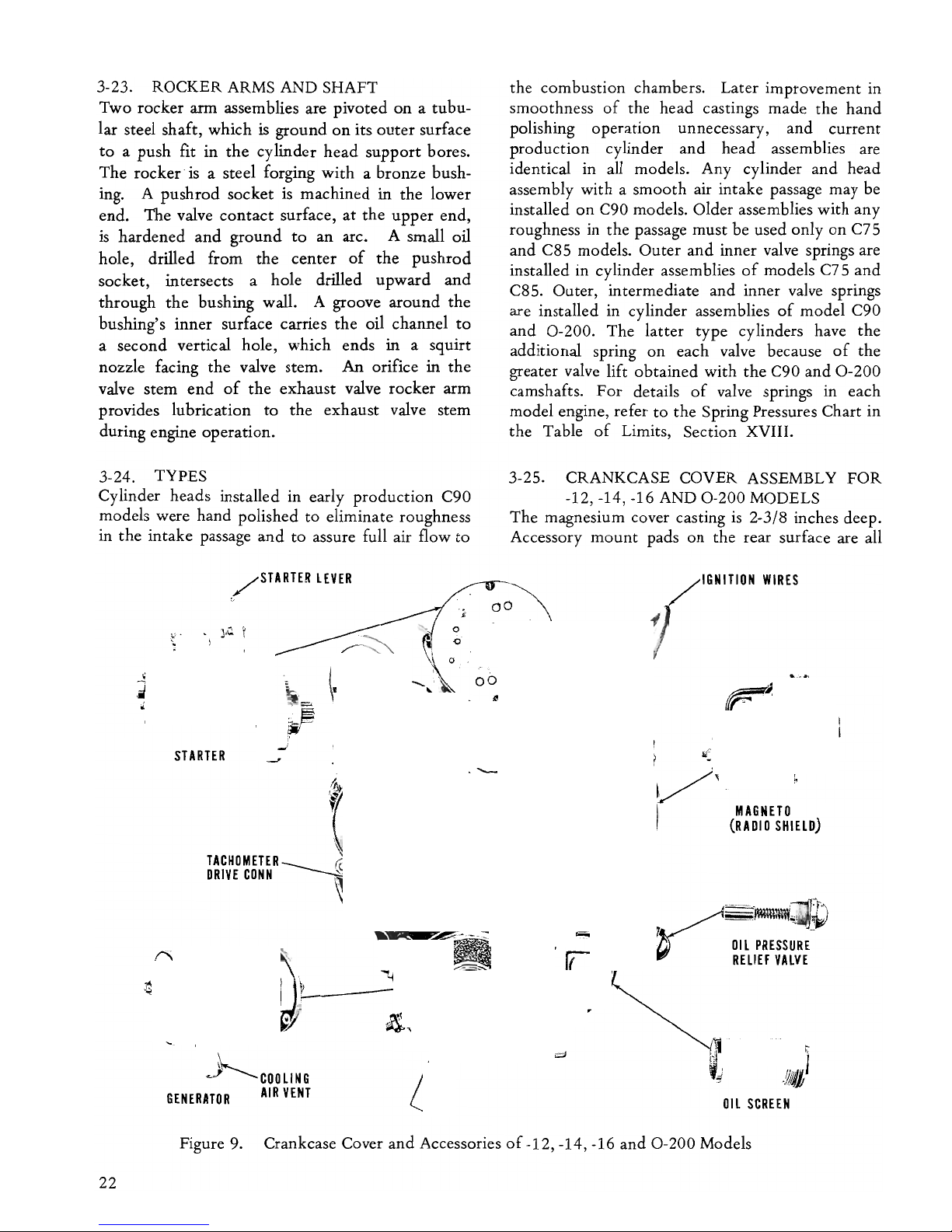

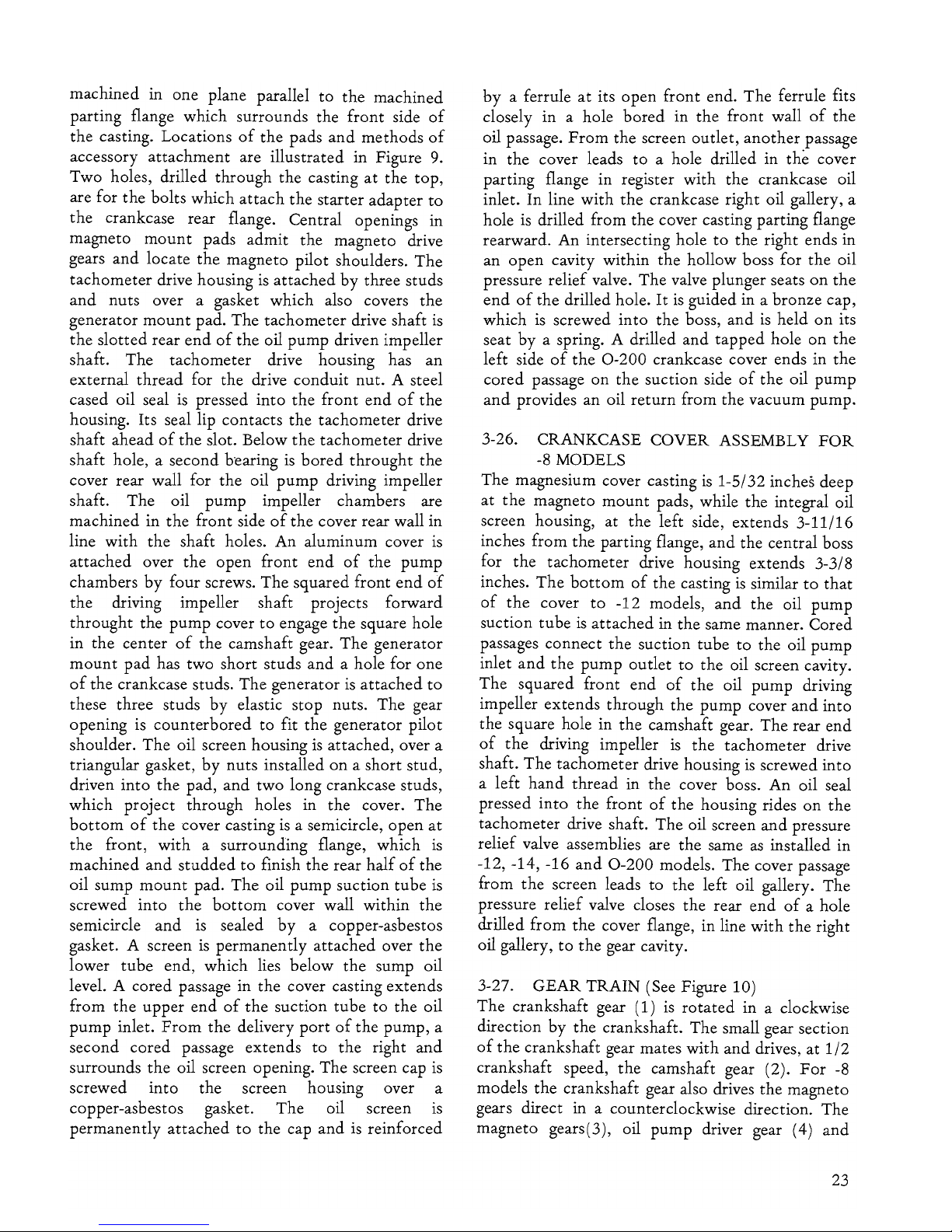

body.