Technical manual

to be saved

by th e user

for future reference

Document n° 286-14 ~ 17/12/2001

Les Fonderie sFranco-Belges

59660 MERVILLE

Phone : 03.28.43.43.43

Fax : 03.28.43.43.99

RC Hazebrouck 445750565B

Subject to modifications

Continental

Room heater La Parisienne

124 03 01 - 124 05 01 - 124 07 01

How to install, use and maintain your stove .

Norme NF D 35-301

Description of the appli ance

Installation instructions

Operating instructions

Spare parts

Warranty c ertificate

FR EN NL ES PT

PL

PL

PL PL PL

Description of the unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Package . . . . . . . . . . . . . . . . . . 3

Specifications . . . . . . . . . . . . . . . 3

Regulations . . . . . . . . . . . . . . . . . 3

Installation instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Warning to the user . . . . . . . . . . . . 4

Location of the unit . . . . . . . . . . . . 4

Chimney . . . . . . . . . . . . . . . . . . 4

Hearth . . . . . . . . . . . . . . . . . . . 5

Connections to flues . . . . . . . . . . . . 5

Mounting the tray . . . . . . . . . . . . . 6

Door closing pressure . . . . . . . . . . . 6

Pre-utilisation check . . . . . . . . . . . . 6

Soot Doors . . . . . . . . . . . . . . . . . 6

Commissioning . . . . . . . . . . . . . . . 6

Operating instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Lighting your stove . . . . . . . . . . . . 7

Air inlets . . . . . . . . . . . . . . . . . . 8

Fuel . . . . . . . . . . . . . . . . . . . . . 8

Maintenance . . . . . . . . . . . . . . . . 8

Fire-bricks . . . . . . . . . . . . . . . . . 8

Trouble Shooting . . . . . . . . . . . . . . 9

Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

CONTENTS Page Page

FRANCO BELGE congratulates you on your choice.

FRANCO BELGE, which has been granted the ISO 9001 certification, guarantees the

quality of its appliances and is committed to meet its customers needs.

FRANCO BELGE, which can boast a 75-year experience in the industry of heating devices,

uses state-of-the-art technologies

to design and manufacture its whole range of products.

This document contains instructions on how to install your appliance and make full use of

its functions, both for your comfort and safety.

Continental "La Parisienne" - ref. : 124 03 01 - 124 05 01 - 124 07 01

2 Technical manual "286"

Warning to the user

A wood stove should only be installed by competent personnel, in the strict

application of normal practices and all safety precautions.

An incorrectly installed wood stove can cause serious accidents (chimney fires,

burning of plastic insulation materials, in partition walls, etc.).

The manufacturers responsibility shall be limited to the supply of the equipment.

1.Description of the unit

1.1. Package

•1 package : Stove complete.

1.2.

Specifications

Reference........................................ 1240301.....1240501..... 1240701

Nominalheatoutput ........................ kW ..........3 ......... 5 ......... 7

Roamheatingvolumecapacity .................. m

3

..........90........ 140 ........220

Weight ................................KGs ..........80 .........95.........105

Dimensions of the firebox

-Width ................................mm ......... 340........ 340 ........340

-Depth................................mm ......... 180........ 180 ........180

-Usableheight ...........................mm ......... 250........ 315 ........420

Logs dimensions

-Lenght ............................... cm..........25 .........30......... 40

-Diameter .............................. cm........ 10-16...... 10-16 ......10-16

Autonomy ............................... h..........8 ......... 8 ......... 8

Chimneydraftrequired....................... Pa ..........10 .........10.........10

Ashpancapacity ......................... Litre ......... 2,5.........2,5.........2,5

1.3.Regulations

Important : Before commencingthe installation of your

new Franco Belge appliance, it is recommended that

the instructions are read and understood.

•Health and Safety at WorkAct1974 : The installation

should comply with the Health and Safety at Work Act

1974 and particular reference to the following.

•Handling : Adequate facilities should be provided for

handling the appliance.

•Glass : On Franco Belge models incorporating glass

doors, extra care should be taken to avoid breakage.

•Fire cement : C are sho uld be taken to avoid fire

cement contacting the skin. The material is causticand

the event of contact being made, wash offimmediately

with clean water.

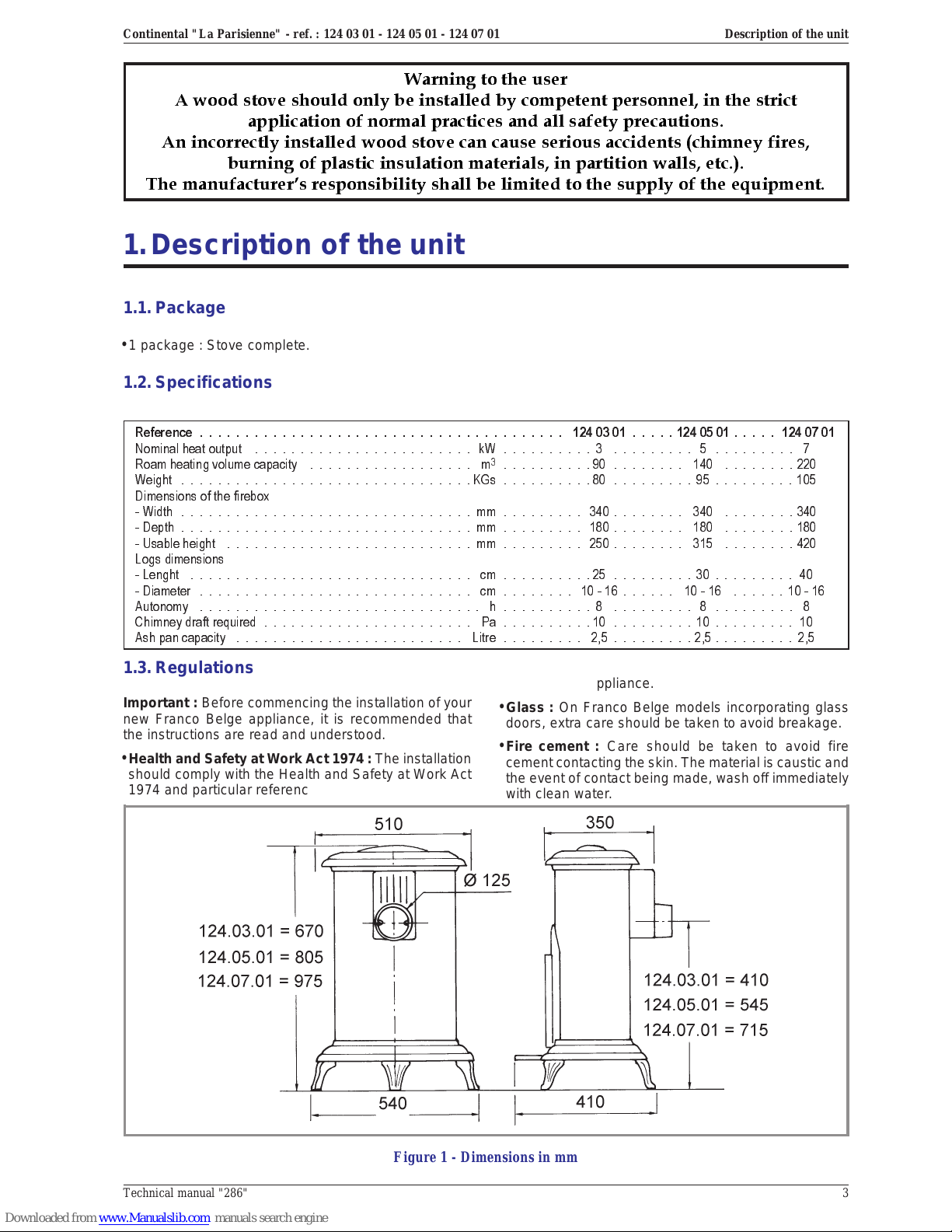

Description of the unit

Figure 1 - Dimensions in mm

Continental "La Parisienne" - ref. : 124 03 01 - 124 05 01 - 124 07 01

Technical manual "286" 3

2.Installation instructions

The Parisienne comes bolted to a wooden pallet with a

box over the top.

2.1.Warning to the user

An incorrectly installed heating appliance can cause

serious accidents (chimney fires, burning of plastic

insulation materials, in partition walls, etc.).

The installation must comply with Current Building

Regulations. If in doubt, consult your Dealer or local

Building Inspector.

It is the installer’s responsability to conform to local

building standards and requirements with regard to

installation.

The manufacturer’s responsibility shallbe limited tothe

supply of the equipment.

2.2.Location of the unit

Ventilation :

For satisfactory operationwith a natural draught, check

that sufficient air for combustion is available in the

room.

Chimney position :

For new chimney installations, select a central position

within the building, to provide a good heat distribution

around the building.

Hearth :

The hearth must be suitable for use with solid fuel

burning applia nces and must comply with Current

Building Regulations. Ifin doubt, consult your Dealer or

local Building Inspector.

Rear wall and ceiling :

The app liance must not be positioned close to

combustible materials, wall & ceiling surfaces etc.,

Consult your Dealer or local Building Inspector if in

doubt.

2.3. Chim ney

The chimney must comply with Current Building

Regulations. If in doubt, consult your Dealer or local

Building Inspector.

Existing flue :

The flue must be suitable for the installation of fuel

burning appliances, otherwise it must necessary to

install a tubing

The flue must be in good condition and must provide

sufficient draught (refer to technical details p. 3 ).

The flue must be clean. It should be swept to remove

soot and dislodge tar deposits.

The flue must be well insulated. If the flue inner wall

surfaces are cold, a good thermal draw is impossible

causing condensation problems (tar formation etc.) to

occur.

Thefluemustbewatertight.

The chimney must have a constant cross section.

The flue must not be shared with other appliances.

The chimney must be at least 4.5 m (15 ft high).

In case of aflat roof or when the roof gradientislower than

15°, the stack must be 1,2 m (4 feet) high at least.

The capping must not restrain the draught.

If the chimney has any down draught tendency, due to

its position in relation to nearby obstacles, then an

anti-down draught cowl must be installed on the

chimney or the chimney height must be increased.

If the chimney draught is excessive or irregular, a

draught stabilizer (barometric dampe r) mu st be

installed to the connector pipe.

Flue non-existent :

The chimney must comply with Current Building

Regulations. If in doubt, consult your Dealer or local

Building Inspector.

The flue must not be supported by the stove.

Consult a chimney specialist for advice on suitable flue

systems for solid fuel appliances.

It must be distant from any combustible material (walls,

cross members)

It must permit an easy sweeping.

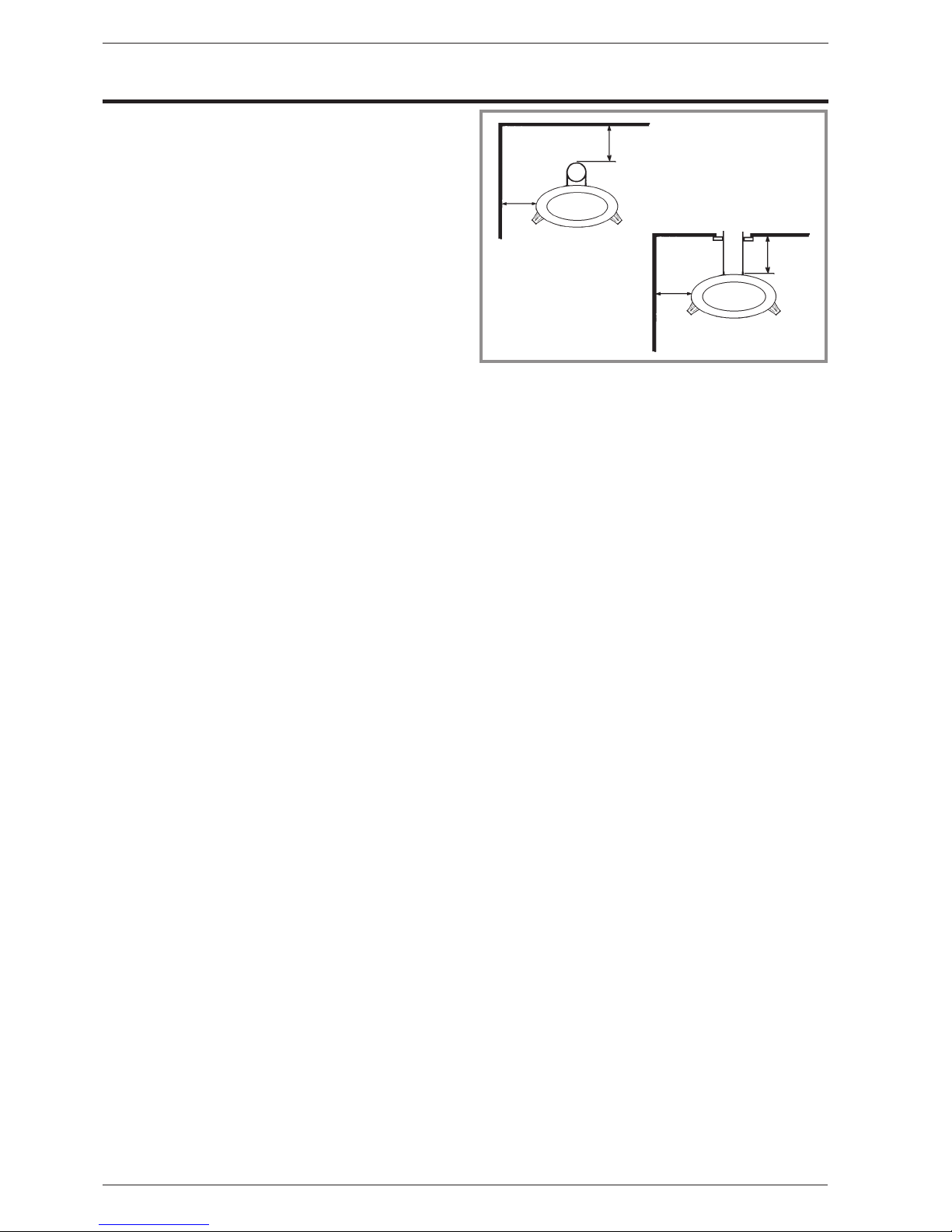

Installation instructions

300

mm

300

mm

300

mm

300

mm

Figure 2 - Minimum clearances

Continental "La Parisienne" - ref. : 124 03 01 - 124 05 01 - 124 07 01

4 Technical manual "286"

2.4. Hearth

The stovemust stand on a fireproofhearth and must be

situated at least 300 mm (12 inches) from any

combustible material.

The positioning of the stove and the size of the hearth

are governed by building regulations for Class 1

appliances.

These building regulations state that the hearth must

extend in front of the stove by at least 300 mm

(12 inches) and to the sides of the stove by at least 150

mm (6 inches) If in doubt as to the positioning of the

stove expert advice should be sought either from the

supplier or the local building inspector.

2.5.Connections to flues

There are several ways of connecting the stove to the

flue.

Horizontal lengths of flue must be kept to a minimum

and should not be more that 150 mm (6 inches) long.

All flue connections must be well sealed.

%

"

#

!

$

%

Installation instructions

X - Forbidden

1 - Flue duct

2 - Stainless funnel-shaped register

3 - Encasing of the flue connector : 40 mm

4 - Funnel-shaped fire cement

5 - Flange

6 - The flange does not extend beyond the encasing

7 - Soot door

Figure 3 - Connections to flue

Continental "La Parisienne" - ref. : 124 03 01 - 124 05 01 - 124 07 01

Technical manual "286" 5

2.6.Mounting the tray

- Centre on tab and lower into place (fig. 4).

2.7.Door closing pressure

Figure 5

The closing latch rotates around a pressure screw

positioned cam.

- Loosen pressure screw 1.

- Turn cam 2 to desired position.

- Tighten pressure screw 1.

2.8. Pre-utilisation check

- Check that the glasses are not damaged.

- Check that the smoke passages are not obstructedby

packaging or removable parts.

- Check that the seals of the smoke-line are in good

condition.

- Check that the doors close correctly.

- Check that all removable parts are correctly installed.

(grates, tray, etc.)

2.9.Soot Doors

It will be necessary to have a soot door to enable the

chimney to be swept. This may either be in the actual

brickworkofthechimneyor in the register plate.Various

type and positions of soot doors are shown in figure 3.

2.10. Commissioning

On completion of the installation and after allowing a

suitable period of time for the firecement and mortar to

dry out, the stove should be lit and checked to ensure

that smoke and fumes are taken from the appliance up

the chimney and emitted safely. Also check all joints

and seals.

Installation instructions

Figure 4 - Fixing the ash lip tray

1 - Pressure screw 2 - Cam

Figure 5 - Door closing pressure

Continental "La Parisienne" - ref. : 124 03 01 - 124 05 01 - 124 07 01

6 Technical manual "286"

3.Operating instructions

Don’t use the oven in mild weather : Under certain

circumstances (e.g. fog and repeated thaw) the

chimney willnotdraw sufficiently well and thusbe atthe

origin of asphyxia.

Awaiting better weather circumstances, don’t use any

coal but only wood.

Note : When the fire is litfor the first time, thestove may

give off fumes from the new paint. This is normal but

ensure the room is well ventilated during the first few

hours operation.

Similarly, the window can becom e cloudy by the

evaporation of the water in the refractory bricks.

It is advisable with any new cast

iron stove to avoid having too

intense a fire in the s to ve for its first

few days of use.

The Parisienne is a quality product

which, if used sensibly will give

many years of trouble free

operation, the following advice is

intended to help you enjoy those

years withoutproblems.

3.1.Lighting your stove

Your Parisienne stove is designed

to be a very efficient heating

appliance. Therefore, the majority

of the heat created by burning fuel

on it is radiated intothe room rather

than disappearing up the chimney,

as is the case with an open fire.

There is a side effect of this gain in

efficiency which can be a nuisance

to you as theuser but can be easily

avoided if, when lighting your stove

from cold, the chimney is heated up

as quickly possible. This will create

an up-draught which is required to

pull air through the stove which in

turn burns the fuel. The easiest way

toproducethiscolumnof air moving

is to open the air inlet wheel on

maxi, use paper or fire lighters and

small pieces of wood in order to

achieve a fast burning fire with little

smoke and plenty of flames. This

will push heat up the chimney and

start the draught working. Now you

can put solid fuel on the stove

because the increased smoke

emission will be drawn up the

chimney instead of trying to escape

into the room. Remember the seals

on your stove are there to prevent

air from being drawn into the stove,

thus allowing control of the burning

rate by adjustment of the air inlet,

not to stop smoke escaping into the

room.If smoke is escaping into your

room then , either your are not

operating it correctly or there is a

chimney draughtproblem. Thismay

be cured by sweeping or you may

need the advice of a chimney

expert.

Note : When refuelling your stove, if

it is burning very slowly, the same

advice willapply as for lightingfrom

cold.

Operating ins truct ions

1

2

3

4

6

9

5

1 - Cover

2 - [Prise de dépression

cheminée]

3 - Top plate

4 - Door lock

5 - Draught control

6 - De-ashing device

7 -Tool

8 - Poker

9 - Ash tray

Figure 6 - Operating devices

8

7

Continental "La Parisienne" - ref. : 124 03 01 - 124 05 01 - 124 07 01

Technical manual "286" 7

3.2. Air inlets

Primarycombustionairentersviatherotatingcontrolon

the front door of the stove (fig. 7). You will discover by

experience how much to open this control, depending

on your particular chimney draught and fuel used.

However, as a guide, start with the following :

Lighting - Unscrew 12 turns (N) from the fully closed

position, (E = 20 mm)

Normal - Unscrew 6 turns (N) from the fully closed

position, (E = 10 mm)

Slumbering - Unscrew 1/2 turn (N) from thefully closed

position, (E = 1,2 mm).

Warning : On no accountshould the front Ash Door be

left open as this could cause overheating of the stove

an damage to the grates.

3.3.Fuel

•Recommended fuel :

The bestfuels for use with the Franco Belge Parisienne

are :

Sunbrite (Small) - Anthracite (Medium)

Dry Woo. - Usehard wood logs which have been cut for

at least two years and stored under shelter.

Hardwood has a higher calorific value per cu metre

(oak, ash, maple, birch, elm, beech, etc.).

•Prohibited fuel :

Any form of bituminous coal or petroleum based coke.

“green wood”. Green or damp wood reduces stove

efficiencyand makes thewindow, the internal wallsand

the flue dirty (soot, tar, etc.).

“used timbers”. Burning treated wood (railway sleepers,

telegraph poles, offcuts of plywood or chip board,

pallets, etc.) quickly clogs the flue ways (soot, tar,

etc.), pollutes the environment (pollution and smell,

etc.) and c ause the fire to burn too quickly and

overheat.

F

Green wood and recovered wood can even-

tually cause a chimney fire.

3.4.Maintenance

Daily - Shake the grate, - Empty the Ash Pan. Do not

allow ashtobuild up under thegratewhenburningsolid

fuel as this will cause overheating and damage to the

grate.

Periodica lly - Clean out the flue ways. Sweep the

chimney at least once a year but more frequently if

necessary. The frequency of any cleaning depends

upon the fuel being used. Remember, gases from

combustion are dangerous and blocked flue ways force

those gases into your room, so do be particular when

cleaning the flue ways.

Check the rope seals now and again and replace if

necessary.

Never use water to clean the stove or glass.

Never b urn plastic, rubber, waste etc. This causes

pollution of the stove, chimney and environment.

Note : The appearance of cracks when burning the

enamelled units is quite usual and tends to disappear

when the appliance is cooling down. It should not be

considered as a defect but rather as a patina of the

enamel which does not affect its quality nor its service

ability.

This crackling is more apparent with the blue enamel

than with the brown and green.

3.5. Fire-bricks

When fire-bricks are replaced, one should respect

48 hours drying before operating the oven.

Operating instructions

Figure 7 - Air control

Figure 8 - Front grate

Continental "La Parisienne" - ref. : 124 03 01 - 124 05 01 - 124 07 01

8 Technical manual "286"

3.6.Trouble Shooting

Problem Probable causes

- Action

Fire difficult to start

Fire goes out

Wood green, too damp or poor

quality fuel

- Usethe recommendedfuel

Logs are too big

- To light the fire, use small, very dry twigs. To maintain

the fire, use split logs

Air starvation

- Openlower spinwheel and top air control lever

Insufficient draught

þ

- Check that the flue is not obstructed, sweep it if

necessary

- Seekadvice froma chimney specialist

Fire burns too quickly Toomuch draught

- Ensurethat thelower spin wheel is closed

- Partially close the top air controllever

Excessive draw

þ

- Install a draught stabiliser. Consult your Dealer

Poor quality wood

- Do not continuously burn small wood, sticks, bundles,

carpentry offcuts (plywood, pallets), etc.

Smokes when lighting up Flue duct is cold

- Burn paper andkindling wood to increase heat

Room is in decompression

- In housesequipped with mechanical ventilation, partly

open a window untilthe fireis well established

Smokes while burning Draught is insufficient

þ

- Consulta chimney specialist.

- Check that the flue is not obstructed, sweep if

necessary

Down draught

- Install an anti-down draught cowl. Consult your Dealer.

Room is in decompression

þ

- In houses equipped with CMV, an outside air intake

must be installed for the chimney

Low heat output Incorrect Fuels

- Usethe recommendedfuel

þ

: This sign me ans that you should

asked for a qualified engineer to do the

work.

Operating ins truct ionsContinental "La Parisienne" - ref. : 124 03 01 - 124 05 01 - 124 07 01

Technical manual "286" 9

4.Spare parts

For any order of spare parts, please indicate : model

number,codeof the colour, description of the part, code

number and colour index of the part.

Example : Stove Continental 124 03 01 L,

Leg, 300120 77

A = 124 03 01 L B = 124 03 01 J C = 124 03 01Y

D = 124 05 01 L E = 124 05 01 J F = 124 05 01Y

G = 124 07 01 L H = 124 07 01 J I = 124 07 01 Y

1 100917 ....Campin............ 12x20M7 .....A....B ...C ... D....E....F ...G ... H....I.. 01

2 105123 ....Knob..........................A....B ...C ... D....E....F ...G ... H....I.. 01

3 105226 ....Firebrick....................................... D....E....F ...G ... H....I.. 01

3 105235 ....Firebrick........................A....B ...C ................................. 01

4 105227 ....Firebrick....................................... D....E....F ...G ... H....I.. 01

4 105236 ....Firebrick........................A....B ...C ................................. 01

5 105228 ....Firebrick....................................... D....E....F ...G ... H....I.. 02

5 105237 ....Firebrick........................A....B ...C ................................. 02

6 105229 ....Firebrick.......................................................G... H....I.. 01

7 105230 ....Firebrick.......................................................G... H....I.. 01

8 105231 ....Firebrick.......................................................G... H....I.. 02

9 110404 ....Hingepin .............6x30.......A....B ...C ... D....E....F ...G... H....I.. 04

11 122809 ....Nameplate.....................................................G ... H....I.. 01

12 142301 ....Adhesiverope ....................A....B ...C ... D....E....F ...G... H....I. 0,76m

13 161025 ....Touch-uppaint.......... (L) .......A.............. D..............G............ 01

13 161027 ....Touch-uppaint.......... (J) ............B ..............E.............. H....... 01

14 179919 ....Threadrod ........... 10x50 ......A....B ...C ... D....E....F ...G ... H....I.. 01

15 181602 ....Ceramicrope........... Ø8.......A....B ...C ... D....E....F ...G... H....I. 1,04m

16 188733 ....Ceramicglass.........220x155x3.....A....B ...C ... D....E....F ...G ... H....I.. 01

17 189104 ....Screw...............6x22.......A....B ...C ... D....E....F ...G ... H....I.. 01

18 189825 ....Screw.............. M6x5 ......A....B ...C... D....E....F ...G... H....I.. 01

19 217105 21 ..Shell......................................... D....E....F ................. 01

19 217106 21 ..Shell.........................................................G... H....I.. 01

19 217107 21 ..Shell..........................A....B ...C ................................. 01

21 300120 EF ..Leg ....................................C..............F ..............I.. 03

21 300120 77 ..Leg ..........................A.............. D..............G............ 03

21 300120 79 ..Leg ...............................B ..............E.............. H....... 03

22 300459 EF ..Base.................................... C..............F ..............I.. 01

22 300459 77 ..Base..........................A.............. D..............G............ 01

22 300459 79 ..Base...............................B ..............E.............. H....... 01

23 301032 EF ..Frame...................................C ..............F ..............I.. 01

23 301032 77 ..Frame.........................A.............. D..............G ............ 01

23 301032 79 ..Frame..............................B ..............E.............. H....... 01

24 301511 EF ..Doorlock .................................C ..............F ..............I.. 01

24 301511 77 ..Doorlock .......................A.............. D..............G............ 01

24 301511 79 ..Doorlock ............................B ..............E.............. H....... 01

25 301740 EF ..Airdamper ................................C ..............F ..............I.. 01

25 301740 77 ..Airdamper ......................A.............. D..............G ............ 01

25 301740 79 ..Airdamper ...........................B ..............E.............. H....... 01

26 301921 ....Oscillatinggrate ...................A....B ...C ... D....E....F ...G ... H....I.. 01

27 302145 59 ..Topplate .......................A....B ...C... D....E....F ...G ... H....I.. 01

28 303618 59 ..Topplate .......................A....B ...C... D....E....F ...G ... H....I.. 01

29 303829 59 ..Fluecollar.......................A....B ...C ... D....E....F ...G... H....I.. 01

30 306112 ....Gratesupport.....................A....B ...C ... D....E....F ...G... H....I.. 01

31 306716 ....Grate .........................A....B ...C... D....E....F ...G... H....I.. 01

32 307420 ....Fuelretainer .....................A....B ...C ... D....E....F ...G ... H....I.. 01

33 309940 EF ..Maindoor................................. C..............F ..............I.. 01

33 988757 ....Completedoor ..........(Y).................C..............F ..............I.. 01

33 309940 77 ..Maindoor.......................A.............. D..............G............ 01

33 988756 ....Completedoor .......... (L) .......A.............. D..............G............ 01

33 309940 79 ..Maindoor............................B ..............E.............. H....... 01

33 988784 ....Completedoor .......... (J) ............B ..............E.............. H....... 01

34 313509 EF ..Cover................................... C..............F ..............I.. 01

34 313509 77 ..Cover .........................A.............. D..............G ............ 01

34 313509 79 ..Cover ..............................B ..............E.............. H....... 01

35 314710 59 ..Exchangerbase ...................A....B ...C ... D....E....F ...G ... H....I.. 01

36 314818 59 ..Exchangercover...................A....B ...C ... D....E....F ...G ... H....I.. 01

37 320409 ....Bearing ........................A....B ...C ... D....E....F ...G... H....I.. 01

38 322312 EF ..Coatofarms ...............................................................I.. 01

38 322312 77 ..Coatofarms ....................................................G ............ 01

38 322312 79 ..Coatofarms ......................................................... H....... 01

39 327900 EF ..Ash-tray..................................C..............F ..............I.. 01

39 327900 77 ..Ash-tray........................A.............. D..............G............ 01

39 327900 79 ..Ash-tray.............................B ..............E.............. H....... 01

40 415504 60 ..Poker .........................A....B ...C... D....E....F ...G ... H....I.. 01

41 454720 ....Gratesupport.....................A....B ...C ... D....E....F ...G... H....I.. 01

42 458403 ....Rod ..........................A....B ...C ... D....E....F ...G... H....I.. 01

43 624032 ....Ash-pan........................A....B ...C... D....E....F ...G ... H....I.. 01

N° Code ....Description............Type ......A....B ...C ... D....E....F ...G ... H....I.. Qty

Spare partsContinental "La Parisienne" - ref. : 124 03 01 - 124 05 01 - 124 07 01

10 Technical manual "286"

44 808001 ED .Handtool ...................... A... B....C ...D ...E... F....G ...H ... I ..01

45 328001 ... Protectionplate ................... A... B....C ...D ...E... F....G ...H ... I .. 01

46 237405 ... Reducingplate ...................A... B....C .................................01

47 228615 ... Square........................ A... B....C ...D ... E... F....G ...H ... I .. 01

48 259015 ... Fixingplate ..................... A... B....C ...D ...E... F....G ...H ... I ..02

49 216116 ... Circulationduct ...................................D ...E... F..................01

49 216117 ... Circulationduct ...................................................G ...H ... I .. 01

53 276001 ... Plate......................... A... B....C ...D ...E... F....G ...H ... I ..01

54 979900 ... Fixingplate ..................... A... B....C ...D ...E... F....G ...H ... I ..07

60 162042 ... Descriptiveplate................... A... B....C ................................. 01

60 162043 ... Descriptiveplate...................................D ...E... F..................01

60 162044 ... Descriptiveplate...................................................G ...H ... I .. 01

70 181613 ... Rope......................... A... B....C ...D ... E... F....G ...H ... I . 0,9m

Spare partsContinental "La Parisien ne" - ref. : 124 03 01 - 124 05 01 - 124 07 01

Technical manual "286" 11

❧ Warranty certificate ❧

❧ Legal warranty

Our products are guaranteed for twelve months against any

defect, flaw or imperfection. During this time, all parts judged

defective by our War rant y control department may be

replaced in our workshops. Incidental costs of transportation

and packing payable by the buyer.

Some parts or components have a longer warranty period :

- Cast-iron shell of boiler : 3 years

- Steel shell of boiler : 3 years

- Removable or independent stainless steel hot water

cylinder : 5 years

- Independent enamelled steel hot water cylinder : 3 years

- Incorporated circulating pump : 2 years.

❧ Terms of the warranty

Thiswarrantyisonlyvalidif:

- T he unit has been installed and checked by a professional

installer before operating,

- All installation and adjustment instructions listed in the

technical manual supplied with the unit have been followed,

- All operation and maintenance instructions have been

followed.

❧ This warranty does not cover:

- Lamps, fuses, spark plugs, cast iron parts directly in

contact with burning coal and wood, firebricks, flue baffles,

glasses .

- Any damage r esulting from the use of fuel not

recommended in our instructions ;

- Parts which are damaged by external causes such as

unadapted chimneys, thunderstorms, damp, faulty pressure

or fail in pressure, thermic anomalies, explosions, etc...

- Electrical parts which are deteriorated by any connection

or use on a supply circuit with voltage within 10% of the

indicted voltage (230 V in EU).

Material subject to modifications without prior notice. This

manual does not engage the responsibility of

FRANCO BELGE.

*

Nameandaddressoftheinstaller: _____________________________

______________________________________________

(

Telephone: _______________________________________

*

Nameandaddressofthecustomer: ____________________________

______________________________________________

Dateofinstallation: ____/____/________

Modeloftheappliance:

Color :

Serial number : ___ ___ ___ ___ ___ ___

• This certificate has to be completed and kept carefully.

In case of claims, send a copy of this to :

Les Fonderies Franco-B elges , rue Orphée Varis cott e, 59660 MERVILLE, FRANCE.

q

1240301

q

124 05 01

q

1240701

❑

L ❑ J ❑ Y

Loading...

Loading...