Continental industries PE-8, PE-12, PE-16, PE-16-IPS, PE-20 Installation Manual

...

Underground Gas Polyethylene (PE) Piping

Fitting Assembly & Sizing Chart

Featuring the Con-Stab I.D. Seal®Fittings

from Continental Industries, Inc. and Driscoplex

®

Performance Pipe

June 2016

TECHNICAL DATA

Part Number Tubing Size Average OD SDR Min. Wall

PE-8

PE-12

PE-16

PE-16-IPS

PE-20

PE-24

PE-32

Normal Pipe Size and SDR must be used to match fittings and IPS PE pipe.

Nominal Pipe Size and Min. Wall must be used to match fittings and CTS PE pipe.

All pipe shall be ASTM D2513.

Visit www.performancepipe.com for more information.

1/2" CTS .625 7.0 0.090

3/4" IPS 1.050 11.0 0.095

1" CTS 1.125 11.5 0.099

1" IPS 1.315 11.0 0.120

1-1/4" IPS 1.660 10.0 0.166

1-1/2" IPS 1.900 11.0 0.173

2" IPS 2.375 11.0 0.216

www.conind.com

Patent #s 5,366,260,5,692,785 & 5,853,272

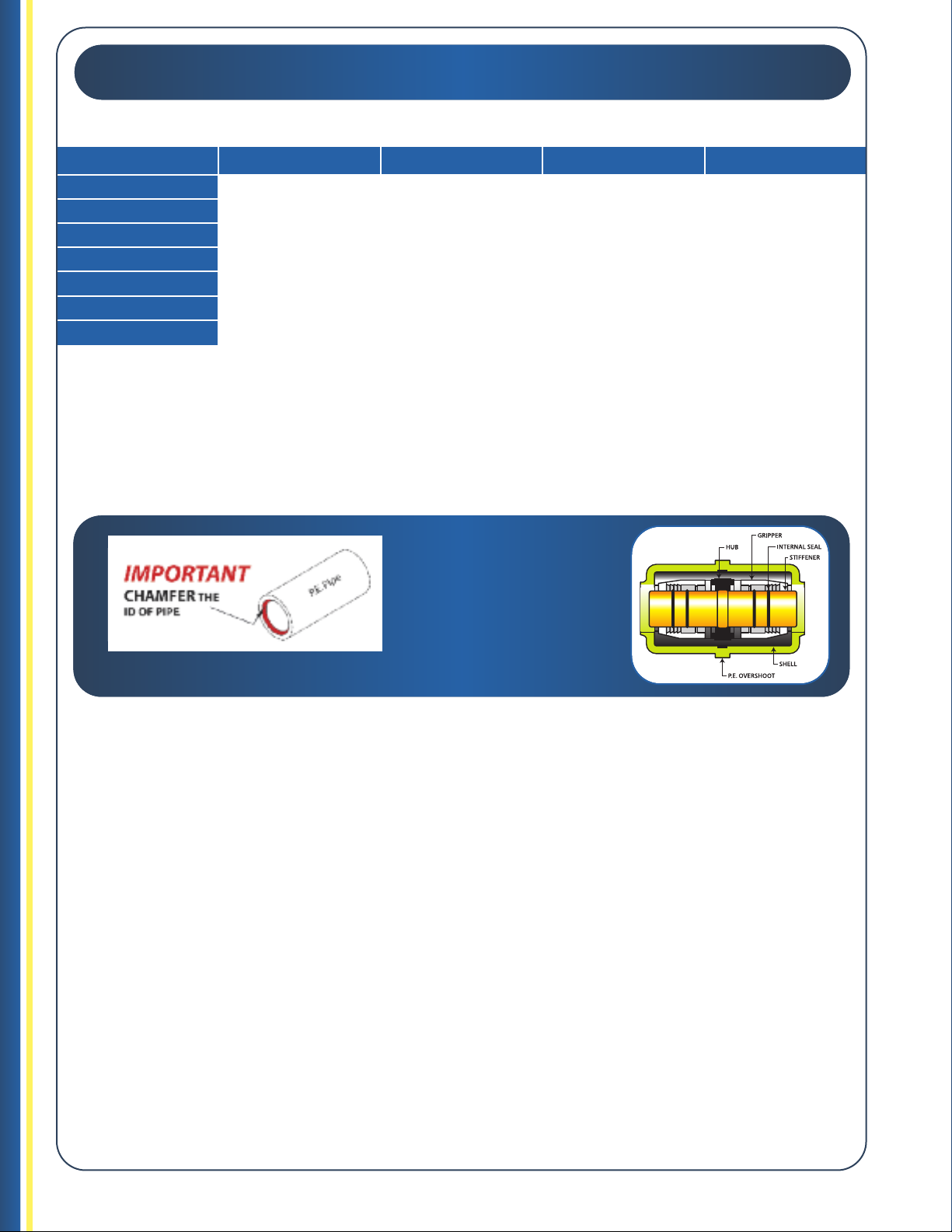

Each Con-Stab I.D. Seal Fitting

provides the following unique

features:

• Two internal seals

• Fixed stiffener

• Self-locking gripper

• Moisture lip

• Uni-body construction

2

Gastite Division • 1116 Vaughn Parkway • Portland, TN 37148

ASSEMBLY INSTRUCTIONS: I.D. SEAL®CON-STAB

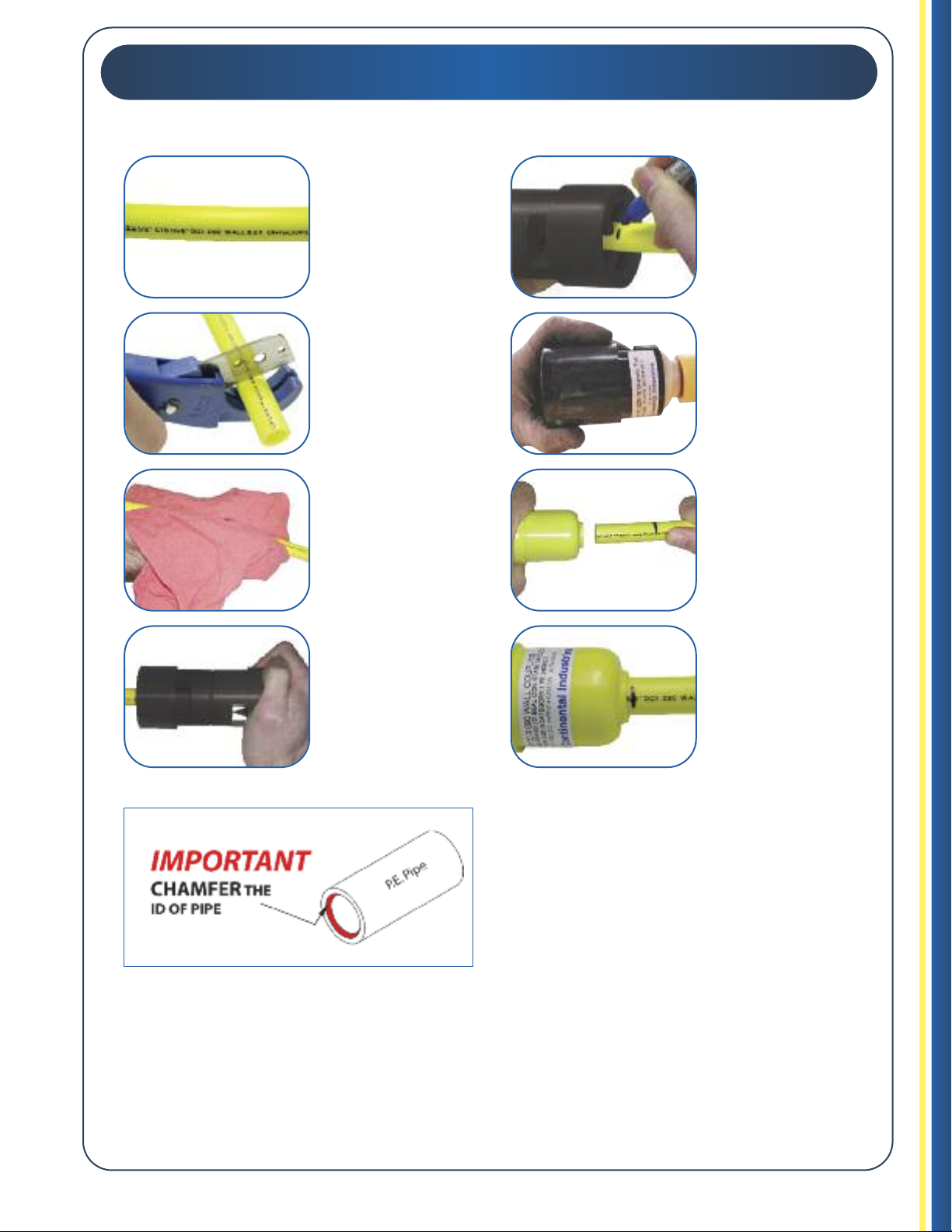

STEP 1

erify the polyethylene

V

(P.E.) pipe being

assembled is the

correct size.

TEP 5

S

Mark the stab depth by

inserting the pipe into

the chamfer tool and

marking the pipe at the

entrance as shown.

STEP 2

Cut pipe ends square.

STEP 3

Clean piping thoroughly

to assure there is no

dirt, grease or oil in

assembly area.

STEP 4

Chamfer end of pipe

using Continental’s

chamfering tool with I.D.

gauge.

STEP 6

If using chamfer tool

with ID gauge, check

for proper chamfer by

inserting pipe over

gauge.

STEP 7

Stab pipe completely

into fitting entrance.

STEP 8

Stab pipe completely

into fitting so that the

mark on the pipe is

within 1/8" from the

fitting entrance.

Patent #s 5,366,260,5,692,785 & 5,853,272

Ph: 1.800.662.0208 • Fax: 615.325.9407 • Web: www.gastite.com

STEP 9

Repeat steps 1 though 4 for all Con-Stab joints.

STEP 10

To assure proper assembly and to comply with 49

CFR 192 Subpart J-Test requirements, the joint shall

be leak tested.

3

Loading...

Loading...