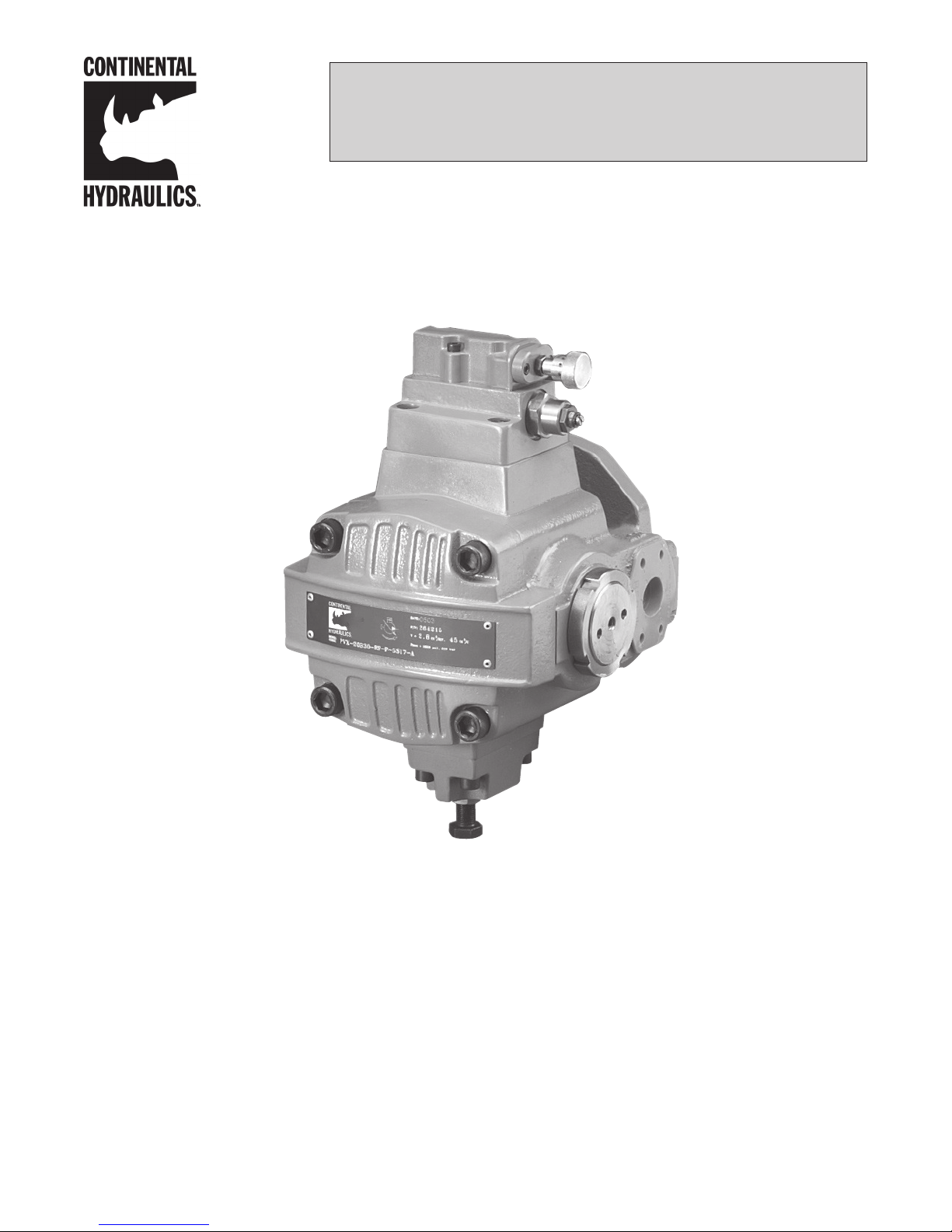

Continental Hydraulics PVX Series, PVX-8, PVX-15, PVX-20, PVX-29 Repair Manual

...

REPAIR PROCEDURES

MANUAL

PVX Series Vane Pumps

“A” Design Series

Step-by-Step Guide to Troubleshooting and Repairing

PVX Series Vane Pumps

Form No. 264728 Rev. 11/08

Introduction

Thank you for choosing Continental

Hydraulics PVX Vane Pumps for your

application.

PVX Pumps are designed to provide reliable

performance, and to be easily repaired

should the need arise. The procedures in

this repair manual will show you how to

repair virtually any part of your pump.

To assure that your repaired PVX Pump

performs reliably, please follow all steps

carefully. It is also very important that your

work area be kept clean to prevent

introducing contaminants into the pump.

In many cases, dirt or contaminants in the

hydraulic system lead to pump wear and

failure. If your PVX pump failed due to dirt or

contamination, be sure to thouroughly clean

and flush all parts of the system, paying

special attention to power unit reservoirs.

You may want to provide additional filtering

to keep your pumps and system operating at

peak performance.

NOTE: All procedures in this manual are

to be performed on a service bench. Do

not disassemble, or attempt to repair a

pump that is connected to a hydraulic

system.

CAUTION – Before attempting to remove

the PVX Vane Pump, be sure that all

pressure has been relieved from BOTH

SIDES of the system.

CAUTION – Before attempting to remove

the PVX Vane Pump, disconnect or lock off

power supply.

CAUTION – Before manually actuating any

PVX Vane Pump, be sure that any resulting

machine function will not endanger persons

or equipment.

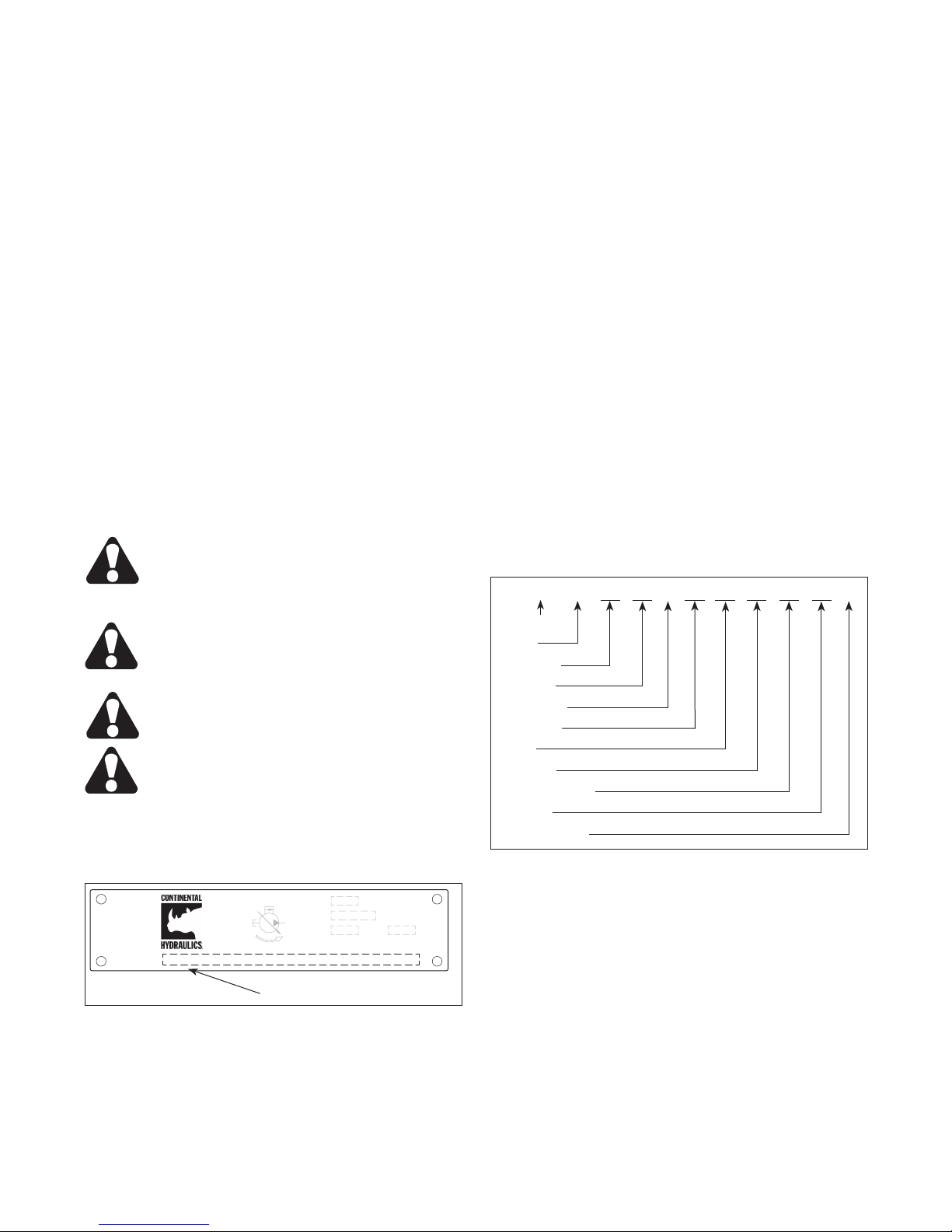

PRODUCT IDENTIFICATION

Each PVX Vane Pump has a Model Code stamped on

its nameplate. See Figure 1 for the location of the

Model Code.

DATE:

P/N:

V =

IN3/REV. CM3/U

MODEL

CODE:

PVX-

75B 00-00-P-00 00 00 00 00-A

Pmax = 3000 psi, 210 bar

This Repair Manual applies to products with Ordering

Codes like the sample in Figure 2.

PVX-75B-_ _ _ _-P-_ _ _ _ _ _ _ _ _ _-A

Basic Pump

GPM

Pressure

Rotation

Seal Type

Mounting

Shaft

Tandem

Control Option

Voltage

Design Letter

Figure 2

Model Code

Figure 1

i

Form No. 264728 Rev. 11/08

Table of Contents

Part Identification

Exploded View Drawing .................. 2

Parts List ......................................... 2

Disassembly Procedures – Pumps

General ............................................ 3

Getting Started ................................ 3

Disassembly Instructions ................ 3-6

Assembly Procedures – Pumps

General ........................................... 7

Getting Started - Kits ...................... 7

Getting Started - Tools ................... 8

Assembly instructions ..................... 8-13

Disassembly Procedure – Two-Stage

Compensator

General ........................................... 14

Disassembly Instructions ................ 14-15

Assembly Procedure – Two-Stage

Compensator

Assembly Instructions .................... 16-18

Disassembly Procedure – Single Stage

Compensator

General ........................................... 19

Disassembly Instructions ................ 19

Adjustment Procedure – Single Stage

Compensator

General ........................................... 23-24

Adjustment Procedure – Two-Stage

Compensator

General ........................................... 25

Multi-Pressure Compensator

General Information ........................ 26

Solenoid Two-Pressure Control ...... 26

Solenoid Vented ............................. 27

Load Sense .................................... 27-29

Torque Limiter ................................. 29-30

Setting the Maximum Deadhead

Pressure (Second Stage Setting) 31

Setting the Torque Limiter .............. 31

Application Notes ........................... 31

Maximum Flow Limiter ................... 31

Fluids, Filters and System Preparation

General Information ........................ 32

Fluid Recommendations ................. 32

Fluid Temperature .......................... 32

Filtration .......................................... 32

Pump Installation Procedure

Installation Instructions ................... 33

Assembly Procedure – Single Stage

Compensator

General ........................................... 20

Getting Started - Kits ...................... 20

Assembly Instructions .................... 20-21

Proper Setting of the Thrust Screw

Adjustment Instructions .................. 22

System Start-Up Procedure

Start-Up Instructions ....................... 34

Trouble Shooting

Trouble, Potential Cause, Remedy 35-37

Dimensions for Double Pumps

Dimension Drawing ........................ 38

Possible Size Combinations ........... 38

Form No. 264728 Rev. 11/08

1

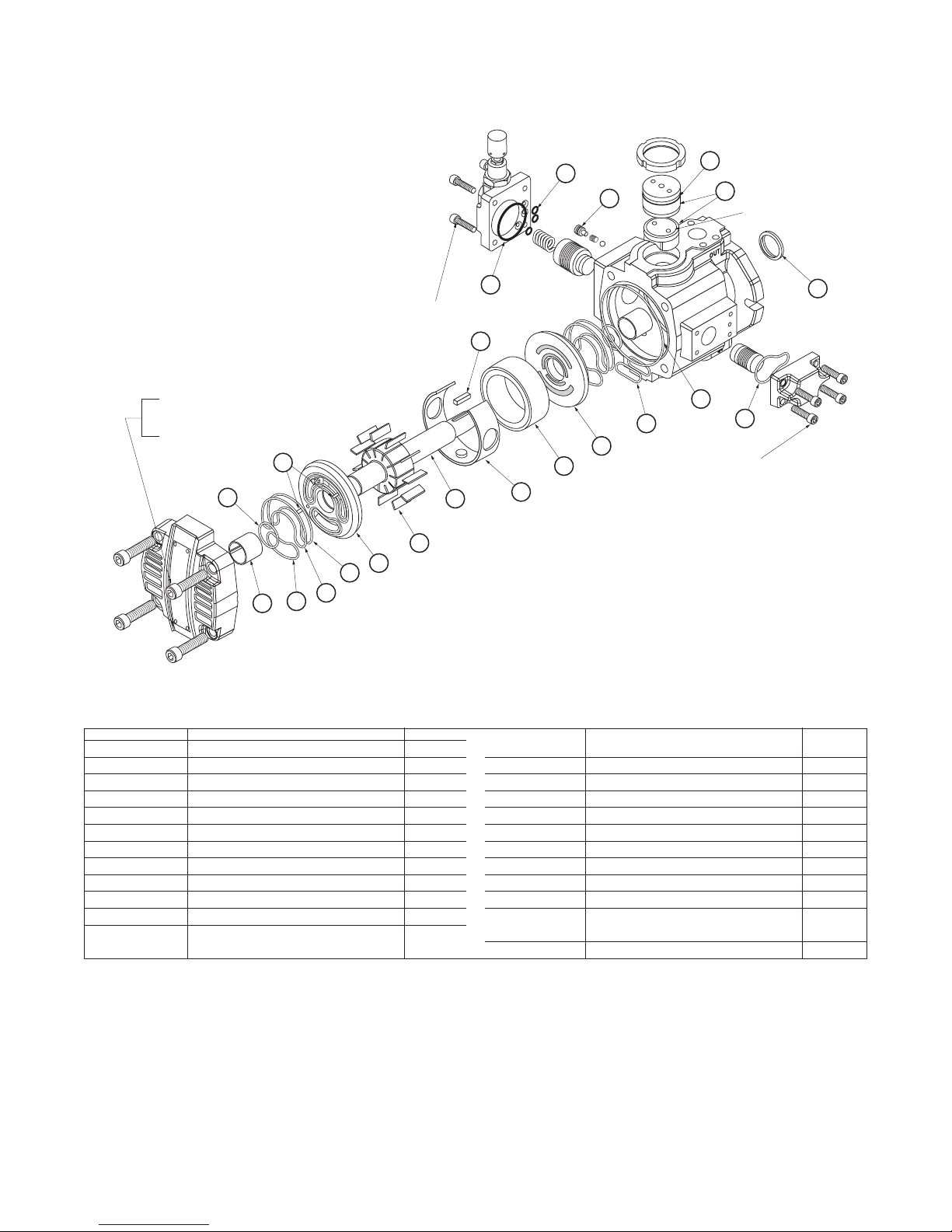

22

4

3

2

8

9

10

15

14

16

17

6

18

1

21

20

19

PVX-20/36

Torque to 1800 lb/in

(Torque to 204 Nm)

Torque to 850 lb/in

(Torque to 96 Nm)

Torque to 850 lb/in

(Torque to 96 Nm)

Torque to 12 lb/in

(Torque to 1.4 Nm)

7

24

23

5

13

PVX-46/60/75

Torque to 4970 lb/in

(Torque to 562 Nm)

Part Identification

Exploded View Drawing

Parts List

REFERENCE DESCRIPTION QTY

1 Key 1

2 Rotor shaft 1

3 Vane kit 1

4 Port plate, cover side 1

5 Roll pin 4

6 Thrust block 1

7 Bearing 2

8 Spacer ring 1

9 Pressure ring 1

10 Port plate, body side 1

13 O-ring, ASA-031 / (ASA-035) 2

14 O-ring, ASA-162 / (ASA-265) 1

REFERENCE DESCRIPTION QTY

2

Form No. 264728 Rev. 11/08

15 O-ring, ASA-130 / (ASA-229) 1

16 O-ring, ASA-146 / (ASA-146) 1

17 Shaft seal 1

18 O-ring, ASA-332 / (ASA-340) 1

19 O-ring, ASA-110 / (ASA-110) 1

20 O-ring, ASA-111 / (ASA-111) 3

21 O-ring, ASA-143 / (ASA-143) 1

22 O-ring, ASA-157 / (ASA-160) 2

23 Back up ring 2

24 O-ring, ASA-139 / (ASA-152) 1

24 O-ring, ASA-237 / (ASA-237) 1

Disassembly Procedures – Pumps

General

The disassembly procedure shown on the following

pages covers the Continental Hydraulics PVX-8 thru

75 variable volume vane pumps. The complete

disassembly procedures are similar for all pumps.

Any differences between the pump models are

described in additional notes.

The step number corresponds to the photo or

illustration of the same number.

Any dimensions or values stated will have the English

value first followed by the metric equivelent in

parenthesis.

Figure 1.

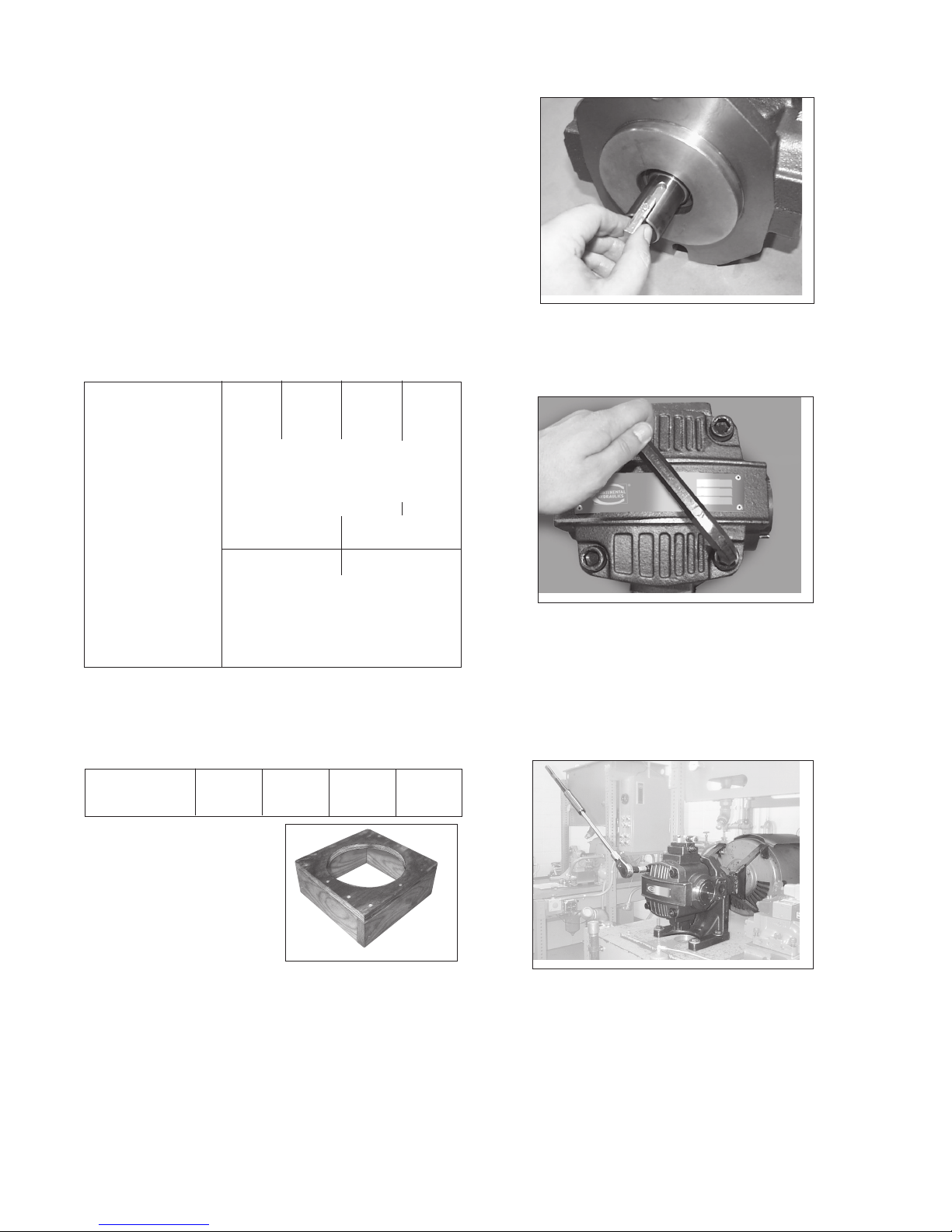

Getting Started - Tools

PVX Model 8 11/15 20/29/36 46/60/75

Cover

Allen Wrench 8 mm 10 mm 14 mm 17mm

4 Soc. Cap Screws

Cover - Removal

Plates - Removal

Tweezers or

Vanes - Removal Pair of Long Needle Nose Pliers

11 Vanes 22 Vanes

Compensator &

Bias Cover

Allen Wrench

2 x 4 Soc. Cap Screws

PVX-8/11/15 - 8 mm Allen Wrench

Thrust Screw PVX-20/29/36/46/60/75 -

Non-Slip Spanner Wrench

Thrust Screw Lock Nut Adjustable Face Spanner Wrench

Bearing - Removal Blind Hole Bearing Puller

Shaft Seal - Removal Hammer & Round Head Punch

2 Flat Blade Screwdrivers

6 mm 8 mm

As an aid for repairing the PVX pump, we recommend

building a wooden fixture. Please see the different

inside diameters for each pump size in the chart

below.

PVX Model 8 11/15 20/29/36 46/60/75

Diameter 3.38 (86) 4.13 (105) 5.13 (131) 6.13 (156)

Min. Height 2 (51) 2.63 (67) 3 (77) 3.88 (99)

2. Remove the four (4) socket hd cap screws on the

cover by using the appropriate size Allen wrench.

Figure 2.

Note: For disassembling the larger pumps, a great

amount of torque will be needed to loosen the cover

bolts. Therefore, we recommend loosening the bolts

before removing the pump from the motor-unit. Use a

socket or extend the length of the allen wrench and

make sure to clamp the pump securely and safely.

Wooden Fixture.

Disassembly Instructions

1. Remove the straight key from the keyway of the

shaft and place the pump side down into the wooden

fixture. See above for details for the fixture.

Figure 2a.

Form No. 264728 Rev. 11/08

3

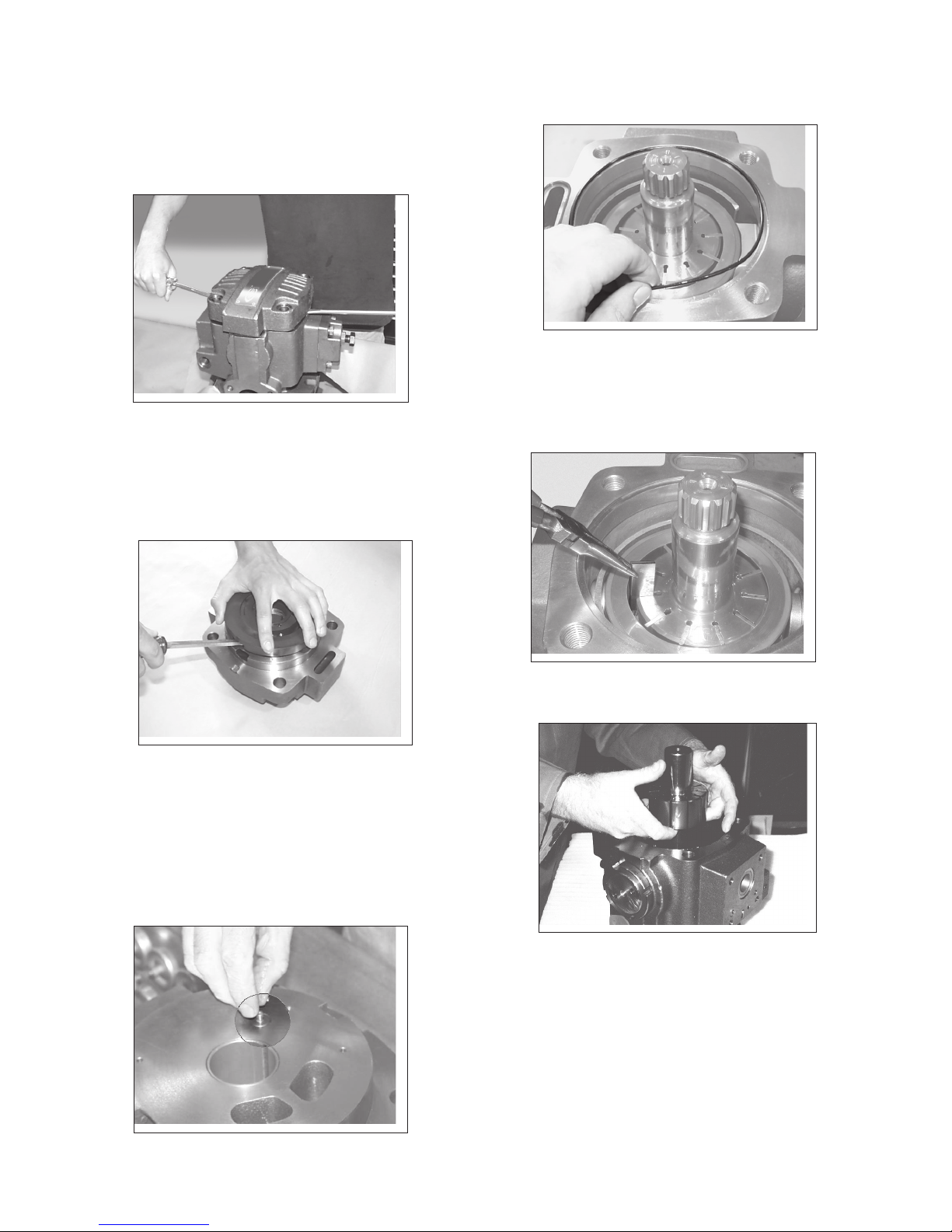

Disassembly Instructions – Pumps (continued)

3. Insert flat blade screwdriver into the slots provided

on each side of the cover. Pry the cover assembly

loose using equal force on each screwdriver. After

the cover is loose, carefully remove it by hand and set

aside in a clean area.

Figure 3.

4. In order to remove the port plate from the cover,

insert flat blade screwdriver into the slots between the

port plate and cover and pry the port plate loose.

After the port plate is loose, carefully remove it by

hand.

5. Remove the cover o-ring.

Figure 5.

6. Remove the vanes from the rotor by using a small

pair of tweezers or long needle nose pliers. Caution

should be taken not to nick or score the vanes,

pressure ring and rotor.

Figure 4.

NOTE: When disassembling a PVX-20 thru 75 pump,

please pay close attention not to loosen the ratio

valve cartridge that is located in the cover and the

ratio valve sealing assembly that is located on the

back of the cover port plate. The ratio valve cartridge

is as essential part of the pump and is not a wear

item, so it is not part of the repair kit.

Fig ure 6.

7. Remove the rotor shaft.

Figure 7.

Figure 4a.

4

Form No. 264728 Rev. 11/08

Loading...

Loading...