Continental Hydraulics PVR15-30B-Flanged Series, D Design Series, PVR15-015B15-RF-0-5-F, PVR15-Manifold Series, J Design Series Service Manual

...Page 1

SERVICE MANUAL

PVR15-30B-Flanged Series Pump

Installation, Startup, Operating Instructions, Parts Pages, Repair Procedures

“D” Design Series

This service manual applies to products with Ordering

Codes like the sample below.

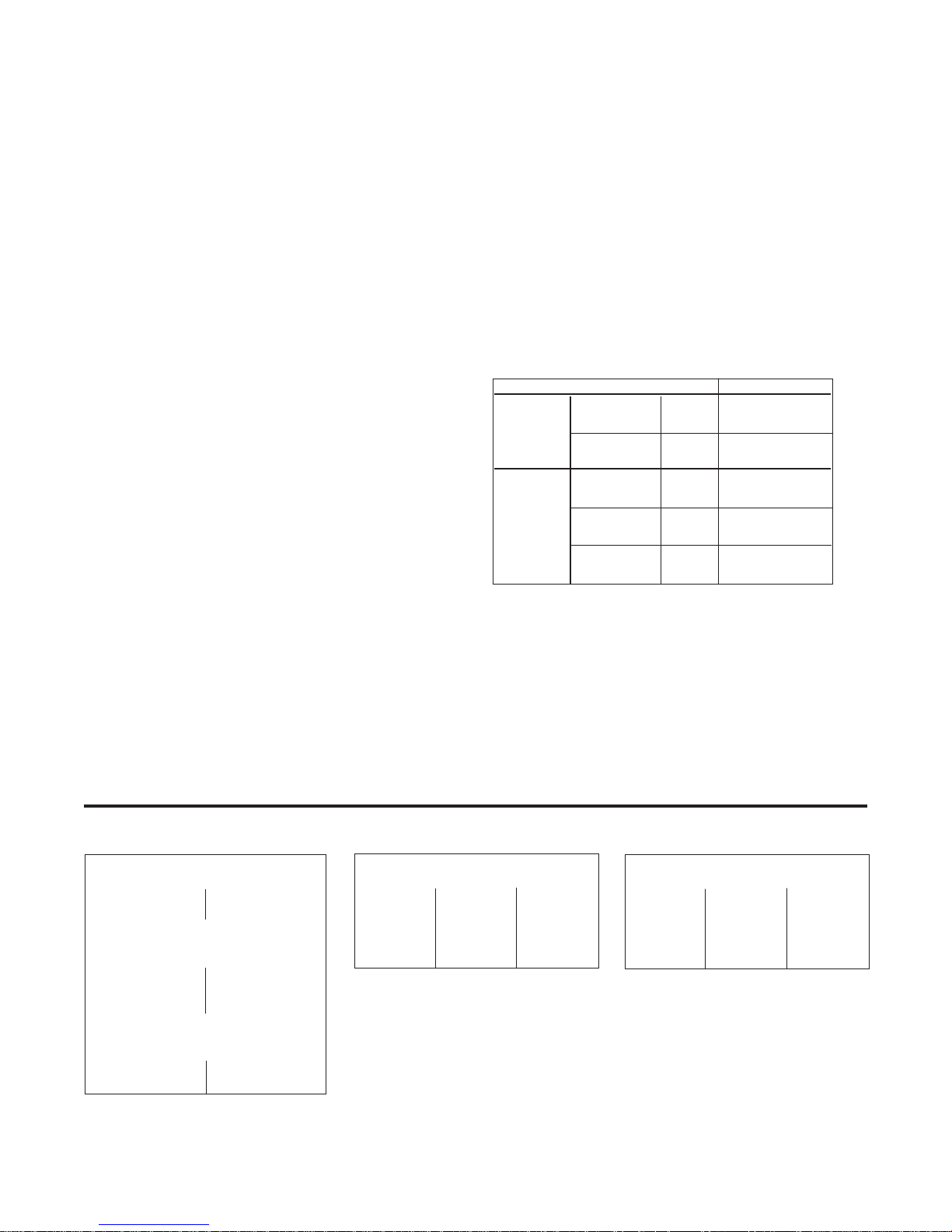

PVR15 - 30B15 - RF - _ - 5 - _ _ _ _ _ - D

Basic Pump

Pump Size

& Pressure

Rotation & Mounting

Seal Type

Mechanical Options

Control Options

Design Letter

INSTALLATION

CAUTION - Before performing any service

operation on any pump, be sure that all

pressure has been relieved from BOTH

SIDES of the system.

CAUTION - Before performing any service

operation on any pump, disconnect or lock

off power supply.

PUMP DRIVE AND MOUNTING

When mounting the pump and motor, care must be

taken to align the pump and motor shafts within .003

T.I.R. (0.076 mm) direct inline through a jaw type/

flexible web coupling. This is recommended for all

pumps. Tire-type flexing elements and chain-type

drives are not recommended. With belt drives, please

consult factory.

CAUTION - Before starting pump, be sure

that any resulting machine function will not

endanger persons or equipment.

PRODUCT IDENTIFICATION

Each pump has an Ordering Code stamped on its

nameplate. See below for the location of the Ordering

Code.

To avoid axial and radical end loading of the pump

shaft, do not couple the pump and motor shafts

rigidly. Allow freedom at the coupling for the two

shafts to ride independently.

To prevent end loading, the space between the pump

and motor shaft ends should be 3/4 inch (19.05 mm)

for PVR15 pumps, or as the coupling manufacturer

specifies.

PIPING AND RESERVOIR

The pump should be mounted with a minimum

number of elbows or fittings. The pump suction

should be at least 1-1/4 inch (31.75 mm) tube/pipe for

PVR15 pumps.

For any system and combination of piping except

High Water Based Fluids (HWBF), the vacuum at the

pump inlet must not exceed seven inches of Mercury,

(5 inch Hg. for fire resistant fluids). HWBF Pumps are

to have a positive inlet head in the range of 0.5-inch

Hg. to 20 inch Hg.

Form No. 265283 Rev. 07/08

1

Page 2

Installation (Continued...)

Piping should be done with pickled pipe or seamless

tubing free of dirt and scale. Do not use galvanized

or other pipe that tends to flake off.

A 100-mesh screen (60 mesh for fire resistant and

HWBF) should be used on the pump suction line.

The screen should be located approximately two

inches (50.8 mm) from the bottom of the tank. All

lines returning oil to the tank should discharge at least

two inches (50.8 mm) below the minimum oil level

and should be separated from the pump suction area

by means of a baffle. These lines should also include

a 10-micron return line filter, with the exception of the

case drain line.

The pump case drain should be connected directly to

the tank. Pressure in excess of 10 psi (0.7 bar) in the

case drain line can result in shaft seal leakage. It is

recommended that the case drain be returned to the

tank by a separate 3/8-inch (9.5 mm) line.

STARTUP PROCEDURES

The following instructions apply for initial startup of

the hydraulic pump. After an extended shutdown

period, start with item 5.

CAUTION - Never start a new pump

installation against a blocked system.

1. Check the nameplate for model number and rpm.

The arrow on the pump casting indicates direction of

rotation.

2. Pump suction line should extend below the lowest

point of oil level but not less than two inches (50.8

mm) above reservoir bottom.

3. The pump and motor shafts must be aligned within

.003 inches (0.076 mm). See Pump Drive and

Mounting directions above for restrictions.

allow free flow from the pump back to tank or connect

the pump outlet line directly to tank. Jog the motor on

and off several times (on two seconds, off three

seconds) until the pump is primed. Check pump for

proper direction of rotation during the jogging.

7. After the pump has been primed, run it for several

minutes at lower than normal pressures with an open

or intermittently open system which permits oil flow.

This will purge entrapped air from the pump and

system.

8. Neither volume adjustment nor pressure

adjustment should be adjusted until the pump has

been primed and running, and air is purged.

9. After air has been purged from the system, the

system can be closed and the pump adjusted to the

required operating pressure.

10. If necessary, the volume adjustment can be

adjusted to limit maximum output.

11. When replacing pumps, the suction screen in the

reservoir must be removed and thoroughly cleaned.

Also, the suction line from the reservoir to the pump

should be flushed inside and out to remove any

contaminants. Pieces of metal from a damaged pump

can back up into this line. If they are not removed,

they will be drawn into the new pump and destroy it.

Start unit by using proper pump start-up procedure

items 1 through 10.

CAUTION - If both pressure and volume

modifications are supplied on the pump, the

pressure should be adjusted before the

volume. Volume should be adjusted at minimum

pump pressure or at deadhead. Stop adjustment at

the volume screw when pressure begins to drop.

OPERATION

4. Connect the case drain directly to tank (or to a

heat exchanger if the pump will be deadheading for

long periods of time during operation), using a fullsize line corresponding to the case drain in the pump

or manifold. If connected to a heat exchanger, the

case drain line should be protected with a 10 psi (0.7

bar) maximum relief valve in parallel with the heat

exchanger. No other return lines should be connected

in common with the case drain return.

5. Rotate pump and motor by hand to insure free

rotation.

6. Set the machine controls to open the circuit and

2

PRESSURE AND VOLUME ADJUSTMENTS

Pressure Control

All pumps are adjusted to reduced pressure before

shipment and must be readjusted to the required

system pressure after installation and start-up.

The pressure adjusting screw is located at the end

face of the compensator chamber. See parts page

item number 30. The adjusting screw has a right

hand thread; clockwise adjustment increases

pressure; counterclockwise reduces pressure.

Form No. 265283 Rev. 07/08

Page 3

Operation (Continued...)

A pressure gauge located at the pump must be used

when making adjustment to insure the pressure

settings do not exceed limits specified for the

particular pump of maximum system pressure.

Make all pressure settings with pump operating

against a closed circuit, that is with the output of the

pump blocked, and then check pressure throughout

the pump flow range.

Volume Control

Adjust volume at minimum pump pressure or at pump

deadhead. The volume adjusting screw is directly

opposite the pressure adjusting screw, see parts page

item number 55. The adjusting screw has a right

hand thread, turning the screw clockwise decreases

the maximum volume, turning the screw

counterclockwise increases the maximum volume.

Pumps are set at a maximum rated volume at the

factory unless otherwise specified.

Stop adjustment of the volume screw when pressure

begins to drop. See Sales Catalog for complete

pump performance specifications.

ADJUSTMENT PROCEDURES

To adjust the maximum output volume use the

following steps:

3. See Pressure and Volume Adjustment Sensitivity

chart below.

4. Deadhead the pump, turn the volume screw the

proper number of turns to obtain the flow desired.

5. Return pump to flow condition and check flow rate.

If output flow is incorrect, switch pump to deadhead

and readjust.

CAUTION - Turning the maximum volume

control in too far can force the pressure ring

over-center and destroy the pump.

Pressure and Volume Adjustment Sensitivity

PUMP SIZE 30B

Pressure psi 240

Pressure Change/Turn (bar) (16.5)

Adjustment Maximum ft.-lbs. 2.7

Torque (m-kg) (0.37)

Flow gpm 4.6

Change/Turn (lpm) (17.4)

Volume Approx. Min. gpm 1.0

Adjustment Flow Adjust. (lpm) (3.7)

Maximum ft.-lbs 3.5

Torque (m-kg) (0.48)

1. Set the pump at minimum pressure.

2. Hand tighten the volume screw until it touches

pressure ring. NOTE: The pump should be at full flow

for this step.

PVR15-30B KIT LIST (Refer to Drawing and Parts List)

WEAR PLATE KITS

Includes Items: 4 & 5

Model Kit Number

30B 252933

SEAL KITS

Includes Items: 13,14,15,16,17,24,25,85,86,99

Model Kit Number

All Buna-N 250008

All Viton 250009

VANE KITS

Includes Items: 7

Model Kit Number

30B 252932

ROTATING KITS

Includes Items: 3, 6 & 21

Model Code Kit Number

30B Consult Factory

30B 12 252935

30B 21 Consult Factory

30B 22 Consult Factory

COMPLETE REBUILD KITS

Includes Items: All Kits Listed Here Plus Items 11 & 22

Model Code Kit Number

30B 252899

30B 12 252938

30B 21 254999

30B 22 255002

Form No. 265283 Rev. 07/08

3

Page 4

PVR15-30B PARTS LIST

ITEM

N0. NO. REQ.

1 550360 Pump Body 1

2 550629 Cover 1

2 18, 24, 25 550630 Cover 1

2 2118, 2218 550631 Cover 1

2 21, 22, 31 550632 Cover 1

2 24**, 25** 550629 Cover 1

3 550109 Rotorshaft 1

3 12 550148 Rotorshaft 1

3 21 550331 Rotorshaft 1

3 22, 31 550332 Rotorshaft 1

4 450169 Port Plate 1

5 450127 Thrust Plate 1

6 350128 Pressure Ring 1

7 252932 Vane Kit (Set of 26) 1

8 306197 Spring Seat 1

9 112927 Governor Spring 1

10 129915 Follower Spring 1

11 251214 Ring Shoe Assembly 1

12 130041 Pin 1

13 124389 Teflon Seal Ring 1

14 Buna-N 124574 O-Ring 1

14 Viton 127746 O-Ring 1

15 125664 Teflon Seal Ring 1

16 Buna-N 108701 O-Ring 1

16 Viton 113215 O-Ring 1

17 Buna-N 102556 O-Ring 1

17 Viton 117505 O-Ring 1

18 199670 Soc. Hd. Cap Screw 4

19 165219 Thrust Screw 1

20 250368 Thrust Screw Plug 1

21 121566 Bushing 2

22 001396 Key 1

23 105643 Dowel Pin 4

24 113988 Lip Seal (Codes 21/22 -Add 2) 2

24 Viton 121587 Lip Seal (Codes 21/22 -Add 2) 2

25 Buna-N 153111 O-Ring 1

25 Viton 162100 O-Ring 1

30 250240 Pressure Adj. Screw Ass’y. 1

38 36 252152 Handwheel 1

39 36 261323 Spring Pin 1

40 004223 Spring Pin 1

PART

CODE

DESCRIPTION

QTY.

ITEM CODE PART DESCRIPTION QTY.

N0. NO. REQ.

43 122975 Shim (.010) A.R.

44 15 301737 Handwheel 1

45 15 004262 Spring Pin 1

50 Valve Refer to Valve Escutcheon 1

51 17,18**,2500, 350946 Dual Pressure Control Ass’y. 1

25**

53 8, 9 256508 Flow Control Valve 1

55 450196 Volume Adj. Screw Ass’y. 1

56 2400, 24**, 350951 Dual Volume Control Ass’y. 1

2500, 25**

57 8, 9 256509 Union 1

58 18**, 24** 256510 Connector 1

59 25** 256514 Run Tee 1

60 18**,24**,25** 256742 Hose - 18” (Code 25** -Add 1) 1

61 24** 350929 Adapter 1

66 307182S Name Plate 1

67 250597 Self-Tapping Screw 4

69 18**,24**,25** 198225 Soc. Hd. Cap Screw 4

70 18**,24**,25** 012144 Hi-Collar Lockwasher 4

80* 21, 31 147655 Flange Cover (Shipping) 1

80* 22 164598 Flange Cover (Shipping) 1

81 21 350663 Spline Coupling 1

81 22, 31 350664 Spline Coupling 1

82 22 450635 Adapter 1

82 31 450634 Adapter 1

83 22 199682 Button Hd. Cap Screw 2

85 Viton 167682 O-Ring 1

85 21, 22, 31 138362 O-Ring 1

86 Viton 144966 O-Ring 1

86 22, 31 144929 O-Ring 1

87 31 258502 Threaded Rod 1

90* 254832 Flange Protector 1

91* 254831 Flange Protector 1

92 256708 SAE O-Ring Plug 1

93 109376 Caplug (Shipping) 1

94 31 199126 Hex. Nut 2

95 21 008446 Caplug 2

95 22, 31 008345 Caplug 2

97* 12, 21, 22, 31 253841 Warning Tag 1

98* 143391 Grease A.R.

99* 132779 LED Plate #250 A.R.

* Not Shown

4

Form No. 265283 Rev. 07/08

Page 5

PVR15-30B PARTS DRAWING

44

45

30

8

10

43

41

9

11

12

40

39

38

55

13

15

5

6

3

4

17

23

2

23

14

16

22

21

18

95

7

93

20

25

19

67

24

21

1

66

3

81

86

85

82

2

95

83

87

94

See Page 6 for Control Options.

PVR15-30B PARTS DRAWING

Codes 12, 21, 22, 31 Tandem Mounting

Form No. 265283 Rev. 07/08

5

Page 6

PVR15-30B PARTS DRAWING

60

99, 51

69, 70, 50

58

92

60

99, 56

50, 69, 70

61

92

60

99, 56

50, 69, 70

61

92

60

99, 51

57

53

Control Options

Code 17 Dual Pressure Control Without Integral Valve

Code 18** Dual Pressure Control With Integral Valve

Code 2400 Dual Volume Control Without Integral Valve

Code 24** Dual Volume Control With Integral Valve

Code 2500 Dual Pressure/Volume Control Without Integral Valve

Code 25** Dual Pressure/Volume Control With Integral Valve

Code 8 Rate Control Valve for Dual Pressure

Code 9 Rate Control Valve for Dual Volume

6

Form No. 265283 Rev. 07/08

Page 7

PVR15-30B PUMP REPAIR PROCEDURES

Spring Housing

C

L

C

L

Oil Groove Position

Thrust

Screw

Item #21

Journal Bushing Orientation

Pressure Ring

Rotor Shaft

Vane

Item #7

Typical Vane Installation

the pump.

DISASSEMBLY PROCEDURE

NOTE: Disassembling a pump to change

components, or for any other reason, may void the

warranty. Refer to Policy Statement and Discounts

Summaries.

1. Remove the key (22) in the rotor shaft keyway.

2. A small amount of oil may remain in the pump.

Remove the four cover bolts (18) and slide the cover

back far enough on the shaft to break the seal

between the housing and cover to allow the pump to

drain.

3. Remove the cover (2). Take care to avoid damage

to the bearing with the end of the shaft when the

cover is removed.

4. The port plate (4) may come out with the cover. Do

not let it drop off the locating pins (23).

5. Remove the vanes (7) with a long nosed pliers or

tweezers. There are two vanes in each slot, 26 vanes

total.

REASSEMBLY PROCEDURE

1. Clean and inspect parts to determine which parts

are worn enough to require replacement.

2. Assemble the new journal bushings (21) in the

housing and cover. The bushing OD's should be

lubricated before they are pressed in the bores. Care

must be taken to orient the "split" and the "oil groove"

in the bushing as shown in the illustration below.

3. After the bushings are in place, check to see that

the rotorshaft will fit into the bushings and provide a

smooth turning fit. If the shaft turns hard, the

bushings should be removed and the bore checked

closely for nicks or burrs before pressing in the new

bushings.

6. Remove the rotorshaft (3) from the pump. Be sure

that the key (22) has been removed from the keyway

so that it will not damage the shaft seals when the

rotorshaft is removed.

7. Turn the pressure adjustment screw (30)

counterclockwise to release the tension on the

governor spring.

8. Remove the pressure ring (6), ring shoe (11),

governor spring (9), spring retainer (41) and follower

spring (10).

9. If the lip seals (24) are to be removed they should

be pushed out from the inside of the housing at this

time. Care must be taken not to damage the journal

bushing in the housing while the lip seals are being

removed. It is recommended that the lip seals be

replaced whenever the pump is disassembled for

maintenance. The seals cannot be reused once they

have been removed.

10. The journal bearings (21) in the pumps are

assembled with a press fit. If they are to be removed

at this time, the bushing in the housing should be

pressed out from the front. The cover bushing should

be pulled out using an expanding type puller. The

bushings should not be reused once they have been

removed.

11. It is unlikely that further disassembly will be

necessary in order to perform routine maintenance on

4. Check all of the replacement parts for nicks or

burrs and then lubricate them with clean oil before

reassembly.

5. Worn port and thrust plates should not be

reground to clean up the wear surface. If the plates

are ground, the assembly clearance will become

excessive and the seal rings in the thrust plate may

rupture. Replace worn port and thrust plates if

necessary.

6. Assemble the springs (9, 10) and spring shoe (11),

pressure ring (6) and rotorshaft (3).

7. To assure proper vane assembly, place the vanes

(7) with the beveled edge out against the pressure

ring.

8. Assemble the four seal rings into the cavity in the

back of the thrust plate. The soft rubber o-rings (14,

16) should be assembled first and the hard square

seal rings (13, 15) should be assembled on top of

them. Stretch the larger soft o-ring slightly so it clings

to the ID at the cavity. Apply clean oil or STP to the

back of the thrust plate before it is placed in the

Form No. 265283 Rev. 07/08

7

Page 8

PVR15-30B PUMP REPAIR PROCEDURES

.374 (9.50 mm)

.100 (2.54 mm)

(Continued...)

locating pins in the body to help hold the parts

together while they are assembled.

9. Before fitting the cover into the housing, check to

assure that the bore in the port plate is concentric to

the bearing bore in the cover. If the bores are not

concentric, the port place must be relocated 180° on

the locating pins.

10. Assemble the cover (2) and port plate (4) onto the

housing and align the bolt holes. Rotate the shaft as

the bolts are tightened to assure that the vanes are

not cocked.

11. Torque the cover bolts (18) to 100 lbs-ft. (135.6

Nm). The shaft should turn by hand when assembly

is complete.

12. Lubricate the ID of the lip seals (24) and press

them into the housing to the depth shown below.

Note the "lip to the inside" orientation of the seals.

13. Adjust the pressure adjustment screw (30) until it

just touches the spring and then give it one more turn

clockwise.

14. Turn pump upside down. Pour one cup of good

grade hydraulic fluid into the intake port while slowly

rotating the shaft in the direction shown by the

rotation arrow.

15. The pump is now ready to test. Refer to front of

this manual for start-up procedure.

Because Continental Hydraulics is continually improving its’ products, specifications and appearance

Form No. 265283 Rev. 07/08 © 2008, Continental Hydraulics. Printed in U.S.A

Continental Hydraulics

5505 West 123rd St.

Savage, MN 55378

Phone: (952) 895-6400 Fax: (952) 895-6444

www.continentalhydraulics.com

are subject to change without notice.

Loading...

Loading...