Page 1

CAUTION – Before performing any service

operation on any pump, be sure that all

pressure has been relieved from the system.

CAUTION – Before performing any service

operation on any pump, disconnect or lock

off power supply.

CAUTION – Before starting any pump, be

sure that any resulting machine function will

not endanger persons or equipment.

PRODUCT IDENTIFICATION

Each HPV Piston Pump has a Model Code stamped

on its escutcheon plate. See Figure 1 for the location

of the Model Code.

Date

Code

Model

Code

Figure 1

This Service Booklet applies to products with Model

Codes like the sample in Figure 2.

Basic Pump

Rotation

Seal Type

Ports

HPV - 6B35-RF-O-1R

Figure 2

SERVICE MANUAL

HPV Axial Piston Pumps

“B” Design Series

GENERAL SPECIFICATIONS

MOUNTING

Any unrestricted mounting position acceptable.

Horizontal mounting preferred. The mounting hub

and two-bolt mounting flange conform to SAE

mounting standards.

Continental Hydraulics does not recommend direct

rigid connection of piston pumps to the Prime Mover.

Use of a flexible coupling, a coupling that allows for

minor misalignment is recommended.

If the shaft connection to the Prime Mover is rigid, the

mounting face diametric concentricity and squareness

must be within .001 inch (0.03 mm) T.I.R. for a flange

mounted pump.

The HPV Piston Pump is designed for in-line drive.

Angle drive creates side loads on the shaft, and is not

acceptable.

SHAFT INFORMATION

Splined:

The coupling interface must be lubricated.

Continental Hydraulics recommends lithium

molydisulfate, or similar grease. The female coupling

should be hardened to 27-45 Rc, and must conform

to ANSI B92.1 Class 5 Fillet or Flat Root Side Fit.

Keyed:

High strength heat treated keys must be used.

Replacement keys must be hardened to 27-34 Rc.

Key corners must be chamfered .030 - .040 inch (.75

- 1.0 mm) at 45° to clear radii in the keyway.

PLUMBING

Connect inlet and outlet lines to the pump’s cover.

HPV fluid connections are SAE straight thread, SAE

flange or BSPP.

MODEL REAR PORT SIDE PORT

HPV-6 SAE-12 or 3/4” BSPP SAE-16 or 1” BSPP

HPV-10 SAE-20 or 1-1/4” BSPP SAE-20 or 1-1/4” BSPP

HPV-15 SAE-20 or 1-1/4” BSPP SAE-20 or 1-1/4” BSPP

HPV-20 SAE-20 or 1-1/4” BSPP SAE1-1/4” Flange*

HPV-29 SAE-20 or 1-1/4” BSPP SAE1-1/2” Flange**

* Per Code 62 ** Per Code 61

Maximum case pressure is 10 psi (0.70 bar). Case

pressure must never exceed inlet pressure by more

than 15 psi (1.0 bar). To prevent fluid drain-down

from the pump when idle, make certain that case

drain plumbing passes above the highest point of the

pump before entering the reservoir. Or, install a 5 psi

(.3 bar) case pressure check valve to assure that the

pump is always filled with hydraulic fluid.

The case drain line must be big enough to prevent

back pressure in excess of 10 psi (0.70 bar).

Form No. R92.00 Rev. 10/03

1

Page 2

PLUMBING (continued...)

Hydraulic fluid from the case drain line should be

returned to the reservoir below the fluid level, and as

far from the supply intake as possible. All fluid lines

(whether pipe, tubing or hose) must be of adequate

size and strength to assure free flow through the

pump. Do not tee return lines together.

SYSTEM RELIEF VALVES

Although HPV series pumps have a very fast offstroke compensator response, fast acting relief valves

are recommended in all cases for safety. They also

help reduce transient pressure spikes.

RECOMMENDED FLUID

Note: The following fluid recommendations

and specifications apply to HPV series

pumps only. Assure that all other

components in the hydraulic system have

compatible requirements.

Petroleum-based, and most phosphate esters. Fluids

should be designated by the manufacturer for use in

hydraulic systems. Fluids should be formulated with

oxidation inhibitors, anti-rust, anti-foam and

deaerating agents. Other fluids may be acceptable,

but special O-rings may be required. Nitrile (Buna)

seals are standard.

VISCOSITY

Maximum at full power . . . . . . .750 SUS (160 Cst)

Optimum for maximum life . . . .140 SUS (30 Cst)

Minimum at full power . . . . . . . 60 SUS (10 Cst)

VISCOSITY INDEX

90 V.I. minimum. Higher values extend the operating

temperature range, but may reduce fluid service life.

Fluid Operating Temperature – Operating

temperature should be determined by the viscosity

characteristics of the fluid used. Fluid temperature in

the reservoir during operation should be kept between

100° F. and 130° F. (38° C. and 54° C.) Because high

temperature degrades seals, reduces service life and

creates hazards, fluid temperature should not exceed

180° F. (82° C.) at the case drain.

CAUTION – Fluid temperatures in excess of

120° F. (49° C.) can cause serious burns and

scalding. Allow fluid to cool before

performing any repairs or maintenance.

Fluid Cleanliness – Control particle contamination by

changing or cleaning all filter elements periodically

BEFORE they become clogged and start to by-pass.

Fluid must be cleaned before and continuously during

operation to a cleanliness level of ISO 18/16/13 or

better. This level of cleanliness can usually be

accomplished by use of 10 micron filters. Better fluid

cleanliness will significantly extend component life.

Since contaminant generation varies with each

application, each must be analyzed to determine

proper filtration to maintain required cleanliness.

After Extended Shutdowns – Some types of

hydraulic fluids become tacky after long periods of

non-use. If possible, hand turn the pump several

times after extended shutdowns to assure that all

components move freely before powering up.

CAUTION – Before hand turning any pump,

be sure that any resulting machine function

will not endanger persons or equipment.

PREVENTIVE MAINTENANCE

This pump is self-lubricating. Preventive maintenance

is limited to keeping the system fluid clean by

changing filters regularly. Since filtering needs can

vary depending on applications, filters used with this

pump should be equipped with indicators that show

when changes are needed. Do not operate the pump

in a system with clogged or bypassing filters.

Keep all fittings and screws tight. Do not operate this

pump at pressures or speeds in excess of stated

limits. If the pump does not operate properly, check

the Trouble Shooting Section of this manual before

attempting to overhaul the pump.

Overhauls are relatively simple, and are covered in

the Repair Procedures Section of this manual.

Note: It is especially important to keep

suction or inlet piping and fittings tight

and in good repair. Air drawn into the

system through loose or damaged intake

fittings can cause the pump to fail.

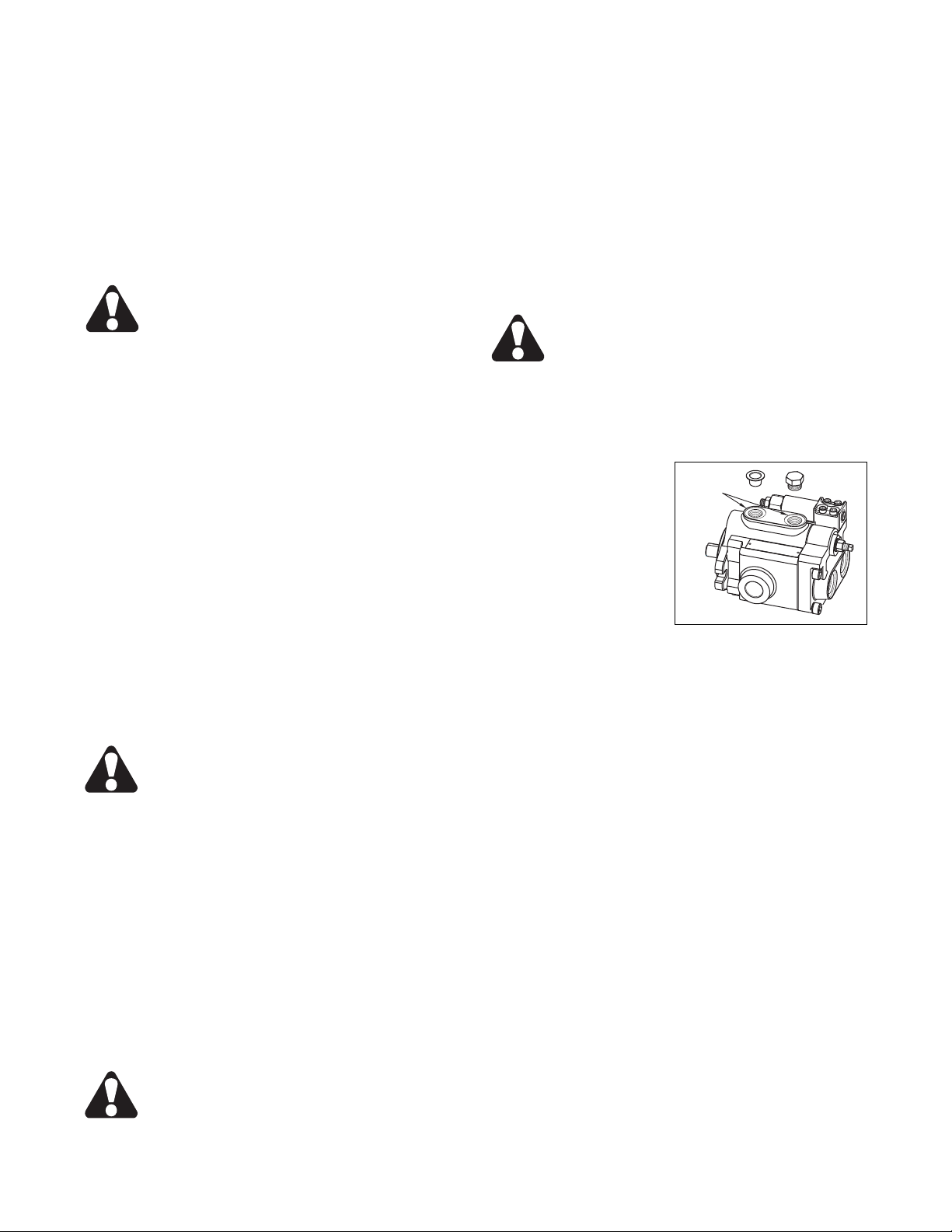

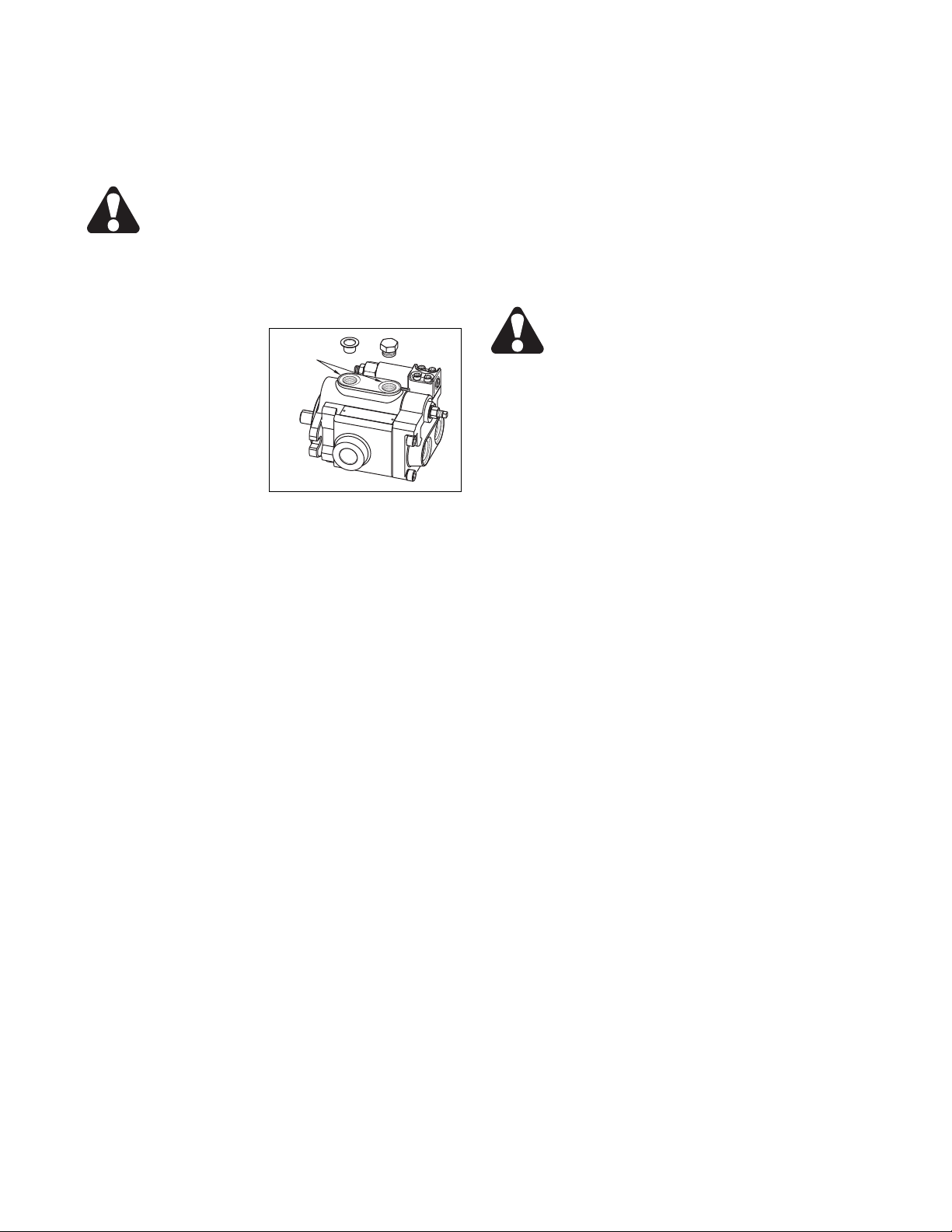

START UP PROCEDURE FOR NEW INSTALLATION

1. Read and understand the Service Manual. Identify

components and their

functions.

2. Visually inspect system

Case Drain

Ports

components and lines for

possible damage.

3. Check reservoir for

cleanliness. Drain and

clean as required.

4. Check reservoir fluid

level and fill as required

with filtered fluid that

Figure 3

meets or exceeds ISO 18/16/13 cleanliness level. Fill

pump through either Case Drain Port (Figure 3).

5. Check drive alignment.

6. Check and activate oil cooler (if included in circuit).

Check fluid temperature.

7. Reduce relief valve pressure settings. Make sure

accurate pressure readings can be made at

appropriate places.

8. If the system includes solenoids, check for proper

actuation.

9. Jog electric motor to confirm proper rotation.

Jogging the electric motor primes the pump and

bleeds air from the system.

10. Start pump drive. Look for leaks, and listen for

excessive noise at the pump. If leaks, chattering or

other noises are observed, immediately turn the pump

off. Corrective actions are covered in the Trouble

Shooting Section.

11. Cycle unloaded machine at low pressure, and

observe actuation (at low speed, if possible).

12. Increase pressure settings gradually. Check for

leaks in all lines, especially in the pump inlet line.

13. Adjust system pressure as needed.

14. Gradually increase system speed to normal

operating level. Be alert for trouble as indicated by

noise, sound changes, system shocks, leaks, or air

bubbles in the reservoir.

2

Form No. R92.00 Rev. 10/03

Page 3

START UP PROCEDURE (continued...)

15. When the system is running normally, check fluid

level and temperature at the reservoir. Repeat these

checks periodically. Excessive fluid temperatures will

damage the pump. If fluid temperature does not

stabilize at 140° F (60° C.) or less, stop the system

and take appropriate corrective action.

16. System is operational. Follow appropriate

maintenance procedures to assure fluid cleanliness

and proper operating temperature.

REPLACEMENT PUMP INSTALLATION

To prevent premature pump failure, make

sure that the entire hydraulic circuit is

flushed completely clean before

installing and operating a replacement

pump.

Simply draining the reservoir or relying on the

system’s filters is not enough to adequately clean the

fluid. Debris trapped in other components or lines

may damage the components themselves, or be

drawn into the pump. Failure to properly flush the

system before installing a replacement pump voids

the pump’s warranty.

The following procedures checklist will help you

replace a hydraulic pump with confidence that it will

provide satisfactory pump life.

1. Determine the cause of the failure (be sure you

have found the cause, and not simply a symptom).

2. Eliminate the cause of the failure.

3. Drain the entire circuit, including cylinders, motors,

reservoirs, control valves, heat exchangers, and

filters.

4. Remove system lines and components. Flush with

a compatible solvent, or clean filtered oil to remove

contamination that may have entered the system

when the pump failed. Be certain that fluid has been

flushed from cylinders.

5. Visually inspect components for possible

contamination, and for proper operation. Pay special

attention to wipers on cylinder rods. Be sure that the

rods are free of nicks and scratches.

6. Flush the reservoir using pressurized solvent. Use

clean, dry, lint-free cloths to ensure a clean interior.

Inspect the filler/breather (if used) and the suction

strainer for cleanliness.

7. Install a new filter with a 10 micron or better

element, and low Beta ratio. If the machine does not

have a filter, install one that meets these

specifications.

8. Fill the reservoir with new, FILTERED oil of the

recommended type. Be certain to monitor the fluid

level, since the entire system (not just the reservoir)

must be filled.

9. Re-install all system lines. Visually inspect to make

sure they are clean, and free of contamination. Be

sure that all inlet fittings are tight and clean.

10. Install the new pump.

11. Follow the start-up procedures given on pages 2

and 3 of this manual.

12. Cycle all cylinders and operate all motors at

normal operating speeds for 20 minutes. While

operating, observe the reservoir fluid level, since all

components will be filling with hydraulic fluid.

13. Replace the filter element, and check the fluid

level. Add new, clean, filtered oil if required.

To assure that your replacement pump performs at

the same level as the original pump, check daily for

proper fluid level, filter condition and leaks. Change

fluid at recommended intervals. Good fluid

maintenance is especially important when using other

than mineral based fluids.

TROUBLESHOOTING GUIDE

Component problems and circuit problems are often

interrelated. Apoorly designed circuit may operate

with apparent success, but cause a component of the

not the cause of the problem. The following general

guide is offered to help you locate and eliminate the

cause of problems by studying their effects.

system to fail. The component failure is the effect,

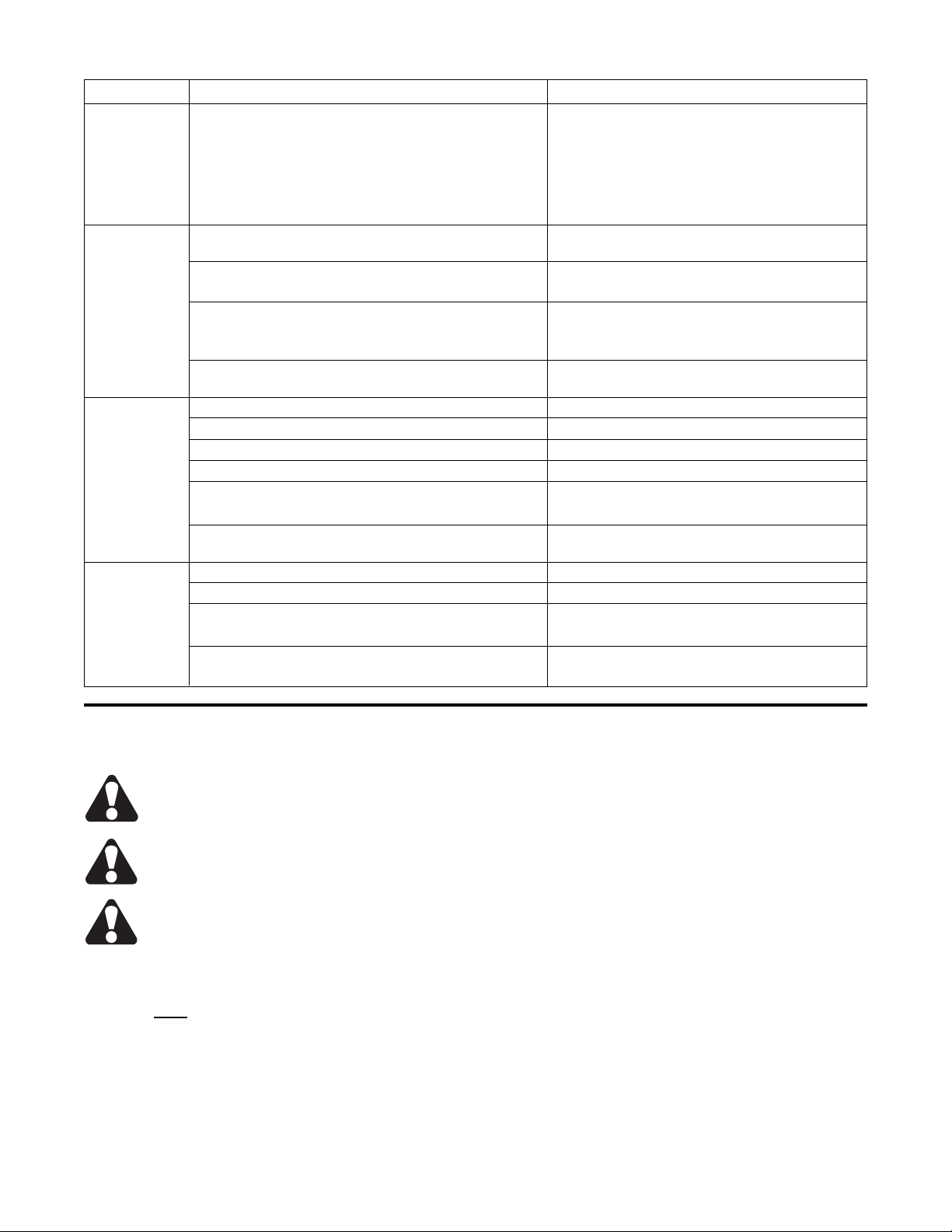

Problem Possible Cause Look For

Noisy Pump Air in fluid Leak in suction line

Leak in shaft seal

Low fluid level

Turbulent fluid

Return lines above fluid level

Gas leak from accumulator

Excessive pressure drop in the inlet line

from a pressurized reservoir

Cavitation in pump rotating group Fluid too cold, too viscous or too heavy

Shaft speed too high

Suction line too small, or collapsed

Suction line strainer dirty or too small

Form No. R92.00 Rev. 10/03

Continued on Page 4

3

Page 4

TROUBLESHOOTING GUIDE

Problem Possible Cause Look For

Noisy Pump Misaligned shaft Faulty installation

Distortion in mounting

Axial interference

Faulty coupling

Mechanical fault in pump Piston and shoe loose or failed

Bearing failure

Incorrect port plate selection or index

Eroded or worn parts in

displacement control

Erosion on Air in fluid Refer to above

barrel

and

Cavitation Refer to above

port plate

High wear Excessive loads Reduce speed or pressure setting

in pump

Contaminant particles in fluid Improper filter maintenance

Filter too coarse

Dirty fluid introduced to the system

Reservoir or breather cap open to

atmosphere

Improper line replacement

Improper fluid Fluid too thick or too thin for operating

temperature range

Fluid breakdown due to age, temperature

or shearing effects

Incorrect additives in new fluid

Reduced additive effectiveness due to

chemical aging

Improper repair Incorrect parts, procedures, dimensions

or finishes

Unwanted water in fluid Condensation

Faulty breather/strainer

Heat exchanger leaking

Faulty clean-up practice

Water in makeup fluid

Pressure Cogging or erratic load movement Mechanical considerations

shocks

Slow acting relief valve Replace with fast acting relief valve

Worn relief valve Repair or replace, as needed

Worn compensator Repair or replace, as needed

Insufficient line capacitance (line volume, Increase line size or length

line stretch, accumulator effects)

Fluid Excessive pump leakage Recheck case drain flow,

overheats repair as needed

Fluid too thin, minimum operating viscosity

60 SUS (10Cst)

Improper assembly

Faulty relief valve Set too low (compared to load

or compensator)

Instability caused by back pressure,

or worn parts

Faulty compensator Set too high (compared to relief)

Worn parts

Faulty heat exchanger Water turned off, or insufficient flow

Ambient water temperature too high

Fan clogged, restricted or inoperative

Mud or scale buildup

Intermittent hydraulic fluid flow through

exchanger

Continued on Page 5

4

Form No. R92.00 Rev. 10/03

Page 5

TROUBLESHOOTING GUIDE (continued)

Problem Possible Cause Look For

Fluid Faulty reservoir Fluid level too low

overheats

(continued)

Entrained air in fluid

Improper, or no baffles

Poor air flow, or ambient air temperature

too high around reservoir

Heat pick up from adjacent equipment

Decrease in Loose compensator adjusting screw Tighten adjusting screw ( No.11 in

set pressure Fig. 14, exploded view)

Defective function or relief valves Repair or replace relief valve

Check relief valve setting

Reservoir fluid level too low Replenish fluid

Check drain (below 5% of discharge at

rated pressure)

Deteriorating pump performance Check pump internal components for wear,

repair or replace as needed.

Pressure Pump turning backward Change the rotating direction

does not rise

Reservoir fluid level too low Replenish fluid

Relief valve or compensator set wrong Readjust and lock

Relief valve or compensator defective Repair or replace

Clogged suction line Inspect and clean suction strainers

Open gate valve

Deteriorating pump performance Check pump internal components for wear,

repair or replace as needed.

Insufficient Reservoir fluid level too low Replenish fluid

flow

Suction line not sealed Tighten fittings

Improper pump stroke control adjustment Readjust as required

Repair or replace as required

Deteriorating pump performance Change compensator

Worn compensator

PISTON PUMP DISASSEMBLY

Precautions

CAUTION – Before performing any service

operation on any pump, be sure that all

pressure has been relieved from BOTH

SIDES of the system.

CAUTION – Before performing any service

operation on any pump, disconnect or lock

off power supply.

CAUTION – Do not attempt to remove the

Barrel Spring. The Barrel Spring is

assembled under high compression. Any

attempt to remove the Barrel Spring will

cause sudden decompression, and may inflict serious

personal injury. The Barrel Spring is NOT field

serviceable. Should the Barrel Spring require service,

the pump must be returned to Continental Hydraulics

or an Authorized Repair Center.

1. Please refer to the exploded view (Figure 14

through 17) for proper names and locations of all

parts.

Form No. R92.00 Rev. 10/03

2. Pump disassembly for inspection and repair should

be undertaken only in the following cases:

Malfunction or leakage due to damage or

wear.

When troubleshooting procedures contained

in this manual do not solve a problem.

3. Disassembly should be done only as far as

necessary to replace or repair worn parts.

4. Perform assembly and disassembly in a clean

environment.

5. Avoid dropping, damaging or contaminating the

machined parts of the pump and compensator.

6. After disassembly, coat the internal parts with a film

of clean oil, and protect them from dirt and moisture.

7. Prior to disassembly, measure and record the

length of the protruding part of adjusting screws (22)

and (28-11) from Figure 14, and if necessary, (18)

from Figure 16 or 17. This will simplify resetting the

pump after reassembly.

5

Page 6

HPV REPAIR PROCEDURES

DISASSEMBLY, INSPECTION and REASSEMBLY

GENERAL

Disassembly in the field by other than an Authorized

Repair Center technician, whether for repair or

modification will void warranty.

NOTE: Certain steps in this procedure

require special tools, and the application

of great force. Care should also be taken

to contain residual oil during

disassembly. Before beginning, read this section

through to make sure that you are prepared for

the job.

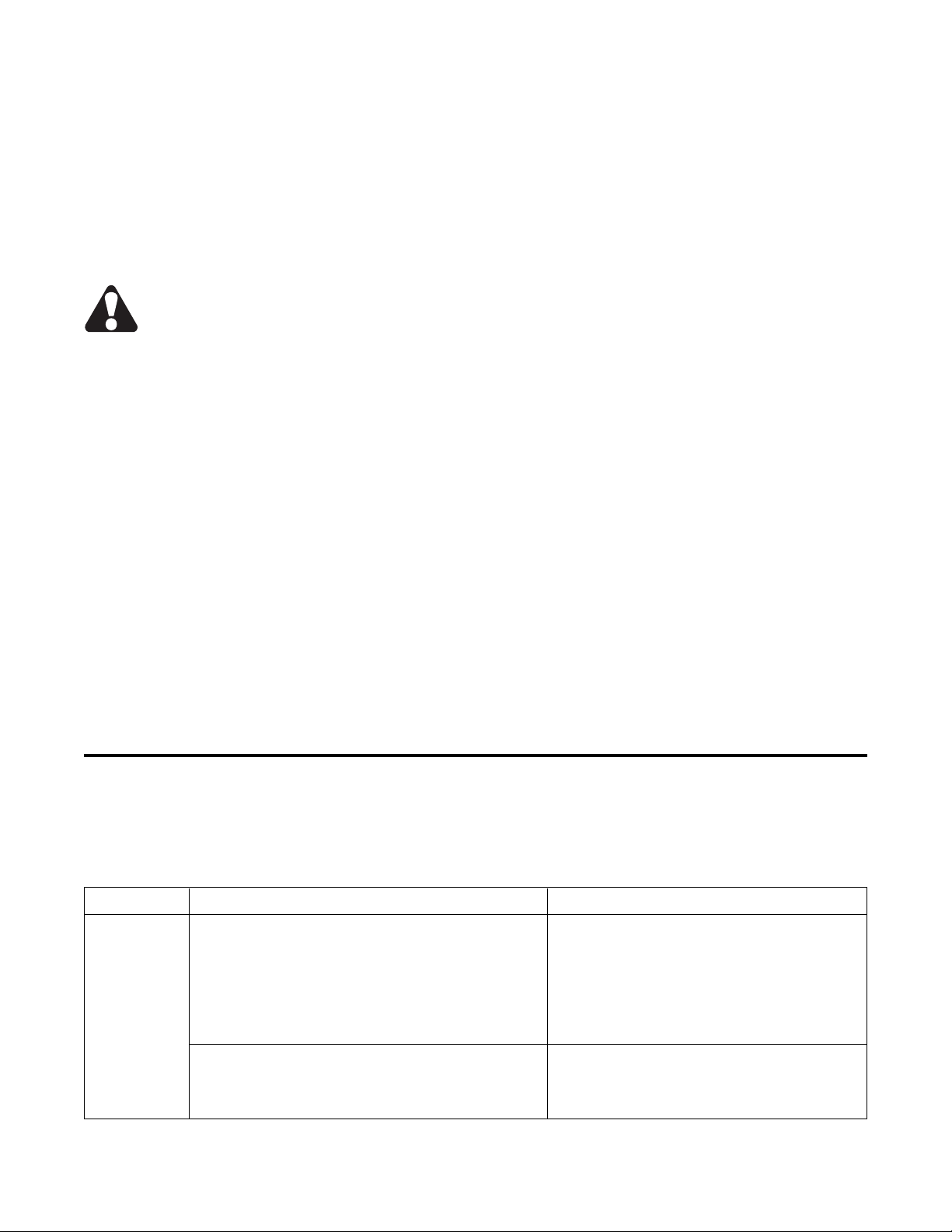

General Disassembly Procedure

1. Drain pump body (1)

via Case Drain Ports.

(Figure 4)

2. Position the pump with

Case Drain Ports up.

3. Remove four

compensator screws (71)

and then remove remove

compensator (28) and Orings (32).

4. Remove four cover

retaining screws (46). Loosen two diagonally

positioned screws first. Then loosen the remaining

two diagonally positioned screws. Remove the

screws and carefully separate the cover (2) from the

pump body. If the gasket holds the cover in place, tap

the cover lightly with a fiber hammer on the side

opposite the compensator.

NOTE: The port plate (4) may cling to the cover (2)

due to oil film between parts. DO NOT ALLOW THE

PLATE TO FALL AND BE DAMAGED.

5. Gently remove the port plate (4) from the barrel (3)

face.

6. Place the pump on a work bench with the shaft in a

horizontal position. Remove the barrel (3) with piston

assembly (5), guide ball (14), guide plate (15), and

dowel pins (56) as a unit.

7. Place the barrel (3) on a clean cloth or plastic film.

Hold the side of the guide plate (15) and gently

remove the piston assembly.

8. Remove the guide ball (14) and dowel pins (56).

9. Place the pump body (1), shaft down, on a fixture

designed to keep it from toppling. Protect with a dustproof plastic film.

10. Place the cover (2) with the assembled guide

sleeve (64), plunger (21) and needle bearing (65) on

a work bench. The guide sleeve must face up.

Protect the parts with a dust-proof plastic film.

NOTE: Following completion of disassembly

procedure steps 1 through 10, necessary pump

inspection can be performed. Further disassembly

may be required if the following inspection steps

reveal specific problems.

11-1. When the barrel (3) is laid flat, the dowel pins

(56) must protrude slightly. If otherwise, or if the

dowel pins are easily pushed in, replace the barrel.

Case Drain

Ports

Figure 4

11-2. If the hanger (9) has little or no inclination

against the shaft (8), or if it can easily be moved by

hand, go to steps 12 through 15.

11-3. If shaft seal leakage or excessive ball-bearing

play is apparent, go to steps 16 through 21.

11-4. If compensator function is erratic, go to steps 23

through 33, as required.

Hanger Removal

12. Place the pump body in a large vise, or on a

working surface adapted to hold the pump body firmly.

13. Remove the trunnions (10) using the blind

threaded holes, and the appropriate trunnion removal

tool. See Figure 9 on page 13 for trunnion removal

tool specifications.

CAUTION: The hanger may be under

tension, and should be secured to

prevent injury.

14. Remove the hanger (9), spring seat (20), and

spring (19) in this order.

15. Proceed to HANGER INSPECTION and

TRUNNION INSPECTION, page 9.

Shaft Removal and Disassembly

16. As required, remove the key (70). Tap gently at

the end of the key with a hammer or chisel if it is

difficult to remove.

17. Remove the retaining ring (41) with a snap ring

pliers.

18. Remove the shaft (8). Pull the shaft toward the

cover. Tap lightly with a fiber hammer on the end of

the shaft if it is difficult to remove.

19. Replace the ball-bearing if it shows excessive

wear, or if noise is heard when rotating the outer race

by hand.

20. To replace the ball bearing, remove retaining rings

(68), and remove the ball bearing (69) with a hand

press or by light hammering.

21. If oil leaks are observed, the shaft seal must be

replaced. Remove the shaft seal (38) from the pump

body (1). Use a push rod of smaller diameter than

the outside diameter of the shaft seal.

NOTE: Do not reuse seals. See Parts List, page 17,

Item 38 for replacement part numbers.

22. Proceed to SHAFT INSPECTION, page 9, and

BALL BEARING INSPECTION, page 11.

Compensator Disassembly

23. Loosen the hex nut (28-12) and remove the

adjusting screw (28-11) from the end cap (28-3).

24. Remove the end cap (28-3).

25. Remove the spring (28-6) and spring seat (28-5).

26. Remove the spool (28-2).

Continue for Codes 7, 19, and 26 compensators.

Item numbers refer to figures 16 and 17, page 20.

27. Loosen the hex nut (12) and remove the adjusting

screw (18) from the body (1).

28. Remove the spring (7) and cone (16).

29. Proceed to PRESSURE COMPENSATOR

INSPECTION, page 11.

6

Form No. R92.00 Rev. 10/03

Page 7

HPV REPAIR PROCEDURES (continued)

NOTE: If the cone is badly worn or damaged, perform

the following steps.

30. For Code 7 or 19 compensators, remove the plug

(20). Using a rod, tap the seat (15) out from the

opposite end.

31. For Code 26 compensators, remove the fitting

(27) and adjusting screw (18) as an assembly.

32. Remove the dowel pin (24) and ball (17).

33. Remove the fitting (29). Using a rod, tap the seat

(15) out from the opposite end.

Rework Limits for Wear Parts

Barrel Bores − Measure each bore in four places,

including one place deep within the bore, where the

piston doesn’t run. Replace the barrel if the

difference in measurements exceeds .0004 in. or .010

mm.

Barrel Face − May be lapped no more than .0002 in.

or .005 mm measured by before and after depths of

oil grooves on barrel face.

Pistons (5) − Measure each piston in four places,

including one at the shoe end, where the piston

doesn’t enter the barrel. Replace Piston if the

difference in measurements exceeds .0006 in. or .015

mm.

Shoe, Piston Assembly − Replace assemblies if end

play exceeds .003 in. or .076 mm.

Shoe, Face − May be lapped up to .004 in. or .102

mm. The difference in shoe flange thickness

between the thinnest and thickest of nine shoes

should not exceed .0012 in. or. 03 mm.

Port Plate (4) − May be lapped .006 in. or .152 mm.

Maintain flatness of .0002 in. or .005 mm.

Wear Plate (16) − Do not lap. Replace if there are

any indications of wear or bending.

Guide Plate (15) − Do not lap. Measure thickness at

several places. Replace if thickness varies more than

.004 in. or .102 mm.

INSPECTION PROCEDURES

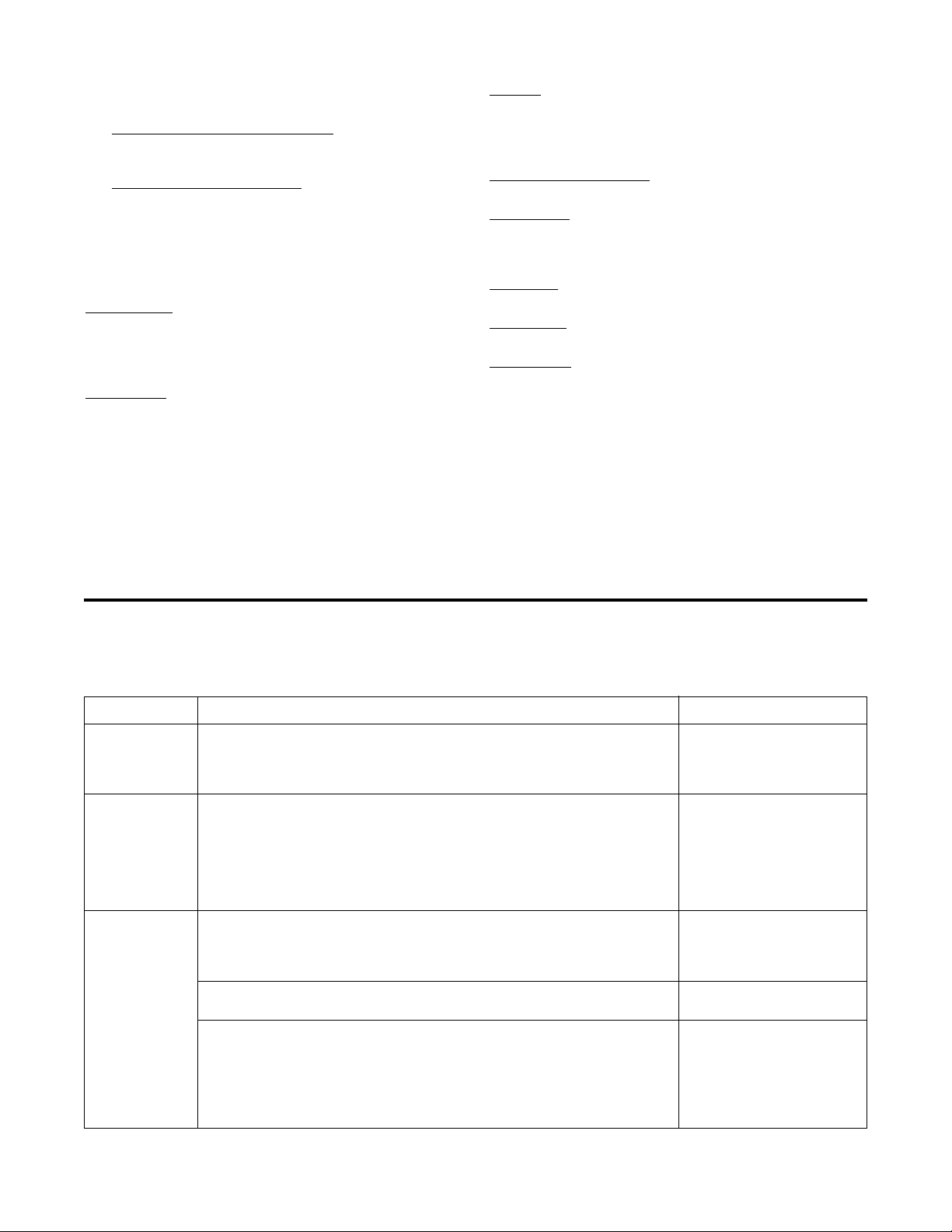

Part (Item No.) Inspection Procedure Corrective Action

Check for cracks around tapped holes.

Pump Body Check for cracks around retainer ring groove. Replace if cracked.

(1) Perform dye penetrant or magnetic particle inspection over

entire housing when oil leakage is observed.

Visually inspect for obvious defects

Check for excessive wear in guide sleeve (64). Axial scratches

should not be detectable with a fingernail. Diameter difference

Cover must not exceed .001 in. or .025 mm when measured at several Replace if defective

(2) random points.

Check for excessive play between drive shaft (8) and needle

bearing (65). (Maximum radial play is .003 in. or .076 mm.)

Repair by lapping until

Visually inspect the barrel face for uniform minute concentric nicks. scratches are removed.

Do not exceed rework

limits listed above.

Visually inspect for deep, localized nicks. Replace barrel. Flush

Barrel reservoir and circuit.

(3) Replace barrel.

Check for

Visually inspect for signs of seizure, scoring or discoloration. correct hydraulic fluid

type, temperature rise,

excessive pressure.

Correct as needed.

Form No. R92.00 Rev. 10/03

Continued on Page 8

7

Page 8

INSPECTION PROCEDURES Continued

Part (Item No.) Inspection Procedure Corrective Action

Barrel Visually inspect the bores’ internal condition for the following

(3) A. Localized polishing at edge. A. Re-use as is.

(Continued) B. Minute, longitudinal nicks. B. Re-use as is.

C. Localized longitudinal nicks. C. Replace part.

Flush reservoir

and circuit.

D. Localized seizure, scoring, discoloration D. Replace barrel and

all piston and

shoe assemblies (5).

Check for correct

hydraulic fluid type,

temperature rise,

excessive pressure.

Correct as needed.

Inspect for bore wear as follows. Wash the barrel bore. Insert a If no resistance,

piston completely into a bore. Cover the kidney-shaped hole replace the barrel

in the barrel, and the center hole on the shoe. Withdraw and piston assemblies.

the piston. If there is resistance

the bore is reusable.

Measure each bore in four places, including one place deep Replace the barrel if the

within the bore, where the piston doesn’t run. difference in

measurements

exceeds .0004 in.

or .010 mm.

Port Plate Visually inspect the surface for uniform minute concentric Repair by lapping

(4) scratches, or deep scratches on the plate. until scratch is

removed. Do not

remove more than

.006 in. or .152 mm.

Maintain flatness

of .0002 in. or .005 mm.

Visually inspect for heat discoloration Use as is. Lap if

excessively discolored.

Do not remove more

than .006 in. or .152 mm

Inspect for cavitation erosion between ports Repair by lapping

until erosion is

removed. Do not

remove more than

.006 in. or .152 mm.

Piston Inspect for shoe end play by pushing and pulling the shoe while Replace piston

Assembly holding the piston. If the shoe clicks, or if movement can be assemblies as a set.

(5) seen, the piston assembly is excessively worn. Check circuit suction

pressure. If less than

-5 in. Hg., raise fluid level

in reservoir, clean intake

strainer and/or correct

faulty circuit design.

Visually inspect shoe face for localized polishing, or random Repair by lapping

radial marks. assemblies as a set.

Shoes may be lapped

up to .004 in. or .102 mm.

Difference in shoe flange

thickness between the

thinnest and thickest of

nine shoes should not

exceed .0012 in.

or .03 mm.

Check circuit suction

pressure. If less than

-5 in. Hg., raise fluid level

in reservoir, clean intake

strainer and/or correct

faulty circuit design.

8

Form No. R92.00 Rev. 10/03

Continued on Page 9

Page 9

INSPECTION PROCEDURES (Continued)

Part (Item No.) Inspection Procedure Corrective Action

Piston Visually inspect the shoe flange for burrs or rolled edges If slight, repair by lapping.

Assembly If severe, replace part.

(5)

(Continued) Inspect the piston outer diameter. Measure each piston in four Replace Piston if the

places, including one at the shoe end, where the piston doesn’t difference in

enter the barrel. measurements exceeds

.0006 in. or .015 mm.

Visually inspect for slight discoloration or cross hatch trace. Reuse as is.

Visually inspect for localized scratch marks running in Replace pistons

a longitudinal direction. as a set. Flush

reservoir and circuit.

Visually inspect for signs of seizure, scoring or discoloration Replace piston and

shoe assemblies (5).

Replace barrel (3).

Check for correct

hydraulic fluid type,

temperature rise,

excessive pressure.

Correct as needed.

Shaft Visually inspect the shaft end outer surface.

(8) A. If burnt brown spots are apparent over entire surface A. Remove with

emery paper.

B. If uneven wear on key side surface B. Check fit to coupling

hub. If loose, replace.

Inspect for pitting or corrosion over all or part of shaft surface. Replace shaft.

Check fit to coupling hub

Check alignment between

prime mover and pump.

Correct as needed.

Visually inspect shaft seal surface for:

A. Seal contact marks. A. Use as is.

B. Bright polish B. Use as is.

C. Contact marks over 0.04 in. or 1 mm wide, can be felt with C. Replace shaft.

fingernail. Inspect and replace

shaft seal as needed.

Visually inspect key groove bottom end for cracks. If in doubt, If cracked, replace shaft.

check with dye penetrant or magnetic particle inspection. Check alignment with

prime mover. Correct

as needed.

Inspect needle bearing rolling contact surfaces for wear. Replace shaft if difference

between bearing contact

and non-contact surfaces

is more than .0008 in.

or .020 mm

Hanger Visually inspect the trunnion bore.

(9) Contact surface not excessively worn Reuse hanger as is.

Contact surface shows obvious wear, uneven contact or Replace the hanger

localized nicks. when inside diameter

difference is directionally

more than .0008 in.

or .020 mm.

Visually inspect contact surface with the plunger (21).

Wear marks up to 0.2 in. or 5 mm wide. Reuse hanger as is.

Wear marks over 0.2 in. or 5 mm wide. Replace hanger.

Adjust volume as needed.

Trunnion Visually inspect contact surface to hanger (9).

(10) Very slight wear. Reuse trunnion as is.

Localized seizure, scoring, discoloration. Replace the trunnion.

Also replace hanger (9).

Check hydraulic fluid

type, temperature rise,

excessive pressure.

Form No. R92.00 Rev. 10/03

Continued on Page 10

9

Page 10

INSPECTION PROCEDURES (Continued)

Part (Item No.) Inspection Procedure Corrective Action

Key Inspect for wear on side surface.

(70) A. Discoloration. A. Remove discoloration

with emery cloth.

Reuse key.

B. Stepped wear. B. Replace key if worn

over .0002 in. or

.005 mm. When

coupling hub-to-shaft fit

is loose, replace the

coupling. Recheck

alignment with prime mover.

Check for excessive

pressure or side load.

Correct as needed

Guide Plate Visually inspect contact surface between guide plate Re-use as is.

(15) and piston shoe. If brightly polished,

Inspect contact surface for indentations. If stepped or indented, Replace guide plate.

Wear Plate Check face condition for:

(16) A. Polish over all or part of the surface A. Re-use as is.

B. Scratches, wear or metal transfer B. Replace wear plate.

Flush reservoir

and circuit.

Check hydraulic fluid

type, temperature rise,

and excessive pressure.

Correct as needed.

Spring Measure free heights. Correct heights are:

(18) A. HPV-6: 1.36” or 34.5 mm Replace when height

B HPV-10: 1.57” or 40 mm is decreased more

C. HPV-15: 1.79” or 45.5 mm than 5% from the

D. HPV-20: 1.97” or 50 mm given heights.

E. HPV-29: 2.05” or 52 mm

Spring Measure free height. Correct heights are:

(19) A. HPV-6: 2.44” or 62 mm Replace when height

B HPV-10: 2.60” or 66 mm is decreased more

C. HPV-15: 3.00” or 76 mm than 3% from the

D. HPV-20: 3.00” or 76 mm given heights.

E. HPV-29: 3.19” or 81 mm

Plunger Inspect contact pattern on spherical surface.

(21) A. Wear pattern less than 0.2 in. or 5 mm wide A. Re-use as is.

B. Wear pattern over 0.2 in. or 5 mm wide B. Replace plunger.

In case of rapid wear,

check hydraulic fluid

type, temperature rise,

and excessive pressure.

Correct as needed.

Guide Sleeve Inspect outer surface contact condition.

(64) A. Slight uneven wear on one side, partial polishing. A. Re-use as is.

B. Distinct localized contact, with strong, bright polishing. B. Replace guide sleeve

and cover (2).

Measure guide sleeve outside diameter at several points. If the difference is more

than .0008 in. or .020 mm

replace guide sleeve and

cover (2). Check

fluid type, temperature

rise, and pressure.

Correct as needed.

Visually inspect for signs of seizure, scoring, or discoloration. Replace guide sleeve

and cover (2).

Check hydraulic fluid

type, temperature rise,

and excessive pressure.

Correct as needed.

10

Form No. R92.00 Rev. 10/03

Continued on Page 11

Page 11

INSPECTION PROCEDURES (Continued)

Part (Item No.) Inspection Procedure Corrective Action

Ball Bearing Inspect for radial play or sticking. Replace ball bearing if

(69) Rotate outer race by hand. excessive play or sticking

is felt, or if unusual

noise is heard.

Replace if obvious

discoloration or pitting

are observed.

Needle Visually inspect rolling surfaces. Replace if obvious

Bearing discoloration or pitting

(65) are observed.

Gasket Replace whenever pump

(24) is disassembled.

Shaft Seal Replace whenever shaft

(38) is removed from pump.

Thread Seal Visually inspect for damage. Replace thread seal

(54) as needed.

ASSEMBLY TOOLS

Shaft Seal Installation Tool

Series A* B C† DE F

HPV-6

HPV-10

HPV-15

HPV-20

HPV-29

In. 1.75 2.17 .185 5.0 1.25 .79

(mm) (44.5) (55.1) (4.7) (127) (31.75) (20.1)

In. 1.75 2.17 .185 5.0 1.25 .79

(mm) (44.5) (55.1) (4.7) (127) (31.75) (20.1)

In. 1.95 2.36 .197 5.0 1.25 .79

(mm) (49.5) (59.9) (5.0) (127) (31.75) (20.1)

In. 2.15 2.56 .204 5.0 1.25 .79

(mm) (54.6) (65.0) (5.2) (127) (31.75) (20.1)

In. 2.15 2.56 .204 5.0 1.25 .79

(mm) (54.6) (65.0) (5.2) (127) (31.75) (20.1)

Material: Steel

* ± .008 in. (± .203 mm)

† +.0 in. (+.0mm)

-.008 in.(-.203 mm)

Figure 5 (not to scale)

Form No. R92.00 Rev. 10/03

11

Page 12

ASSEMBLY TOOLS (continued)

Ball Bearing Installation Tool

Series A B* C D

HPV-6

HPV-10

HPV-15

HPV-20

HPV-29

In. 2.36 2.08 1.02 4.33

(mm) (59.9) (52.8) (25.9) (110)

In. 2.76 2.44 1.02 4.52

(mm) (70.1) (62.0) (25.9) (114.8)

In. 3.15 2.83 1.22 5.19

(mm) (80.0) (71.9) (31.0) (131.8)

In. 3.54 3.15 1.42 6.30

(mm) (89.9) (80.0) (36.0) (160.0)

In. 3.54 3.15 1.42 6.30

(mm) (89.9) (80.0) (36.0) (160.0)

Material: Steel

* +.012 in. (+.305 mm)

-.004 in.(-.102 mm)

Figure 6 (not to scale)

Protective Cone

Series A* B† CDE

HPV-6

HPV-10

HPV-15

HPV-20

HPV-29

In. 1.00 0.75 2.24 1.65 1.57

(mm) (25.4) (19.1) (56.9) (41.9) (39.9)

In. 1.00 0.875 2.68 2.08 2.00

(mm) (25.4) (22.2) (68.1) (52.8) (50.8)

In. 1.20 0.875 2.68 2.08 2.00

(mm) (30.5) (22.2) (68.1) (52.8) (50.8)

In. 1.40 1.25 2.68 2.08 2.00

(mm) (35.6) (31.8) (68.1) (52.8) (50.8)

In. 1.40 1.25 2.68 2.08 2.00

(mm) (35.6) (31.8) (68.1) (52.8) (50.8)

Material:Teflon preferred, or steel heat treated to

Rc40 or Rc45, and chromium plated.

*± .004 in. (± .102 mm)

† +.008 in. (+.203 mm)

-.004 in.(-.102 mm)

Trunnion Assembly Tool

Series A B C

HPV-6

HPV-10

HPV-15

HPV-20

HPV-29

In. 1.75 .997/.996

(mm) (44.45) (25.32/25.30)

In. 1.75 .997/.996

(mm) (44.45) (25.32/25.30)

In. 2.00 1.247/1.246

(mm) (50.80) (31.67/31.65)

In. 2.25 1.497/1.496

(mm) (57.15) (38.02/38.00)

In. 2.25 1.497/1.496

(mm) (57.15) (38.02/38.00)

1/2-13 UNC X 3/4 DP

1/2-13 UNC X 3/4 DP

3/4-10 UNC X 1 DP

3/4-10 UNC X 1 DP

3/4-10 UNC X 1 DP

Material: Steel, or rework trunnion to B diameter.

12

Form No. R92.00 Rev. 10/03

(3.0 to 5.0 mm)

Figure 7 (not to scale)

Figure 8 (not to scale)

Page 13

ASSEMBLY TOOLS (continued)

Trunnion Removal Tool

Series A B C D E F

DIA. DIA. THD. DIA.

HPV-6 In. 1.75 1.50 .56 4.25

HPV-10 (mm) (44.5) (38.1) (14.2) (108) (63.5)

HPV-15

HPV-20 In. 2.25 2.00 .81 4.75

HPV-29 (mm) (57.15) (50.8) (20.6) (121) (76.2)

In. 2.00 1.75 .81 4.50

(mm) (50.8) (44.5) (20.6) (114) (69.8)

1/2-13

3/4-10

3/4-10

2.50

2.75

3.00

Material:

Item . . . . . . . . . . . . . . . Material

(1) Sleeve . . . . . . . . . . Steel

(2) Spacer . . . . . . . . . . Steel

(3) Nut . . . . . . . . . . . . . Hardened Steel GR.5

(4) All-Thread Rod . . . . Hardened Steel GR.5

ASSEMBLY PROCEDURES

Figure 9 (not to scale)

Pump Assembly

Piston Pump assembly must be done more carefully

than disassembly. The working environment must be

clean. All parts must be clean and inspected for wear

or damage in accordance with the Inspection

Procedures listed on pages 7 through 11.

1. Compare the disassembled parts with the exploded

view shown in Fig. 14 or 15 on page 20 for missing

parts or irregularities.

2. Inspect retaining rings. Replace if deformed.

3. Place the pump body (1) in a press, with the

mounting flange facing up.

4. Apply grease between the lips of the shaft seal.

Grease should not protrude above the tip of the lip,

and should fill approximately 80% of the space.

5. Use a press, and the tool shown in Fig. 5 on page

11, slowly force the shaft seal into the pump body (1)

until seated.

6. Assemble a retaining ring (68) on the shaft end.

The sharp edge of the retaining ring must always be

facing away from the part being retained.

7. Using the ball bearing installation tool shown in Fig.

6 on page 12, press the ball bearing (69) onto the

shaft. Do not exceed the maximum pressing force

guidelines listed as follows.

8. Install the remaining retaining ring (68).

Pressing Force

Series Bearing Part No Lbs. N

HPV-6 258191 1330 5900

HPV10 258192 1500 6700

HPV10 258193 1690 7500

HPV10 258194 2200 9800

HPV10 258194 2200 9800

9. Rotate the bearing manually to check for unusual

noise or binding.

10. Fit the protective cone shown in Fig. 7 on page 12

over the end of the shaft. Apply a light coating of

lithium grease to the outer surface of the cone. Slide

the protective cone and shaft through the shaft seal,

positioning the ball bearing in place.

11. Assemble the retaining ring (41) into the pump

body.

12. Place the housing on a fixture with the shaft end

facing down. Insert the spring (19) and spring seat

(20) into the pump body.

13. Lightly coat the wear plate (16) with grease, and

mate to the hanger (9). Then fit into the pump body.

14. Press the hanger (9) until approximately

horizontal, using a press if necessary. Then install

the trunnions.

NOTE: A used trunnion shaft, turned

down to a slip fit simplifies hanger

installation. Slip the modified trunnion

into one side to hold it in place while the

working trunnion is press-fit into the opposite

side. See Fig. 8, page 12 for trunnion assembly

tool specifications.

15. Lightly coat the trunnions with teflon-based

sealing paste. Avoid putting sealing paste on the

section of the trunnion that will be held in the hanger.

Press them through the pump body, and into the

hanger.

NOTE: Be certain the hanger bores are

correctly aligned with the pump body.

After the trunnions have been installed,

confirm that the hanger moves freely on

them.

Form No. R92.00 Rev. 10/03

13

Page 14

PUMP ASSEMBLY (continued)

16. Place the barrel (3) on a clean working surface.

Insert the washers (27) and spring (18) into the center

hole. The washers (27) should be located on both

ends of the spring.

17. Compress the spring (18) using a mechanical

press. Secure the spring with the retaining ring (40).

18. Place the barrel (3) on a clean sheet of paper or

cloth. Insert the three dowels (56) into the holes

located outside of the spline hole. Place the guide

ball (14) on top.

19. Compress manually, and confirm spring(18) force.

20. Hold the guide plate (15) horizontal with one

hand, and insert the nine piston assemblies (5) into

the guide plate bores. The piston shoes should move

freely on the pistons.

21. Support the guide plate horizontally, and insert the

piston assemblies (5) into the barrel bores (3).

22. Place the pump body (1) so that the shaft (8) is

horizontal. Assemble the barrel (3), piston assemblies

(5), guide ball (14) and guide plate (15) together onto

the shaft.

CAUTION: Do not force the shaft spline

into the barrel groove. Carefully rotate

the parts, and apply slight pressure to

work them together. Assembly is correct

when the edge of the barrel is approximately .25

in. below the edge of the pump body.

23. Place the pump body (with shaft end pointing

down) on a fixture, and coat the face of the barrel with

clean hydraulic fluid. Place the gasket (24) on the

pump body.

24. Assemble the plunger (21) and port plate (4) onto

the cover (2).

25. Lightly coat the port plate (4) with grease. Place

the port plate on the cover (2), locating the “U”

shaped slot over the pin (66). See Fig. 10

Series N - m Lbs. - Ft.

Min. Max Min. Max

HPV-6 5.4 6.9 4.0 5.1

HPV-10 7.8 9.8 5.8 7.3

HPV-15 21.6 25.5 16.0 18.9

HPV-20 39.2 43.1 29.0 31.9

HPV-29 39.2 43.1 29.0 31.9

28. Attach rebuilt pressure compensator to pump

cover (2). Pressure compensator assembly

procedures are listed below, and on the next page.

29. Install the thread seal (54) and hex nut (45) on the

adjusting screw (22), then screw into the hole in the

pump cover (2). Finger tighten until the adjusting

screw bottoms against the plunger. Adjust to desired

volume.

Series No. of Turns Full to Zero Vol.

HPV-6 8.5

HPV-10 8.5

HPV-15 8.5

HPV-20 9.7

HPV-29 10.5

30. Using a lever or hub, rotate the shaft several

times in the direction indicated by the arrow on the

escutcheon plate (61). Confirm that the pump rotates

freely and smoothly.

31. With the palm of your hand, cover the port on the

side on which the compensator is mounted. Rotate

the input shaft. If air is forced out of the piping port,

the pump is working properly.

32. Screw the case drain plug (58) into the pump

body. Seal other openings with plastic cap seals.

33. Clean the outside of the pump, and re-install onto

the original equipment. If the pump will be stored

before re-installation, coat all unpainted surfaces with

a light coating of oil, and store in a sealed plastic bag.

Figure 10

26. Hold the cover so the plunger (21) does not fall

off. Then carefully place the cover on the pump body.

27. Secure the cover (2) with socket head screws

(46), tightened diagonally. The final tightening torque

should be as follows:

14

Form No. R92.00 Rev. 10/03

STANDARD PRESSURE COMPENSATOR

CONTROL (28) ASSEMBLY

1. Carefully clean the compensator body (28-1) and

spool (28-2). Soak in clean hydraulic fluid.

2. Check O-rings (28-8) and (28-9) for deformation or

wear. Replace as needed. Assemble O-ring (28-8) to

cap (28-3). Assemble O-ring (28-9) to spring seat

(28-4).

3. Carefully insert the spool (28-2) into the

compensator body (28-1).

4. Fit the spring seats (28-4) and (28-5) onto both

ends of the spring (28-6). Assemble into the

compensator body.

5. With the adjusting screw (28-11) and nut (28-12)

set on the cap, place the cap on the spring seat (28-

4), and screw into the threaded hole in the

compensator body. Tighten until the edge surface is

flush. Screw (28-11) adjustment rate

approximately 650 psi (45 bar) per turn.

Page 15

PUMP ASSEMBLY (continued)

6. Check O-rings (32) for deformation and wear.

Replace as needed. Install the O-rings.

REMOTE PRESSURE (Code 7), AND LOAD

SENSING CONTROL (Code 19) ASSEMBLY

See Figure 16

1. For initial assembly, follow steps 1 through 5 of the

Standard Pressure Compensator Assembly listed

above. For Load Sensing Control (Code 19) only,

install the pin (28-24) into the spool.

2. To install the seat (28-15), insert the open end into

the bore, and press into place. Install plug (28-20)

and tighten.

3. Fit the washer (28-23) and spring (28-7) onto the

adjusting screw (28-18). Fit the cone (28-16) into the

spring, and assemble into the body.

4. Set the adjusting screw to the measurement taken

at disassembly, and lock into place with nut (28-12).

Cover with acorn nut (28-22).

5. Install the O-rings (32). Assemble the compensator

to the pump cover.

HORSEPOWER LIMITING CONTROL (Code 26)

ASSEMBLY

See Figure 17

1. For initial assembly, follow steps 1 through 5 of the

Standard Pressure Compensator Assembly listed

above.

2. To install the seat (26-15), insert the open end into

the bore, and press into place. Install plug (26-20)

and tighten.

3. Fit the washer (26-23) and spring (26-7) onto the

adjusting screw (26-18). Fit the cone (26-16) into the

spring, and assemble into the body.

4. Set the adjusting screw to the measurement taken

at disassembly, and lock into place with nut (26-12).

Cover with acorn nut (26-22).

5. Place the ball (26-17) into the body, atop the

orifice.

6. Insert the pin (26-24) into the fitting assembly (26-

27), and tighten in the valve body.

7. Install O-ring (26-21) onto the fitting (26-29) and

screw into the compensator.

8. Install the O-rings (32). Assemble the compensator

to the pump cover.

TEST PROCEDURES AND SPECIFICATIONS

Pump Performance Test

1. With the operating speed at 1750 ± 35 rpm, record

delivery flow rate, drain flow rate, and fluid

temperature at minimum outlet pressure and

maximum rated continuous pressure.

Series Max. Rated Continuous Pressure

HPV-6 3500 PSI (241 bar)

HPV-10 3500 PSI (241 bar)

HPV-15 3500 PSI (241 bar)

HPV-20 3500 PSI (241 bar)

HPV-29 3000 PSI (207 bar)

2. Rate of flow at minimum outlet pressure, and

maximum rated continuous pressure should fall within

the following range:

Flow Rate At: GPM (lpm)

At Minimum At Rated

Series Outlet Continuous

Pressure Pressure

HPV-6 6.0-7.1 (22.7-26.9) 5.9 Min. (22.3)

HPV-10 9.5-10.3 (36.0-39.0) 8.7 Min. (32.9)

HPV-15 15.0-16.6 (56.8-62.8) 14.4 Min. (54.5)

HPV-20 20.0-21.4 (75.7-81.0) 18.6 Min. (70.4)

HPV-29 28.0-30.4 (106.0-115.1) 26.6 Min. (100.7)

3. Case Drain flow at maximum rated continuous

pressure and zero flow is as follows:

Series Case Drain Flow at Zero Flow

HPV-6 .93 GPM (3.5 lpm) Max.

HPV-10 .98 GPM (3.7 lpm) Max.

HPV-15 1.06 GPM (4.0 lpm) Max.

HPV-20 1.60 GPM (6.1 lpm) Max.

HPV-29 1.90 GPM (7.2 lpm) Max.

Pressure Compensator Test

Control Option Adjustment Procedures - Standard

Compensator

1. With a pump running at deadhead (no-flow), adjust

the compensator pressure to 3500 ± 35 PSI (241 ±

2.5 bar).

2. The following flow rates should be achieved:

Flow Rate, GPM (lpm)

Series Pressure, PSI (bar) Flow, GPM (LPM)

HPV-6 3325 (229.3) 5.9 (22.3) Min.

HPV-10 3325 (229.3) 8.7 (32.9) Min.

HPV-15 3325 (229.3) 14.4 (54.5) Min.

HPV-20 3325 (229.3) 18.6 (70.4) Min.

HPV-29 2850 (196.5) 26.6 (100.7) Min.

3. The pump shall return to a stable condition, with no

loss of conttrol, within one (1) second after being

cycled from full flow to zero flow.

4. Cycle the pump from zero flow to full flow to zero

flow. The zero pressures shall not vary more than

±30 psi (2 bar).

Form No. R92.00 Rev. 10/03

15

Page 16

PUMP ASSEMBLY (continued)

5. The pressure ripples at zero flow and partial flow

shall not exceed ±50 psi (3.5 bar).

6. Case drain flow shall be stable.

Control Option Adjustment Procedures - Remote

Compensator

1. Be sure the pin (24) is not in the compensator

spool. See Figure 16.

2. Attach a vent line, with needle valve, into the vent

line, between the compensator and tank.

Figure 11

3. Close the valve in the vent line.

4. Start the pump and adjust the load to deadhead

(no flow). If there is a check valve installed before the

pressure gauge, allow some flow in the circuit (up to

10% of full flow).

5. Open the vent valve, and set the “minimum

pressure adjustment screw” (see Fig. 11) to 250 ± 25

psi (17 ± 1.7 bar).

6. Close the vent valve. Set the “upper pressure limit

adjustment” to the maximum desired compensator

setting. See Figure 11 for adjuster location.

7. Open and close the vent port several times. When

the valve is open, discharge pressure should drop to

the differential setting of 250 ± 25 psi (17 ± 1.7 bar).

When it is closed, discharge pressure should go to

the maximum compensator setting. Cycle the pump

from deadhead to full flow with the compensator

vented or unvented.

8. If flow is within accepted limits, and no leaks are

detected, remove the needle valve from the vent port.

9. The pump is now ready for remote control.

1. Make sure the pin (24, Fig. 16) is in the

compensator spool.

2. Install a sense line between the load valve and the

speed valve.

3. Open the load valve.

4. Back the upper pressure limit adjustment screw out

two (2) turns. (Fig. 12, page 16)

5. Using a speed valve, adjust the pump to zero flow

(deadhead). Note: if there is a check valve installed

before the pressure gauge, allow some flow in the

circuit (up to 10% of full flow).

6. Adjust the pressure differential adjustment screw to

∆250 ± 25 psi (17 ± 1.7 bar). (Fig. 12)

7. Using the speed valve, adjust the pump to partial

flow (25-50% of full flow).

8. Close the load valve.

9. Set the upper pressure limit adjustment to the

desired compensator setting.

10. Open and close the load valve several times.

When the load valve is open, discharge pressure

should drop down to the pressure differential setting

of ∆250 ± 25 psi (17 ± 1.7 bar). When the load valve

is closed, discharged pressure should go to the

maximum compensator setting.

11. Using the load valve, adjust the discharge

pressure from 500 psi (34.5 bar) to 2500 psi (172.4

bar). The differential pressure should be at ∆250 ± 25

psi (17 ± 1.7 bar) throughout the range.

12. Using the speed valve, cycle the pump from zero

flow (deadhead) to full flow.

13. If flow is within accepted limits, and no leaks are

detected, the compensator is ready for operation.

Control Option Adjustment Procedures - Horse

Power Limiting Compensator

1. Be sure the proper orifice is installed in the pump

discharge port.

2. Install the sense line into the circuit.

Control Option Adjustment Procedures - Load

Sensing Compensator

Figure 12

16

Form No. R92.00 Rev. 10/03

Figure 13

Page 17

3. Using the High Pressure Flow Adjustment (Fig. 13),

preload the spring.

4. Back out the High Flow Pressure Adjustment (Fig.

13) until there is no resistance.

5. Start the pump.

6. Using the Compensator Override Adjustment (Fig.

13), set the compensator 500 psi (34.5 bar) above the

desired pressure (P1). Note: if the pump is not at

zero flow, adjust the relief valve until zero flow is

achieved.

7. Adjust the relief valve to the desired pressure (P1).

8. Adjust the High Pressure Flow Adjustment (Fig. 13)

to achieve full flow at 95% of the desired pressure

(P1). Note: if the discharge pressure drops below the

desired value, readjust it using the relief valve.

9. Adjust the relief valve to the desired pressure (P1)

plus 1/2 turn.

10. Using the Compensator Override Adjustment, set

the pump at the desired pressure (P1). Note: the

pump should be at zero flow.

11. Adjust the pump to the desired flow (F2). At the

same time, use the High Flow Pressure Adjustment to

set the discharge pressure to the corresponding full

flow pressure (P2).

12. Check the flow at 95% of P1. If it is not as

desired, adjust it by using the High Flow Pressure

Adjustment.

STANDARD SETTINGS

Series HP P1 P2 F1 F2

HPV-6 8 3500 PSI 1700 PSI 2.4 GPM 5.9 GPM

HPV-10 12 3500 PSI 1700 PSI 4.0 GPM 8.7 GPM

HPV-15 19 3500 PSI 1700 PSI 6.0 GPM 14.4 GPM

HPV-20 24 3500 PSI 1700 PSI 8.0 GPM 18.6 GPM

HPV-29 29 3000 PSI 1700 PSI 13.0 GPM 26.6 GPM

13. Adjust system pressure from high pressure to low

pressure while observing HP draw. If draw is not as

desired, repeat steps 10 and 11.

14. If HP draw is within accepted limits, and no leaks

are detected, the compensator is ready for operation.

Form No. R92.00 Rev. 10/03

17

Page 18

PART AND ASSEMBL Y IDENTIFICATION

PARTS LIST

The following chart, and Figures 14 - 17 may be used to

identify individual parts and assemblies in Piston Pumps.

DESCRIPTION QTY HPV-6 HPV-10 HPV-15 HPV-20 HPV-29

1 Pump Body 1

Cover, Rear Port - RH Kit

Cover, Rear Port - LH Kit

Cover, Side Port - RH Kit

21BSPP-Con. CHD BSPP-Con. CHD BSPP-Con. CHD

Cover, Side Port - LH Kit

Cover, Tandem - RH Kit N/A

Cover, Tandem - LH Kit N/A

550745 SAE 550750 SAE 550754 SAE 550759 SAE 550764 SAE

550748 BSPP 550749 BSPP 550756 BSPP 550757 BSPP 550758 BSPP

260293 SAE 260294 SAE 260295 SAE 260296 SAE 260297 SAE

BSPP-Con. CHD BSPP-Con. CHD BSPP-Con. CHD BSPP-Con. CHD BSPP-Con. CHD

261191 SAE 261192 SAE 261193 SAE 261194 SAE 261195 SAE

BSPP-Con. CHD BSPP-Con. CHD BSPP-Con. CHD BSPP-Con. CHD BSPP-Con. CHD

261774 SAE 261776 SAE 261778 SAE

261775 SAE 261777 SAE 261779 SAE

BSPP-Con. CHD BSPP-Con. CHD BSPP-Con. CHD

SAE-Con. CHD SAE-Con. CHD

BSPP-Con. CHD BSPP-Con. CHD

SAE-Con. CHD SAE-Con. CHD

BSPP-Con. CHD. BSPP-Con. CHD

261780 261782

261781 261783

Contact CHD 264609

Contact CHD 264325

3Barrel 1 552078 550876 552035 552021 550868

Port Plate - RH

4

Port Plate - LH 552041 550939 550962 550947 550927

1

550910 550877 550898 550897 550867

5 Piston and Shoe Ass’y. 9 258093 258094 258095 258096 258097

Keyed Shaft 550766 550879 550893 550894 550866

Splined Shaft

8

1

Tandem Shaft N/A

550901 550883 550891 550895 550904

550903 Splined 550846 Splined 552007 Splined 552008 Splined

552005 Keyed 552006 Keyed 550847 Keyed 550905 Keyed

9 Hanger 1 550885 550880 550884 550890 550864

10 Trunnion 2 258943 258985 258909

14 Guide ball 1 258098 258099 258100 258101 258102

15 Guide Plate 1 450700 450696 450698 450699 450721

16 Wear Plate 1 259025 258944 258986 258989 258912

18 Spring (Barrel) 1 258166 258167 258168 2588169 258170

19 Spring (Hanger) 1 258302 258303 258304 258305 258306

20 Spring Seat (Hanger) 1 259019 259499 258983 258991 258917

21 Plunger 1 259027 258938 258982 258988 258918

258959 Rear 258959 Rear 259411Rear 259411Rear 258919 Rear

22 Adjustment Screws 1 258959 Side 258959 Side 259411 Side 259411 Side 258919 Side

N/A 258959 Tandem 258584 Tandem 258581 Tandem 259141 Tandem

24 Gasket * 1 258426 258425 258424 258423 258422

27 A-Washer (Barrel) 2 258108 258109 258110 258111 258112

Pressure Compensator Kit 261097 Buna-N

(Standard) 261098 Viton

Remote Pressure SAE 260199 Buna-N SAE 261100 Viton

Compensator Kit (Code 7) BSPP 261101 Buna-N BSPP 261102 Viton

Remote Load Sensing SAE 261103 Buna-N SAE 261104 Viton

Compensator Kit (Code 19) BSPP 261105 Buna-N BSPP 261106 Viton

28 1

Rear BSPP 261109 Buna BSPP 261113 Buna BSPP 261117 Buna BSPP 261121 Buna BSPP 261129 Buna

Power Limiter

Port SAE 261108 Viton SAE 261112 Viton SAE 261116 Viton SAE 261120 Viton SAE 261128 Viton

Control Kit (UNF)

(Code 26)

Side/Tandem BSPP 262122 Buna BSPP 261113 Buna BSPP 261117 Buna BSPP 261125 Buna BSPP 261133 Buna

Port(s) SAE 262121 Viton SAE 261112 Viton SAE 261116 Viton SAE 261124 Viton SAE 261132 Viton

32 Compensator O-Ring 3

Shaft Seal - Buna-N

38

Shaft Seal - Viton 258299 258300 258301

SAE 261107 Buna SAE 261111 Buna SAE 261115 Buna SAE 261119 Buna SAE 261127 Buna

BSPP 261110 Viton BSPP 261114 Viton BSPP 261118 Viton BSPP 261122 Viton BSPP 261130 Viton

SAE 262120 Buna SAE 261111 Buna SAE 261115 Buna SAE 261123 Buna SAE 261131 Buna

BSPP 262123 Viton BSPP 261114 Viton BSPP 261118 Viton BSPP 261126 Viton BSPP 261134 Viton

001512 Buna-N

101194 Viton

1

258081 258082 258083

40 Retaining Ring (Barrel) 1 258157 258158 258159 258160 258178

Retaining Ring

41

(Bearing/Housing)

Retaining Ring

43

(Shaft Seal)

1 258330 258331 258332 258333

1 258327 258328 258329

45 Nut, Hex. 1 199127 199134 199136

Screw, Soc. Cap (Metric)

(Rear Ports) *

46

Screw, Soc. Cap (Metric)

Side Ports & Tandem) *

49 O-Ring

Codes 22 & 23 1

Codes 21 & 31 2

4

199989 199911 199918 199717 199231

198644 199985 199717 199234

N/A

120689 Buna-N

141714 Viton

18

Form No. R92.00 Rev. 10/03

Page 19

PARTS LIST (continued)

DESCRIPTION QTY HPV-6 HPV-10 HPV-15 HPV-20 HPV-29

50 O-Ring

51 Coupling

52 Adaptor

53 Screw, Soc. Cap

Code 22

Code 23 N/A 103999 Buna-N 259659 Viton

Code 21 N/A 351354 351240 351394 351186

Code 22

Code 23 N/A 351392 351102

Code 31 N/A 351355 351101 351393 351185

Code 21 N/A 450634

Code 22

Code 23 N/A 450672

Code 31 N/A 450634

Code 22 2

Code 31 6

1

1

1

54 Threadseal 1

56 Dowel Pin (Barrel) 3 258103 258104 258105 258106 258107

Plug, Case Drain SAE

58 1

Plug, Case Drain BSPP

61 Escutcheon Blank 1 261163S

62 Screw 2 250597

64 Guide Sleeve * 1 259026 258940 258984 258990 258920

65 Needle Bearing * 1 258127 258128 258129 258130 258131

66 Pin (Cover) * 1 258336 258337 258338 258339

67 Expander Plug * 1 259176

Retaining Ring

68

(Shaft/Bearing)

2 258290 258291 258292

69 Ball Bearing 1 258191 258192 258193 258194

70 Key 1 126225 101580 001396 259001

71 Screw, Soc. Cap 4 199233 Standard 199086 Codes 7, 19, 26

83 Threaded Rod 2 N/A 259691

84 Nut, Hex. Jam 2 N/A 199127

* Included in Cover Kit.

N/A 144929 Buna-N 144966 Viton

N/A 351355 351101 351393 351185

N/A 450635

N/A 199682

258412 Buna-N 258416 Buna-N 258415 Buna-N

258434 Viton 258419 Viton 258437 Viton

251248 Buna-N 259414 Buna-N 259138 Buna-N

259831 Viton 259415 Viton 258264 Viton

258525 Buna-N 258526 Buna-N

260662 Viton 260309 Viton

KIT LIST

DESCRIPTION HPV-6 HPV-10 HPV-15 HPV-20 HPV-29

Seal Kit - Buna-N 258076 258077 258078 258079 258080

Seal Kit - Viton 258294 258295 258296 258297 258298

Rotating Group Kit (CW Rotation) 258132 258133 258134 258135 258136

Rotating Group Kit (CCW Rotation) 258181 258182 258183 258184 258185

Keyed Shaft Kit 258122 258123 258124 258125 258126

Splined Shaft Kit 258259 258261 258262 258278 258279

Tandem Shaft Kit (Keyed) N/A 259938 259939 259940 259941

Tandem Shaft Kit (Splined) N/A 259934 259935 259936 259937

Form No. R92.00 Rev. 10/03

19

Page 20

PARTS LIST (continued)

28

Shipping

Item

60

58

10

61

62

43

38

1

10

68

19

20

9

16

15

69

41

70

8

12

11

3

8

4

9

6

5

1

14

5

3

21

64

18

24

56

27

40

65

66

71

32

2

14

4

67

2

46

22

For Use With

28

Horsepower

Limiting Control

Only

54

45

Figure 14, HPV Pump and Standard Pressure Compensator, Parts Identification

Figure 15, HPV Side Port, Parts Identification

20

Form No. R92.00 Rev. 10/03

Page 21

PARTS LIST (continued)

Figure 16, Code 7 and Code 19 Pressure Compensator, Parts Identification

Orifice not shown.

Figure 17, Code 26 Horse Power Limiting Pressure Compensator, Parts Identification

Form No. R92.00 Rev. 10/03

21

Page 22

Continental Hydraulics

12520 Quentin Avenue South

Savage, MN 55378 U.S.A.

Phone: (952) 895-6400 Fax: (952) 895-6444

www.continentalhydraulics.com

22

Because Continental Hydraulics is continually improving its products, specifications and appearance

are subject to change without notice.

Form No. R92.00 Rev. 10/03 © 2003 Continental Hydraulics Printed in U.S.A.

Loading...

Loading...