Page 1

Continental Hydraulics Installation Manual

CEM-SD-A

Description:

This closed loop position module is designed to quickly and accurately move hydraulic cylinder

loads. Position and velocity commands are from analog sources. Cylinder position feedback is

from a digital (SSI) source, or an analog source.

Stroke dependent deceleration is used to provide quick and repeatable positioning. Internal ramp

and velocity adjustments allow for easy system tuning.

A wide range of analog signals are accepted. User may select either voltage or current input

mode. These inputs are easily scaled to match system requirements.

Forward and Reverse “jog” inputs allow for manual load control. A user definable window for “in

position” triggers an output for communication to the next machine function.

Output is an analog voltage, 0 to +/- 10v, suitable for directly driving a proportional directional

valve with on board electronics.

This module is easily adapted to a variety of system requirements. All variables are user adjusted

with easy to use software on your Microsoft Windows laptop. Control variables are stored in nonvolatile memory internal to the module. All variables can be read by the laptop, and reproduced

exactly on other modules.

Technical Data:

Power Supply

Analog Inputs

SSI Feedback

Electrical Connection

Consumption

Impendance ohm 33k

Impendance

Resolution

Sample Time mS

(Speed Input) Voltage

(Speed Input) Impendance ohm 90k

Programming Port

Power and Signal

vDC 12 to 30 (including ripple)

mA

<100mA

3 (medium action)

AExternal Fuse

vDC 0 to + 10

Voltage

mA 0 to 20 (typ 4 to 20)

Current

Monitor

Ground via DIN Rail

250

ohm

%

0.01

1.0

0 to +10

vDC

RS-422 150k baud

0 to 10

vDC

5 (max)

mA

RS-232 3.5mm Stero Jack

8 strips with 4 screw terminals each

Digital Inputs

Digital Outputs

Analog Output

Housing

Resolution

Combustability Class

Protection Class

Storage Temperature

Electro Magnetic Compatibility

Humidity

Emission

Immunity

Vibration Resistance EIC 60068-2-6

Page 1 of 15 CEM-SD-A CHI 1013477 May 2012

V

Logical 0 = < 2

Logical 1 = > 10

V

ohm

25kImpendance

VVLogical 0 = < 2 (50mA max)

Logical 1 = ~ Power Supply

vDC 0 to +/- 10

Voltage

Current

Module

Material

5 (max)

mA

%0.024

Snaps to 35mm DIN Rail EN 50022

Polyamide PA 6.6

V0

UL94

IP 20

-20 to +60

CWorking Temperature

C

-20 to +70

% 95 (non condensing)

EN 61000-6-2

EN 61000-6-3

Page 2

Continental Hydraulics Installation Manual

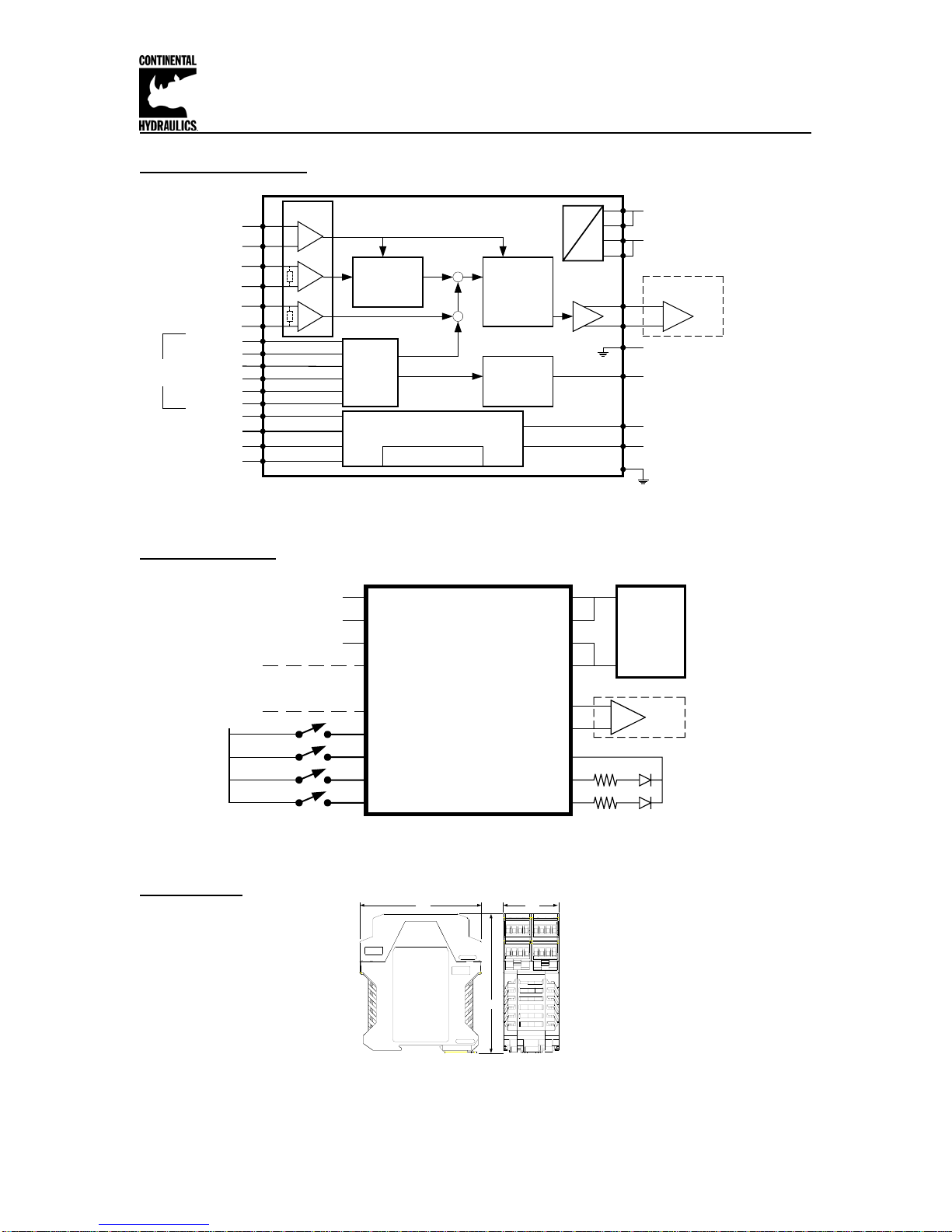

Functional Diagram:

0 to +10v

+

-

+

+

-

Command Speed

Command Position

0 to +10v or

4 to 20 mA

Analog

Feedback Position

24v supply

0v

SSI Digital

Clock +

Feedback

Clock -

Position

Data +

Data -

Enable

Start (Run)

Hand + (jog)

Hand - (jog)

Wiring Example:

Analog Speed (optional)

Analog Command Position

Analog Positi on Feedback

(Software select Digital or Analog)

SSI Serial

Communication

+24v

Input

Scaling

10

9

13

11

14

11

31

32

25

26

27

28

8

Active = high

7

Active = high

5

Active = high

6

Active = high

v

ws xd

Feedback

Sensor

Profile

Generator

SSI

Control Program

CEM-SD

w

x

Programming Port

RS-232 3.5mm jack

Output

Control

SSI

Analog

Output

u

Active = high

Active = high

DC

DC

3

+12 to 24v

19

4

0v

20

15

16

12

Ground

17

SSI Analog Position

(0 to +10v)

1

2

Differential Input on

Control Valve

+

-

Ready

In Position (InPos)

Ground via DIN rail

10/9

13/11

14/11

25-32

(6 pins)

Speed

Command

Feedback

SSI Digital

Position Feeback

8

Enable

7

Start (Run)

5

Hand + (jog)

6

Hand - (jog)

Valve out +

Valve out -

+24v

+24v

Gnd

Gnd

Gnd

Ready

In Pos

3

19

Power

Supply

4

20

15

16

Differential

+

Input on

-

Control Valve

12

1

2

Dimensions:

Page 2 of 15 CEM-SD-A CHI 1013477 May 2012

3.9"

1.8"

4.5"

Page 3

Continental Hydraulics Installation Manual

Steps to install and configure a new application:

1. Mount the module in a suitable location

2. Connect the power supply and valve solenoids

3. Adjust current range to match valve

4. Adjust PWM/Dither to optimize performance of the valve

5. Adjust analog input to voltage or current, and scale input to desired system speed

6. Adjust ramping (if desired)

7. Adjust internal monitor functions (if desired)

6. Adjust customized current to of valve flow gain (if desired)

All parameters are adjusted using VEA-USB programming cable and CHI-PC Microsoft Windows

application:

Module Mounting Location:

This module is to be mounted in a cabinet for protection from the local environment.

Ensure there is adequate free space around the module to allow for cooling air flow.

This module is designed to snap onto an industry standard 35mm DIN rail.

Do not mount near other modules that emit high power electrical interference, such as motor

controllers and high power contactors.

Power Supply:

This module is designed to operate on DC power from a regulated power supply ranging from 12

to 30 volts.

A 3 amp medium action fuse is recommended in the “+” power supply line.

Adjust MODE to STD or EXP:

Simple parameters may be adjusted while in STD mode.

EXP mode allows for more complex parameter adjustments.

MODE parameter valid options are STD and EXP. Default is STD.

TS parameter:

TS sets the sample time of the closed loop control system. Valid settings are from 5 to 30 Units

are msec. Default is 10. It is advised to keep this parameter set to 10.

Page 3 of 15 CEM-SD-A CHI 1013477 May 2012

Page 4

Continental Hydraulics Installation Manual

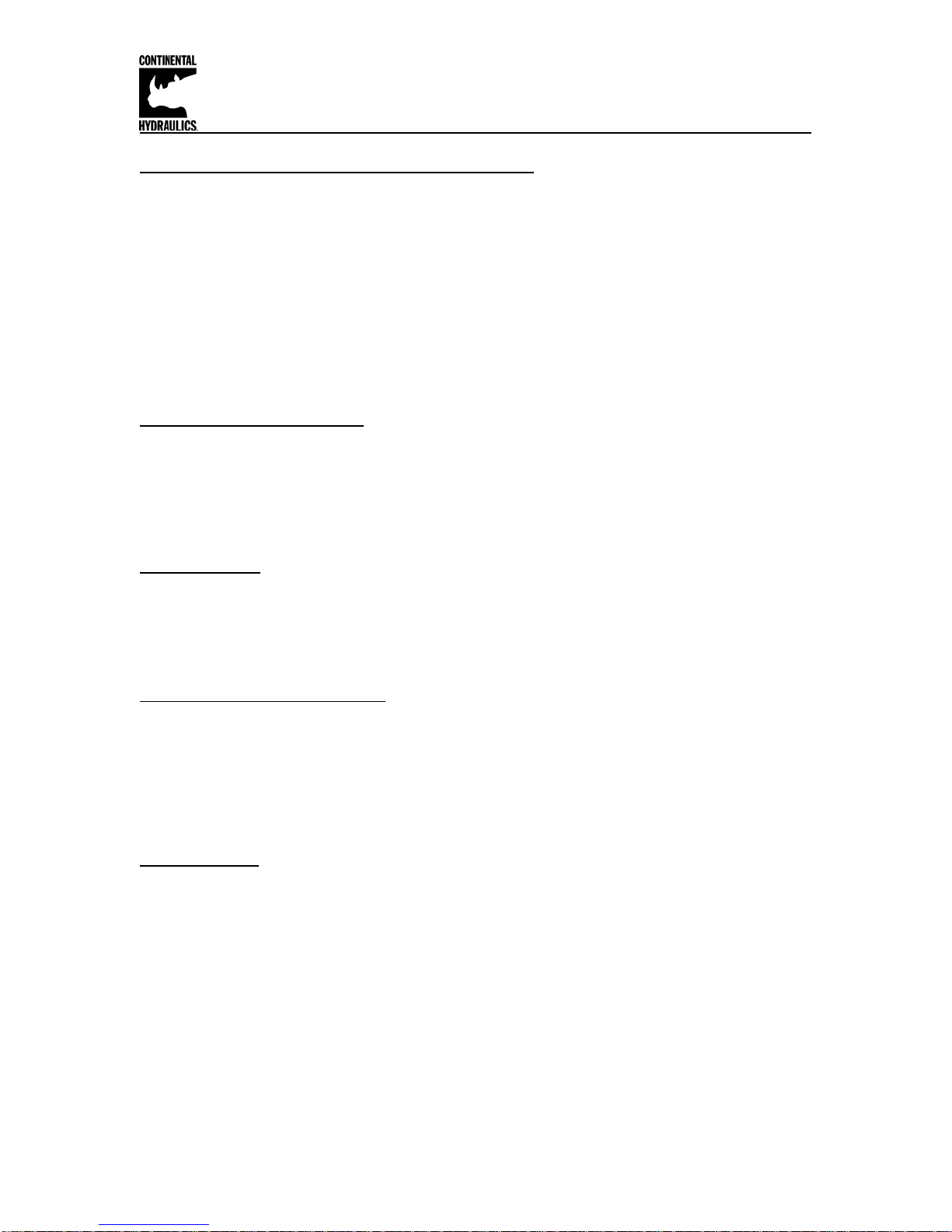

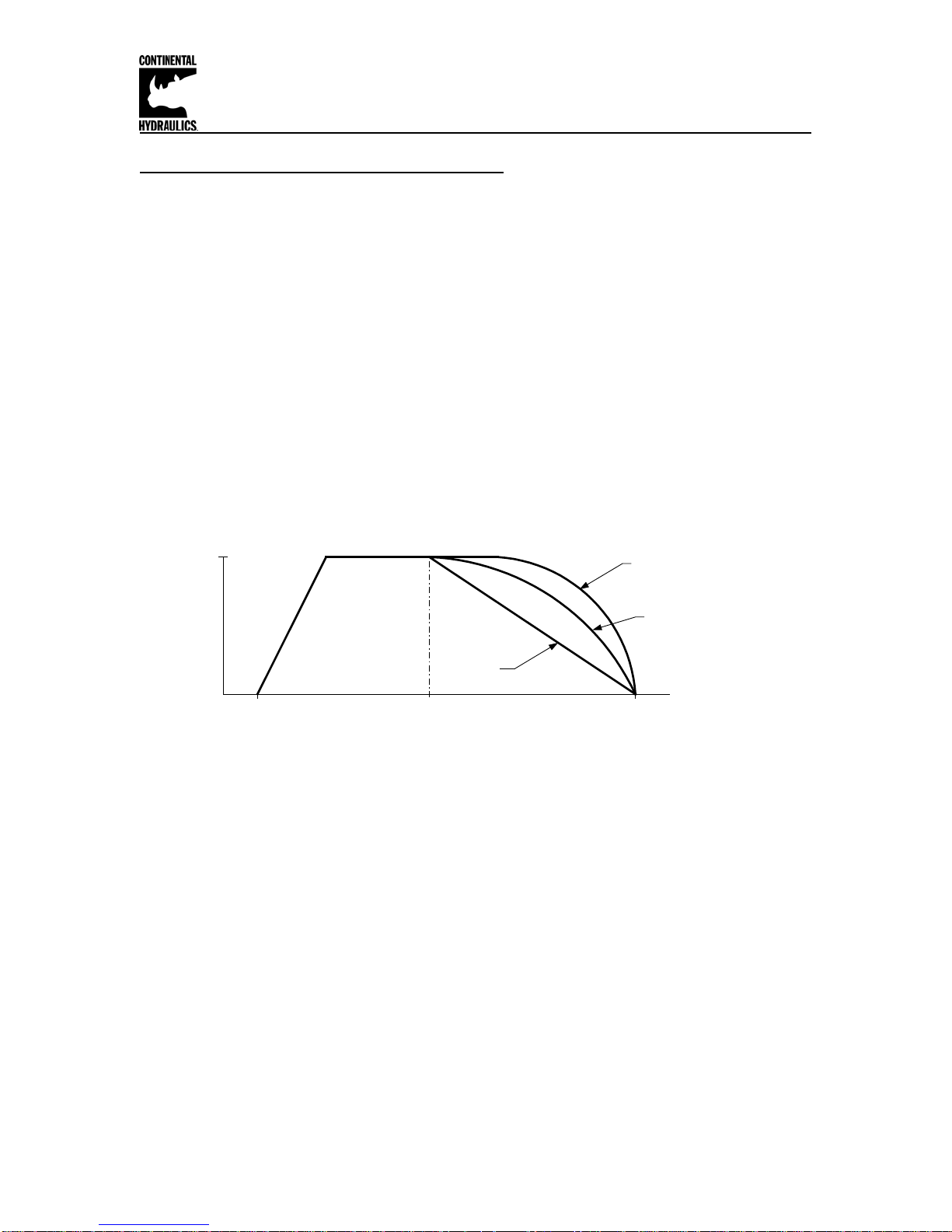

Stroke Dependent Deceleration:

The CEM-SD module uses the position control theory of stroke dependant deceleration. When a

new position is commanded, the initial motion profile is ramped and speed controlled in open loop

mode. As the load travels, it soon gets to a preprogrammed point, termed the braking point. At

the braking point, the module converts to closed loop control, constantly adjusting the speed of

the load, homing in on the final stopping point.

100%

Adjustable Top Speed

Speed

0%

0%

Adjustable

Acceleration

Ramp

Position

Adjustable Deceleration

Start Point (Braking Point)

"Square Root"

Deceleration

100%

The main parameters used to control this profile include:

STROKE: load distance.

A:A and A:B: ramping times

VELO: internally controlled velocity

D:A and D:B: Deceleration start point

STROKE defines the full motion. Valid options are 10 to 10000. Default is 100. Units are mm.

A:A and A:B parameters are acceleration (ramp) rates. A:A is the direction of the load connected

to the A work port of the proportional directional valve (+voltage out of CEM-SA Pin 15). A:B is

acceleration of the B port. Valid options are 1 to 5000. Default is 100. Units are msec.

All ramp rates are set via software. All ramps are specified in milliseconds, and are actually “time

to ramp for a 0 to 100% signal change.”

Example: A value of 2000 will give a ramp time of 2 seconds for a VELO parameter of

100% (10000). The ramp time will be 1 second for a VELO parameter of 50% (5000).

VELO

parameter

D:A and D:B are the deceleration start points(braking points). Valid options are 1 to 10000.

Default is 10. Units are mm.

Page 4 of 15 CEM-SD-A CHI 1013477 May 2012

100%

50%

0%

(A:A = 2000)

0

123

Time (seconds)

4

Page 5

Continental Hydraulics Installation Manual

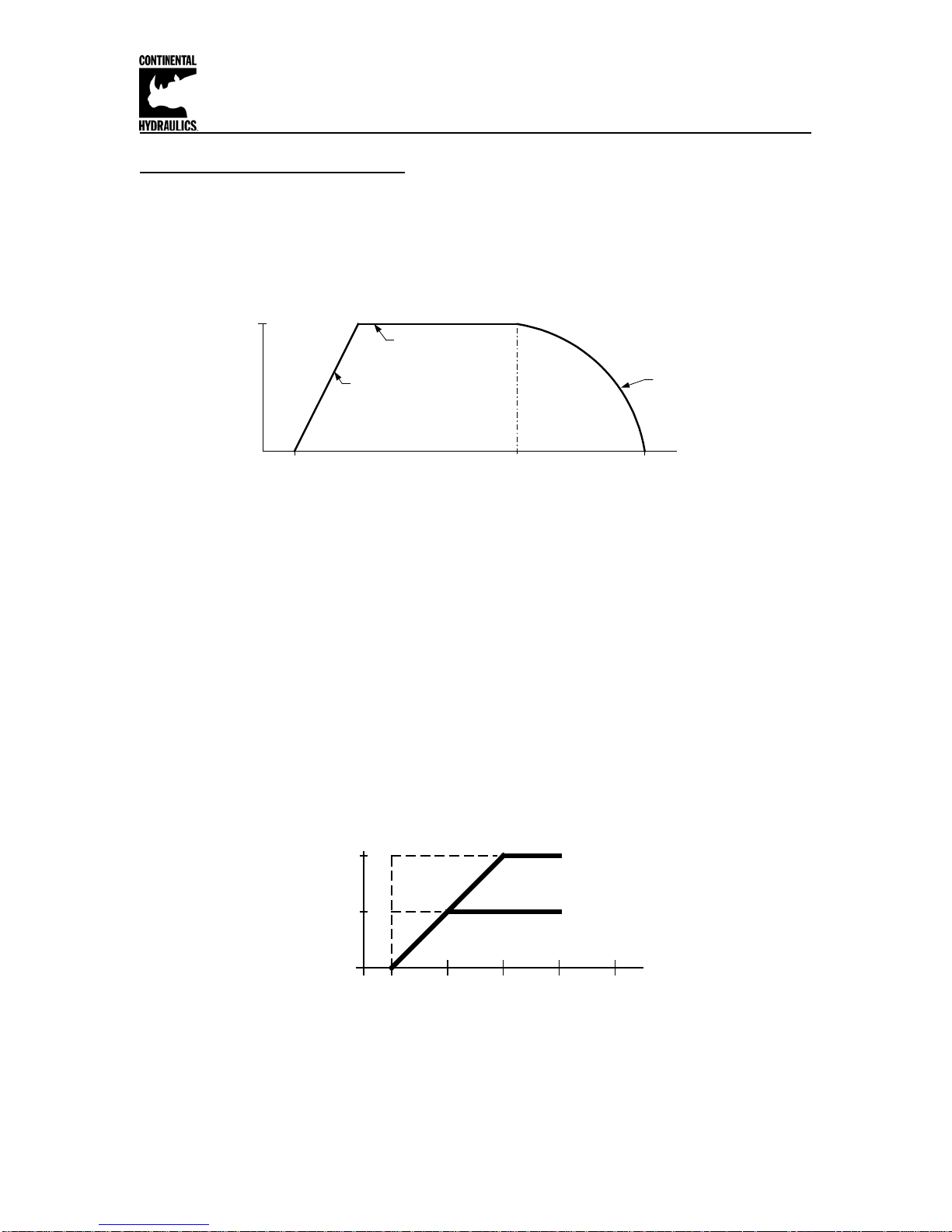

Stroke Dependent Deceleration (continued):

System velocity command can be either external or internal.

VS can be set to either INT or EXT. INT is default.

INT requires the speed to be set with the VELO parameter.

VELO valid values are 0 to 10000. Default is 10000(100%). Units are 0.01%

EXT uses the 0 to 10v analog voltage at pins10/9 to command speed.

This speed signal may be ramped with the VRAMP parameter.

VRAMP valid values are 1 to 5000. Default is 50. Units are msec.

Deceleration characteristic is controlled by the CTRL parameter.

CTRL valid options are LIN, SQRT1, and SQRT2. Default is SQRT1.

SQRT1 gives the best performance for most systems. SQRT1 balances quick motion control with

accurate final position holding.

SQRT2 increases the gain at the final position, which may provide more precise load holding.

This higher gain may introduce final position instability.

LIN gives the most stable option, but requires more time to complete the motion profile.

100%

Speed

0%

0%

Position

(gain ~1)

Deceleration

Start Point D:A

SQRT2

(gain ~ 5)

SQRT1

(gain ~ 3)

LIN

100%

Page 5 of 15 CEM-SD-A CHI 1013477 May 2012

Page 6

Continental Hydraulics Installation Manual

Adjust module output to match valve requirements:

The CEM-SD module has a 0 to +/-10v differential output. This output is designed to directly

interface to proportional valves with on board electronics.

This output signal may be configured to more closely match the valve characteristics. The

parameters used to adjust the output signal include:

MAX:A and MAX:B

MIN:A and MIN:B

TRIGGER

MAX:A and MAX:B are set with software as a percentage of the native +10v output. MAX:A and

MAX:B are set at 100% (10000) for a valve that has a 10v input rating. To reduce the maximum

flow from a valve with a spool that is too large, set MAX to a number less than 100%. Valid range

is from 5000 to 10000. Default is 10000. Units are 0.01%

MIN:A and MIN:B are adjusted via software for the purpose of deadband elimination. A valve

with a minimum control point (cracking point) will give best performance if this deadband is

eliminated. Valid range is 0 to 5000. Default is 0. Units are 0.01%.

Example: A directional control valve has an input range of 0 to +/-10v. The valve is

factory calibrated to begin flow at 1v, and max flow is at 10v. Adjust the CEM-SA parameters:

MAX:A = 10000 (100% of +10v)

MIN:A = 900 (9% of 10v = +0.9v)

MAX:B = 10000 (100% of -10v)

MIN:B = 900 (9% of -10v = -0.9v)

Voltage Output +10v

Max A =

% of Range

Module output -100%

Max B =

% of Range

Min B =

% of Range

Voltage Output

-

Trigger = % of Output

10v

Min A =

% of Range

Module output +100%

TRIGGER and MIN can be used together to optimize valve performance near zero.

When using a proportional valve with an overlap spool, adjust TRIGGER to 200 (2%), and MIN:A

and MIN:B to slightly less than the “crack point” of the valve.

Page 6 of 15 CEM-SD-A CHI 1013477 May 2012

Page 7

Continental Hydraulics Installation Manual

Adjust module output to match valve requirements (continued):

When using a proportional valve with an underlap spool (“zero” lap), the flow gain in the area of

the underlap is about double that outside the underlap area. Adjusting TRIGGER and MIN:A and

MIN:B as suggested will give more stable results.

Example: Adjust TRIGGER to 200 (2%) and MIN:A and MIN:B to 100 (1%). These

settings reduce the flow gain in the underlap region, and usually allow for a shorter

braking distance (D:A and D:B). This scheme gives quick motion, with stable load

holding.

Module output -100%

Max B

Voltage Output +10v

Min B

Min A

Module output +100%

Trigger

Voltage Output

-

Max A

10v

Choosing between overlap spool and underlap spool proportional valves:

There are performance tradeoffs in choosing an overlap spool valve vs. an underlap

spool valve:

An overlap spool valve will do a better job of holding the load in a static condition. An overlap

valve can be commanded to go to center. In this center condition, the valve port-to-port leakage

is lowest. When trying to hold a load at a fixed position with the control system inactive, the

overlap valve in a centered condition will allow a smaller amount of port-to-port leakage.

A negative feature of a overlap spool valve is the time delay in electronic deadband elimination.

An overlap spool valve needs time to jump back and forth across the deadband during the near

zero flow portion of the motion profile. This time delay will show up as slower response to

external forces moving the load from the commanded position.

Adjusting the deadband elimination feature may be time consuming.

The underlap spool valve does not lose time jumping across the deadband area. The high flow

gain in the underlap region provides small active position holding errors. There is an energy cost

penalty in choosing the underlap spool, due to the port-to-port leakage in the center position.

Page 7 of 15 CEM-SD-A CHI 1013477 May 2012

Page 8

Continental Hydraulics Installation Manual

Command input with Voltage:

An analog source voltage may be either “differential” or “ground referenced”. The CEM-SA

accepts an analog position command and feedback inputs that are ground refe renced. The

optional velocity command input is a differential input. Examples are shown for position

command only, feedback signals are wired to Pin 14(+) and Pin 11 (GND).

3

Position Command

Analog Voltage Source

"Ground Referenced Voltage"

(PLC, Digitial Motion

Controller, etc.)

+

-

13

11

Gnd

+24v

Gnd

An external position command voltage source must be referenced to ground for proper o peration.

+24v

Gnd

External

Voltage

Reference

Gnd

+10v

0v

potentiometer

( 5k ohm typical)

Position command

13

11

(Gnd)

DC

4

Power Supply

3

4

Line

AC

DC

AC

Power Supply

Line

The speed command input accepts differential voltage.

3

Speed Command

Analog Voltage Source

"Differential Voltage"

(PLC, Digitial Motion

Controller, etc.)

+24v

+

-

10

9

Gnd

Gnd

DC

AC

Line

4

Power Supply

A ground referenced speed command must be referenced to the CEM-SA ground.

3

Speed Command

Analog Voltage Source

"Ground Referenced Voltage"

(PLC, Digitial Motion

Controller, et c.)

+24v

+

-

10

9

Gnd

4

Gnd

DC

AC

Line

4

Power Supply

Page 8 of 15 CEM-SD-A CHI 1013477 May 2012

Page 9

Continental Hydraulics Installation Manual

Command input with Current:

The analog position and feedback inputs may be software set to accept a current command.

Either input can be individually adjusted to accept either voltage or current. When current is

chosen, a 250 ohm resistor is internally inserted across terminals 13 and 11, and/or between

terminals 14 and 11. This resistor converts the current to a voltage. This voltage is measured by

the amplifier to become the system command (13/11) or the system feedback (14/11).

Input current range is 0 to +20 mA, and is typically used at 4 to 20mA. This current is converted

to voltage, and software scale and offset parameters are applied to meet system requirements.

Power Supply

AC

Line

DC

4 to 20mA

Transmitter

Loop Monitor

(optional)

A

13

11

(Gnd)

+24v

Gnd

3

DC

AC

Line

4

Power Supply

All analog input signal cables must be shielded!

Good analog system design requires that all analog signals in an electrically noisy environment

be shielded. Long wires act like antennas that pick up analog noise. The wire connecting the

analog command source to command this module must be shielded! An unshielded cable can

allow electrical noise to be added to the desired command signal, and can make the system

response erratic.

Shielding a noise sensitive wire is accomplished by wrapping a noise blocking foil or braided

shield around the signal wire. This shield must be grounded at only one end, usually the end that

sends the signal. A control cable may have many individual conductors. The conductors may be

shielded individually, or may be shielded as a group. Short signal wires in electrically quiet

environments may not need to be shielded.

The CEM family of modules all have an internal ground connection to the DIN rail. For this

module ground to be effective, please insure the DIN rail is properly grounded.

Page 9 of 15 CEM-SD-A CHI 1013477 May 2012

Page 10

Continental Hydraulics Installation Manual

Scaling of analog input:

This module has a native analog voltage input range of 0 to +10v for command and feedback.

These inputs can be scaled and offset with software to allow a wide variety of input voltages. A

few examples are:

0 to +10v, 0 to +5v, +1 to +5v, +0.5 to +4.5v

The AIN:W parameter adjusts command port, and AIN:X parameter adjusts the feedback port.

Each can be independently set for either voltage or current command, and each can be

independently scaled.

Example: AIN:W V will set the command input to voltage. Default range = 0 to +10v

Example: AIN:W C will set the command input to current. Default range = 4 to 20mA

Example: AIN:X V will set the feedback input to voltage. Default range = 0 to +10v

Example: AIN:X C will set the feedback input to current. Default range = 4 to 20mA

Analog voltages or currents are scaled with the following linear equation:

Output = A/B * (Input – C)

“Output” of this scaling equation must always be equal to the module native input range, 0 to

+10v. “Input” can be any voltage within this 10v range.

The ratio of A/B allows for a decimal scaling factor. These two numbers are chosen to provide a

“gain” to the input signal. A and B must be whole numbers. Range is -10000 to 10000.

(Default; A = 1000, B = 1000)

C is an offset, measured as a percentage of range. C has units of 0.01%, and has the range of

–10000 to 10000. (Default; C = 0)

Scaling of voltage inputs:

Example: Typical AIN parameter settings for popular command and feedback voltages:

Command A B C description

0 to +10v 1000 1000 0 100% scale, 0% offset

0 to +10v 1 1 0 100% scale, 0% offset

0 to +10v 10 10 0 100% scale, 0% offset

0 to +5v 10 5 0 200% scale, 0% offset

+1 to +9v 10 8 1000 125% scale, 10% offset

+0.5 to +4.5v 10 4 500 250% scale, 5% offset

0 to 8v 10 8 0 125% scale, 0% offset

Scaling of current inputs:

Example: Typical AIN parameter settings for popular command and feedback currents:

Command A B C description

4 to 20mA 20 16 2000 125% scale, 20% offset

4 to 20mA 1250 1000 2000 125% scale, 20% offset

4 to 20mA 5 4 2000 125% scale, 20% offset

0 to 20mA 20 20 0 100% scale, 0% offset

Page 10 of 15 CEM-SD-A CHI 1013477 May 2012

Page 11

Continental Hydraulics Installation Manual

Swapping polarity with the POL parameter:

The output drive polarity may be swapped with the POL command.

Valid parameter values are “+” and “-“. (Default = +).

Adjustment of SENS internal monitoring function:

This module has optional input and internal monitoring functions. The module can monitor

command inputs for proper range.

There are three choices for SENS; OFF, ON, and AUTO (default).

OFF disables the internal sensing function.

ON and AUTO enable the internal sensing functions. The difference between ON and AUTO is

how the module handles error correction.

When ON is selected, if the module detects an error, the module will disable.

After the error is corrected, the ENABLE pin must be cycled to reactivate the

module.

When AUTO is selected, if the module detects an error, the module will disable.

When the error is corrected, the module will resume function without cycling

ENABLE.

If the module has been configured to accept current commands, a command value outside of 4 to

20 mA will disable the module, and cause the green READY LED to blink.

HAND+ (jog+) (pin 6) and HAND- (jog-) (pin 5) digital inputs:

HAND:A and HAND:B are digital inputs that are active high.

HAND:A adjusts the speed command to the valve. The valve will move the load in open loop

mode at the rate set by HAND. Once the HAND input is released, the new position command

setpoint is whatever the position was when hand is released. HAND:A and HAND:B have valid

values from –10000 to +10000. Units are 0.01%. Default for HAND:A is 3333(+1/3), and

HAND:B is –3333(-1/3).

START(RUN) takes priority over HAND.

EOUT parameter:

EOUT sets a default module output value. When ENABLE (pin 8) has been removed, or the

module has become disabled, the output may be set to a value other than zero. This allows the

machine to slowly extend or retract in the case of loss of electro hydraulic control.

Parameter valid –10,000 thru +10,000. Default is 0. Units of 0.01%

Page 11 of 15 CEM-SD-A CHI 1013477 May 2012

Page 12

Continental Hydraulics Installation Manual

OFFSET parameter:

OFFSET is a fixed adjust to the output. OFFSET valid values are from –4000 to +4000. Units

are 0.01%. Default is 0.

ENABLE (pin 8) digital input:

ENABLE is a digital input that is active high.

When the ENABLE input is low, there is no output to the valve. Command input and feedback

input values are ignored. All other inputs are also ignored.

To active the HAND function, ENABLE must be held active.

If ENABLE is removed during an active motion profile, the output to the valve is instantly brought

to zero.

START (RUN) (pin 7) digital input:

START (RUN) is a digital input that is active high.

Bringing pin 7 high (while holding pin 8(ENABLE) high), forces the module into closed loop

position control mode.

If RUN is removed during an active motion profile, the output to the valve is ramped to zero

during the preset emergency stop distance parameter (D:S). Units of D:S are mm. Default is 10.

InPOS pin 2 digital output:

InPOS (pin 2) is a digital output that is normally low. When the module is in active control, this

output will be high, as long as the controller is within INPOS parameter. INPOS parameter is

valid from 2 to 10000. Units are micrometer. Default is 1000.

When the control module is active, but outside of the INPOS parameter, the InPOS output will go

low. The module continues to actively control the valve.

Page 12 of 15 CEM-SD-A CHI 1013477 May 2012

Page 13

Continental Hydraulics Installation Manual

READY pin 1 digital output:

The READY digital output reports the system status.

Pin 5 will be held “high” (on) when ENABLE is connected, and there are no system errors.

Pin 5 will be pulled “low” (off) under the following conditions:

1. When ENABLE is removed

2. When SENS is turned on and the input is outside the 4 to 20mA range

3. When other internal errors are present

LED function:

Green (Ready) Steady on System OK

Blinking 4 to 20mA current input command is out of range

Blinking internal error sensed

Yellow (Status) Steady on Load is within InPOS tolerance

Off Load is not within InPOS tolerance

Page 13 of 15 CEM-SD-A CHI 1013477 May 2012

Page 14

Continental Hydraulics Installation Manual

Interface for Digital SSI feedback:

The SSI digital feedback sensor communicates with the CEM-SD over a RS-422 serial interface.

Power and ground to supply the sensor are also provided.

Pin 25 + Clock

Pin 26 - Clock

Pin 27 + Data

Pin 28 - Data

Pin 31 24v power

Pin 32 0v ground

Analog output of digital feedback signal (pin 17):

The SSI digital feedback sensor values are available as an analog voltage. Digital position of 0 to

100% is available as an analog voltage of 0 to +10v. (5mA max)

Parameter adjustments for SSI digital feedback:

INPX parameter:

This parameter allows the selection of either analog feedback input (pins 14/11), or the digital SSI

feedback. Valid parameters are ANA or SSI. Default is ANA.

SSI:OFFSET parameter:

The digital feedback signal may be calibrated with a fixed offset. Valid parameter range is

+1,000,000 to –1,000,000. Units are micrometers.

SSI:POL parameter:

Digital SSI feedback polarity may be swapped from “+” to “-“. Default is “+”.

SSI:RES parameter:

Digital SSI feedback resolution is defined with this parameter. Valid range is 100 to 10000.

Default is 500. Units are nanometers (0.01micrometers).

Example: parameter 100 = 1 micrometer sensor resolution

SSI:BITS parameter:

The number of data bits in the digital sensor serial data stream is defined with this parameter.

Valid values are 8 to 31. Default is 24.

Page 14 of 15 CEM-SD-A CHI 1013477 May 2012

Page 15

Continental Hydraulics Installation Manual

Parameter adjustments for SSI digital feedback: (continued)

SSI:CODE parameter:

Digital SSI feedback sensors data may be defined as either GRAY scale, or BINary. Default is

GRAY.

Parameter monitoring using software:

The following parameters may be monitored in real time using Windows configuration software.

Parameter Description Unit

WA Command mm

W Command after scale & ramp mm

X Feedback after scaling mm

XD Command – Fe edback mm

V Velocity command 0.01%

U Output 0.01%

Page 15 of 15 CEM-SD-A CHI 1013477 May 2012

Loading...

Loading...